Tube explosion closing valve

A technology for closing valves and squibs, applied in safety valves, balance valves, valve devices, etc., can solve problems such as failure to close the squib shut-off valve in time, variable medium pressure, and easy failures, etc., and achieve the flexibility of closing pressure High, improve reliability, avoid the effect of valve closing water hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

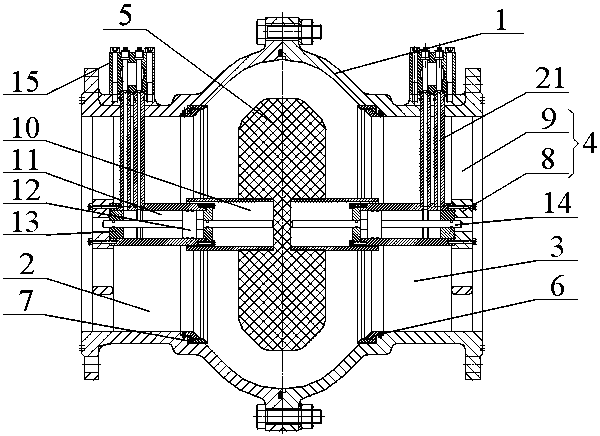

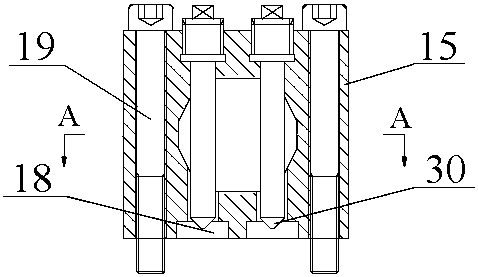

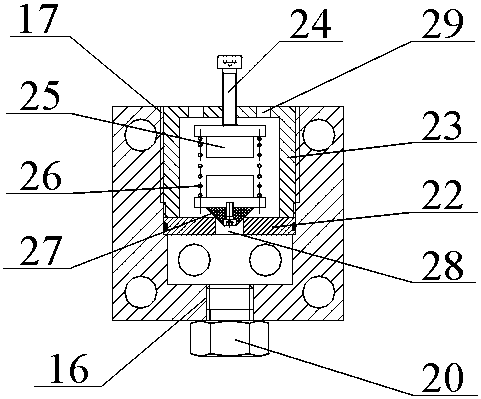

[0023] Combine below Figures 1 to 3 The structure and invention of the squib shut-off valve of the present invention are described.

[0024] Such as figure 1 As shown, a squib shut-off valve includes a valve body 1, a water inlet channel 2 and an outlet channel 3 arranged at both ends of the valve body 1, a support plate 4 respectively arranged in the water inlet channel 2 and the water outlet channel 3, and a The valve disc 5 inside the valve body 1 , the driving mechanism arranged at both ends of the valve disc 5 and controlling the opening and closing of the valve disc 5 , the valve seat 6 sealingly matched with the valve disc 5 and the sealing ring 7 installed on the valve seat 6 . The valve seats 6 are respectively arranged on the water inlet channel 2 and the water outlet channel 3 to cooperate with the valve disc 5 .

[0025] The valve body 1 is symmetrically arranged in two identical structures and fixedly connected by several bolts.

[0026] Both the water inlet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com