Method for crushing foods

A technology of food and solid food, which is applied in household utensils, applications, kitchen utensils, etc. It can solve the problems of reducing the relative speed between the blade and food, unfavorable mixing of solid and liquid, and single flow of liquid, so that it is not easy to burn and improves cutting. Efficiency, effective smashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

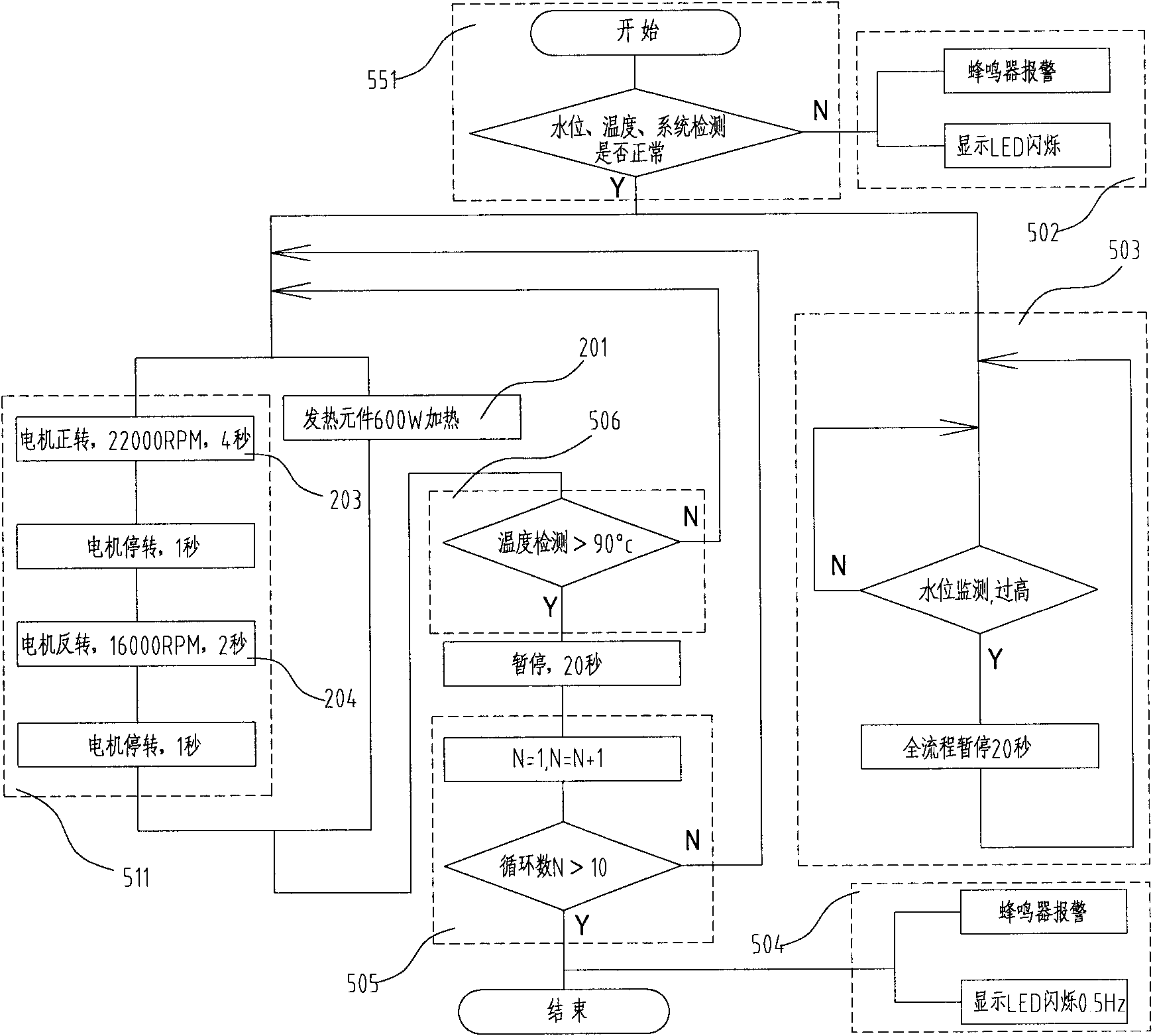

[0044] In order to make the method of the present invention clearer and clearer, it will be described in further detail below in conjunction with specific embodiments and accompanying drawings:

