Gear grinding machining method and device

A grinding process and gear technology, applied in the field of gear processing methods and equipment, can solve the problems of low processing efficiency, frequent dressing of grinding wheels, etc., achieve high grinding efficiency, improve the contact state of tooth surfaces, and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with the accompanying drawings, the gear abrasive belt grinding method and its equipment involved in the present invention will be further described.

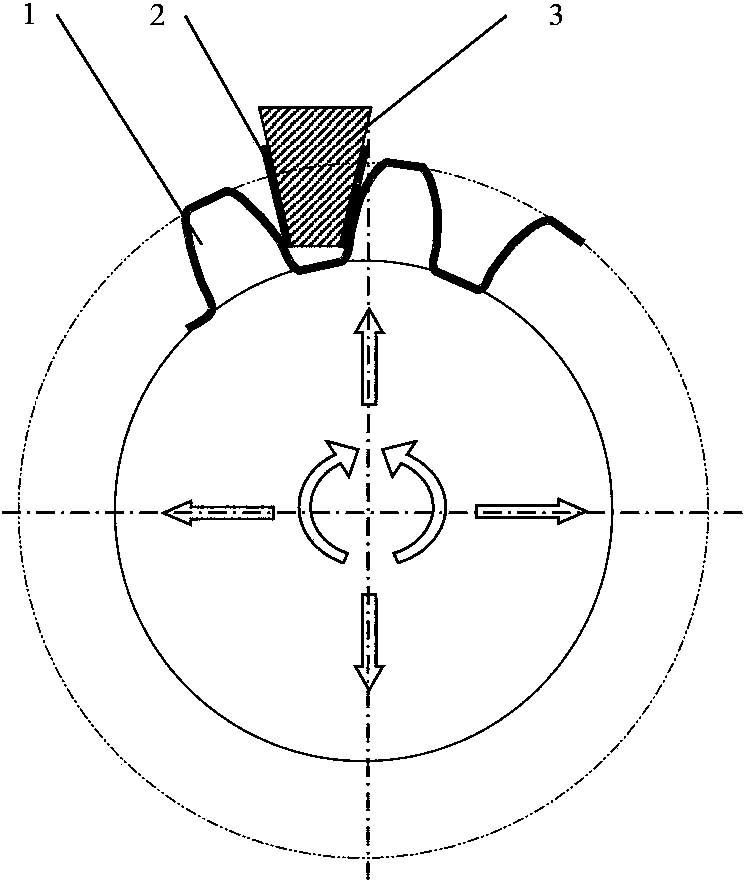

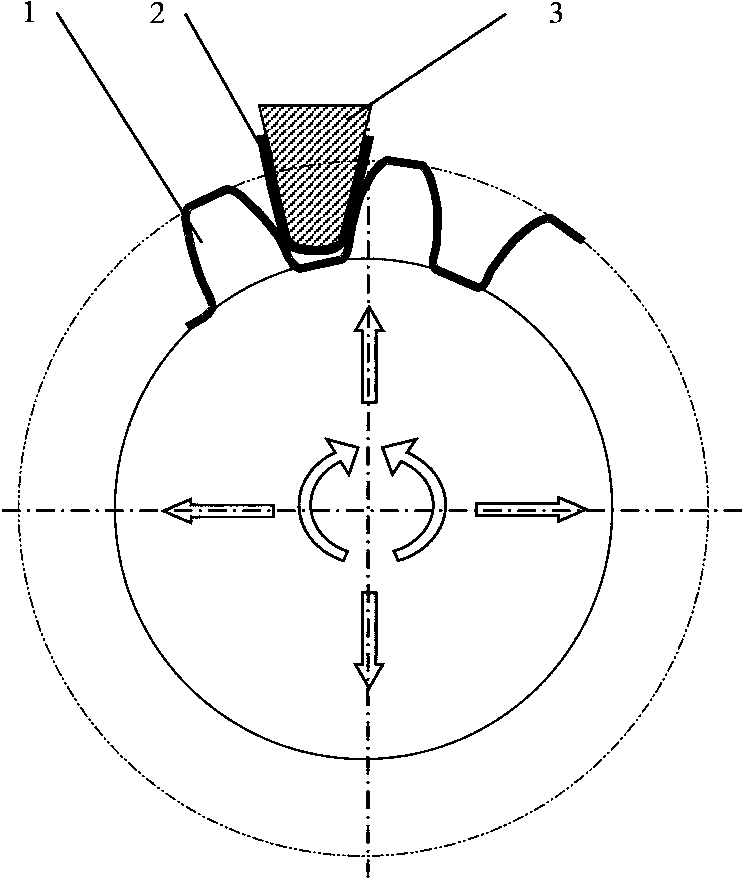

[0036] figure 1 It is a schematic diagram of the method embodiment 1 of the present invention. The inner sides of the two sections of the annular abrasive belt 2 lean on the grinding plate 3, and the sand-planting surface of the abrasive belt faces outward and the wedge-shaped grinding plate 3 constitutes a single-tooth rack of the grinding gear. (wedge shape with consistent tooth profile); the annular abrasive belt moves at high speed along the width direction of the tooth surface, that is, the direction of the gear axis, and the tooth blank rolls without slipping along the baseline of the rack under the drive of the motion unit controlled by the numerical control system. That is to say, the tooth blank is rolling while it is moving in translation. The condition of no sliding is that the speed of tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com