Drive-by-wire system with redundancy function

A brake-by-wire and functional technology, which is applied in the direction of brake safety systems, can solve problems such as driving safety hazards and brake failure, and achieve the effects of improving reliability, improving brake response speed, and reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0039] A brake-by-wire system with redundant functions, including a brake-by-wire brake with a modular design, a brake pump housing 11, a liquid storage chamber 12, a first spring 13, a first piston assembly 14, a retaining ring 15, Rubber ring 16, second spring 17, second piston assembly 18, brake pedal 19, angle sensor 20, controller 22;

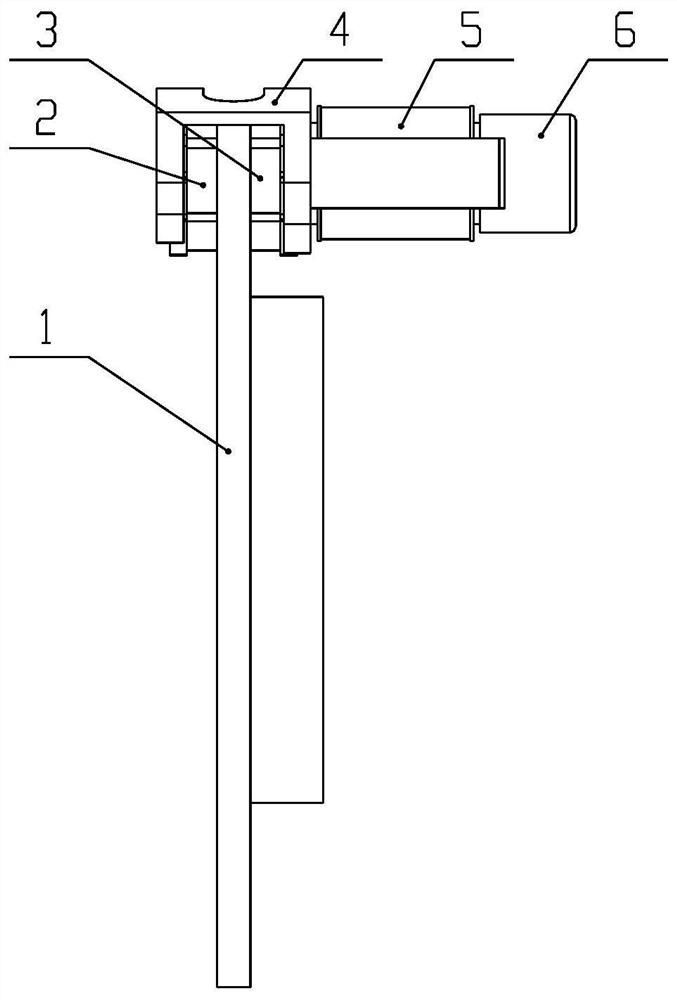

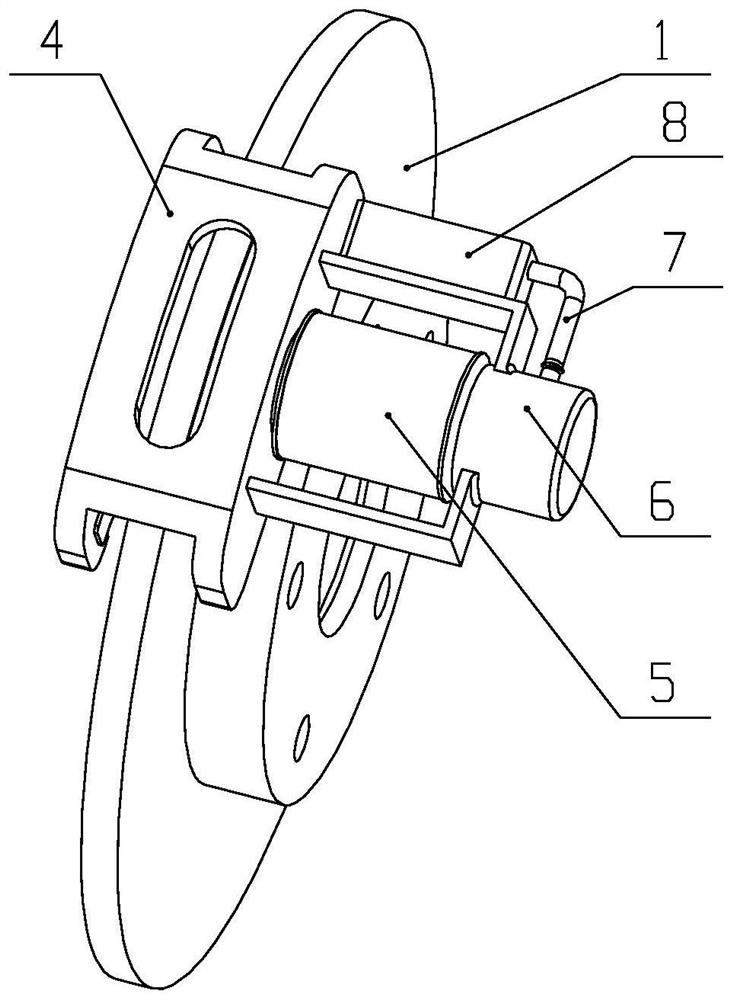

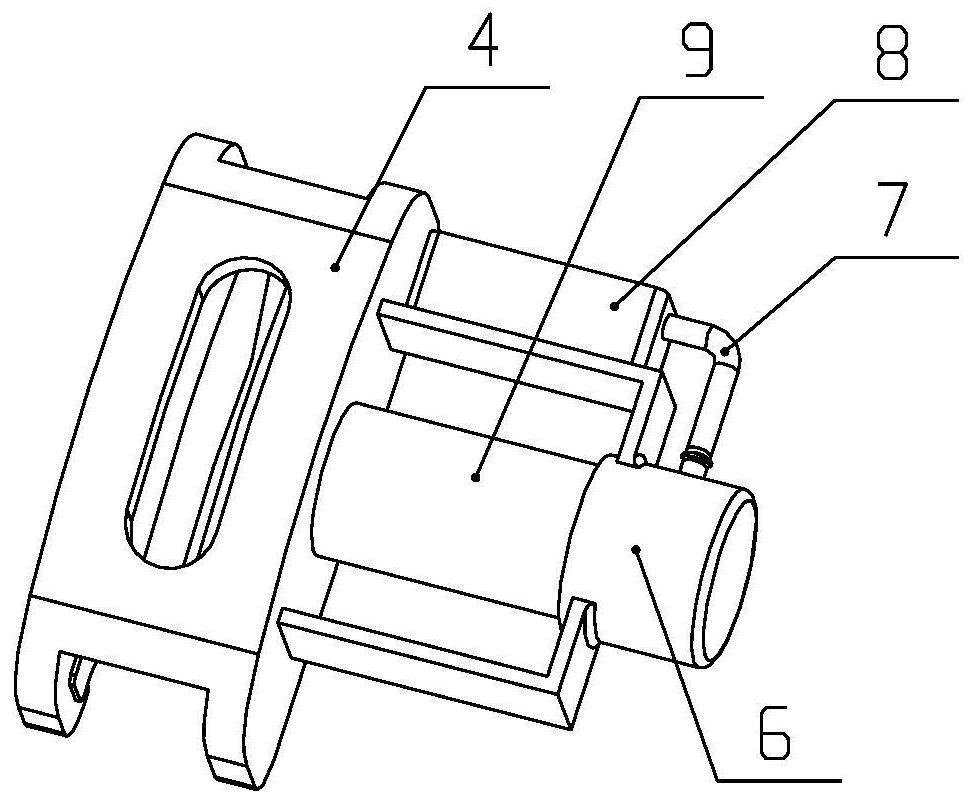

[0040] like figure 1 , figure 2 , image 3 As shown, the brake-by-wire brake includes a brake disc 1, a left friction plate 2, a right friction plate 3, a caliper 4, an electromagnetic coil 5, a cylinder assembly 6, a brake pipeline 7, a hydraulic control unit 8, a brake Moving piston 9, magnetostrictive rod 10, wheel speed sensor 21; described brake disc 1 is connected with axle bolt, and left friction plate 2, right friction plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com