Patents

Literature

52results about How to "Improve tumbling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

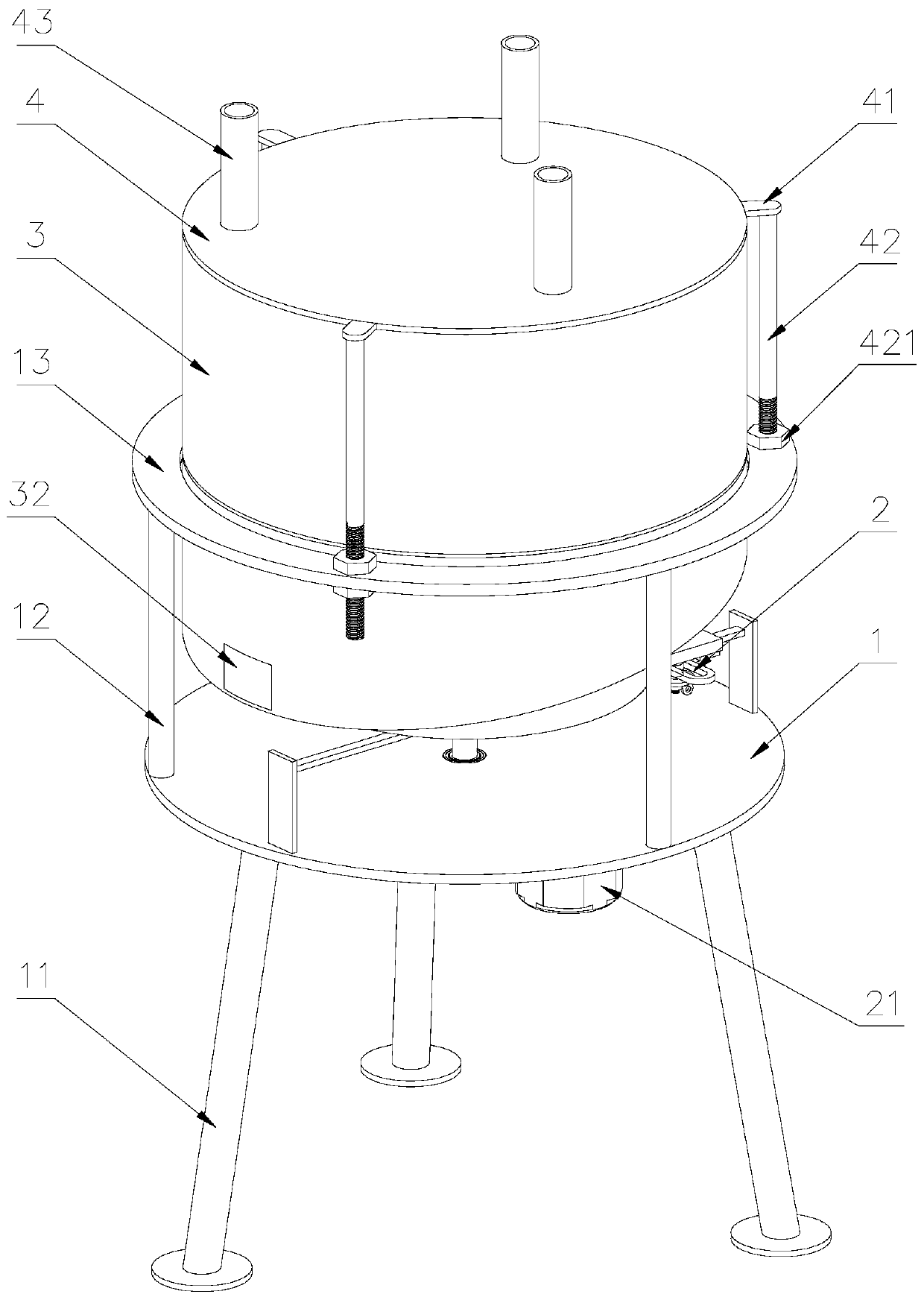

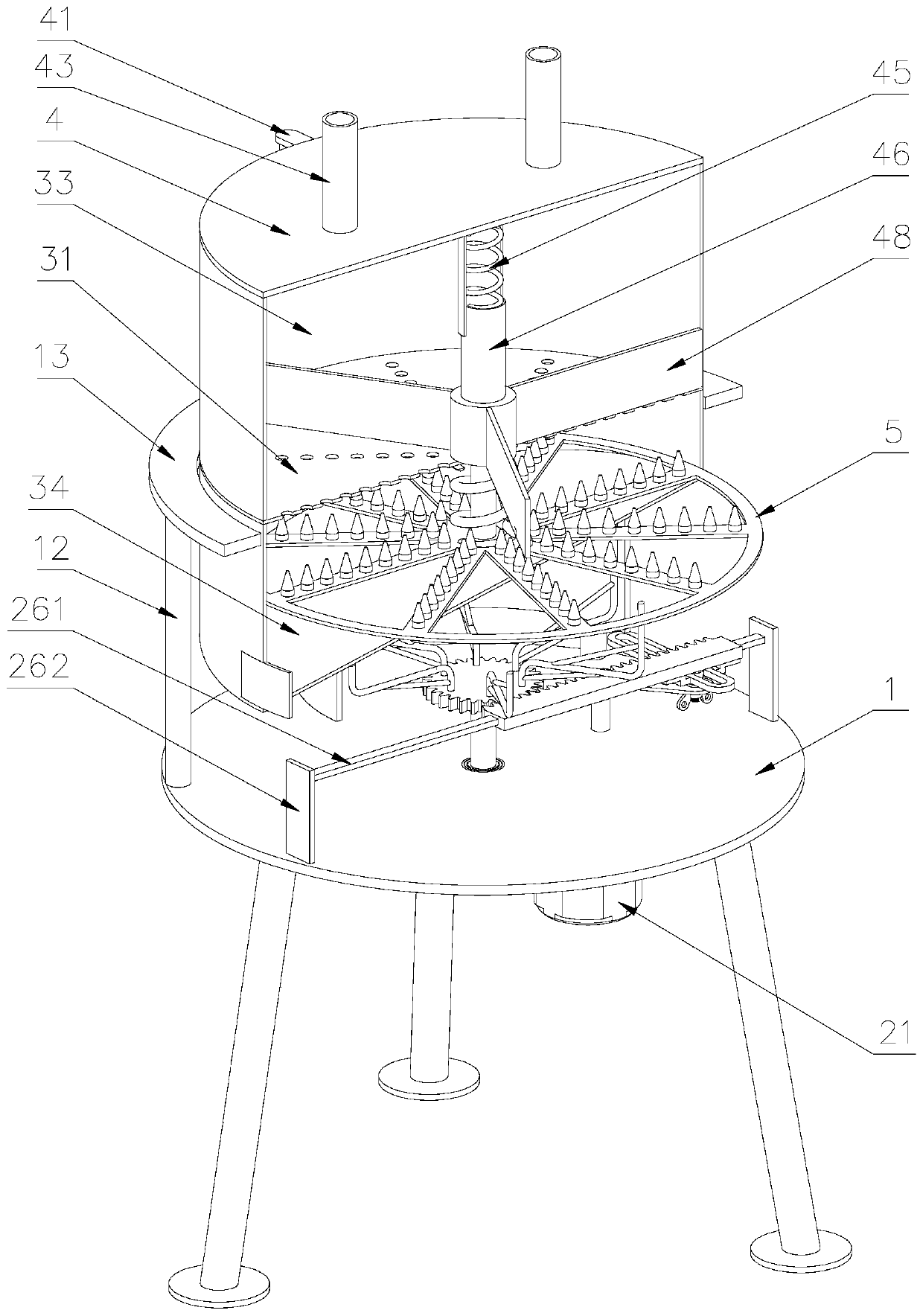

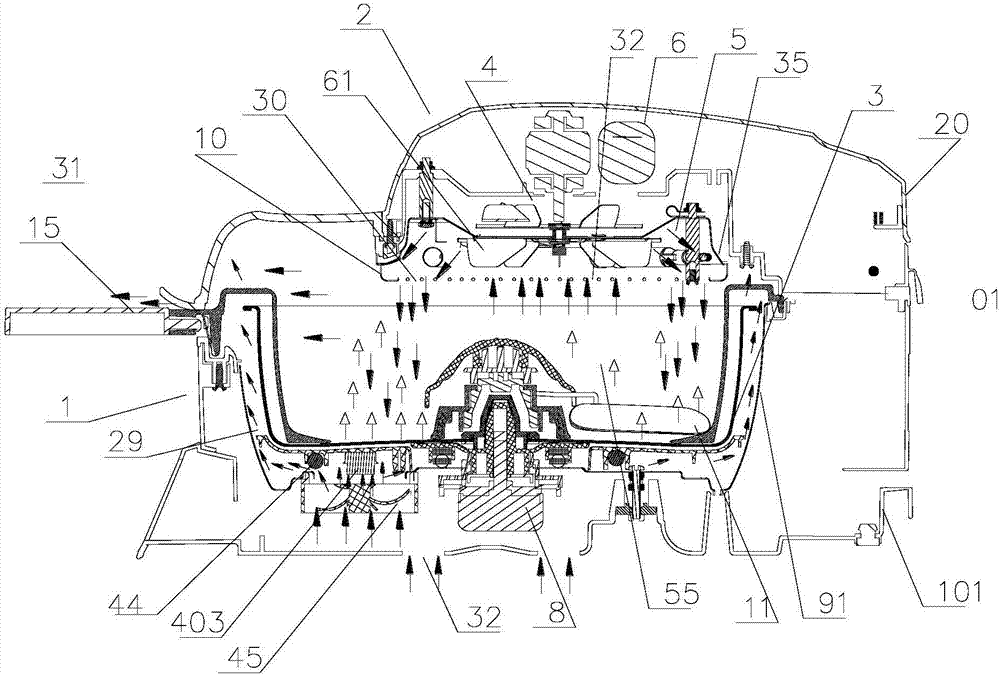

Baking pan capable of efficiently saving energy

InactiveCN106343895AEvenly heatedHard on the outside and soft on the insideRoasters/grillsEngineeringThermal radiation

