Dust removing equipment

A technology for dust removal equipment and dust collection chambers, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of complicated pipelines, large floor space, air flow path restrictions, etc., and achieves simple internal structure and construction. Low-cost, widely applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

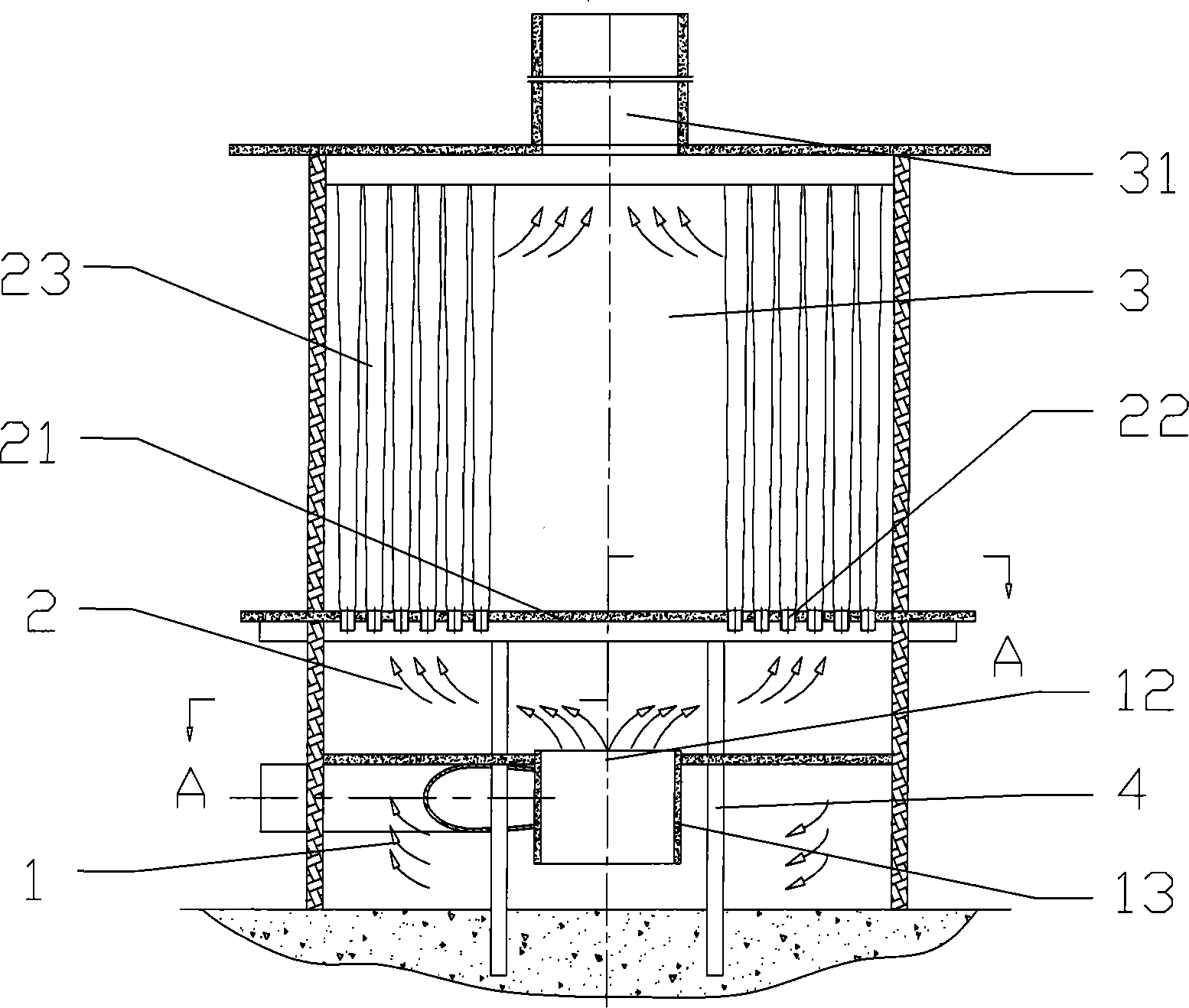

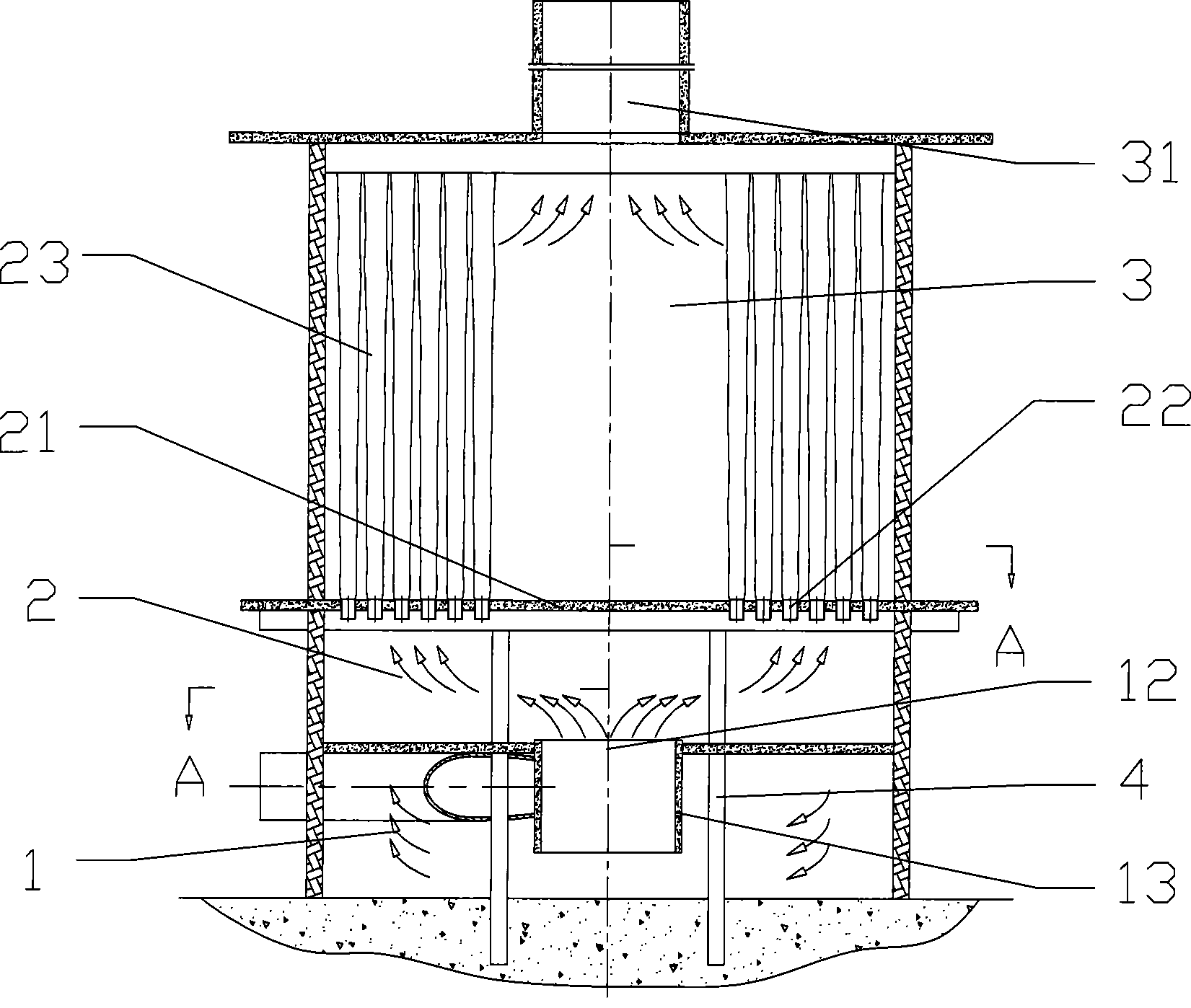

[0017] The dust removal equipment implemented according to the present invention includes a cyclone chamber 1 for cyclone dust removal, a diffusion chamber 2 for static dust removal, and a baghouse 3 for baghouse dust removal from bottom to top.

