Side suction dust removal system for railway ballast bed suction-type dirt removal truck and corresponding dust removal method

A technology of dust removal system and sewage suction vehicle, which is applied in separation methods, chemical instruments and methods, track cleaning, etc., can solve problems such as lack of explosion-proof function, and achieve the effect of preventing the spread of explosion accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

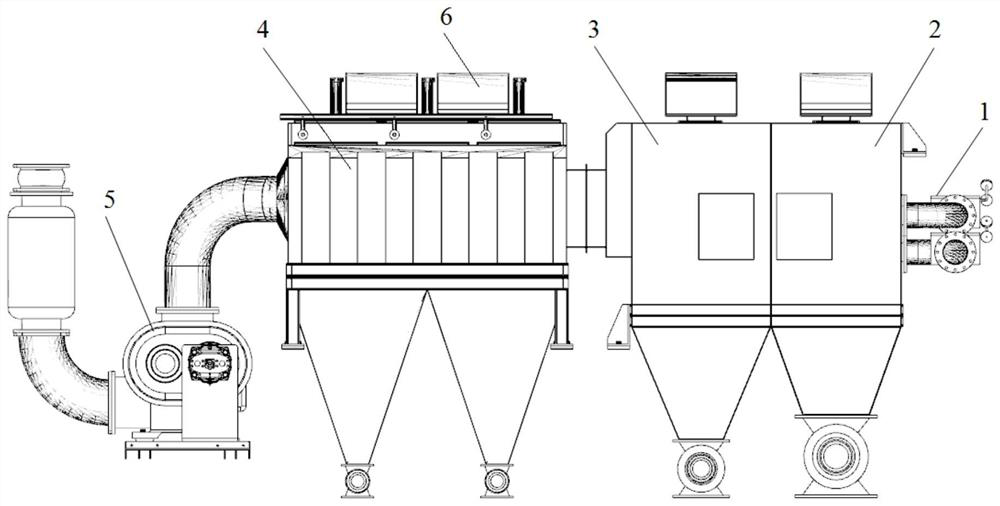

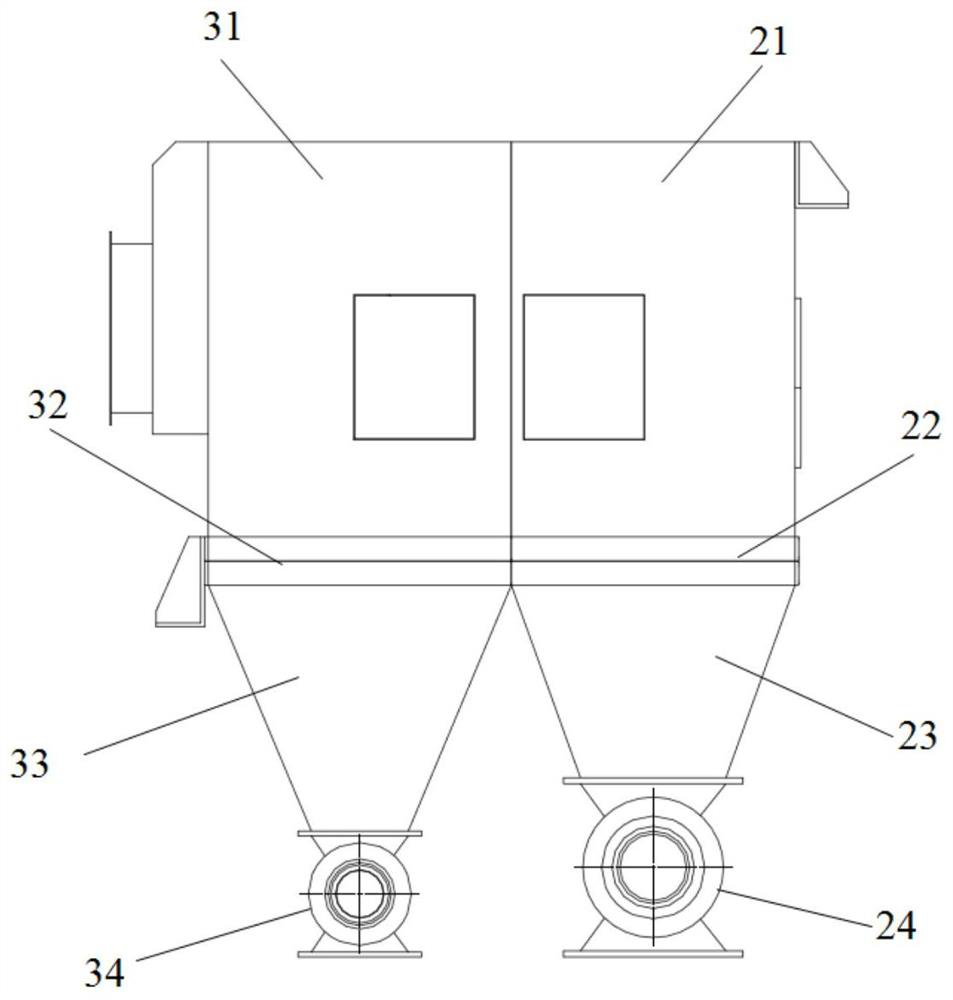

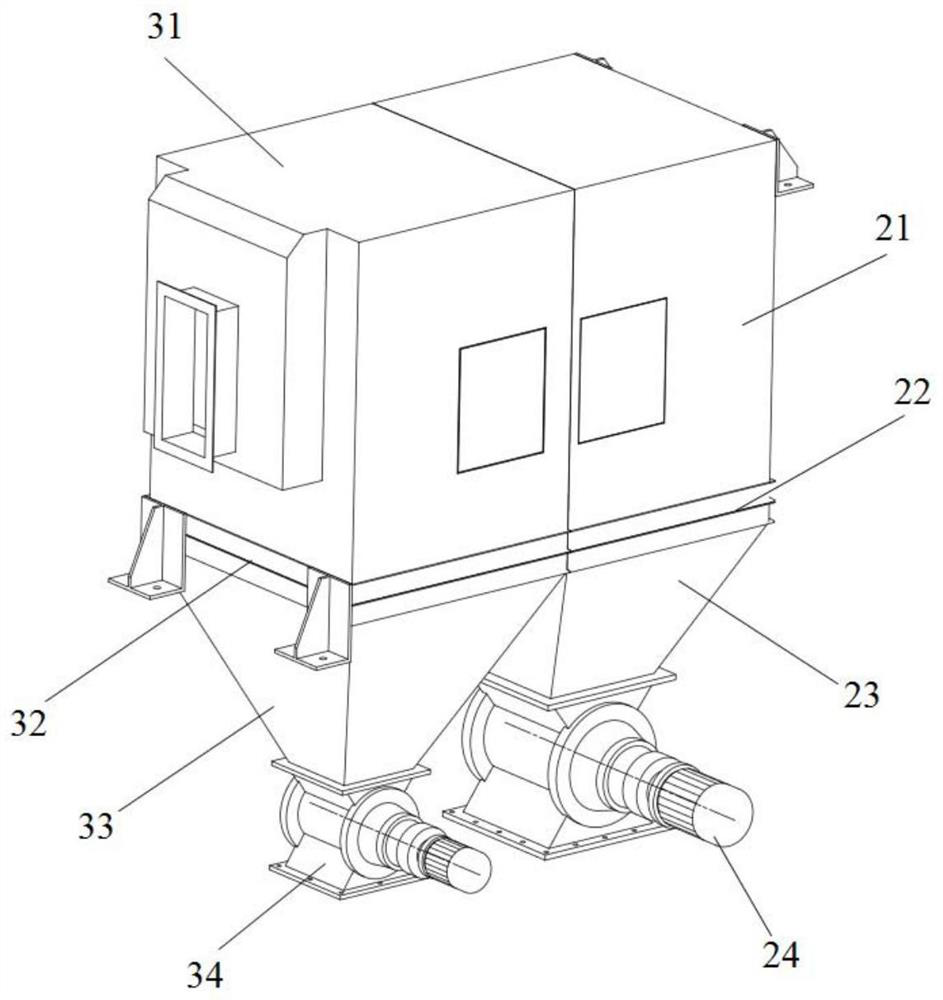

[0061] Embodiment 1.1: a side suction dedusting system for a railway track bed sewage suction vehicle, used to cooperate with a side suction cleaning device to clean the railway track bed of dirt (especially pulverized coal). Such as figure 1 As shown, the side suction dust removal system includes: explosion-proof device 1, gravity dust collector 2, multi-tube cyclone dust collector 3, bag filter 4, fan 5, and installed on gravity dust collector 2, multi-tube cyclone dust collector 3, Explosion relief device 6 on top of bag filter 4. Wherein, the entrance of the explosion-proof device 1 is connected with the air outlet of the working device for cleaning the dirt on the railway track bed through a pipeline, the air inlet of the gravity dust collector 2 is connected with the outlet of the explosion-proof device 1 through the air inlet pipe, and the gravity dust collector The air outlet of 2 is connected with the air inlet of multi-pipe cyclone dust collector 3, the air outlet o...

Embodiment 12

[0082] Embodiment 1.2: A side suction dedusting system for a railway track bed sewage suction vehicle, the same as embodiment 1.1, the difference is that the circular outlet of the air outlet pipe 46 of the bag filter is directed toward one of the two tracks relative to the center line of the track The side rails are offset by 200cm.

Embodiment 13

[0083] Embodiment 1.3: A side suction dedusting system for a railway track bed sewage suction vehicle, the same as embodiment 1.1, the difference is that the circular outlet of the air outlet pipe 46 of the bag filter is directed towards one of the two tracks relative to the center line of the track The side track is offset by 510mm. At this time, due to the change of the position of the fan relative to the longitudinal beam of the frame, if the Figure 8 , Figure 9 When the shown fan base 65 remains unchanged, the design position of the longitudinal beam of the vehicle frame needs to be changed, or when the vehicle frame does not change, Figure 8 , Figure 9 The bracket 651 in the fan base 65 shown is no longer applicable, the bracket 651 in the fan base 65 can be removed, the height of the fan base 65 can be raised, and the bending plate 652 can be directly fixed on the surface of the vehicle frame.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com