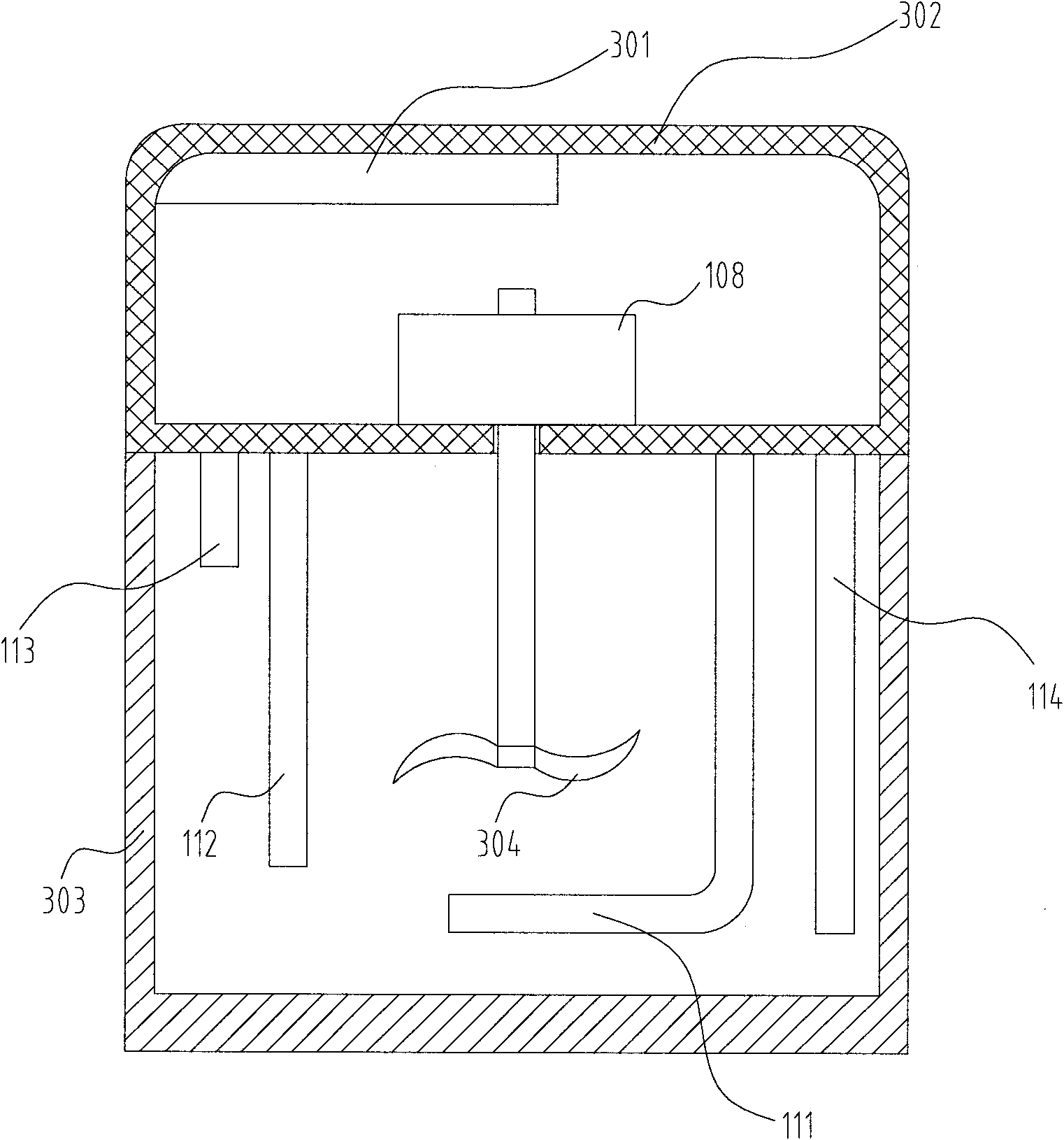

[0045] A household soybean milk machine mechanism such as figure 1 shown. Bottom is the cup body 303, buckle machine head 302 above, there are circuit unit 301, motor 108 in the machine head 302; Motor 108 output shaft stretches in the cup body 303, is fixed with blade 304 on the shaft head; Low water level sensor 112 on 302, high water level sensor 113, temperature sensor 114, heating element 111 all extend in the cup body 303.

