Automatic explosion-proof device for underground coal mine

An automatic and explosion-proof technology, used in mining devices, safety devices, mining equipment, etc., can solve the problems of difficult processing, complex structure, harmful secondary explosion, etc., to achieve low processing difficulty, high action sensitivity, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

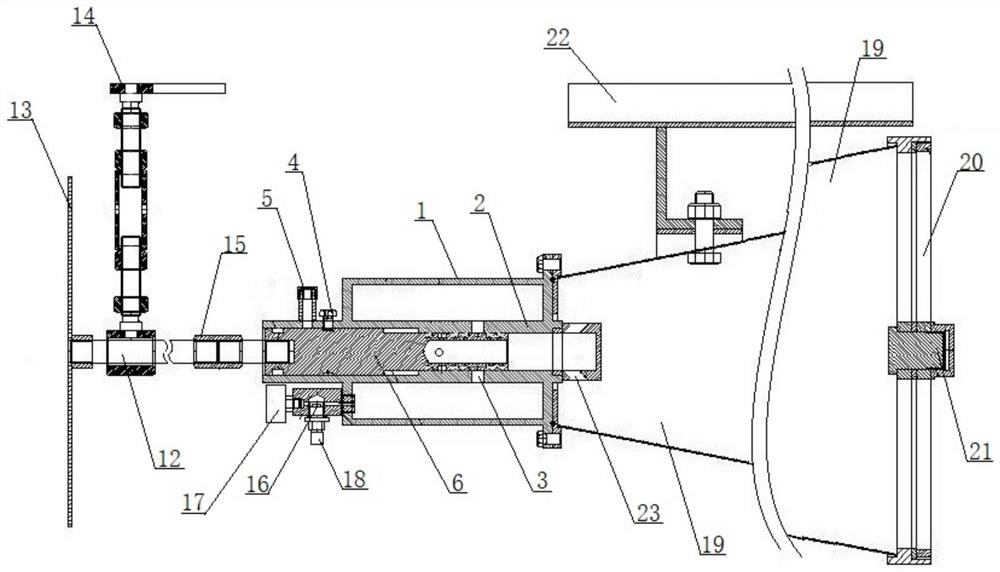

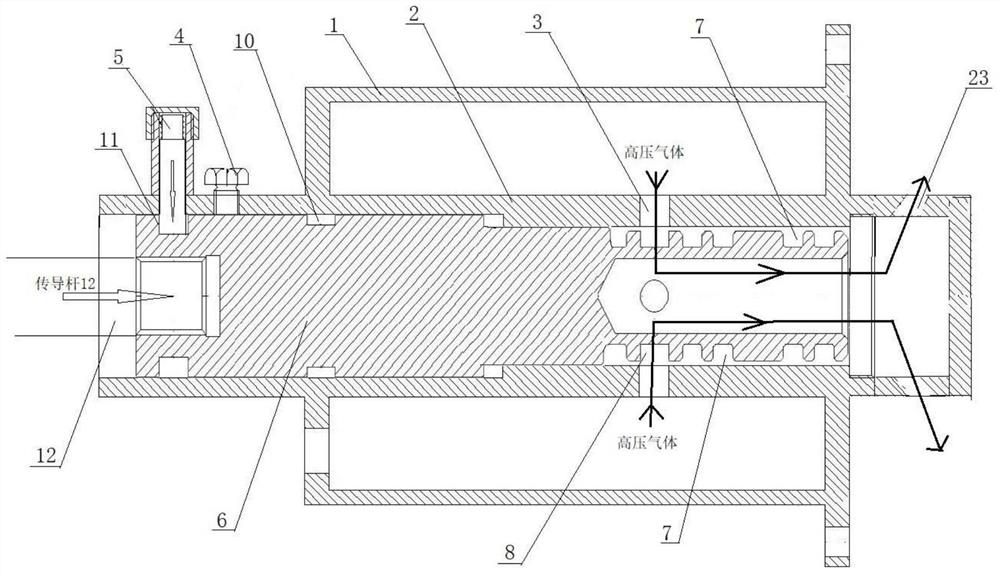

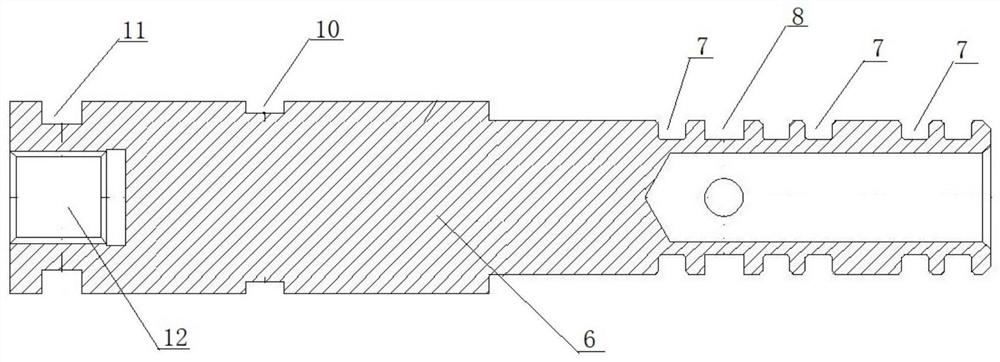

[0027] An automatic explosion-proof device for underground coal mines, including a pressure receiving mechanism, a trigger mechanism, and a reaction mechanism connected in sequence. The trigger mechanism includes a pressure chamber 1, and the pressure chamber 1 is provided with an axial sleeve 2, and the middle position of the axial sleeve 2 is Vent holes 3 are uniformly arranged around the circumference of the cross-section of the pipe wall; the length of the axial sleeve 2 is greater than the length of the pressure chamber 1, and the axial sleeve 2 beyond the pressure chamber 1 is radially provided with a positioning lock pin 4, and the axial sleeve The tail end of the tube 2 is radially provided with a safety lock 5; the axial sleeve 2 is provided with a trigger piston 6, the trigger piston 6 is a cylindrical structure provided with an axial cavity, and the outer circumference of the front end of the trigger piston 6 is provided with five sealing grooves 7. There is a Y-shap...

Embodiment 2

[0029]An automatic explosion-proof device for coal mines, including a pressure receiving mechanism, a trigger mechanism and a reaction mechanism connected in sequence. The trigger mechanism includes a pressure chamber, and an axial casing is arranged in the pressure chamber. The middle position of the axial casing surrounds the pipe wall and traverses Vent holes are evenly arranged on the surface circumference; the length of the axial sleeve is greater than the length of the pressure chamber, the axial sleeve beyond the pressure chamber is radially provided with a positioning lock pin, and the radial end of the axial sleeve is provided with a safety lock; There is a trigger piston inside the shaft sleeve. The trigger piston is a cylindrical structure with a shaft cavity. There are seven sealing grooves on the outer circumference of the front end of the trigger piston. There are Y-shaped sealing rings in the sealing grooves. Counting from right to left There is an air release gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com