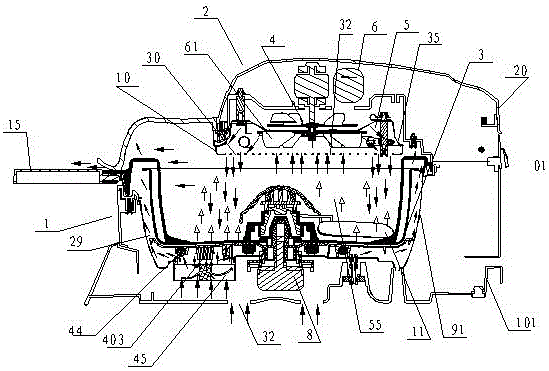

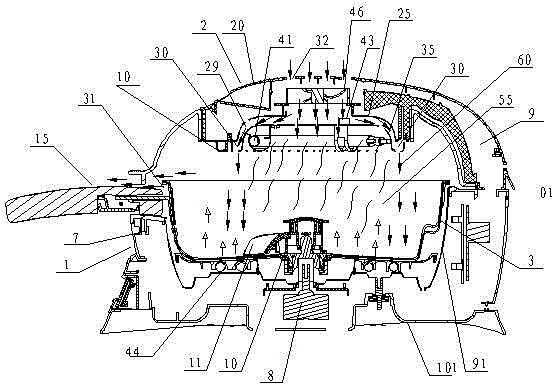

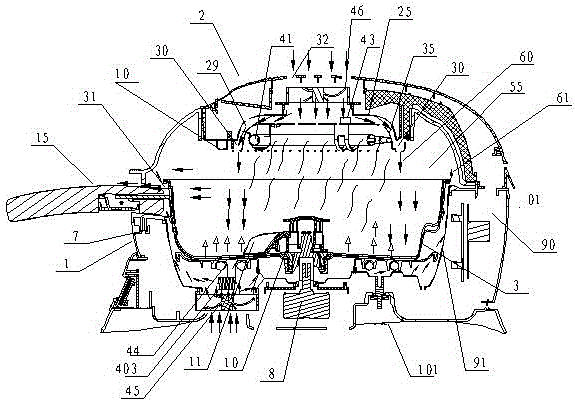

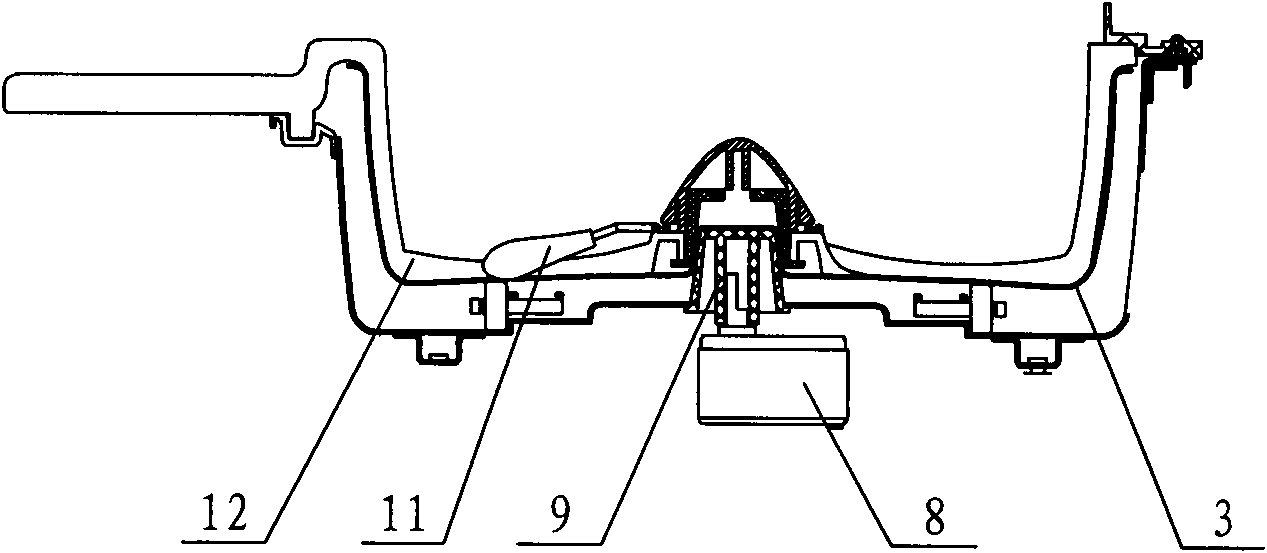

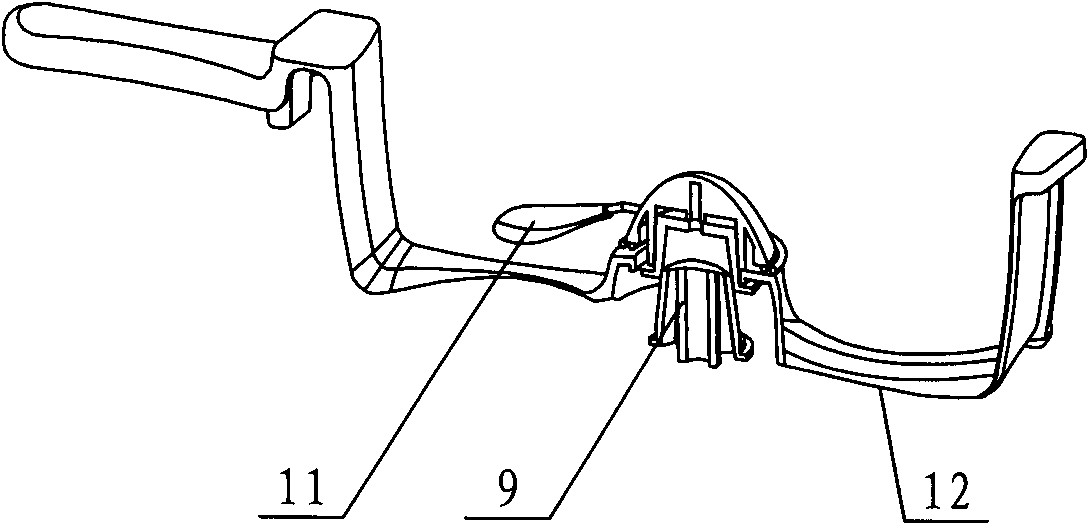

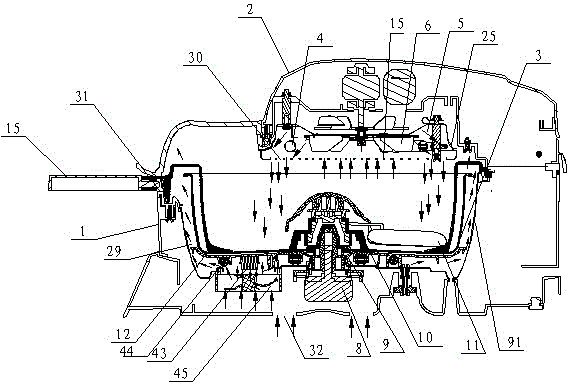

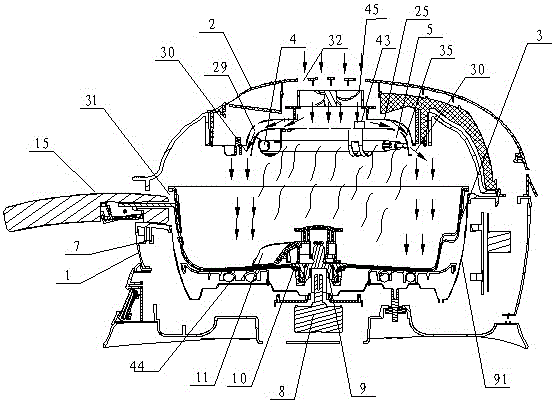

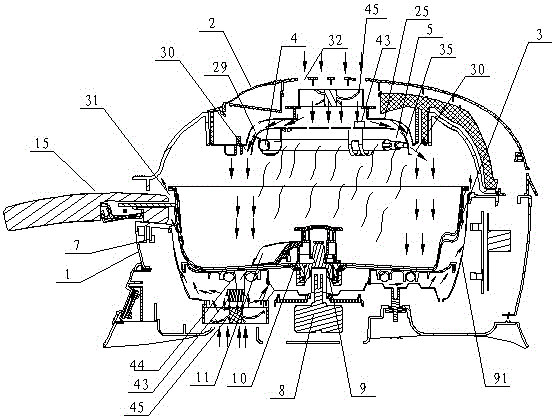

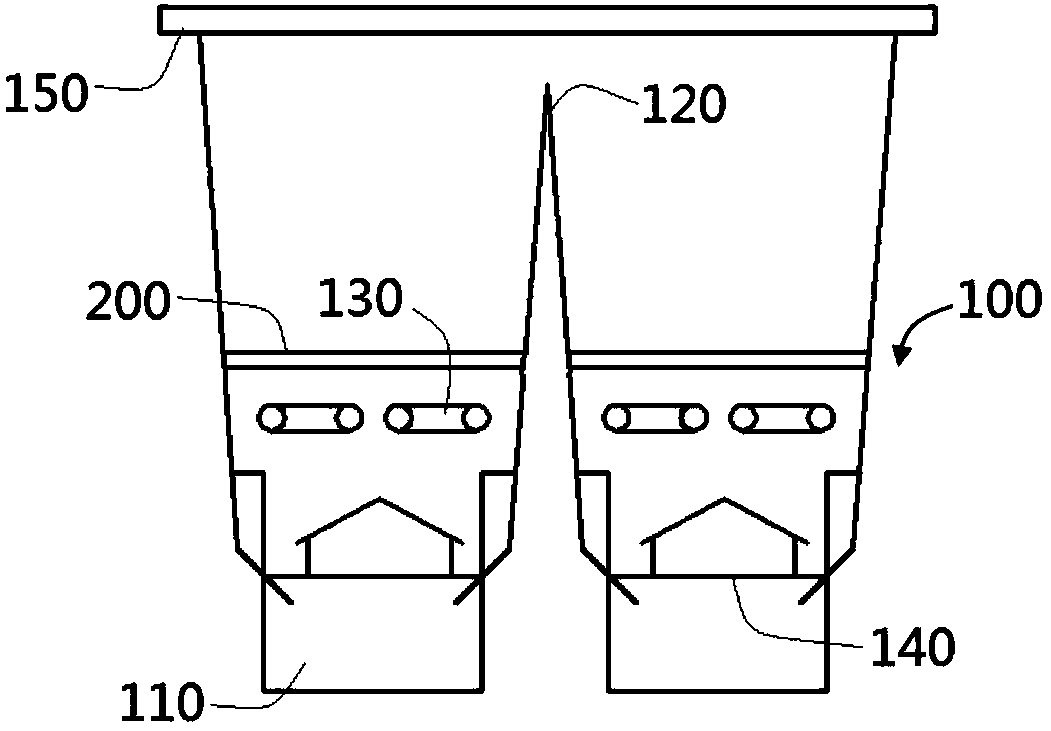

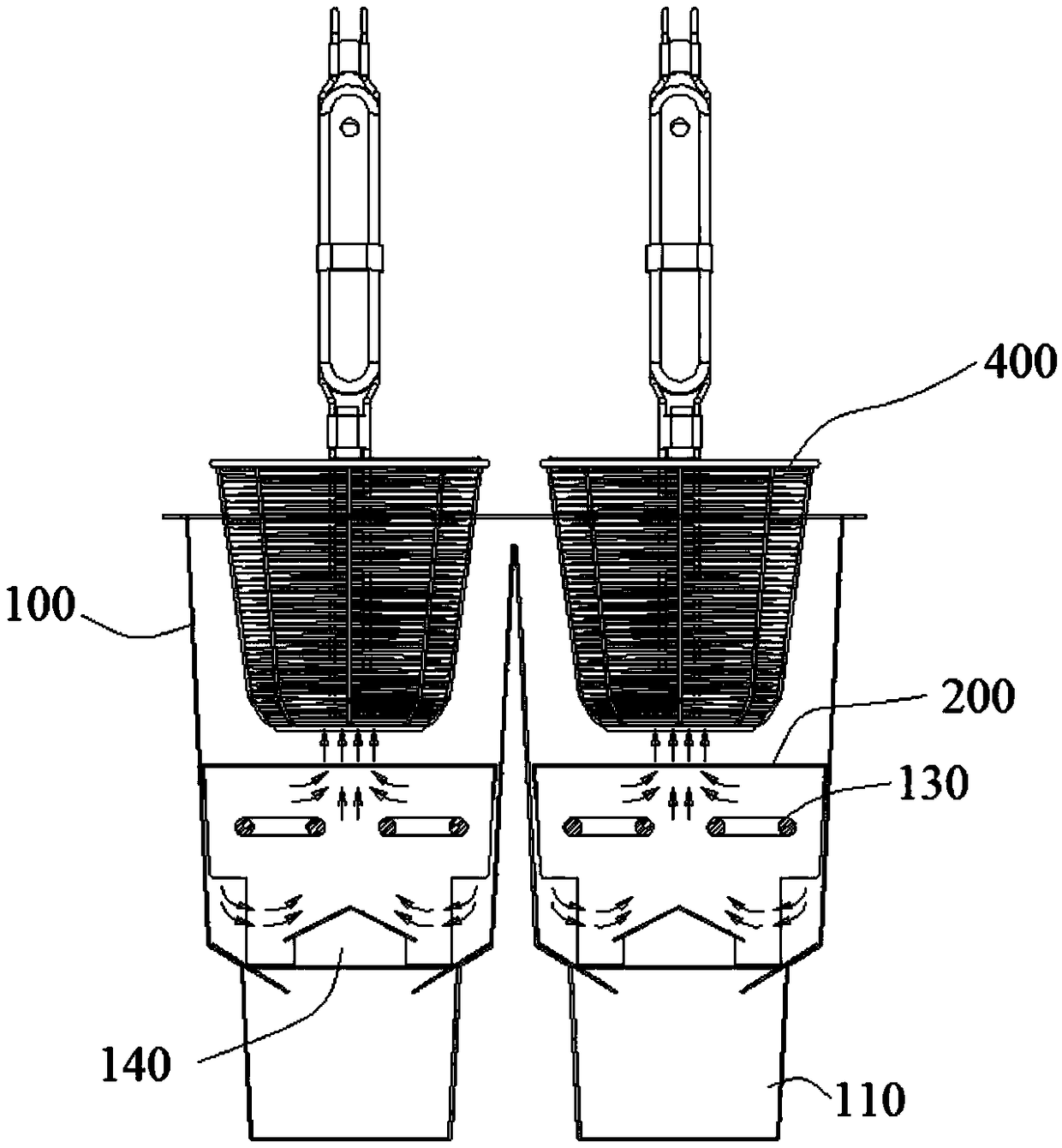

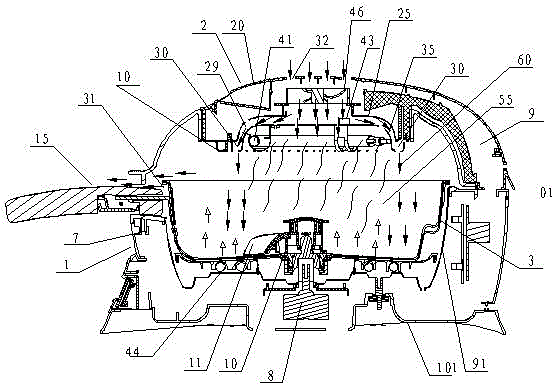

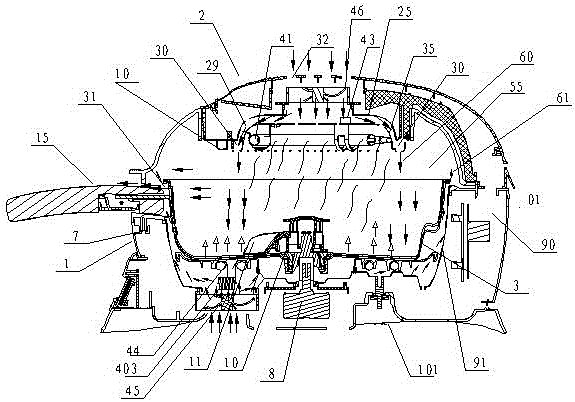

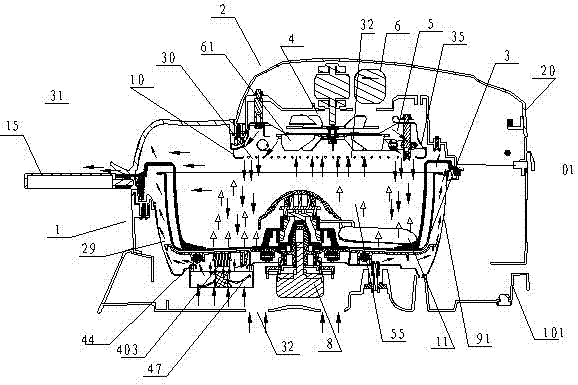

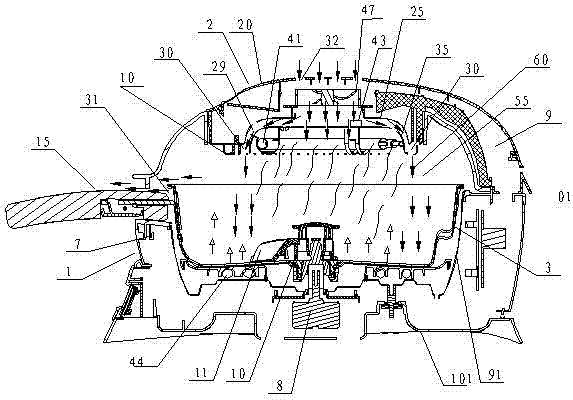