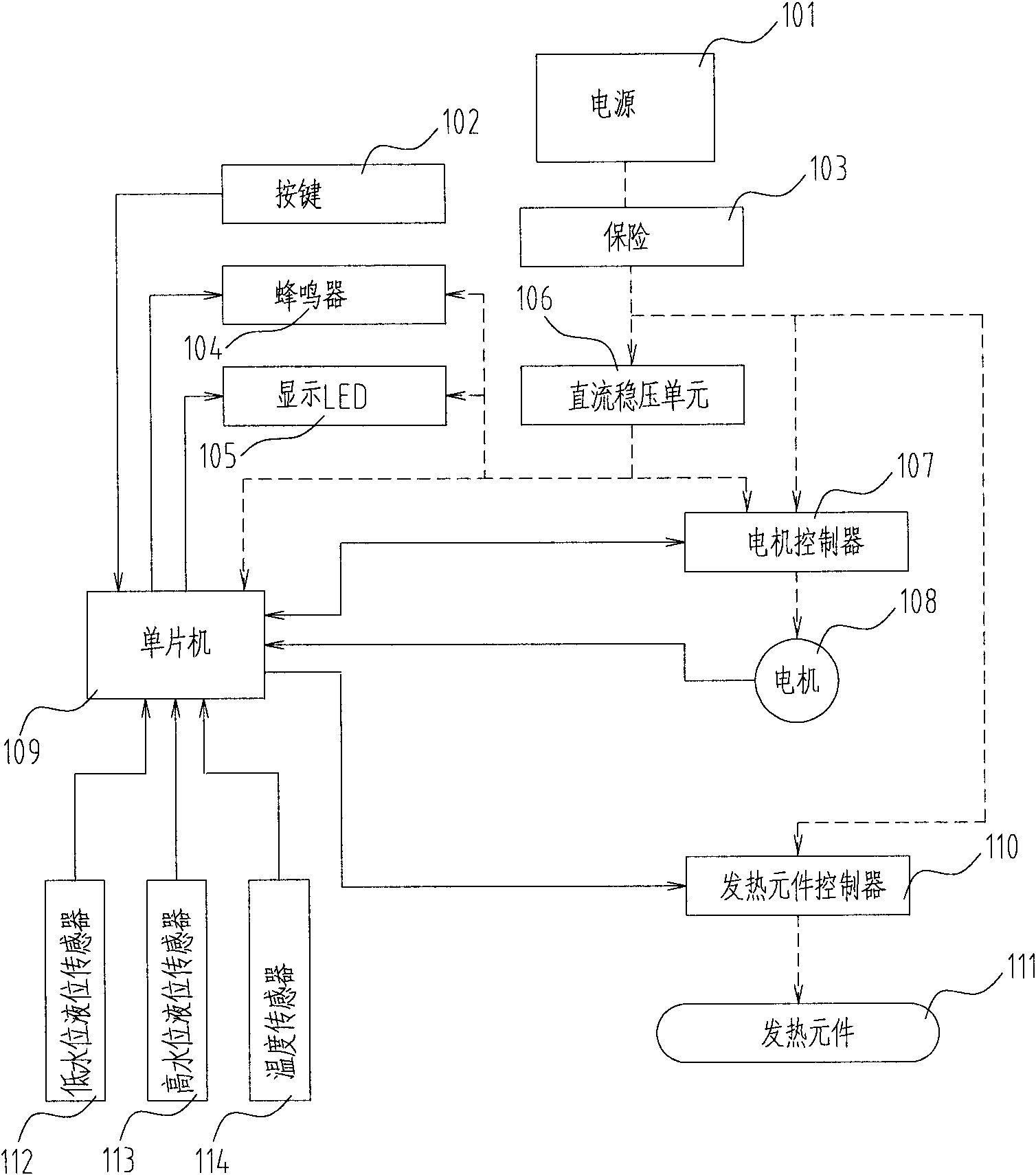

[0046] The circuit principle of this soybean milk machine is as follows: figure 2 shown. Power supply 101 passes through insurance 103, connects DC voltage stabilizing unit 106, motor controller 107, heating element controller 110 and supplies power to it; Motor 108 is a brushless motor, and motor controller 107 is a brushless motor driver, connects moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com