Battery connection support

A battery connection and battery technology, used in secondary batteries, battery pack components, circuits, etc., can solve the problems of slow heat transfer, easy battery skew, difficult movement, etc., to achieve strong shock resistance and increase contact. Reliability, the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

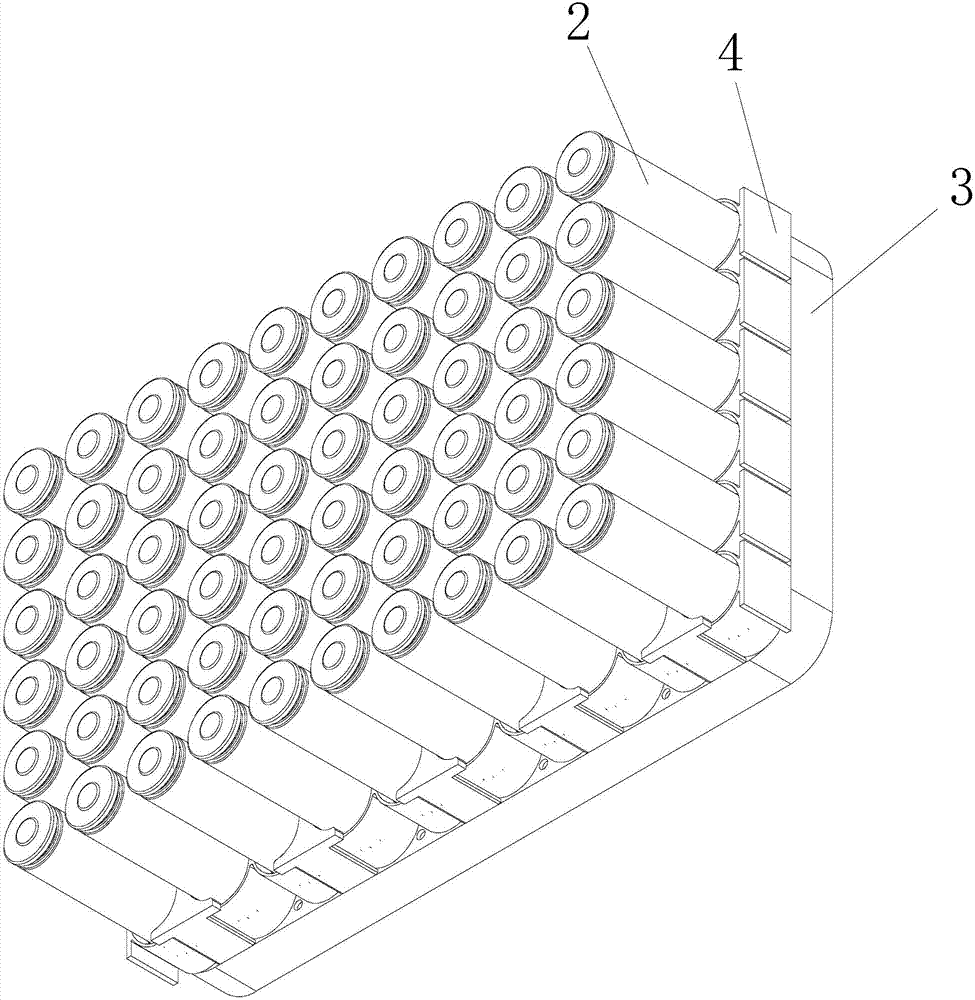

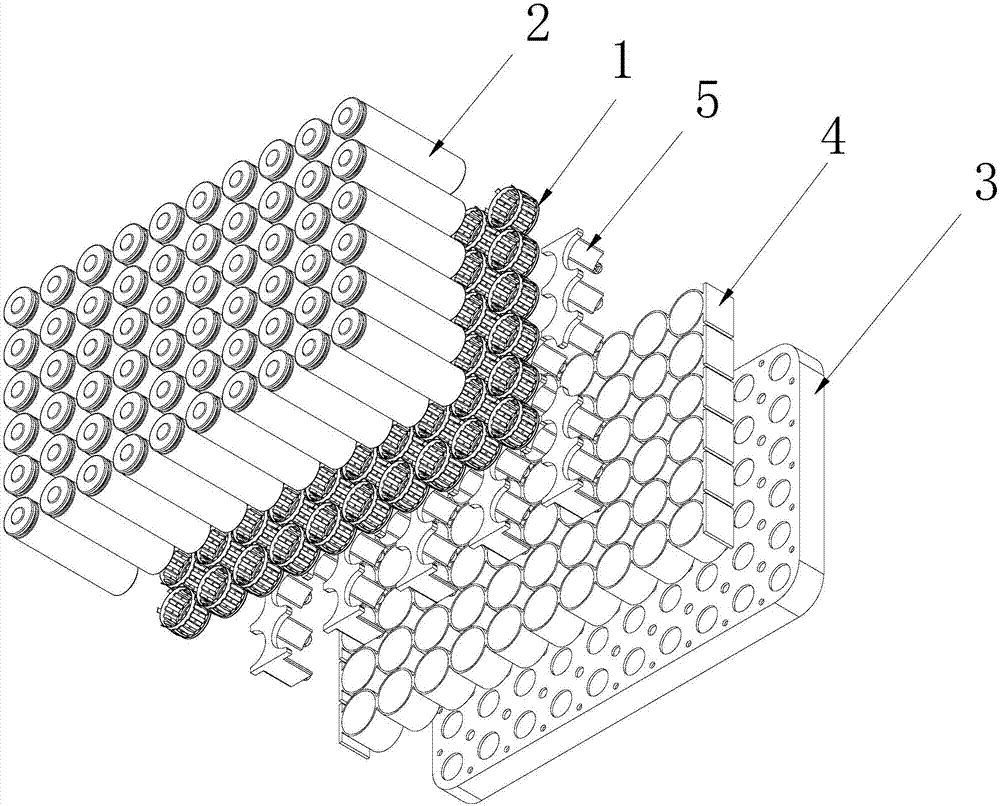

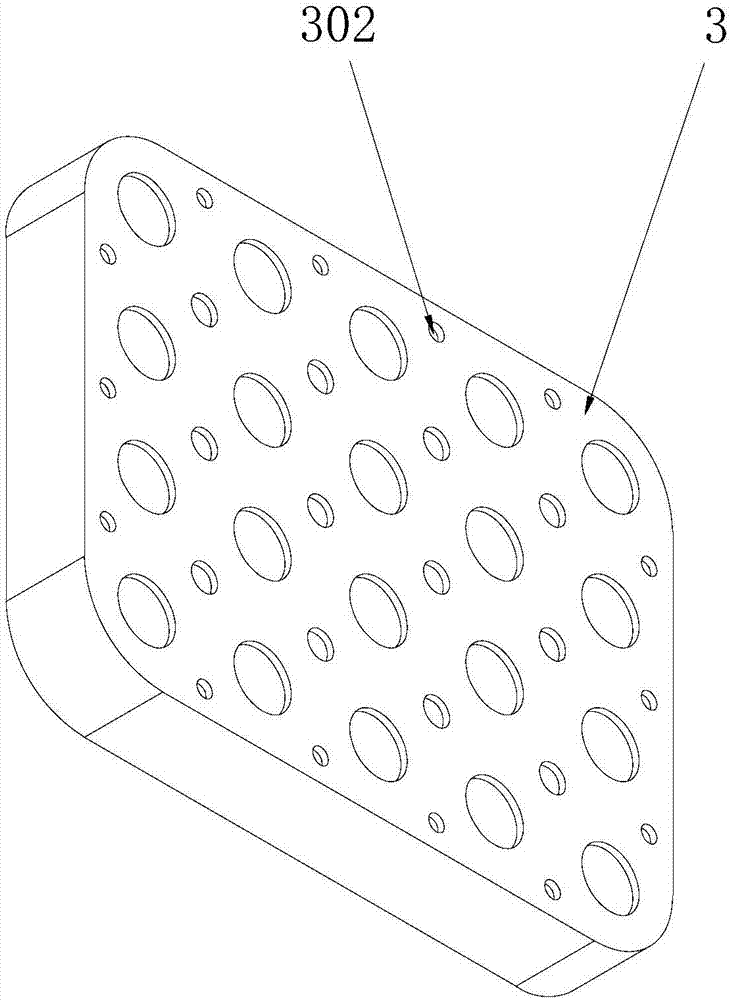

[0046] Figure 1 to Figure 7 It shows a specific application example of the battery connection bracket of the present application in a battery module, the battery module is a cylindrical lithium-ion battery module, which is the same as the traditional battery module, and also includes a battery connection Bracket (also known as battery bracket in the industry), the battery connection bracket is formed with numerous battery insertion holes distributed in a matrix, each battery insertion hole is embedded with a battery series piece 1, and each battery insertion hole A cylindrical lithium-ion battery cell 2 is inserted in each of them. Specifically, in this embodiment, the negative terminal of the battery cell 2 is inserted into the battery insertion hole of the battery connection bracket, and is directly contacted (not welded) with the battery series piece 1 in the battery insertion hole.

[0047] The key improvement of this embodiment is that the above-mentioned battery connec...

Embodiment 2

[0069] Figure 8 to Figure 14 It shows a specific application example of the battery connection bracket of the present application in another battery module. The structure of the battery module in this example is basically the same as that of the battery module in Implementation 1. The main differences are:

[0070] First, in this embodiment, the positive end of each battery cell 2 (instead of the negative end of the battery cell in Embodiment 1) is inserted in the battery insertion hole of the battery connection bracket, and is connected to the battery insertion hole. The battery series sheet 1 is welded and connected (rather than the separate contact connection in the first embodiment), specifically, the positive terminal of the battery cell 2 is welded to the protrusion 102a on the bottom sheet 102 of the battery series sheet 1 .

[0071] Second, in this embodiment, the metal parallel bar 4 no longer adopts the integrated structure in Embodiment 1, but is formed by butting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com