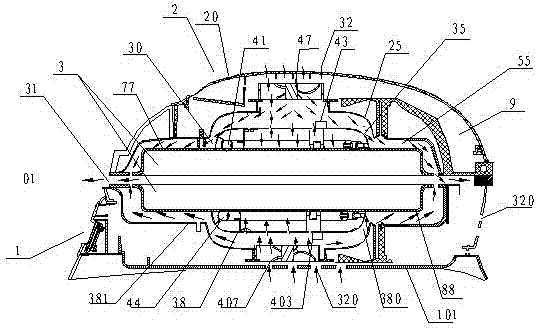

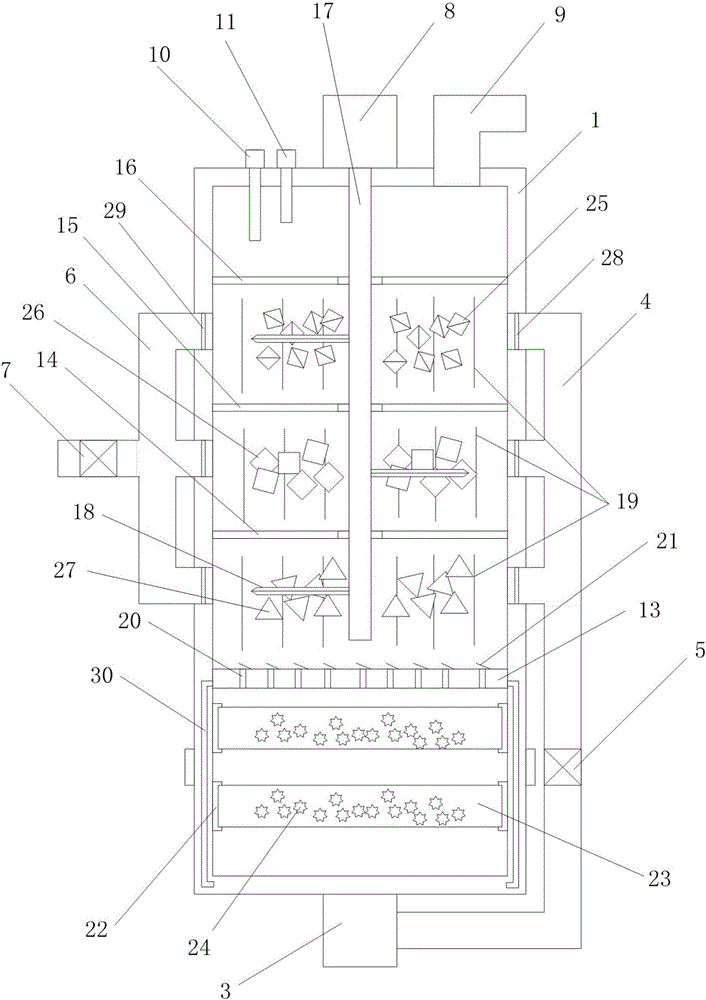

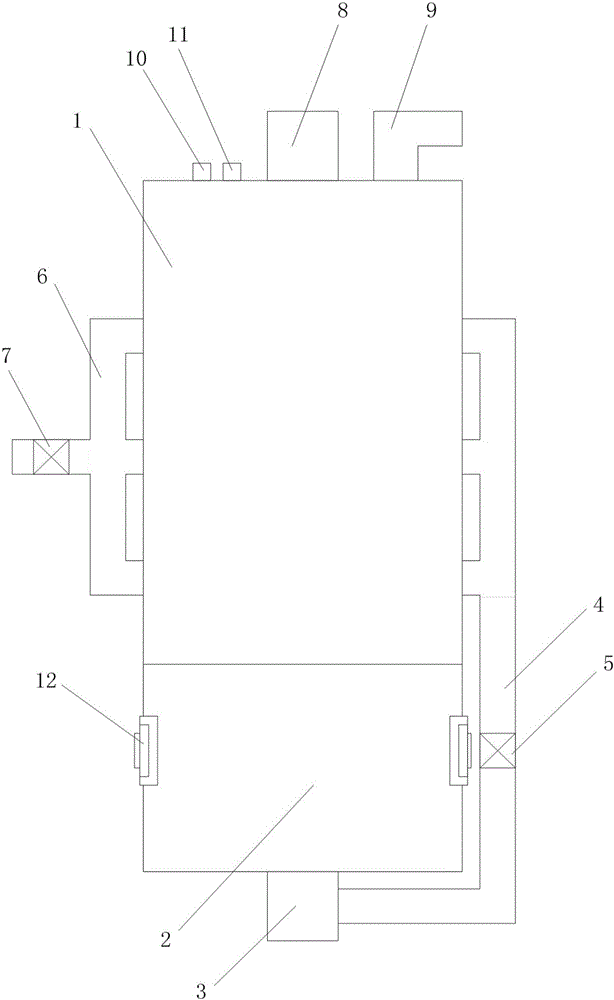

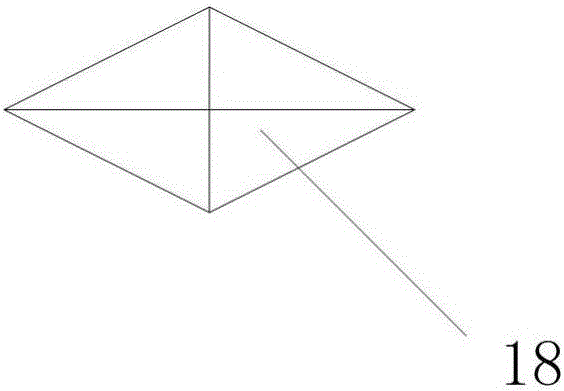

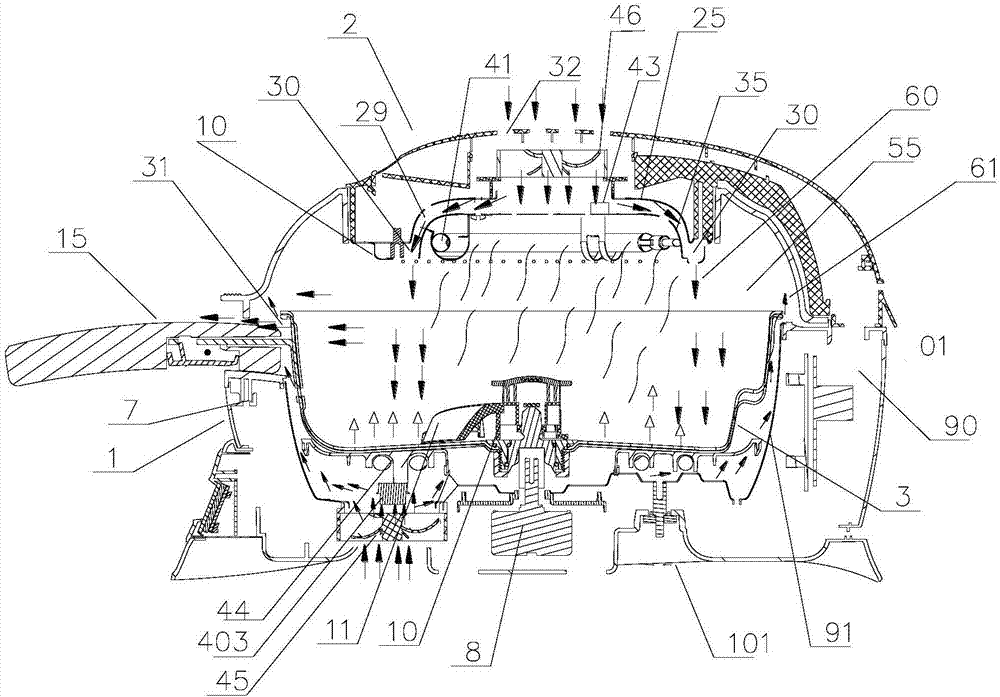

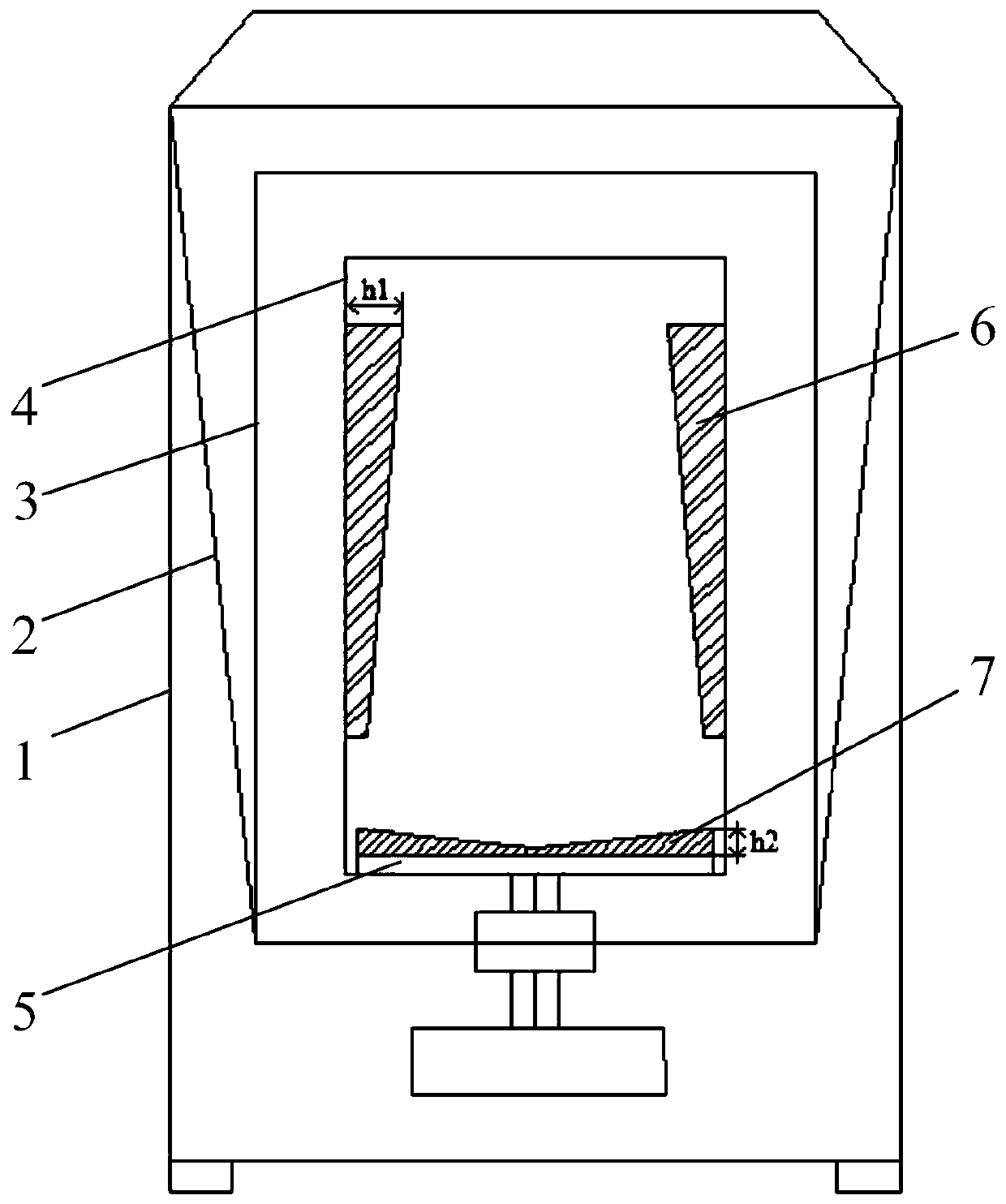

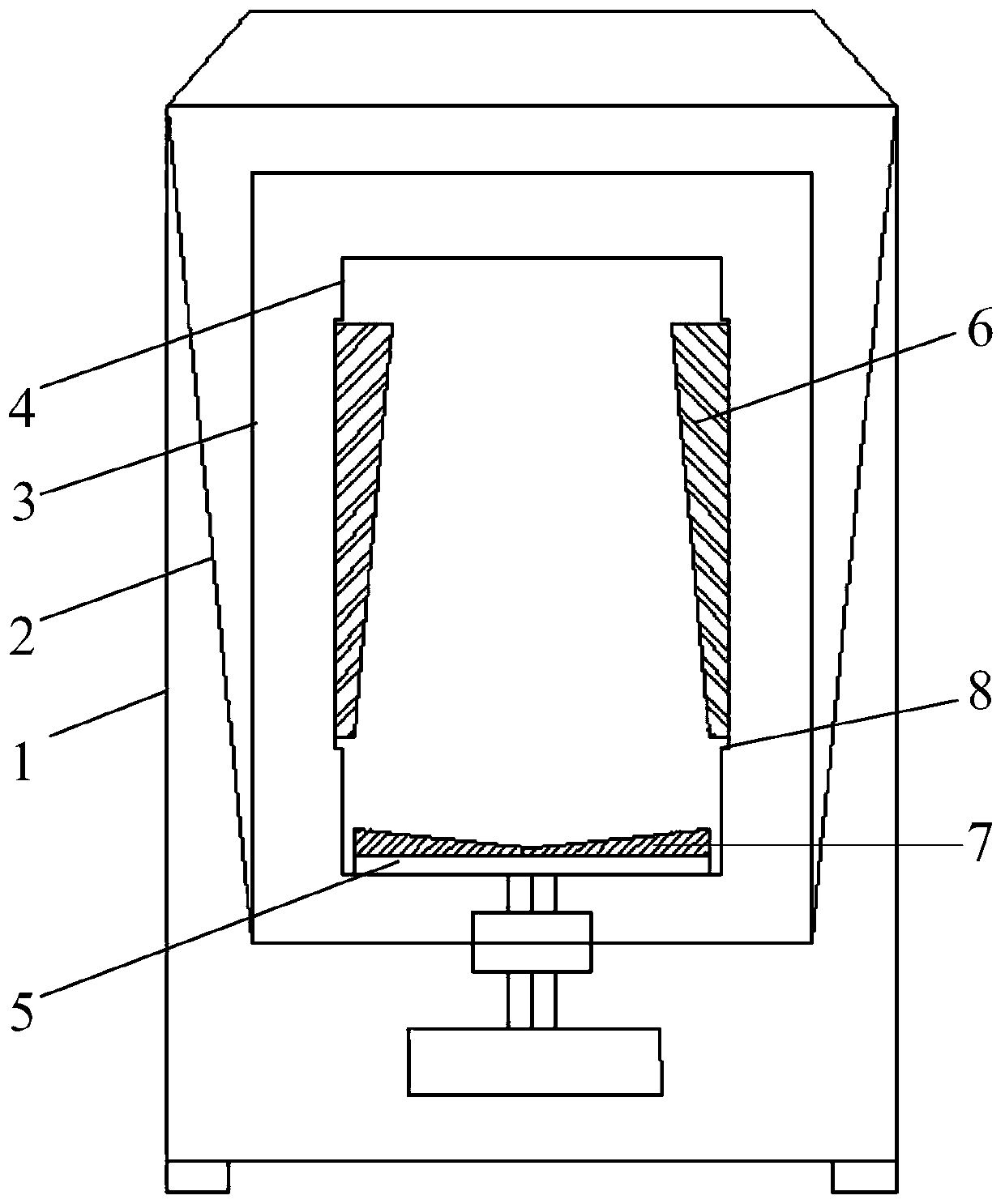

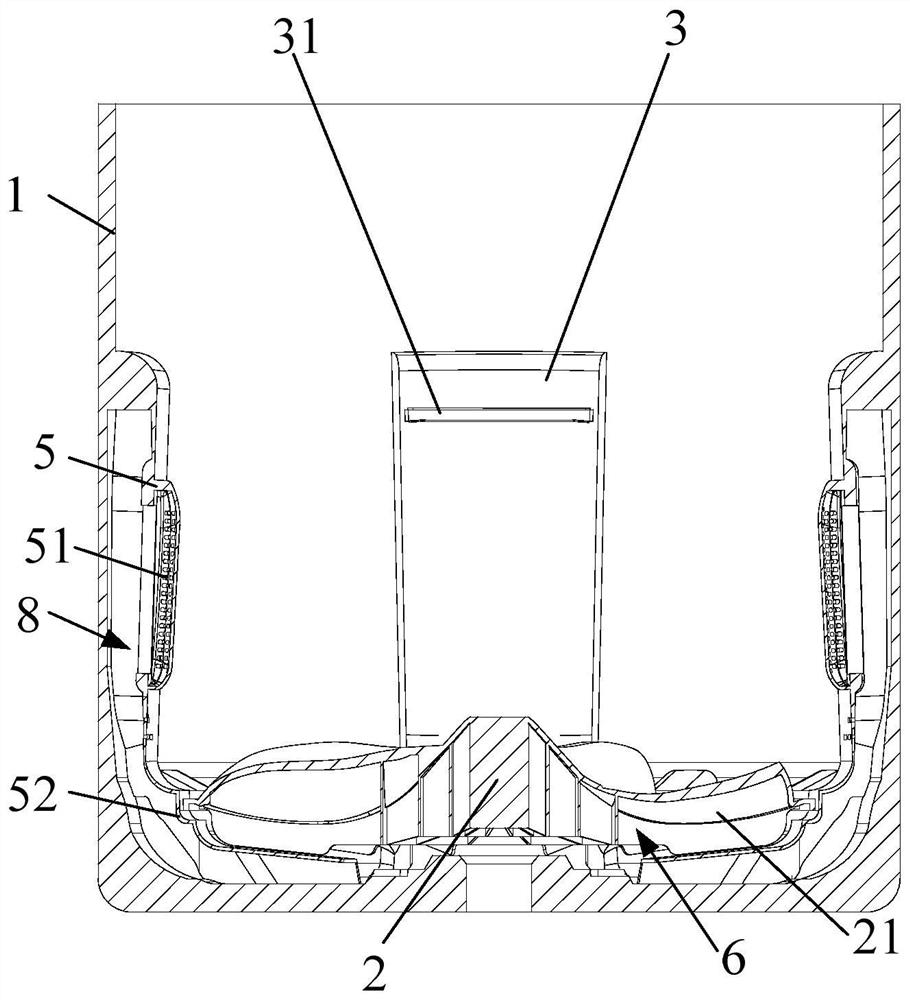

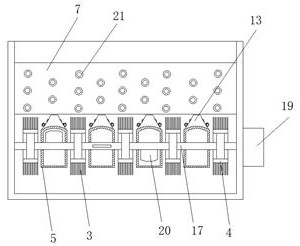

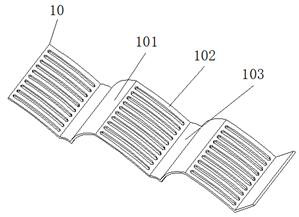

Provided is a baking pan capable of efficiently saving energy. The baking pan mainly comprises a large body, an upper cover, heaters, a pan body, a food rolling device, an air inlet hole and a cooling fan. The heaters comprise the upper heater and the lower heater, and the baking pan is characterized in that the large body is used for containing the pan body (3), the food rolling device (11) and the lower heater (44), and the large body (1) provides a conduction heating heat source for the bottom of food; the upper cover (2) provides a heat radiation or illumination radiation heat source for the upper surface of the food; the upper cover (2) and the large body (1) are closed to form a stereoscopic heating cavity (55) with the upper portion providing heat radiation or illumination radiation and the bottom providing conduction heating; the cooling fan is used for carrying out constant-temperature heating on the interior of the stereoscopic heating cavity (55) or carrying out relative cooling heating on the interior of the stereoscopic heating cavity (55), and the cooling fan is arranged outside the stereoscopic heating cavity (55); the food rolling device (11) is used for overturning the food, so that the food is evenly heated and stereoscopically heated. The baking pan has the advantages of being good in cooking effect, easy to mount and demount, easy to clean and wide in application range.

