Negative pressure bidirectional detonation flame-proof device

An explosion-proof and detonation technology, which is applied in the direction of valve devices, multi-way valves, safety valves, etc., can solve the problem of increasing the explosion pressure of explosion-proof chambers and pipelines, unable to remotely monitor the normal working status of explosion-proof valves in real time, and explosion-proof Valve damage and other problems, to achieve the effect of automatic monitoring and control, improve efficiency and safety, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

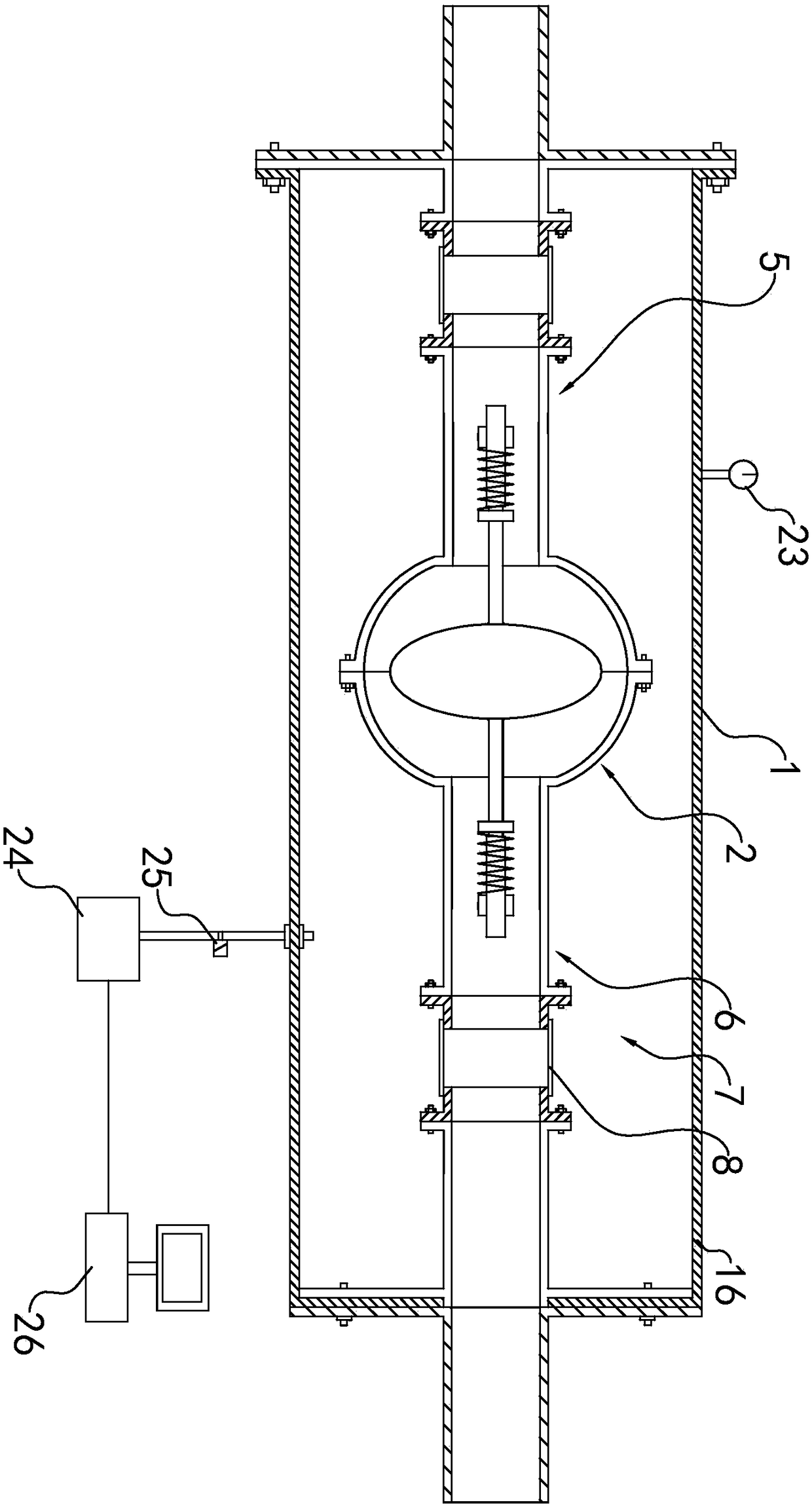

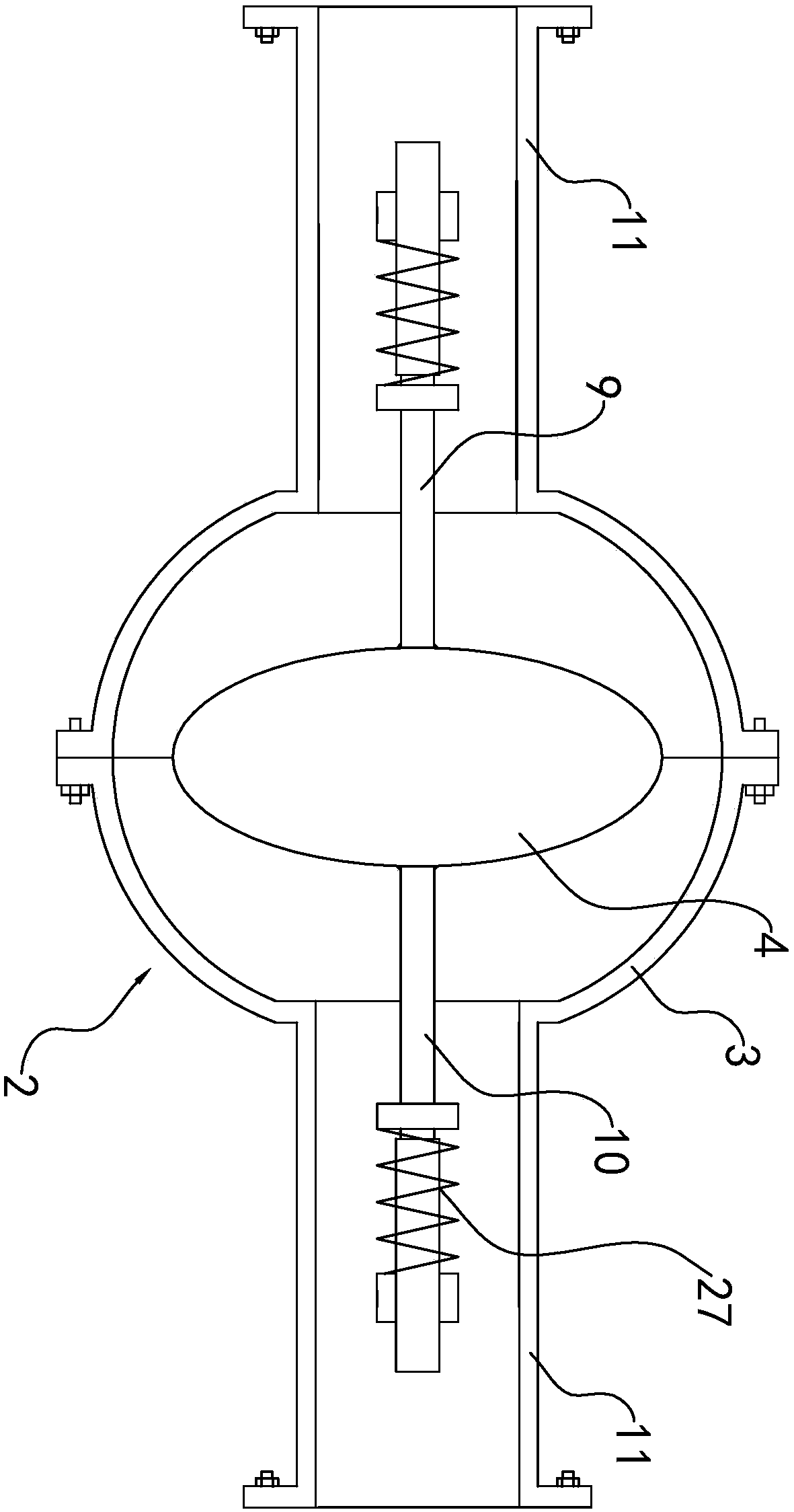

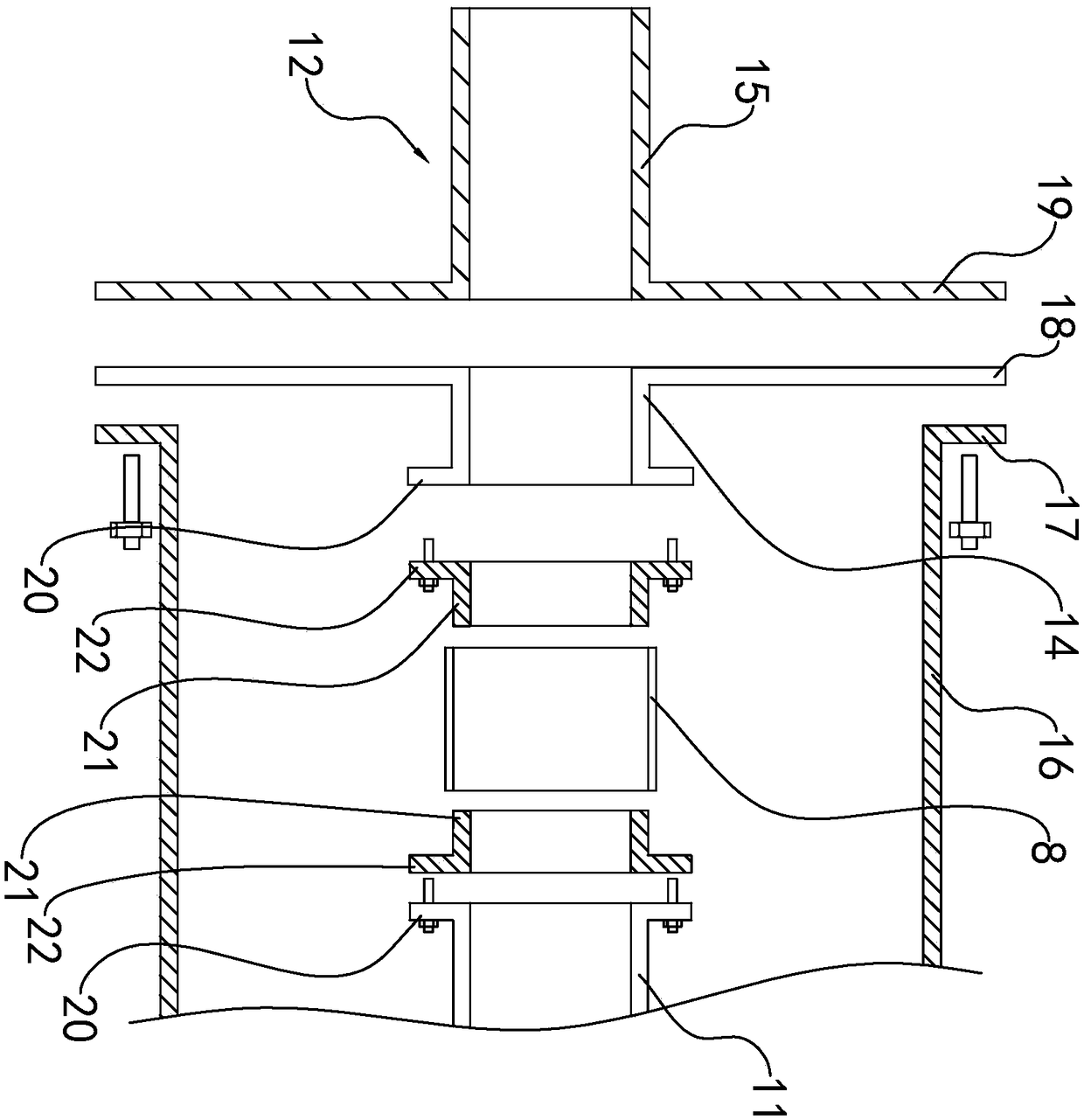

[0021] refer to Figures 1 to 4 , a negative pressure two-way detonation explosion-proof device, including a negative pressure chamber 1 and a two-way explosion-proof valve 2 arranged in the negative pressure chamber 1, the two-way explosion-proof valve 2 includes a valve core 4 containing chamber inside The valve body 3 and the valve core 4 are arranged in the cavity of the valve core 4. The two ends of the valve body 3 are respectively provided with a first pipeline 5 and a second pipeline 6 which pass through the negative pressure chamber 1 and communicate with the outside world. In order to enhance the explosion-proof effect, the negative pressure chamber tube 1 is sealed and connected with the outer walls of the first pipe 5 and the second pipe 6 respectively to form a negative pressure chamber 7, and the walls of the first pipe 5 and the second pipe 6 are respectively provided with brittle The annular bursting disc 8 is provided in the negative pressure chamber 7 . In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com