Battery fixture for battery module

A technology of battery fixtures and battery modules, which is applied to battery components, batteries, secondary batteries, etc., can solve the problems of slow heat transfer, difficult movement, and difficult processing of large parts, and achieve strong shock and vibration resistance, Improve heat dissipation and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

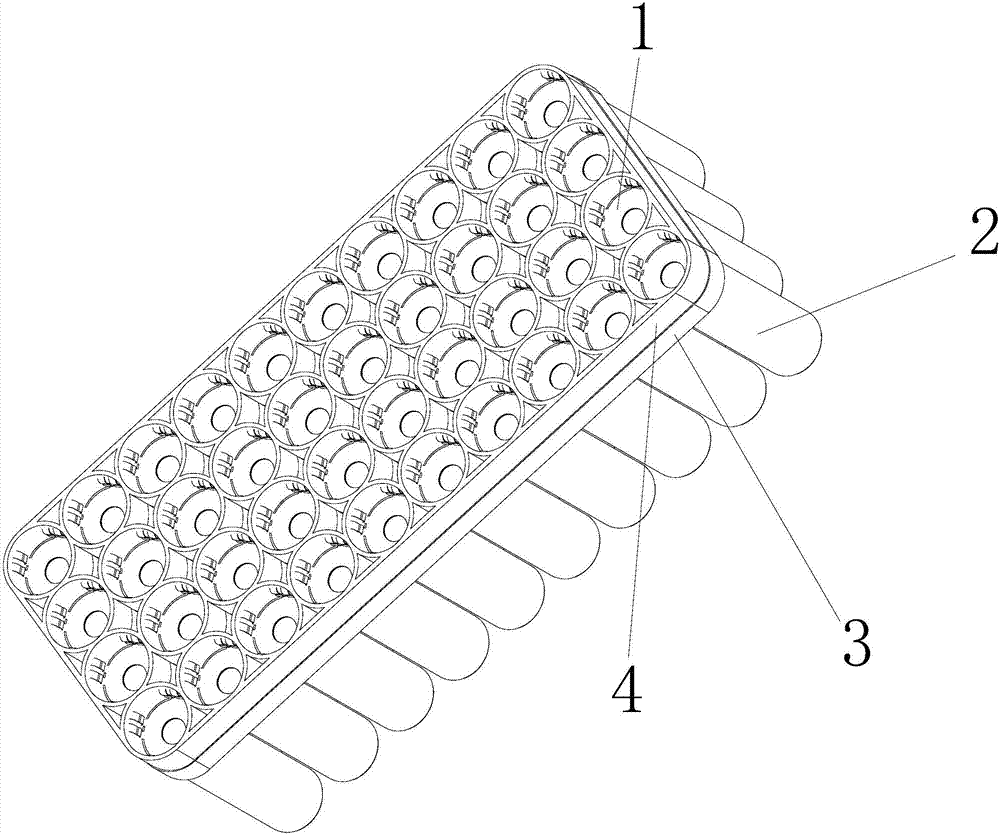

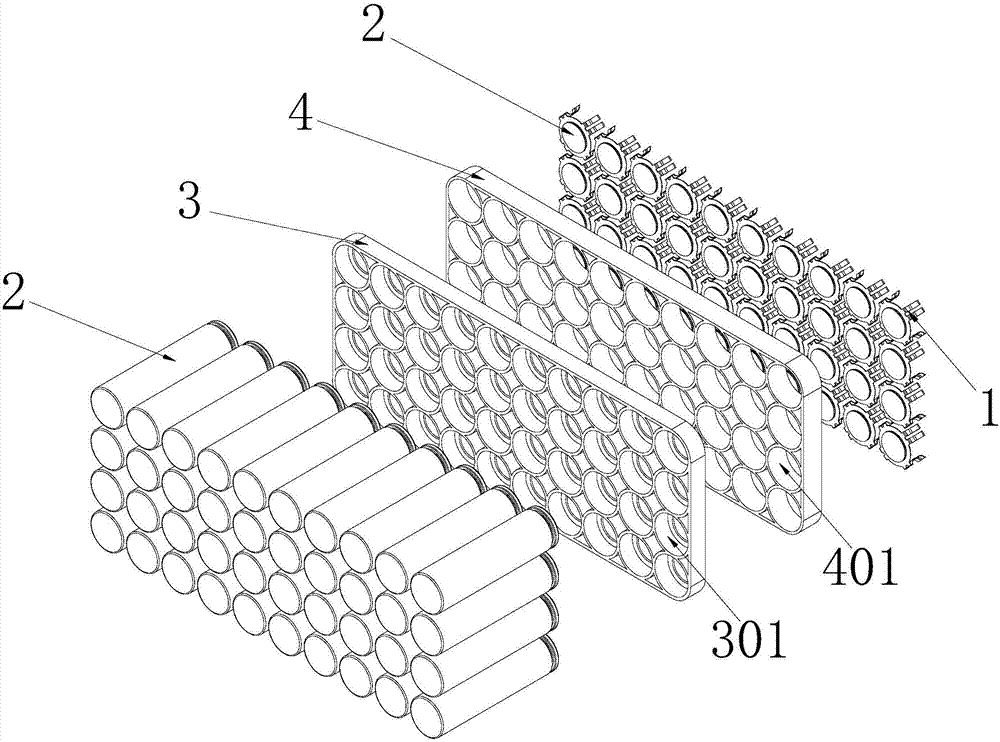

[0037] Figure 1 to Figure 4 A specific application example of the battery clamp of the present application in a battery module is shown, the battery module is a cylindrical lithium-ion battery module, which is the same as the traditional battery module, and also includes a battery clamp ( It is also called battery connection bracket in the industry), and the battery fixture is formed with many battery insertion holes distributed in a matrix, each battery insertion hole is embedded with a battery series piece 1, and each battery insertion hole is A cylindrical lithium-ion battery cell 2 is inserted. Specifically, in this embodiment, the negative terminal of the battery cell 2 is inserted into the battery insertion hole of the battery fixture, and is connected to the battery series piece 1 in the battery insertion hole.

