Safe explosion venting device

An explosion venting and safety technology, applied in the field of explosion venting, can solve the problems of secondary explosion, loss, casualty and property, etc., and achieve the effect of avoiding secondary explosion, improving safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

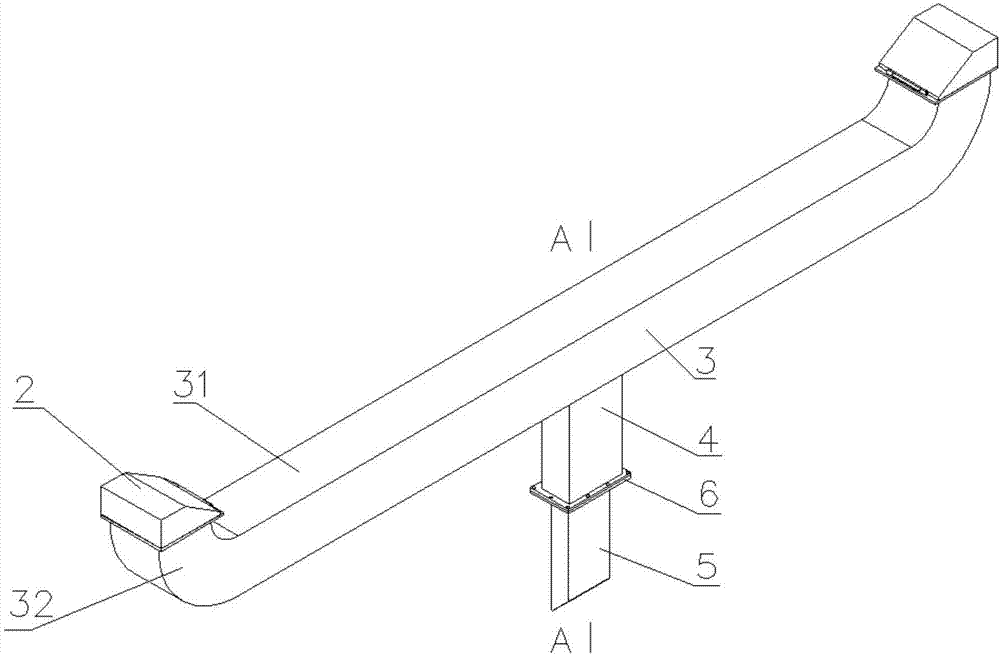

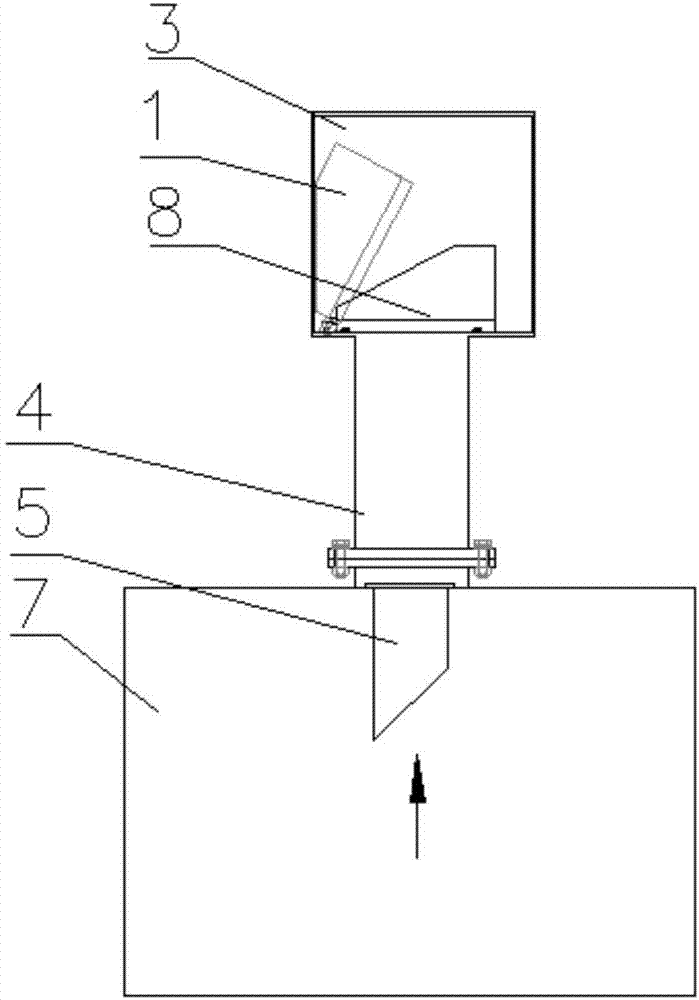

[0023] Such as figure 1 and figure 2 Shown: a safety explosion venting device, including a primary blast vent door 1 and a secondary blast vent door 2, an isolation cavity 3 is provided between the primary blast vent door 1 and the secondary blast vent door 2, and the isolation cavity 3 Filled with nitrogen.

[0024] The lower end of the primary explosion venting door 1 is fixedly connected with a hollow cavity 4, the lower end of the hollow cavity 4 is fixedly connected with the gas pipeline 5 through the flange 6, the lower end of the gas pipeline 5 extends into the working chamber 7, and the gas pipeline 5 is used to deliver nitrogen gas to the isolation chamber 3. The first-stage explosion venting door 1 is set in the isolation chamber 3, the upper end of the hollow cavity 4 is provided with a connecting seat 8, one end of the first-stage explosion venting door 1 is hinged with the connecting seat 8, and the other end is provided with a counterweight, which is connected...

Embodiment 2

[0029] The difference from Embodiment 1 is that the isolation cavity is filled with carbon dioxide.

[0030] Others are with embodiment 1.

Embodiment 3

[0032] The difference from Embodiment 1 is that there is one secondary explosion vent door, and the secondary explosion vent door is connected to the arc-shaped corner at one end of the isolation chamber. The other end of the isolation cavity may directly close one end of the cuboid without setting an arc-shaped corner; it may also be provided with a closed arc-shaped corner.

[0033] In this embodiment, the counterweight of the secondary explosion venting door may be greater than that of the secondary explosion venting door in Embodiment 1.

[0034] Other structures are with embodiment 1.

[0035] Since this embodiment can be understood by those skilled in the art, it is not shown in the drawings again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com