Material property detecting method and device based on grating effect of standing wave excitation transient body

A technology for material characteristics and detection devices, which is applied in measurement devices, material analysis by optical means, and material analysis, etc., can solve the problem that the optical path adjustment error has a great influence on the grating characteristics, the optical path is complicated, and the stability and reliability of the detection system are adversely affected. And miniaturization and other issues, to achieve the effect of simple optical path, stable grating characteristics, and reduced power level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

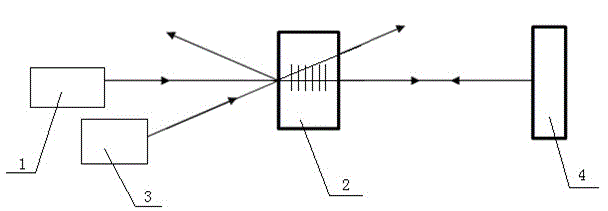

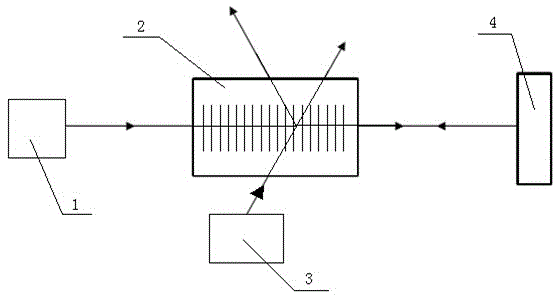

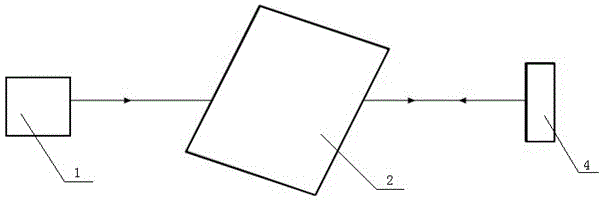

[0031] A material property detection method based on standing wave excitation transient volume grating effect, comprising the following steps:

[0032] (1) First, the pump light source 1 is used to emit a pump beam to the surface of the tested sample 2. The pump beam enters the inside of the tested sample 2 and finally exits from the back of the tested sample 2. The emitted pump beam is set on the surface of the tested sample The reflection of the high-reflectivity mirror 4 at the back end of the test sample 2 reenters the interior of the test sample 2 to overlap with the initial incident pump beam, and a standing wave is formed in the overlapping area due to the optical interference effect, resulting in a periodic light intensity distribution. When the periodic light intensity distribution interacts with the measured sample material, it will produce periodic spatial modulation on the measured sample material properties, forming a transient volume grating;

[0033] (2) The det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com