One-way explosive-proof valve

An explosion-proof, one-way technology, used in valve details, control valves, safety valves, etc., can solve problems such as inability to reach and protect, and achieve the effect of avoiding secondary explosions, increasing the area of action, and ensuring equipment safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

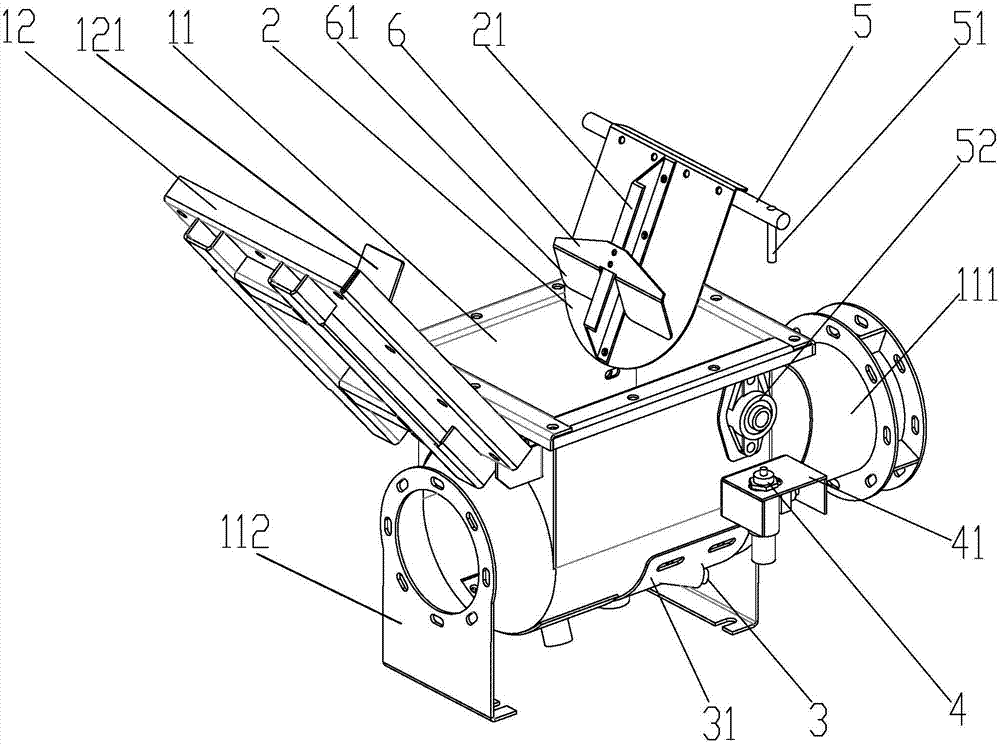

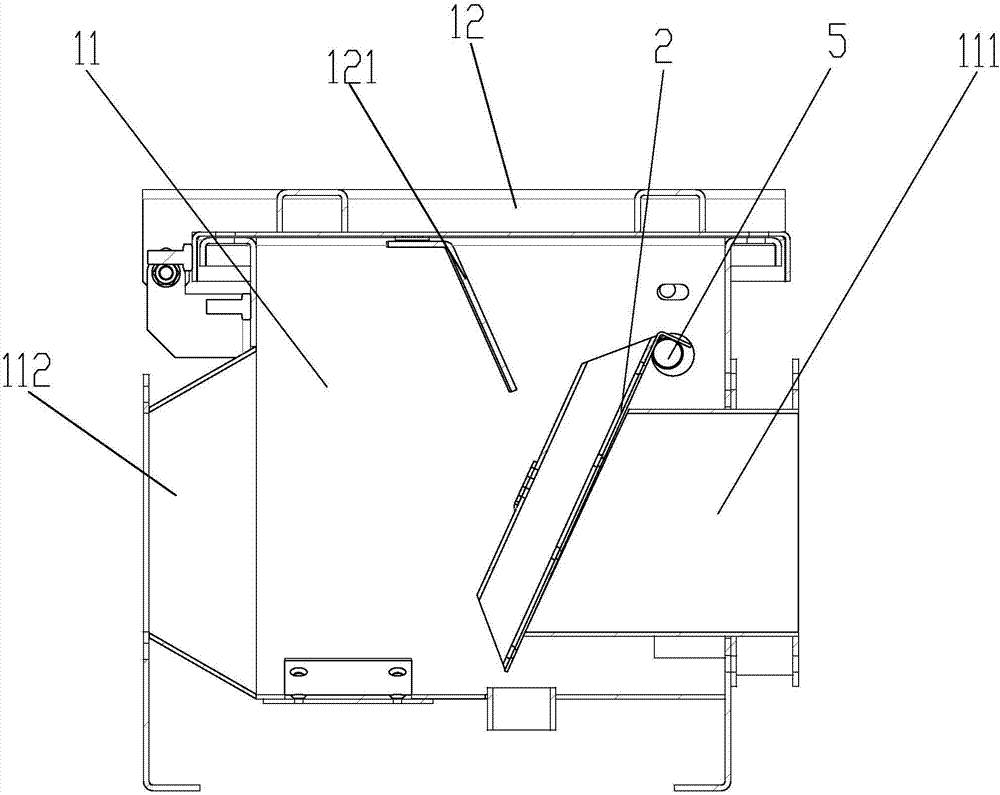

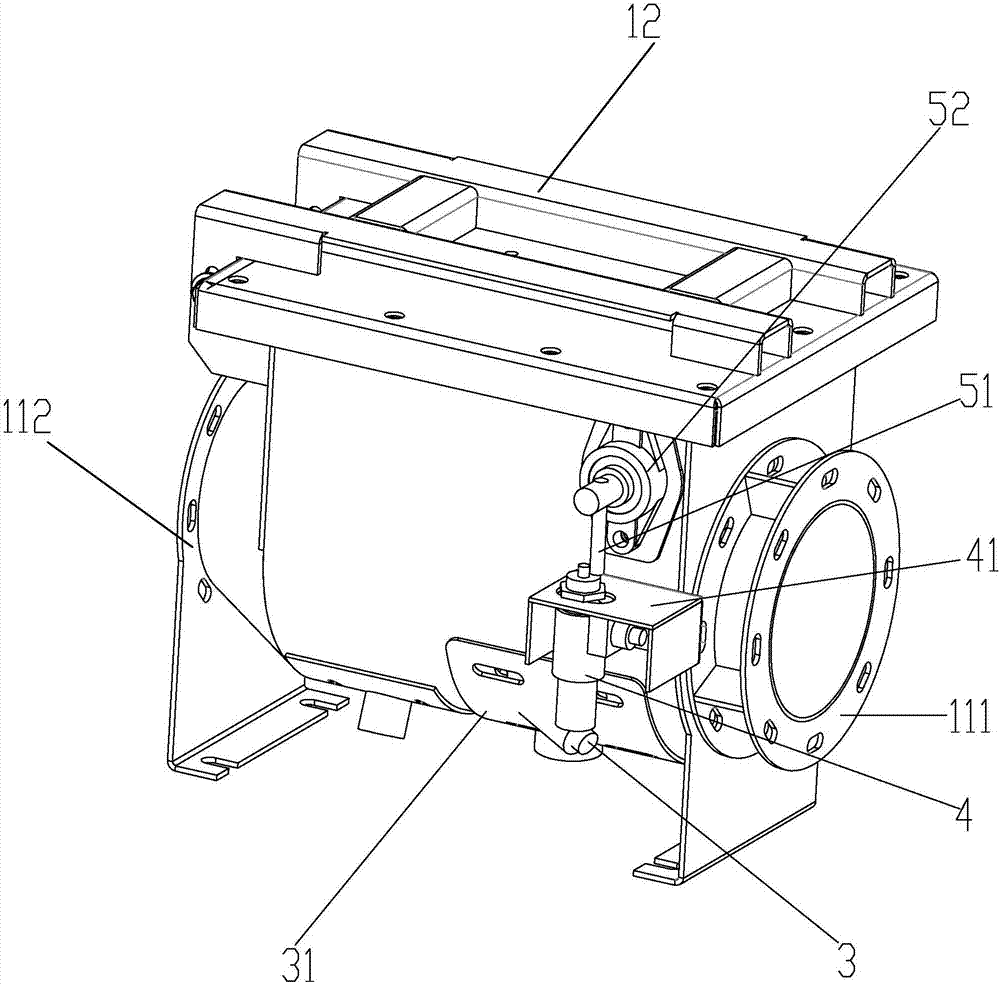

[0024] Figure 1-4 The one-way explosion-proof valve according to an embodiment of the present invention is schematically shown. Such as Figure 1-5 As shown, the one-way explosion-proof valve includes a valve housing 1, a valve disc 2, a proximity switch 3, and a latch 4.

[0025] Both ends of the valve housing 1 are provided with an inlet flange 111 and an outlet flange 112 respectively. The valve housing 1 is provided with a cavity for containing the valve flap 2. The valve housing 1 includes a valve body 11 and a valve cover 12. The top and both ends of the valve body 11 are open. The openings at both ends facilitate the flow of medium and gas through the valve body 11. The opening at one end of the valve body 11 is connected with the inlet flange 111, and the opening at the other end of the valve body 11 is connected with the outlet flange 112. The flanges at both ends of the valve body 11 function as a connection, so that the one-way explosion-proof valve can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com