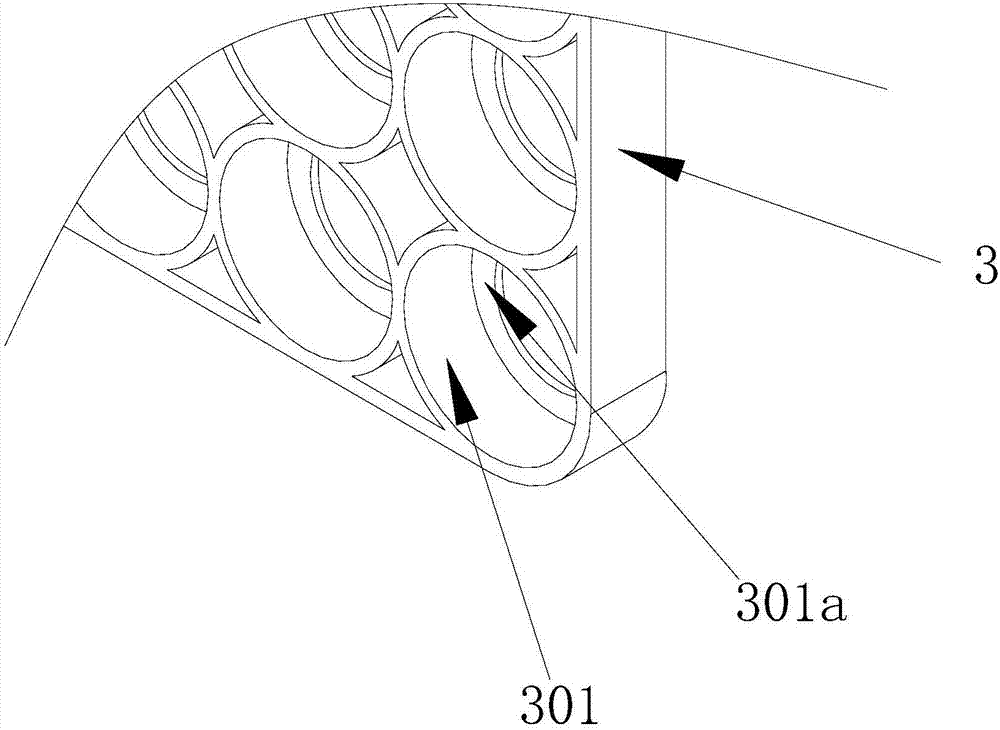

[0038] The key improvement of this embodiment is that the above-mentioned battery clamp adopts a new structural form, such as figure 1 , which is mainly com...

Embodiment 2

[0051] Figure 5 to Figure 7 It shows a specific application example in which the battery clamp of this application is applied to another battery module. The structure of the battery module in this embodiment is basically the same as that of the battery module in Embodiment 1. The main difference lies in the following points: point:

[0052] First, the structural form of the conductive support 4 in the present embodiment is different from that of the conductive support in Embodiment 1. The conductive support 4 in this example is a piece of which is provided with some through holes (these through holes constitute the said conductive support holes) The aluminum plate is not formed by arranging multiple metal tubes together and fixing them by welding or sintering. The conductive bracket 4 can be cast from aluminum. Compared with the first embodiment, the conductive support 4 with the structure of the present embodiment has stronger integrity and higher structural strength. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com