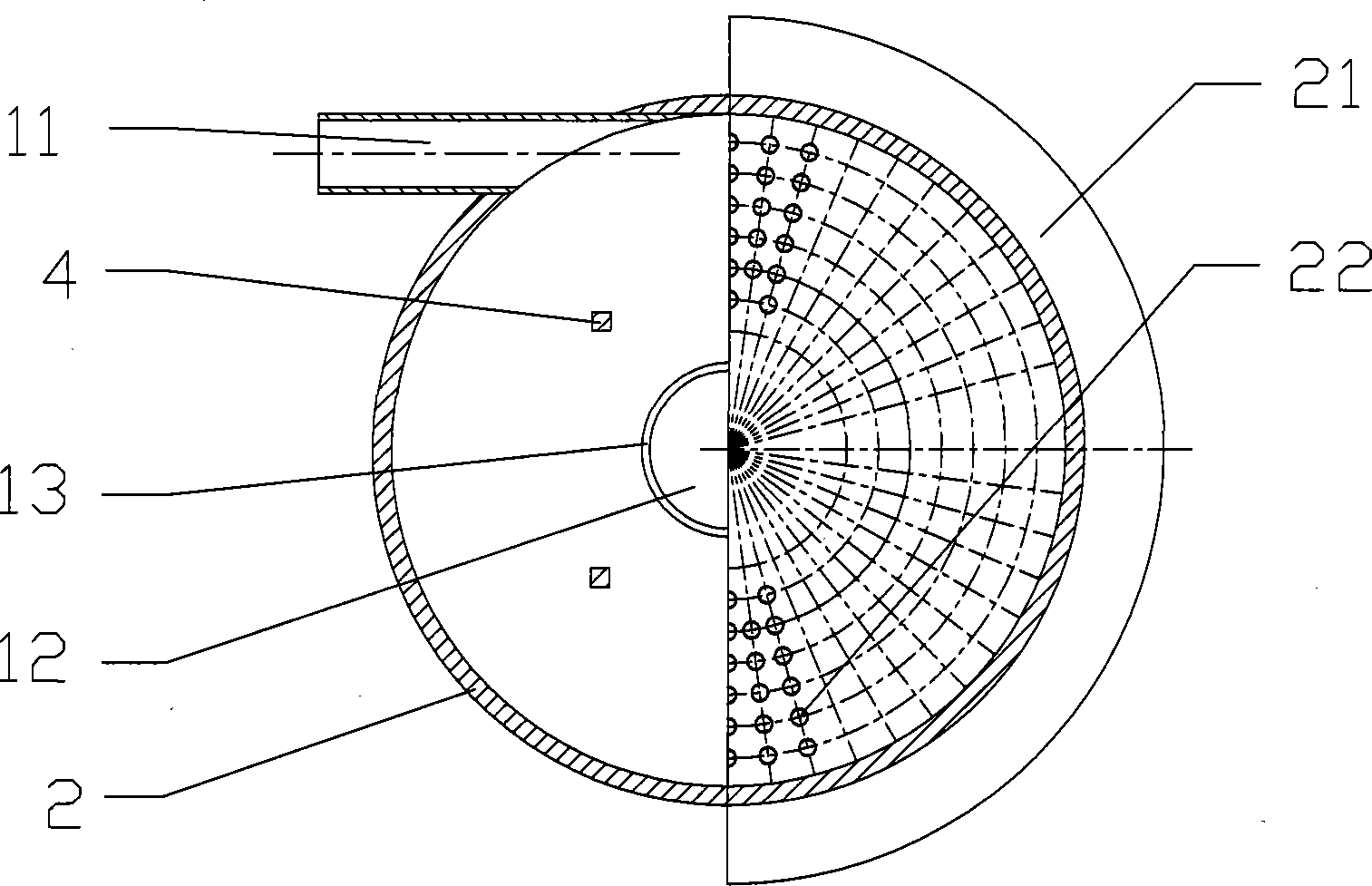

[0018] as attached figure 1 And attached figure 2 As shown, the dust removal equipment is an upright cylindrical shape with a total height of 13 meters and a diameter of 10 meters, and its bottom end is a cyclone chamber 1 with a height of 3 meters. An inlet passage 11 is opened on the side wall of the cyclone chamber 1, and a circular outlet passage 12 is opened in the middle of the top wall. A cylinder 13 with a height of 2 meters and a diameter of 2 meters extends downward from the top wall at the edge of the outlet passage 12 .

[0019] The diffusion chamber 2 located above the cyclone chamber 1 is 2 meters h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com