Fuel gas water heater

A gas water heater and water heater technology are applied in the fields of heat exchangers and multi-functional energy-saving gas water heaters, which can solve the problems that the water heater cannot achieve instant heating, the water heater cannot be used normally, and the gas utilization rate is not high, and the heat exchange efficiency can be improved. The effect of prolonging the heat exchange time and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

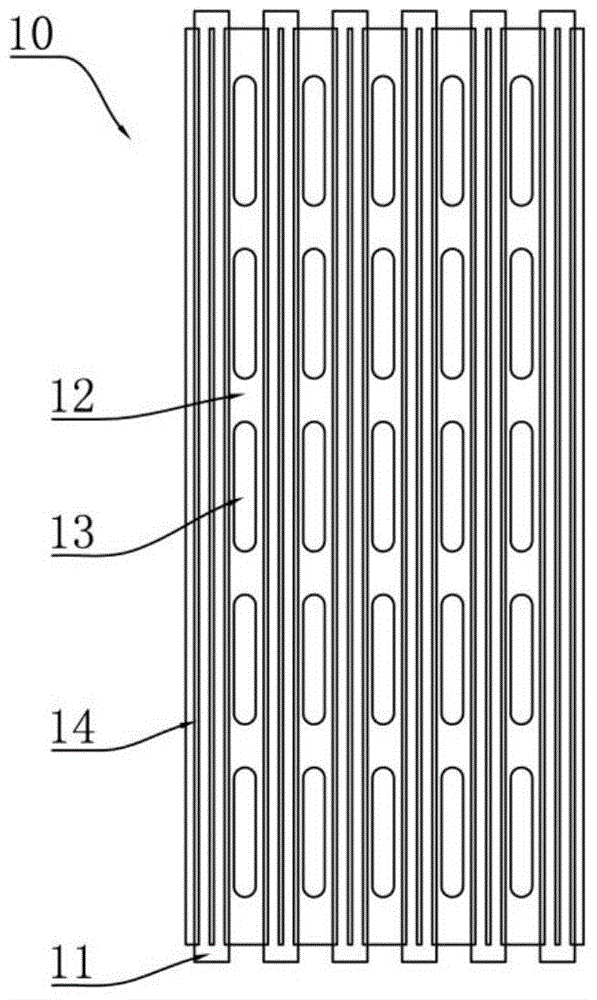

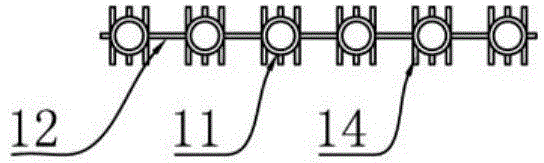

[0065] see figure 1 and figure 2 . The heat exchange fins 10 described in this embodiment schematically present six heat exchange tubes 11 parallel to each other and equal in length, and the distance between two adjacent heat exchange tubes 11 is equal. Two adjacent heat exchange tubes 11 are fixedly connected by six connecting plates 12 arranged at equidistant intervals, and there is a through hole 13 between adjacent two connecting plates, which is an important part of the flue in use. During installation, the heat exchange fins 10 are placed horizontally.

[0066] Arranging fins 14 on the exchange tube 11 can increase the heat-reducing area of the heat exchange fins, and arranging fins under the heat exchange tubes can also prolong the time that the hot gas stays below the heat exchange fins 10. According to design requirements, the fins 14 It is arranged on one side or both sides of the heat exchange sheet 10. figure 2 It shows the situation that fins 14 are provid...

