Lithium ion battery module and high-capacity lithium ion battery

A lithium-ion battery and battery technology, applied in battery pack components, secondary batteries, circuits, etc., can solve problems such as increased cost and complexity, unsuitable for mechanized operations, and difficult to control elasticity, and achieves a compact and stable structure , good rigidity, prolonging the life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Lithium-ion battery module and high-capacity lithium-ion battery

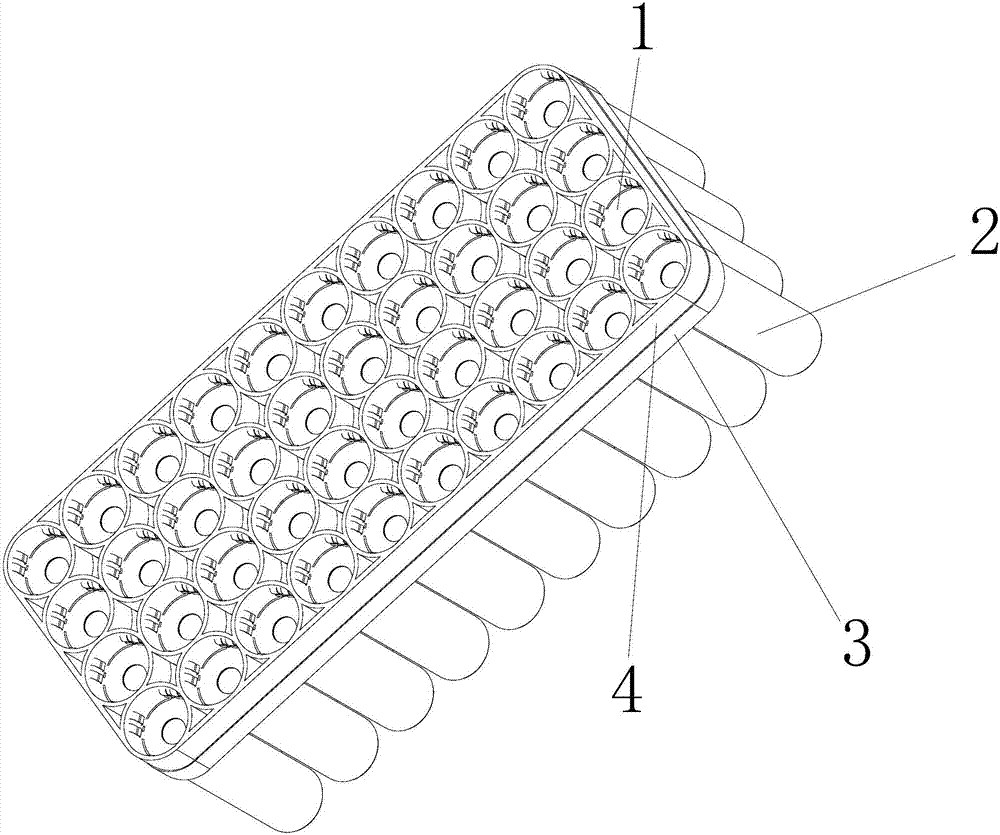

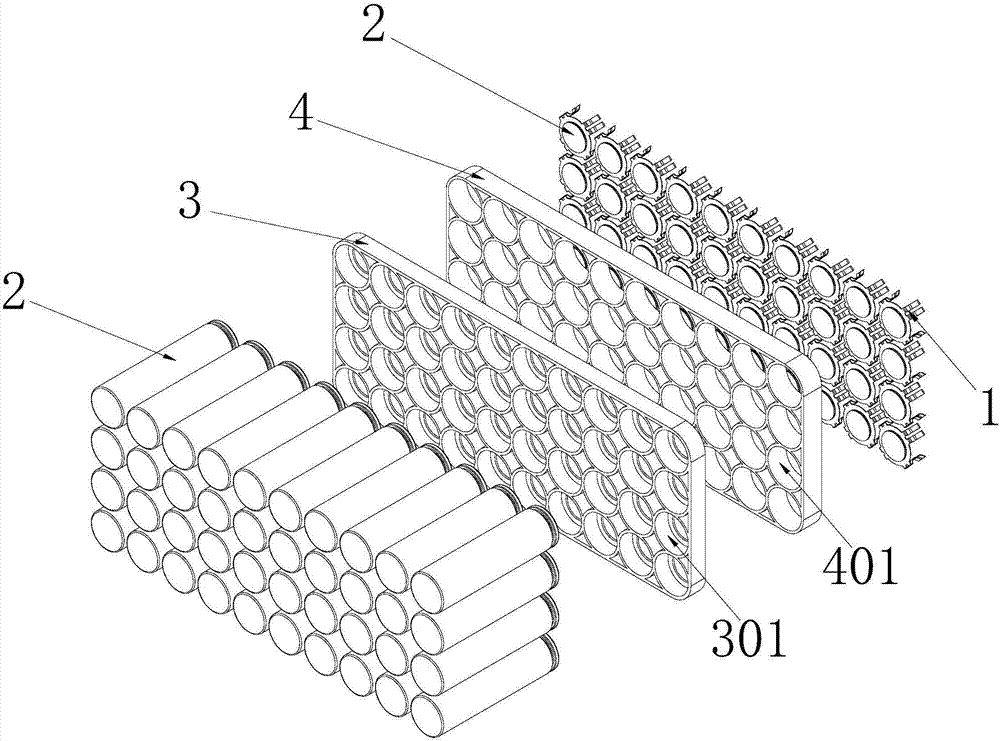

[0046]figure 1 and figure 2 A preferred embodiment of the battery module of the present application is shown. The battery module is a cylindrical lithium-ion battery module. It is the same as the traditional battery module and also includes a battery clamp (also called a battery holder in the industry). connection bracket), the battery fixture is formed with numerous battery insertion holes in a matrix distribution, each battery insertion hole is embedded with a battery series piece 1, and each battery insertion hole is inserted with a cylindrical Shaped lithium-ion battery cell 2. Specifically, in this embodiment, the negative terminal of the battery cell 2 is inserted into the battery insertion hole of the battery fixture, and is connected to the battery series piece 1 in the battery insertion hole.