Owner:周林斌

Multi-functional cooking pan

InactiveCN102151094AEvenly heatedHard on the outside and soft on the insideRoasters/grillsWaste managementAir drying

The invention discloses a multi-functional cooling pan, which comprises a body, a cover and a heater. A cooking pan container is arranged in the body; a food rolling device is arranged in the cooking pan container; the body and the cover enclose a relatively sealed cavity together; a cooling and air drying airduct is arranged in the cavity; a cooling and air drying fan is arranged in the cooling and air drying airduct; the cavity is provided with an air outlet and an air inlet; one end of the cooling and air drying airduct is communicated with the air outlet, while the other end is communicated with the air inlet which is communicated with the outside; the air outlet faces the food rolling device. The cooling and air drying airduct comprises a first cooling and air drying airduct and a second cooling and air drying airduct; the first cooling and air drying airduct is arranged in the cover; and the cooling and air drying fan and the second cooling and air drying airduct are arranged in the body and outside the cooking pan container. The multi-functional cooling pan has the characteristics of good cooking effect, simple disassembly and cleaning, and wide application range.

Owner:周林斌 +1

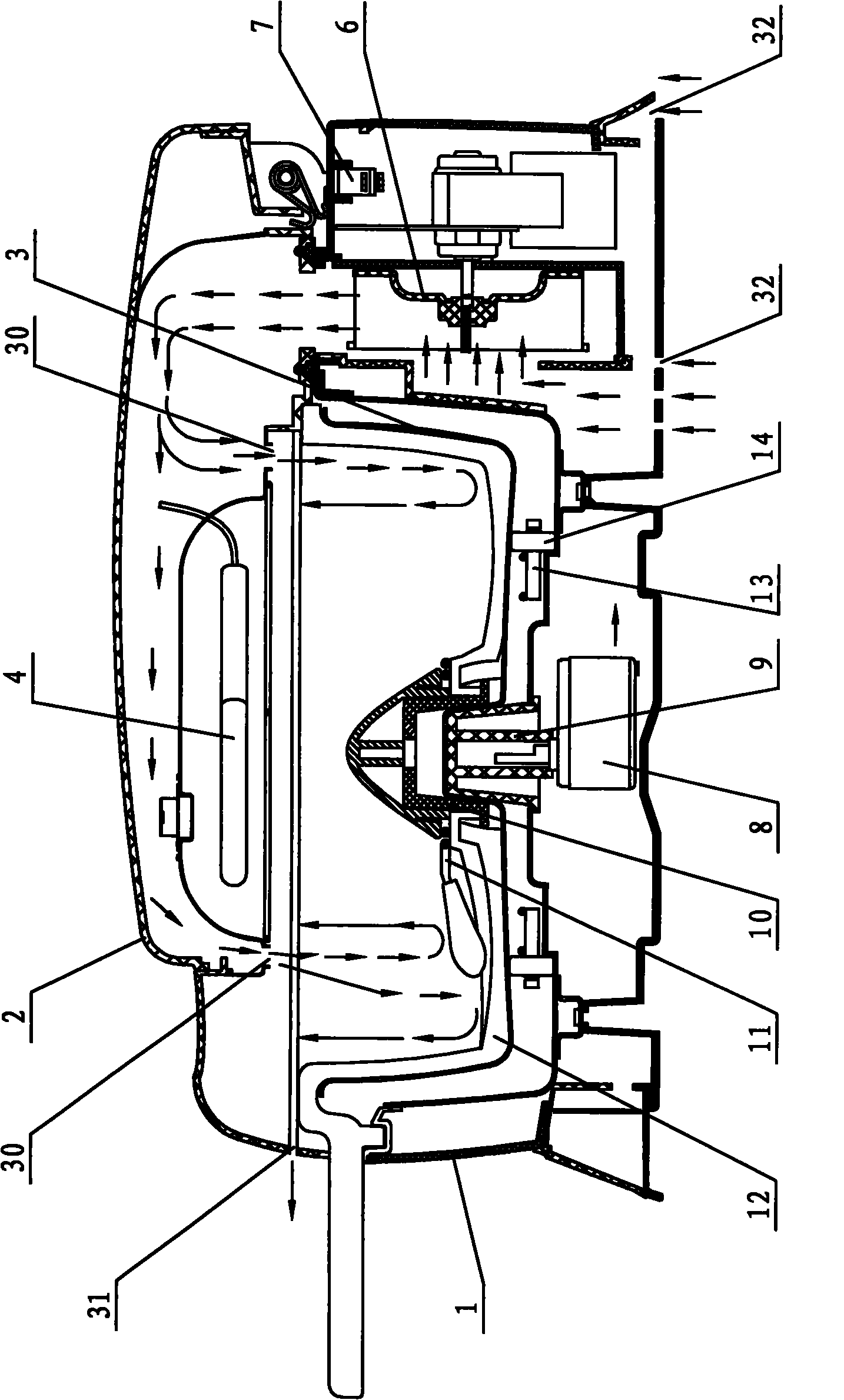

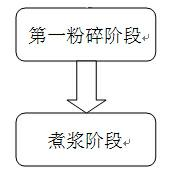

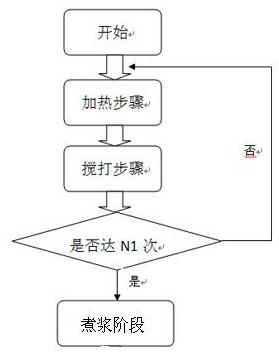

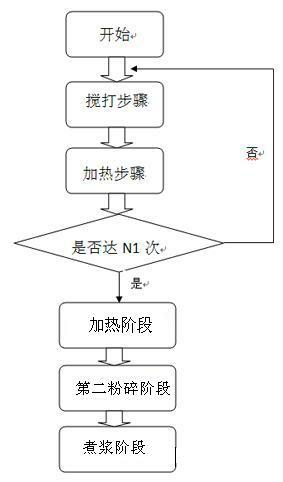

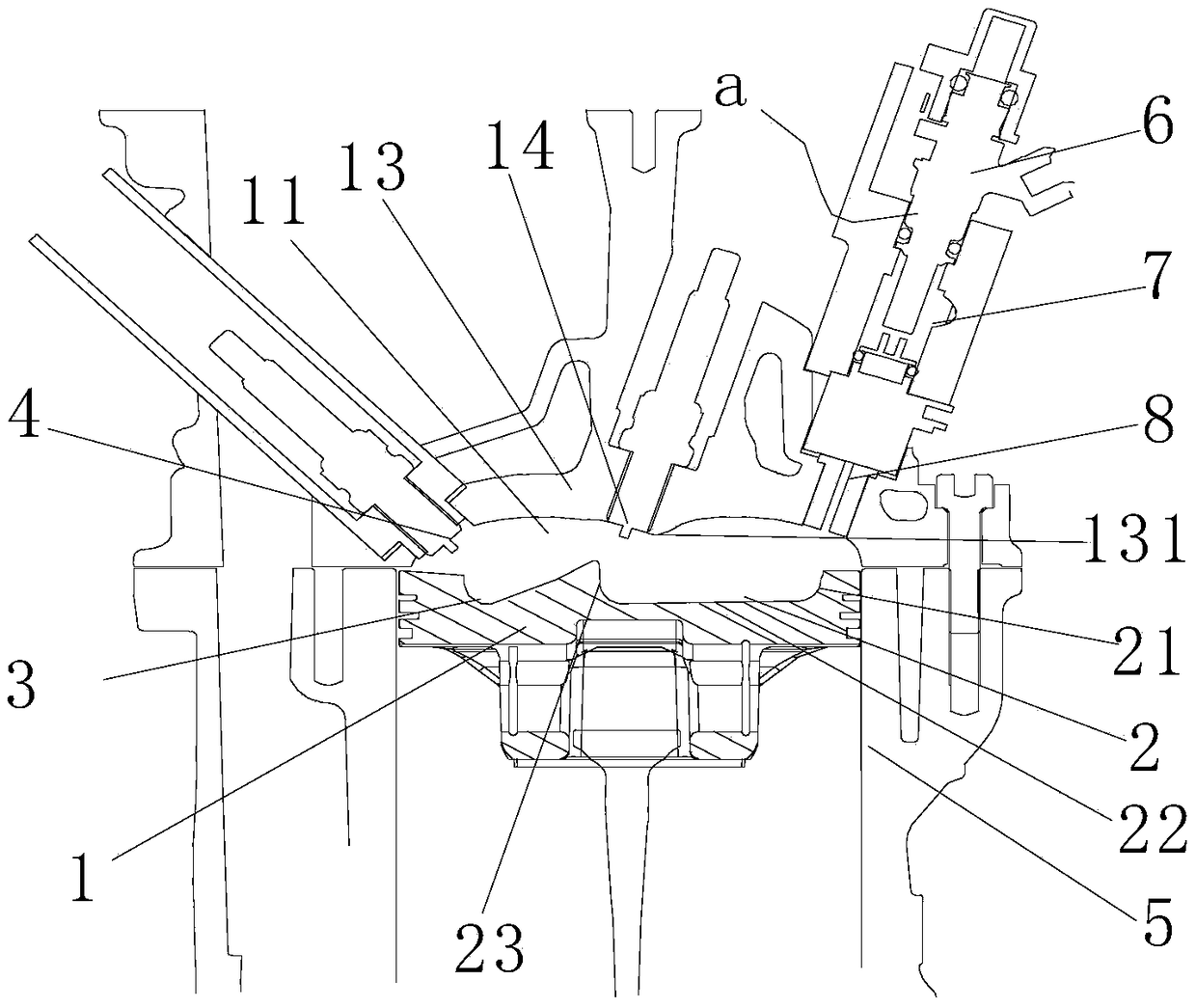

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

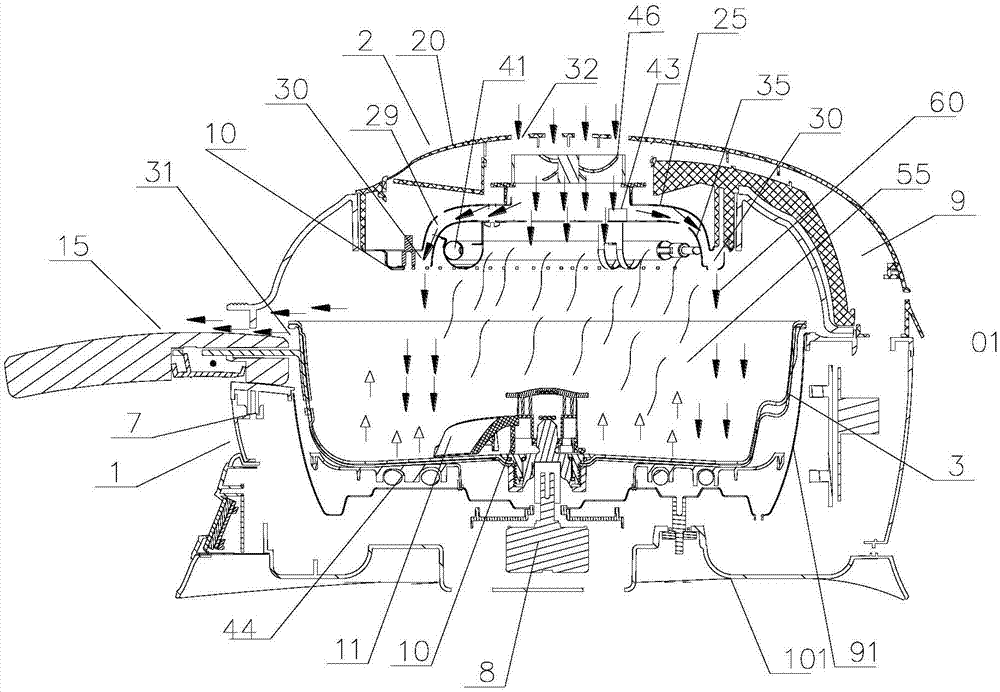

