Coal mine automatic explosion-proof device with two-way triggering

A two-way triggering, coal mine technology, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of increasing equipment cost and installation workload, unsafe device backwards, and inability to install devices, etc. The effect of fire extinguishing efficiency, convenient operation, and convenient production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

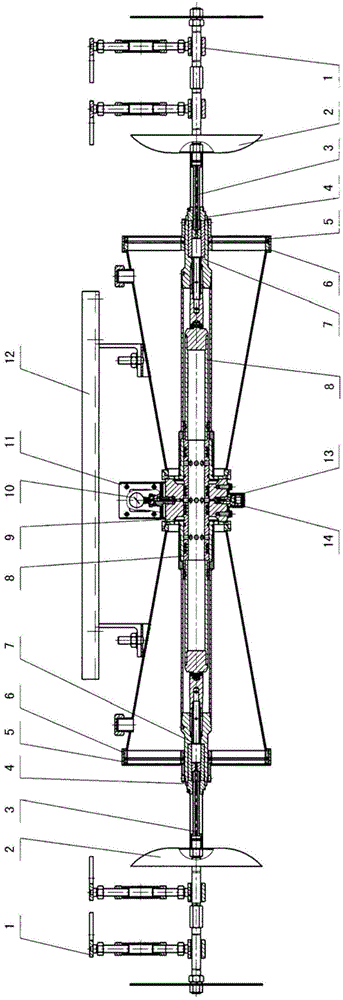

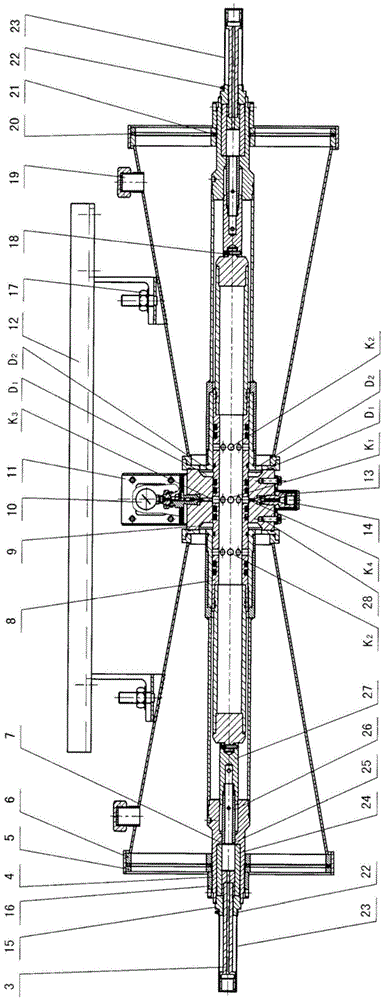

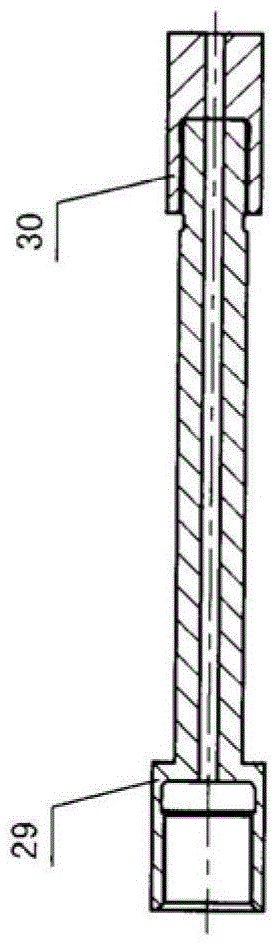

[0028] exist figure 1 The overall structure of the coal mine underground automatic flameproof device with two-way triggering of the present invention is shown in . The device is composed of a receiving rod hanging device 1, a shock wave receiving device 2, and a main body; the main body is composed of an action trigger assembly 7, an air jet pipe assembly 8, an intermediate sleeve assembly 9, an outer cover assembly 6, and a compacting screen assembly 5 , pressure gauge assembly 10, pressure gauge protective cover 11, valve needle 13, inflatable cover assembly 14, main body hanging device 12, etc. Among them, the receiving rod hanging device 1, the shock wave receiving device 2, the action triggering assembly 7, the outer cover assembly 6, and the pressing screen assembly 5 are two sets of left and right and arranged symmetrically with the axial vertical center line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com