Gas firefighting explosive-proof valve

A gas and fire-fighting technology, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve problems affecting dust transportation, etc., and achieve the effects of avoiding valve disc damage, increasing sealing, and avoiding secondary explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

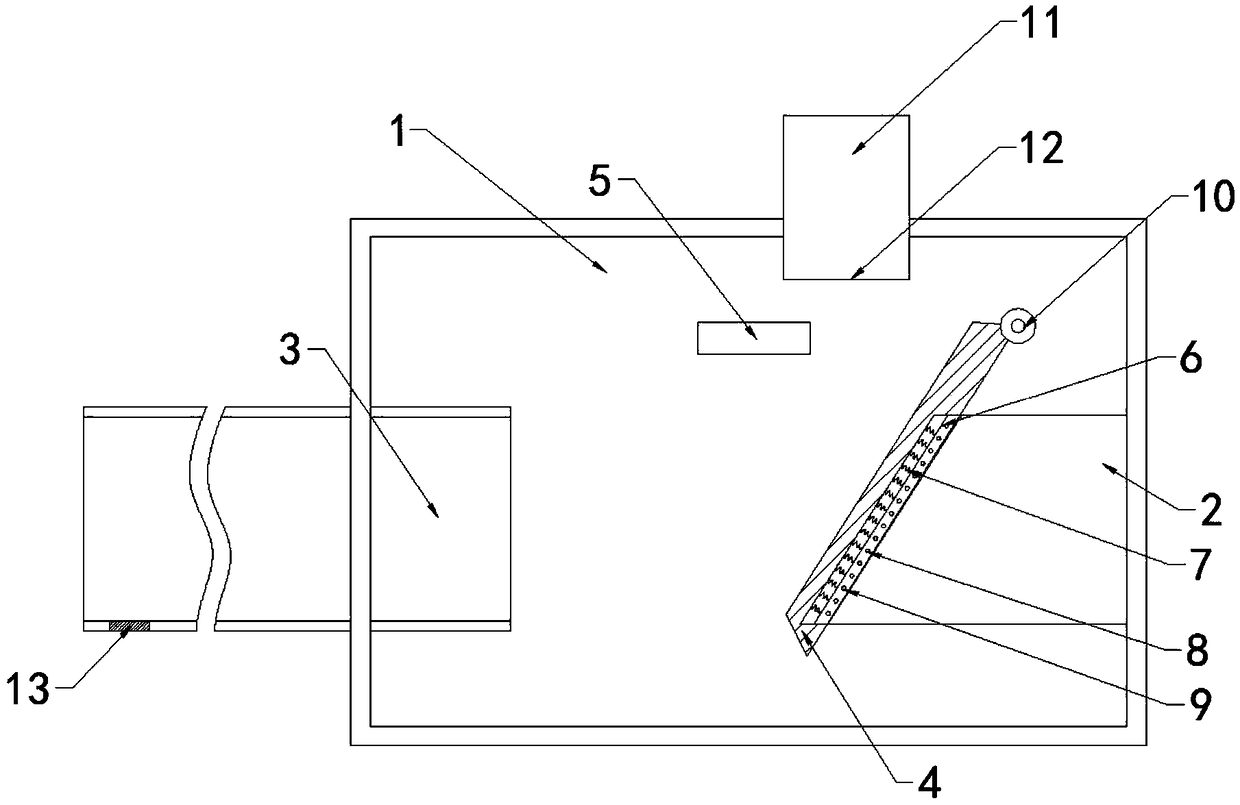

[0036] A gas fire-fighting explosion-proof valve, comprising a housing 1, the two ends of the housing 1 are respectively provided with a feed pipe 2 and a discharge pipe 3, and a valve flap 4 for opening and closing the feed pipe 2; one end of the valve flap 4 A rotating shaft 10 is provided, and the valve disc 4 can rotate around the rotating shaft 10 to realize the opening and closing of the feed pipe 2; the valve disc 4 is made of metal magnetic material, and the inner wall of the housing 1 is provided with a magnet 5 that can absorb the valve disc 4,

[0037] The housing 1 is provided with a gas fire-fighting mechanism 11 on the upper part of the valve flap 4, and the lower part of the gas fire-fighting mechanism 11 is provided with an air outlet 12, and the gas outlet 12 is located above the valve flap 4; The temperature sensor 13, the temperature sensor 13, and the gas fire-fighting mechanism 11 are all connected with the control system.