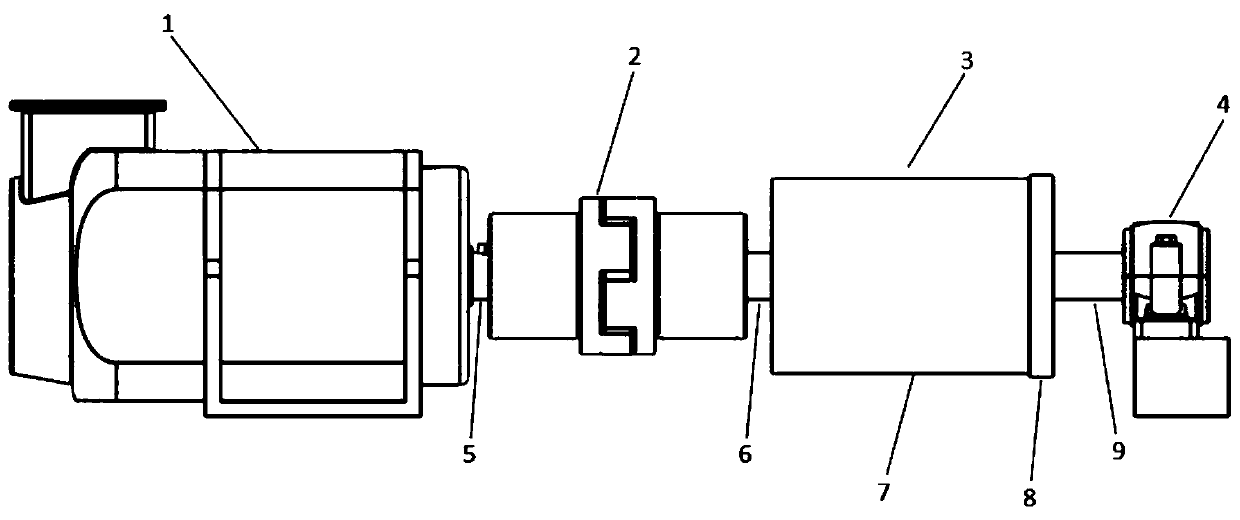

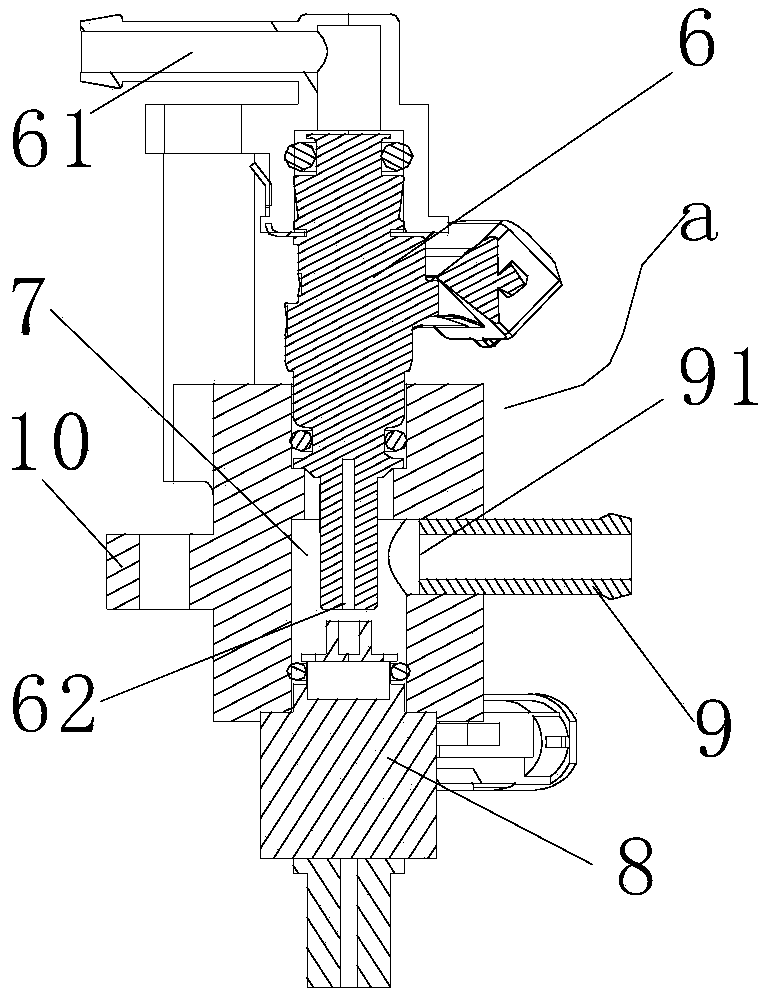

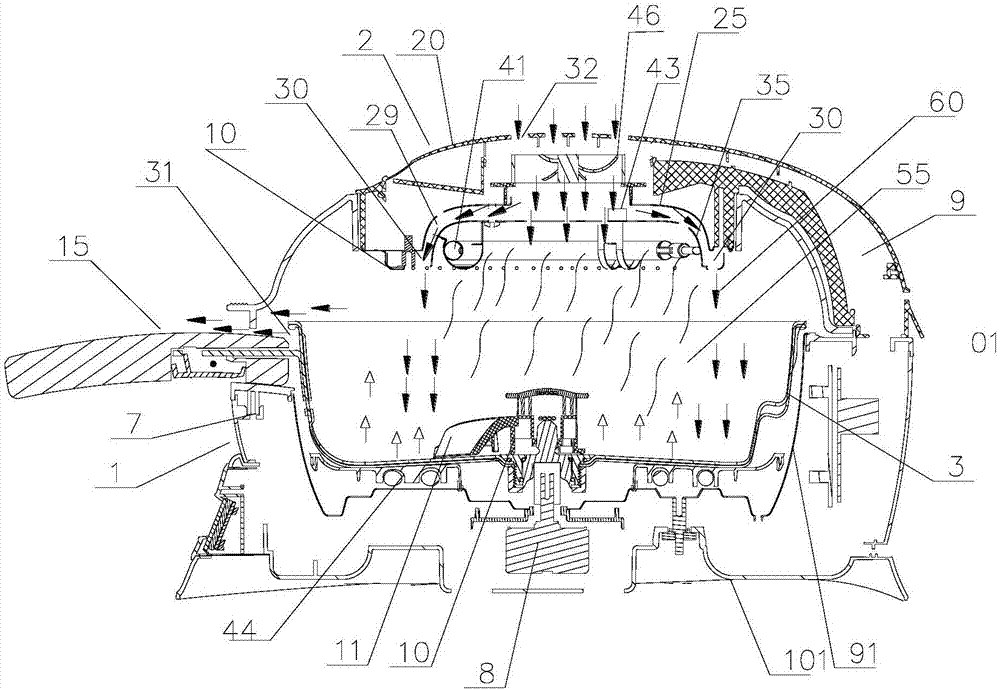

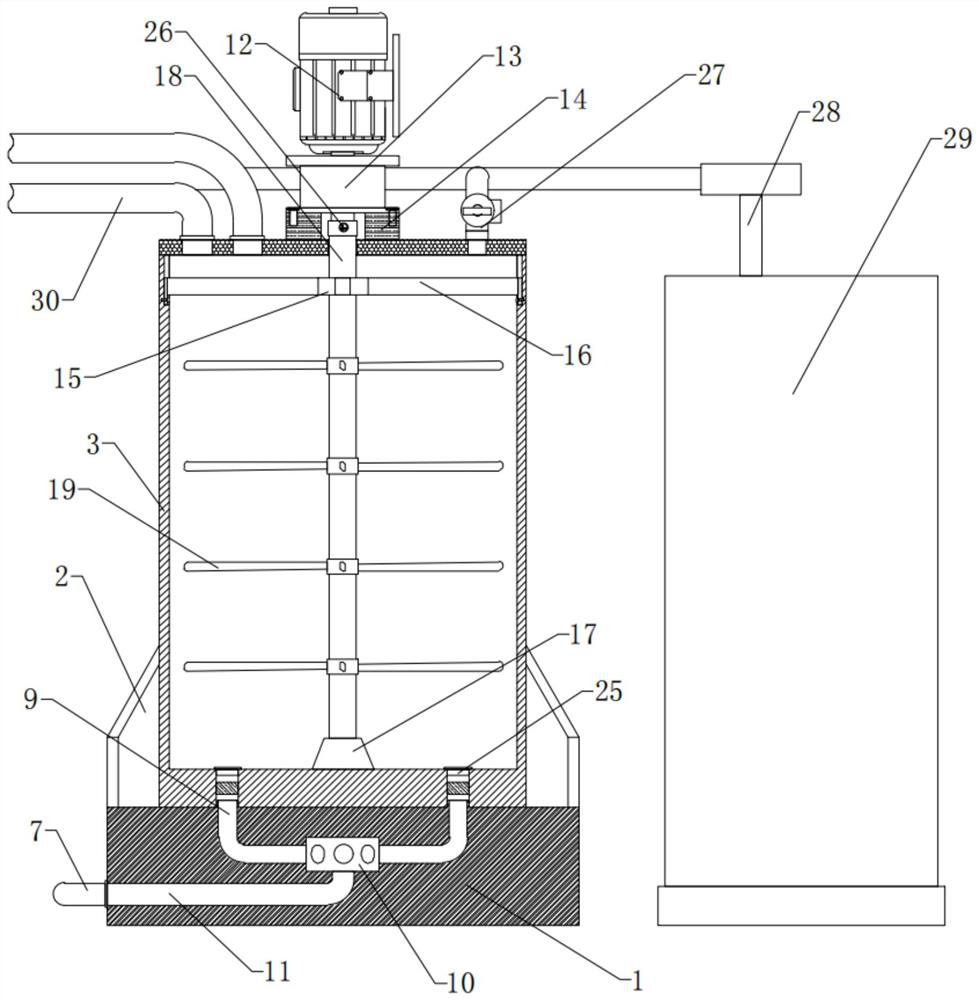

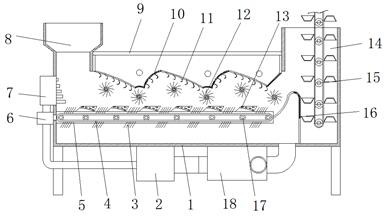

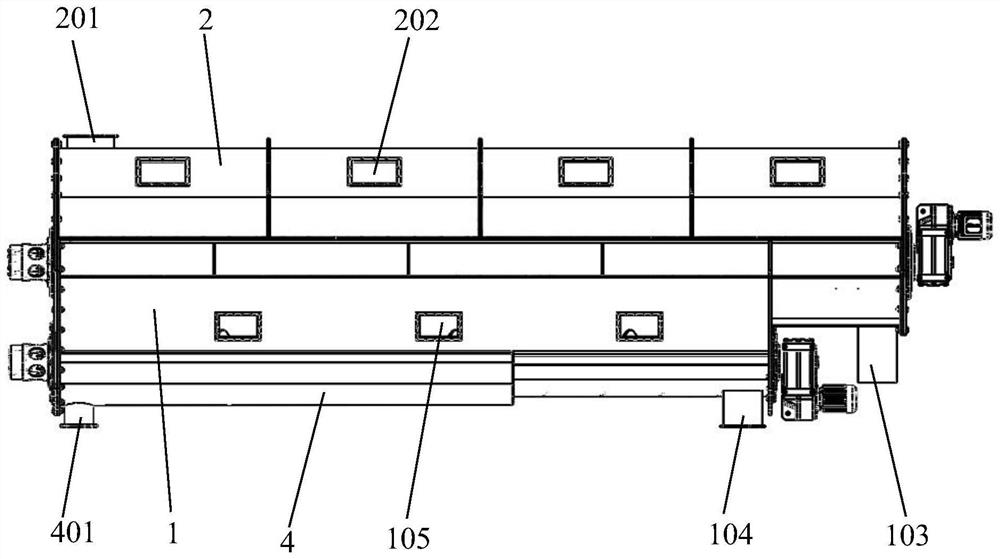

High-efficiency energy-saving roasting pan and methods for heating, cooling, and exhausting thereof

InactiveCN107242769AAvoid rapid exodusExtended stayCooking-vessel lids/coversCooking insertsTemperature controlWater vapor

The invention discloses a high-efficiency energy-saving roasting pan and methods for heating, cooling, and exhausting thereof. The roasting pan comprises a main body, an upper cover, a heater, a pot body, a food rolling-over device, a cooling fan, and at least a temperature controller or temperature control probe. The heater comprises an upper heater and a lower heater. The cooling fan is arranged on the outer part of a three-dimensional heating cavity, one end is communicated and connected with external air, and the other end is communicated and connected with the three-dimensional heating cavity. Through air blowing, external low-temperature air is mixed in the three-dimensional heating cavity at high temperature, to make temperature of the three-dimensional heating cavity constant or relatively cool or heat the three-dimensional heating cavity, and water vapor in the three-dimensional heating cavity is exhausted along an air outlet or a gap on the main body. The high-efficiency energy-saving roasting pan is characterized by good cooking effect, easy assembling and dismounting, easy cleaning, and wide application range.

Owner:ZHONGSHAN CITY GOLDLABO ELECTRIC CO LTD +1

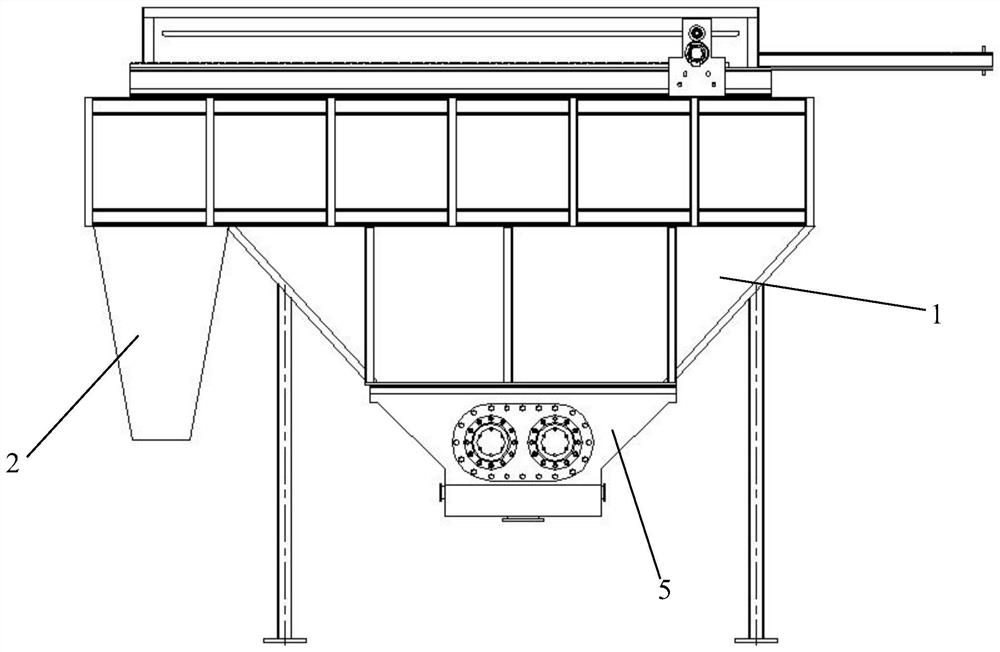

