Automatic explosion-proof device for underground coal mine

An automatic and explosion-proof technology, used in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of complex installation, many processing procedures, complex structure, etc., to avoid radial jamming, rapid and effective transmission, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] This embodiment is an automatic explosion-proof device for underground coal mines.

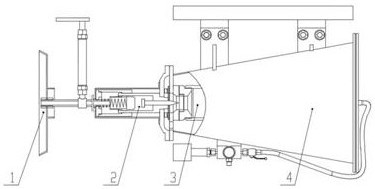

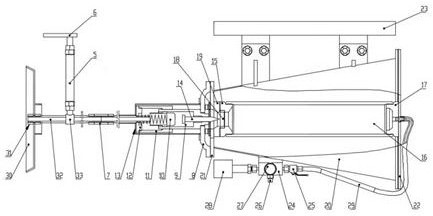

[0029] Such as Figure 1-2 As shown, the transmission mechanism 1 is included, the trigger mechanism 2 is fixedly installed on the outer surface of one end of the transmission mechanism 1, the gas storage cylinder group 3 is fixedly installed on the outer surface of one end of the trigger mechanism 2, and the outer surface of one side of the gas storage cylinder group 3 is fixedly installed. There are horn set 4.

[0030]The transmission mechanism 1 includes a receiving plate 30, a nut 31, a transmission rod 32, a suspension rod 33, an adjustment pipe 5, a hanger 6 and a pipe collar 7, and the transmission rod 32 is located at the middle of the outer surface of one side of the receiving plate 30, and the suspension rod 33 is located at The outer wall of the transmission rod 32, the adjustment tube 5 is located at the upper end outer surface of the suspender 33, the hanger 6 is located ...

specific Embodiment 2

[0033] This embodiment is an embodiment of the transmission mechanism 1 in an automatic explosion-proof device for underground coal mines.

[0034] Such as figure 1 , 2 As shown, a transmission mechanism 1 for an automatic explosion-proof device in a coal mine, the transmission mechanism 1 includes a receiving plate 30, a nut 31, a transmission rod 32, a boom 33, an adjustment tube 5, a hanger 6 and a pipe collar 7, and the transmission The rod 32 is located in the middle of the outer surface of one side of the receiving tray 30, the suspender 33 is located on the outer wall of the transmission rod 32, the adjusting pipe 5 is located on the upper outer surface of the suspender 33, the hanger 6 is located on the upper outer surface of the adjusting pipe 5, and the pipe collar 7 Located between two groups of transmission rods 32; the transmission rod 32 is fixedly connected to the receiving plate 30 through the nut 31, the transmission rod 32 and the suspension rod 33 are in a ...

specific Embodiment 3

[0036] This embodiment is an embodiment of a trigger mechanism 2 for an automatic explosion-proof device in a coal mine.

[0037] Such as figure 1 , 2 As shown, a trigger mechanism 2 for an automatic explosion-proof device in a coal mine, the trigger mechanism 2 includes an air diffuser 8, a guide seat 9, a trigger top block 10, a guide cylinder 11, a guide cylinder cover 12, a protective cover 13 and a striker 14 The protective cover 13 is positioned at the outer wall of one end of the transmission rod 32, and the guide cylinder cover 12 is positioned at the outer surface of one end of the guide cylinder 11, the trigger top block 10 is positioned at the inside of the guide seat 9, and the diffuser disc 8 is positioned at the outer surface of one end of the guide seat 9, The striker 14 is located on the outer surface of one side of the guide seat 9, and the outer wall of the guide seat 9 is provided with three sets of through holes; the guide seat 9 and the diffuser plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com