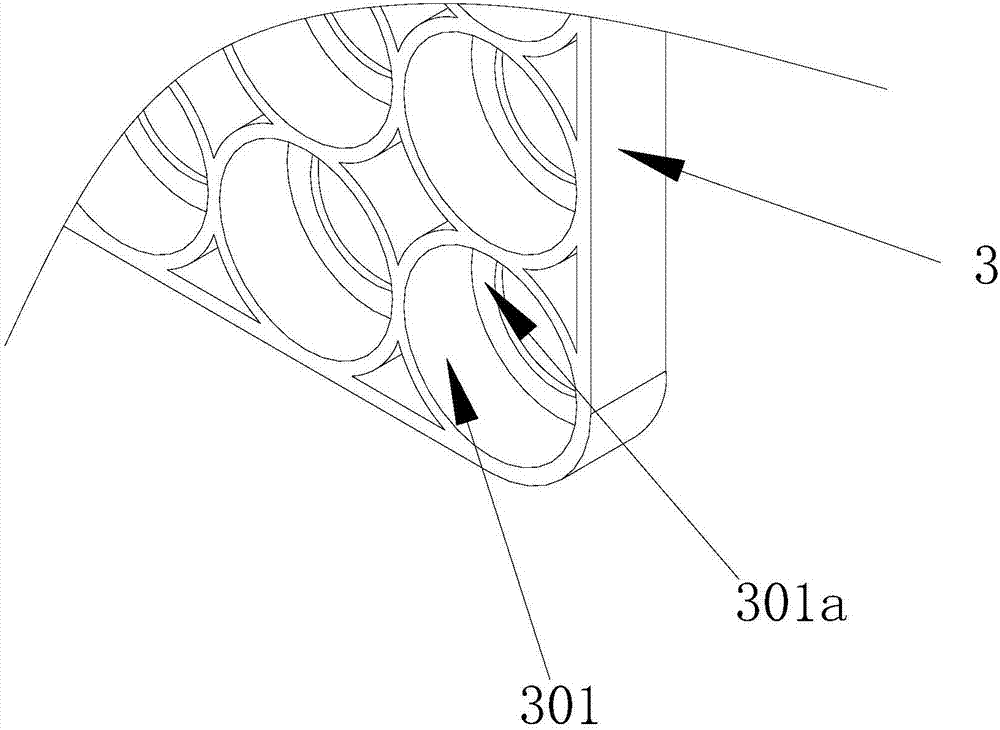

[0047] The key improvement of this embodiment is that the above-mentioned battery cla...

Embodiment 2

[0058] Embodiment 2: Lithium-ion battery module

[0059] Figure 5 to Figure 7 It shows another preferred embodiment of the battery module of the present application, its structure is basically the same as that of the battery module in Embodiment 1, the main difference lies in the following points:

[0060] First, the structural form of the conductive support 4 in the present embodiment is different from that of the conductive support in Embodiment 1. The conductive support 4 in this example is a piece of which is provided with some through holes (these through holes constitute the said conductive support holes) Instead of arranging a plurality of metal tubes together and fixing them by welding or sintering, the conductive support 4 can be cast from aluminum. Compared with the first embodiment, the conductive support 4 with the structure of the present embodiment has stronger integrity and higher structural strength. The disadvantage is that it uses more materials and is hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com