Refining process method for producing anhydrous aluminum chloride through high aluminum fly ash

A technology of anhydrous aluminum chloride and high-aluminum fly ash, which is applied in the direction of aluminum chloride and aluminum halide, can solve the problems of low purity of anhydrous aluminum chloride and complicated process, and facilitate large-scale industrial production , High product purity, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

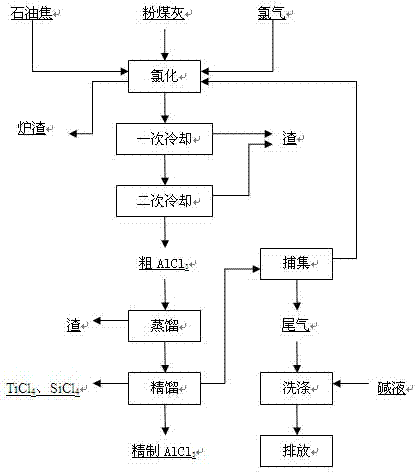

[0020] The process method of the present invention uses aluminum-containing fly ash as a raw material, is equipped with a certain amount of carbon value reducing agent and chlorine, and undergoes a chlorination reaction in a chlorination furnace. The main gases discharged from the chlorination furnace after the chlorination reaction are: MgCl 2 , CaCl 2 , NaCl, KCl, TiCl 4 , SiCl 4 , FeCl 3 , FeCl 2 , AlCl 3 , CO, CO 2 , N 2 , COCl 2 , Cl 2 The unreacted slag mainly includes: SiO 2 , CaO and MgO etc.

[0021] The mixed gas from the chlorination furnace is cooled by a two-stage dust collector, and the temperature is reduced to 320~400℃, so that MgCl 2 , CaCl 2 , NaCl, KCl, FeCl 2 Most of the impurities are removed in solid form; after two-stage cooling, the gas enters the first-stage separation tower for distillation, and further removes a small amount of MgCl2, CaCl2, NaCl, KCl, FeCl 2 And a lot of FeCl 3 For impurities with high boiling point, the temperature is required to be 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com