Embodiment 2

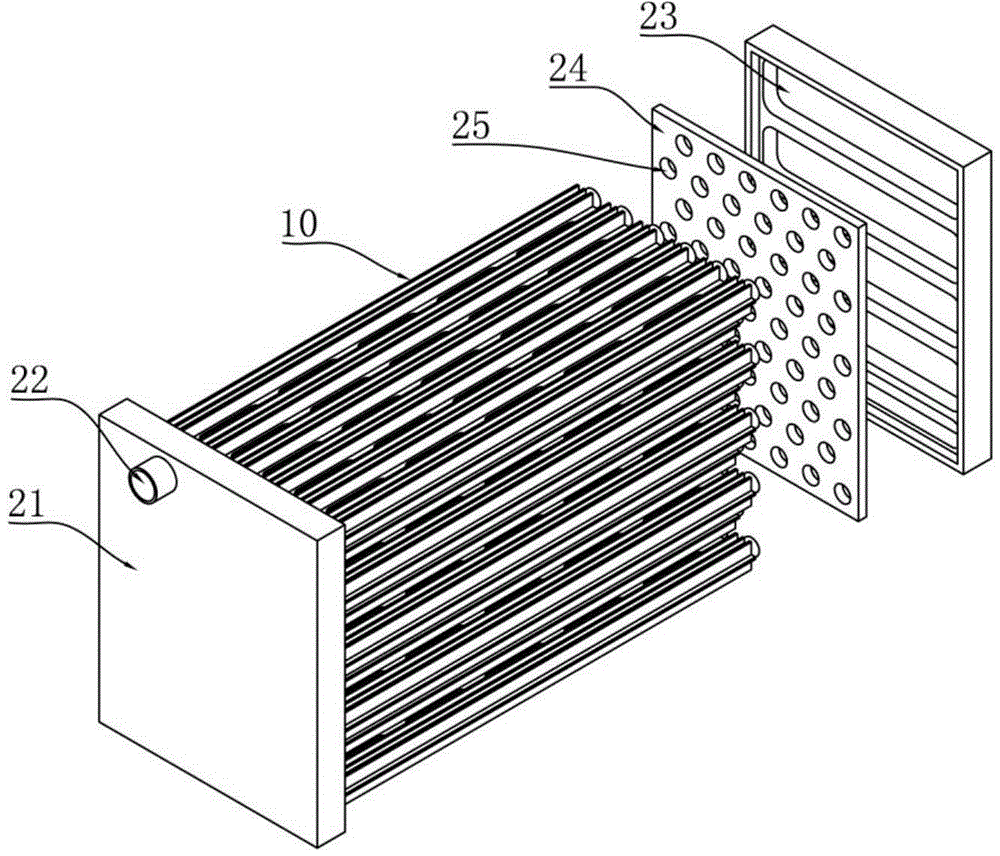

[0069] see figure 2 and Figure 8 . The heat exchanger described in this embodiment includes the heat exchange fins 10 described in Embodiment 1. The shape and structure of the heat exchange fins 10 have been clearly described in Embodiment 1, and will not be repeated in this embodiment. This embodiment schematically presents nine heat exchange fins 10 . Each heat exchange fin 10 is arranged horizontally, the heat exchange fins 10 are stacked and staggered, and the heat exchange fins are arranged equidistantly in the vertical direction. The heat exchange tubes 11 are all connected in series with end caps at both ends of the heat exchange fins 10, of course, part of them can also be connected in series.

[0070] The end cover is divided into two parts, namely an outer end cover 21 and an inner end cover 24. A plurality of connecting water tanks 23 are horizontally arranged on the outer end cover 21, and a cold water inlet is arranged on one of the two outer end covers. 26...

Embodiment 3

[0073] see Figure 4 to Figure 18 . The gas water heater 100 described in this embodiment includes a water heater casing, a fire pan, an igniter 102, a cold water pipe and a hot water pipe 106. The cold water enters through the cold water pipe and flows out from the hot water pipe after being heated. An air intake pipe is installed at the lower end of the fire pan. 44. It also includes a condensation jacket 30, a combustion chamber lower cover 46, a blower fan 101, a lifting mechanism, self-generating equipment and a zero cold water emptying mechanism. These devices can be selectively installed according to their respective functions. Correspondingly, if a certain function is not selected, the existing technology will be used to replace it if necessary. For example, when self-generating equipment is not used, the external 220V voltage power supply technology of the prior art is used. This embodiment provides that all functions are concentrated into the same gas water heater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com