Embodiment 2

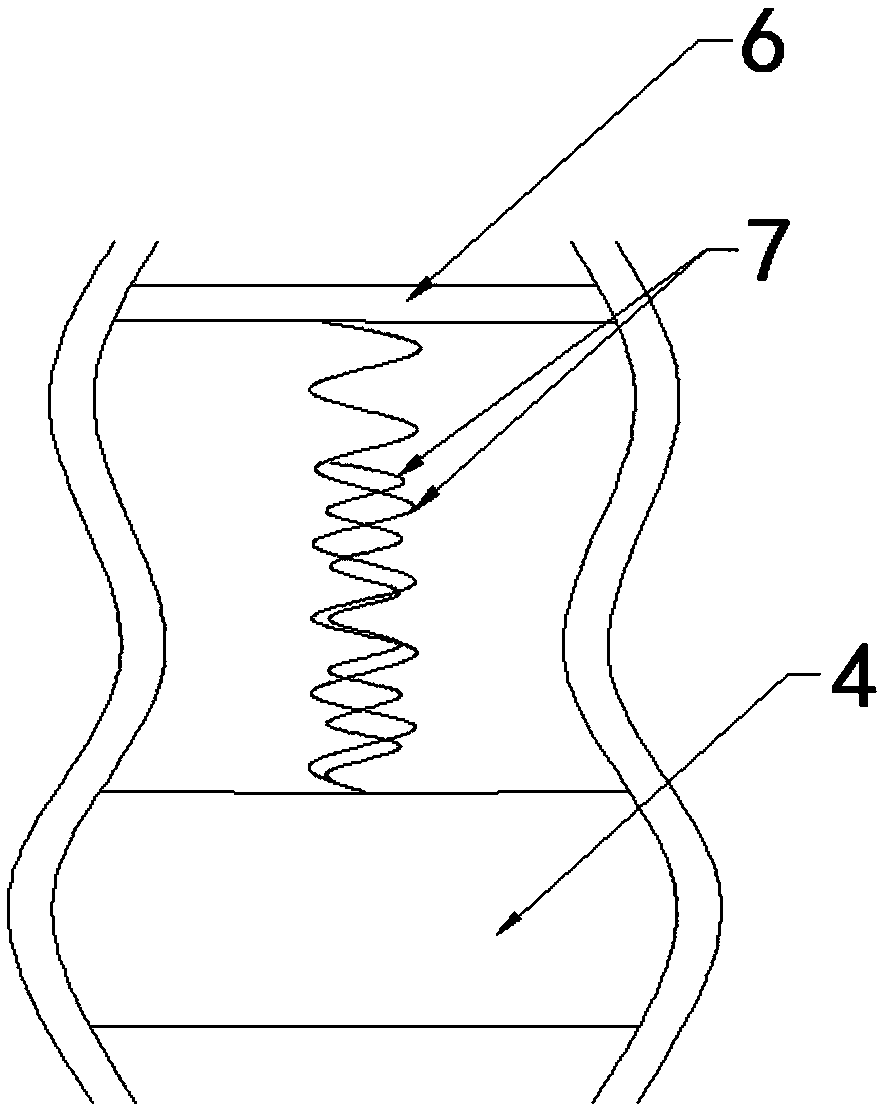

[0039]This embodiment is further optimized based on Embodiment 1. The valve disc 4 is located at the contact position with the feed pipe 2 and is provided with a buffer plate 6, and a plurality of buffer devices are arranged between the buffer plate 6 and the valve disc 4; each buffer device It includes a plurality of coaxially arranged springs 7, and the heights of the plurality of springs 7 in the same buffer device are all different;

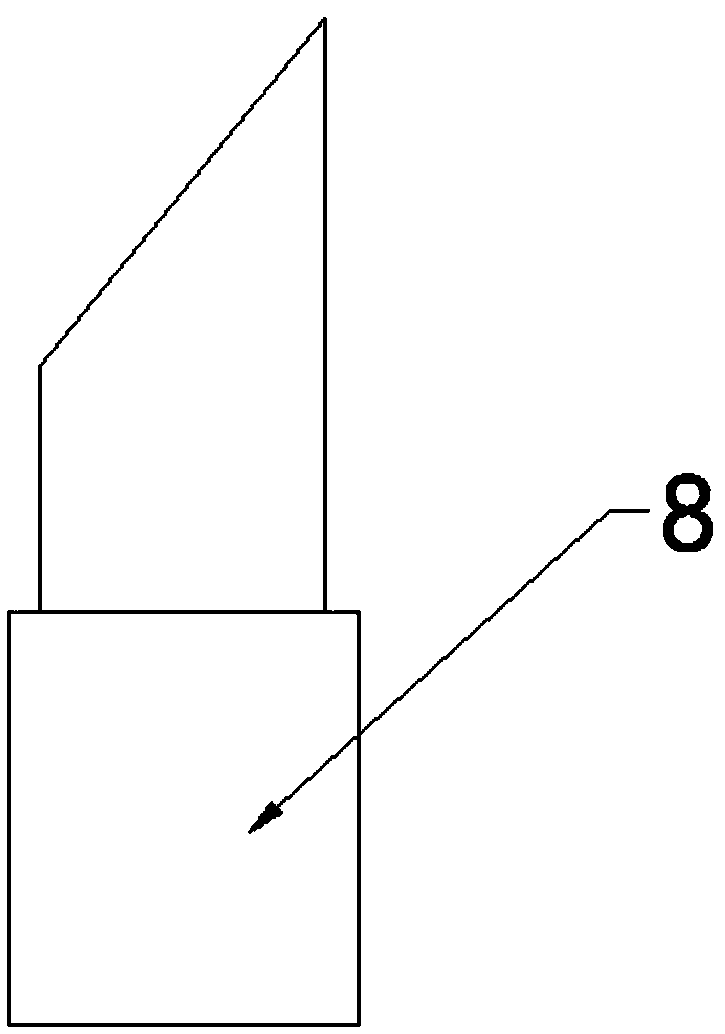

[0040] The feed pipe 2 is provided with a plurality of elastic rods 8 on the outer circumferential surface of one end of the valve disc 4, and a plurality of fixing holes 9 are arranged on the valve disc 4 corresponding to the positions of the elastic rods 8, and the elastic rods 8 cooperate with the fixing holes 9 to hold the valve disc 4 is connected with feed pipe 2;

[0041] The top of the elastic rod 8 is an inclined surface, and the inclined surface is arranged on one side of the valve flap 4, so that the elastic rod 8 is pressed down d...

Embodiment 3

[0045] This embodiment is further optimized based on Embodiment 2. The fixing hole 9 is a through hole, so that when the valve disc 4 is separated from the feed pipe 2, it can directly pass through the fixing hole 9, and the elastic material stuck in the fixing hole 9 can be directly passed through the fixing hole 9. The rod 8 shrinks, thereby facilitating the separation of the valve disc 4 and the feed pipe 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com