Pressure relief explosion-proof valve

An explosion-proof valve and pressure relief technology, which is applied in safety valves, balance valves, valve devices, etc., can solve problems such as limited application range, inconvenient use, and limited installation methods, so as to achieve a wide range of applications, avoid secondary explosions, and prevent air pollution. entry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

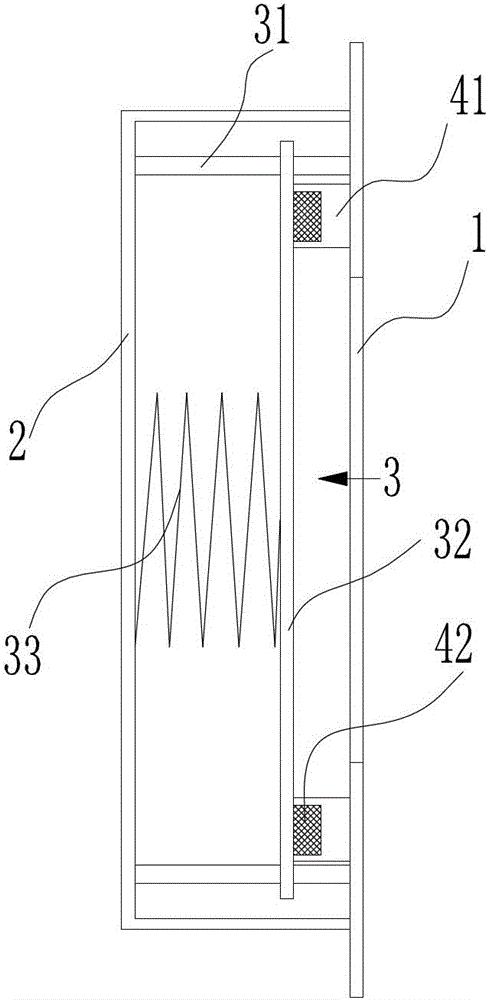

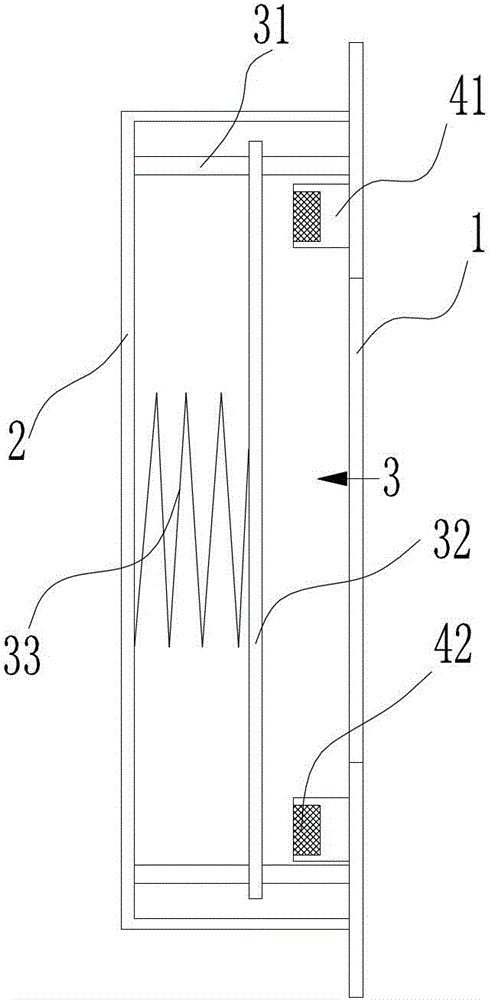

[0015] like figure 1 As shown, the pressure relief explosion-proof valve includes a flange 1, a sealing cover 2, an explosion-proof door 3 installed between the flange 1 and the sealing cover 2, and a sealing ring between the explosion-proof door 3 and the flange 1. In this embodiment, the explosion-proof door includes two guide rails 31 symmetrically arranged between the flange 1 and the sealing cover 2, an explosion-proof door body 32 sealed on the circumference of the central hole of the flange 1, and the explosion-proof door body 32 A spring 33 that is sealingly connected to the circumference of the center hole of the flange 1, the spring 33 is arranged between the explosion-proof door body 32 and the sealing cover 2 and is in a compressed state; the seal ring includes a sealing groove fixed on the circumference of the center hole of the flange 1 41 and the gasket 42 set in the sealing groove 41.

[0016] An air outlet is provided on equipment with potential explosion haz...

Embodiment 2

[0020] The difference between this embodiment and the first embodiment is that the sealing gasket 42 is fixedly connected with the explosion-proof door body 32 and matches with the sealing groove 41 . At normal pressure, the gasket 42 is embedded in the sealing groove 41 , and when the pressure is released, the gasket 42 pops out with the explosion-proof door body 32 and separates from the sealing groove 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com