Environment-friendly biomass particle forging furnace

A technology of biomass particles and forging furnaces, applied in forging furnaces, furnaces, furnace types, etc., can solve the problems of affecting the combustion effect and heating effect, unsatisfactory energy saving effect, and blocking ventilation holes, etc., to prevent heat from escaping , reduce waste, energy-saving ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

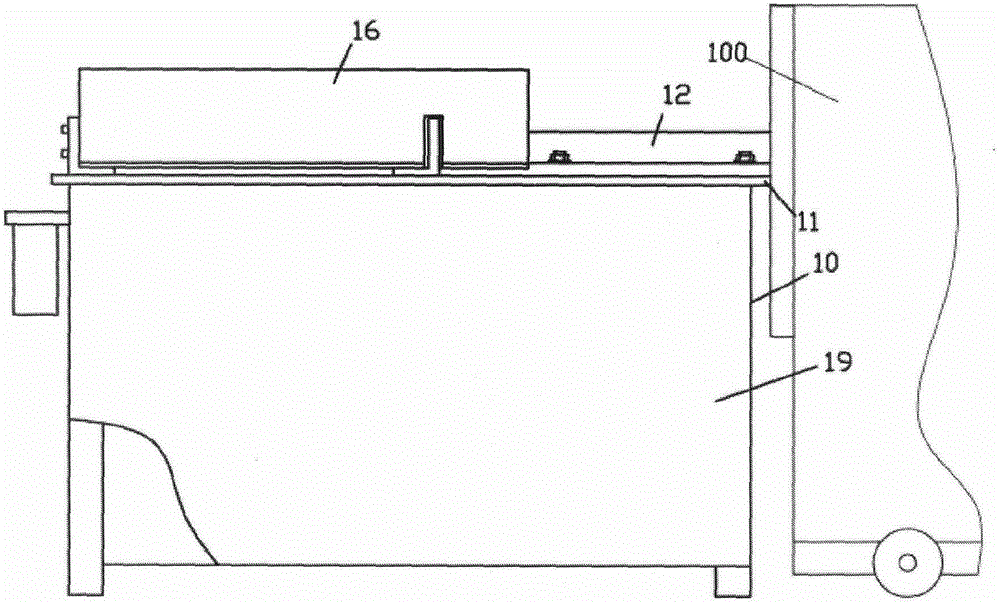

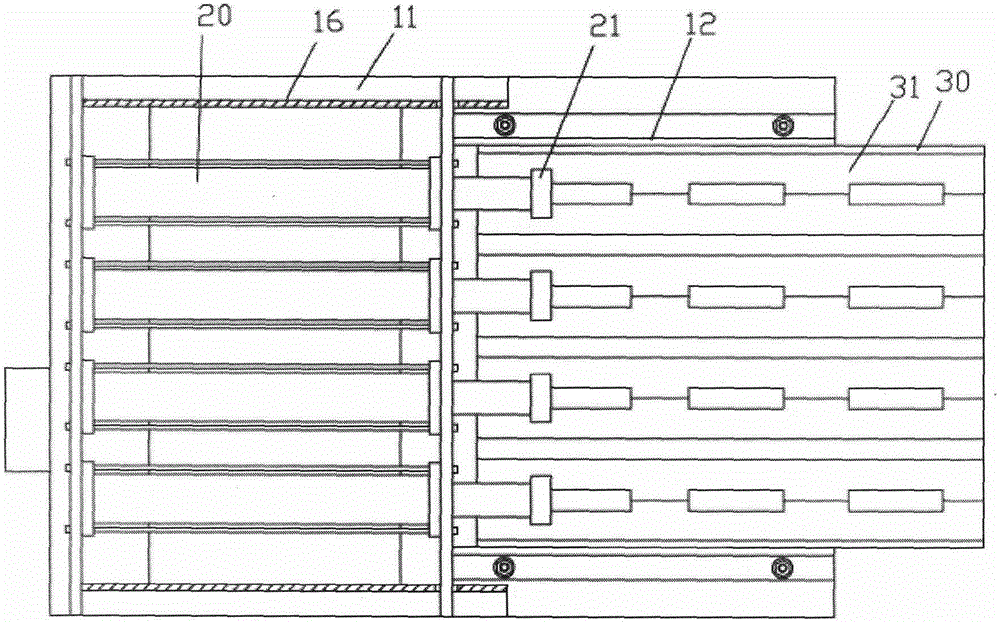

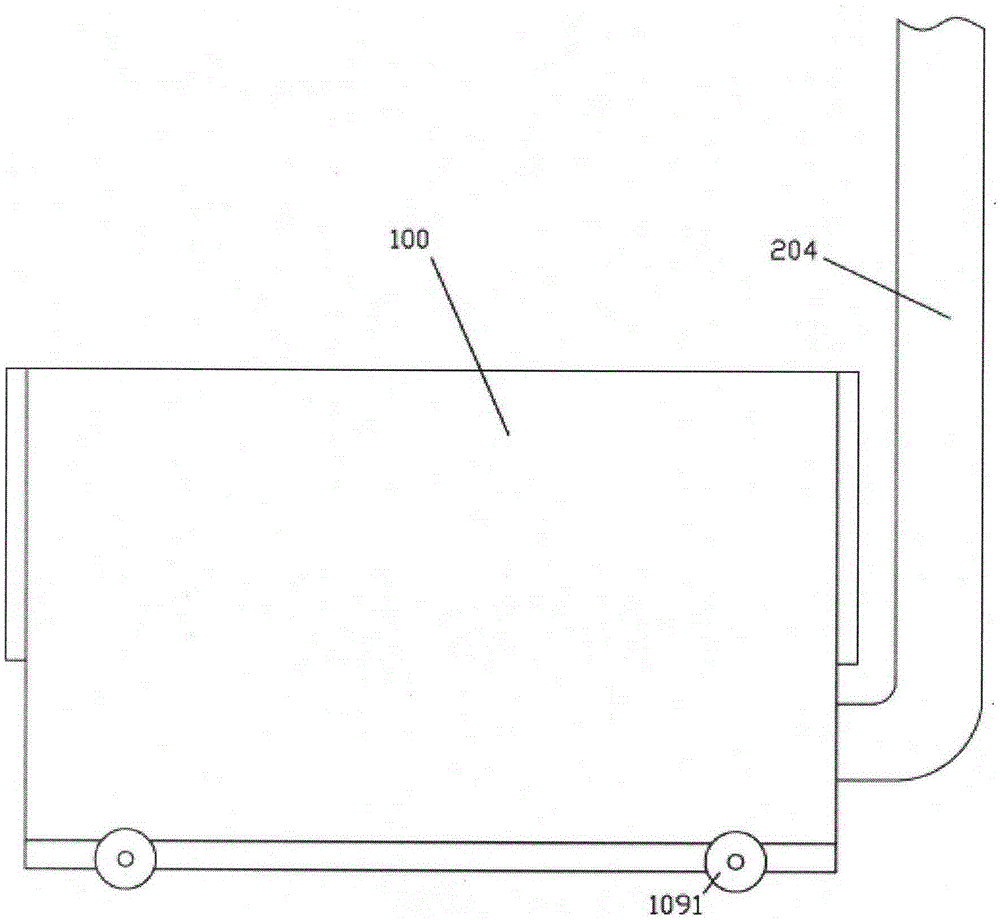

[0044] Examples, see e.g. Figures 1 to 14 As shown, an environment-friendly biomass particle forging furnace includes an automatic feeding device, a forging furnace cavity shell 100, a combustion furnace body 300 and a smoke filter device, and the automatic feeding device is installed in the forging furnace cavity shell 100 The front of the furnace, the combustion furnace body 300 is on the side of the forging furnace cavity shell 100, the smoke exhaust filter device is behind the forging furnace cavity shell 100, and the exhaust pipe 204 of the smoke exhaust filter device is fixed on the forging furnace cavity shell 100 and communicate with the exhaust through hole 203 on the forging furnace chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com