Assembled flat-plate photobioreactor

A photobioreactor and reactor technology, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve difficult promotion and implementation, lack of actual assembly modules Structural characteristics, lack of technical characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

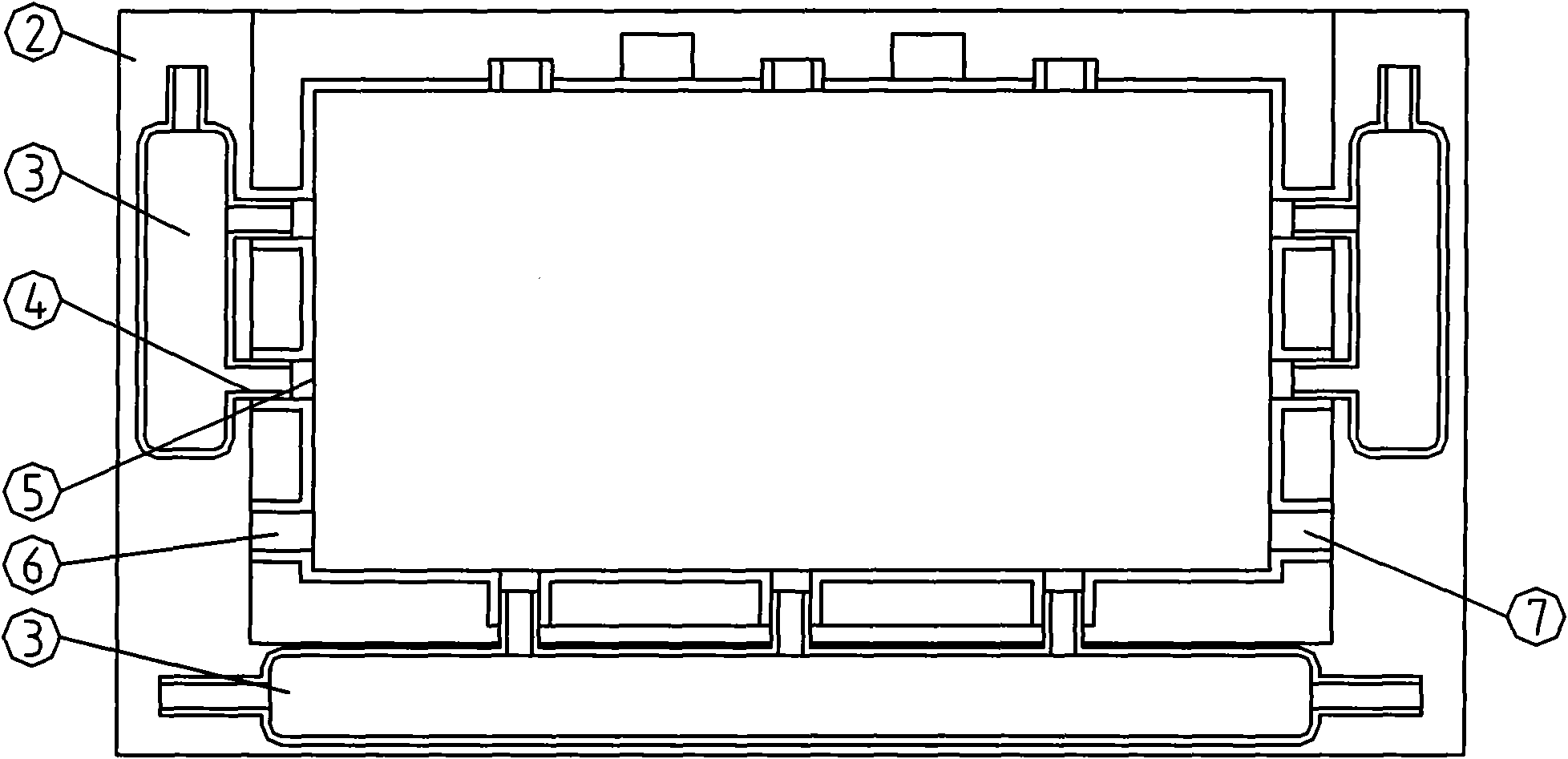

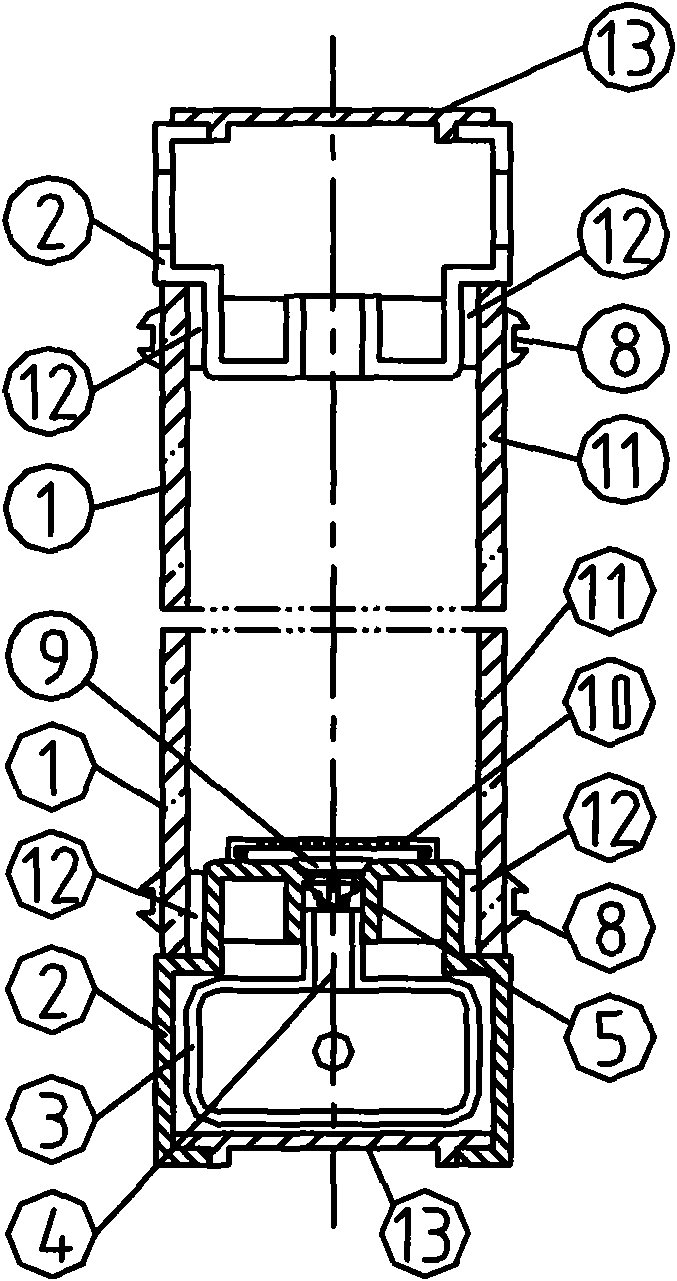

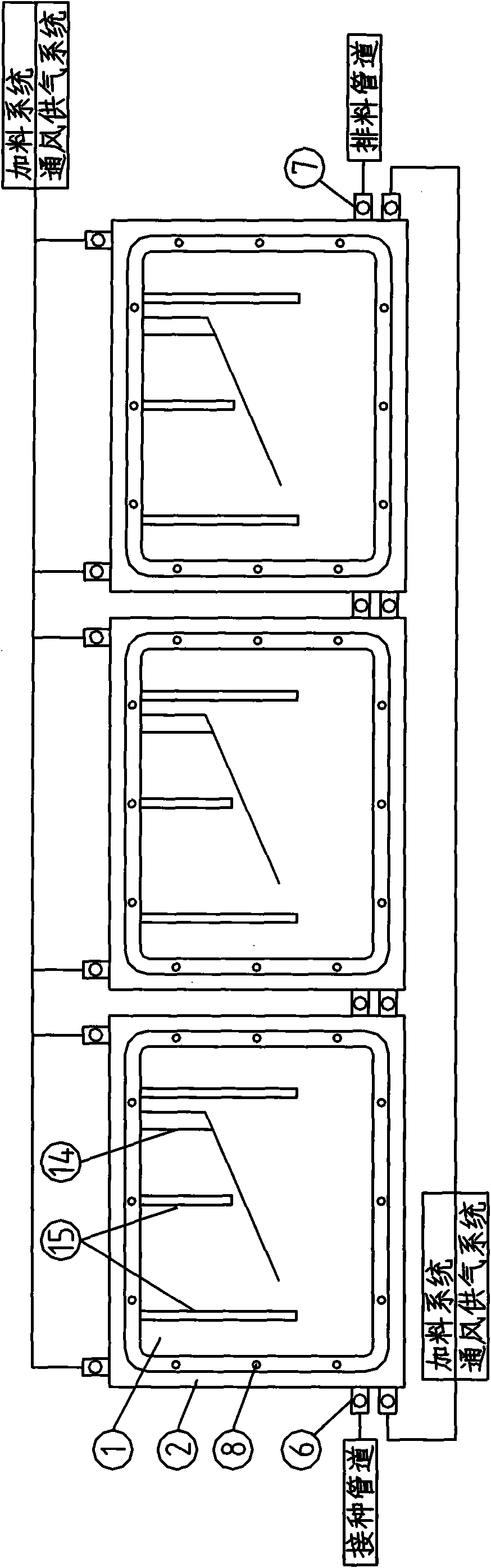

[0032] like figure 1 and figure 2 As shown, the assembled flat plate photobioreactor of the present invention includes a front side wall 1 of the reactor, a rear side wall 11, a frame 2, and a sealing function installed between the front side wall 1 and the rear side wall 11 and the frame 2 The gasket 12, the fastener 8 that plays a fixing role, also includes the feeding hole 5 on the frame 2, the check valve 9 installed on the feeding hole 5, the distributor 10 fixed on the frame 2, and fixed on the frame 2 The distribution pipe 3 in the hollow tank, the distribution joint 4 on the distribution pipe 3 is matched with the feeding hole 5 and connected with the feeding hole 5 .

[0033] figure 1 It is a schematic cross-sectional view of the frame and distribution pipe assembly of the flat photobioreactor of the present invention. In the figure, in the base of the reactor frame 2 and the hollow groove columns on both sides, the distribution pipe 3, the distribution joint 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com