Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

A soymilk maker and soymilk technology, which is applied in applications, dairy products, household appliances, etc., can solve the problems that the degree of improvement needs to be improved, and achieve the effect of improving the emulsification effect, improving the taste, and enhancing the bean flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

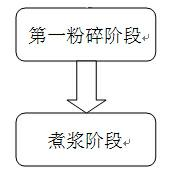

[0038] Such as figure 1 As shown, the original grinding and pulping method of the soybean milk maker of the present invention includes:

[0039] (a) The first crushing stage, the first crushing stage is a process in which the motor of the soybean milk machine drives the crushing tool to crush the pulping materials, specifically, in this stage, the motor of the soybean milk machine drives the crushing While the cutter is pulverizing the pulping material, the heating component heats the material in the cup. The time of the first pulverizing stage is t2, t2≤5 minutes, and the liquid temperature of the first pulverizing stage is less than or equal to 70°C;

[0040] (b). The boiling stage, the boiling stage is a process in which the heating component of the soymilk machine heats the slurry until the slurry is cooked. Specifically, at this stage, the slurry is heated for a period of time, and then the heating is stopped After a period of time, heating is performed again. The number of c...

Embodiment 2

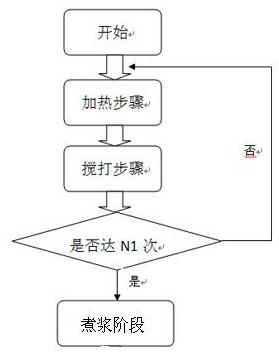

[0052] Such as figure 2 As shown, the original grinding and pulping method of the soybean milk maker of the present invention includes:

[0053] (a) The first crushing stage, the first crushing stage is a process in which the motor of the soymilk machine drives the crushing tool to crush the pulping materials, specifically, the first crushing stage includes the heating component to the cup The heating step of heating the material in the body and the whipping step of pulverizing the pulping material driven by the motor of the soymilk machine. The heating step is performed first, and then the whipping step is performed, cycle N1 times, N1≥1 , The liquid temperature in the first crushing stage is less than or equal to 70°C;

[0054] (b). The boiling stage, the boiling stage is a process in which the heating component of the soymilk machine heats the slurry until the slurry is cooked. Specifically, at this stage, the slurry is heated for a period of time, and then the heating is stopp...

Embodiment 3

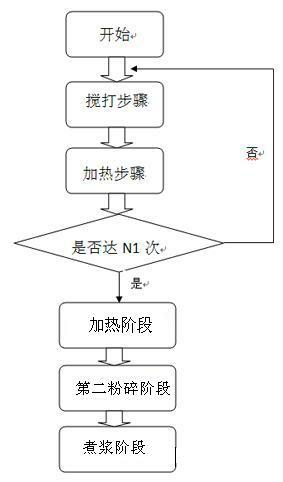

[0062] Such as image 3 As shown, the original grinding and pulping method of the soybean milk maker of the present invention includes:

[0063] (a) The first crushing stage, the first crushing stage is a process in which the motor of the soymilk machine drives the crushing tool to crush the pulping materials, specifically, the first crushing stage includes the heating component to the cup The heating step of heating the material in the body and the whipping step of pulverizing the pulping material driven by the motor of the soymilk machine. The whipping step is performed first, and then the heating step is performed, looping N1 times, N1≥1 , The liquid temperature in the first crushing stage is less than or equal to 70°C;

[0064] (b) Heating stage, in the heating stage, the slurry is heated to a predetermined temperature T2, in this embodiment, the slurry is heated to about 90 °C;

[0065] (c). In the second crushing stage, the pulping materials are pulverized in a cycle. The pulp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com