Tea leaf residue removing and screening device

ActiveCN111282793AImprove screening efficiencyEasy dischargeSievingScreeningGear wheelElectric machinery

The invention discloses a tea leaf residue removing and screening device. A driving device includes a driving motor, a waist-shaped ring, a rack, and a gear. One end of an output shaft of the drivingmotor is connected to a first rotating shaft, a connecting plate is arranged at one end of the first rotating shaft, a shift rod is arranged at the other end of the connecting plate, and a shift headis arranged at one end of the shift rod. The rack meshes with one side of the gear, the rack is provided with a guide groove, and a guide rod is arranged inside the guide groove. The two ends of the guide rod are fixedly installed on a supporting seat through vertical plates, the two sides of the waist-shaped ring are arranged on the rack through hanging lugs, the waist-shaped ring is provided with a waist-shaped groove, and the shift head is installed inside the waist-shaped groove. The lower part of a screen drum is fixedly installed on the gear through a plurality of fixing rods, a sieve plate is arranged inside the screen drum, a residue outlet is formed in one side of a residue storage cavity, and a residue outlet door is arranged at the residue outlet. The rack drives the gears to move in reciprocating and rotary modes so as to drive the screen drum to move in reciprocating and rotary modes, tea leaves are continuously turned over inside the screen drum, and the sieve plate screens the residues in the tea leaves, so that the screening efficiency of the tea leaf residues is improved.

Owner:张家界诺康生态茶业有限公司

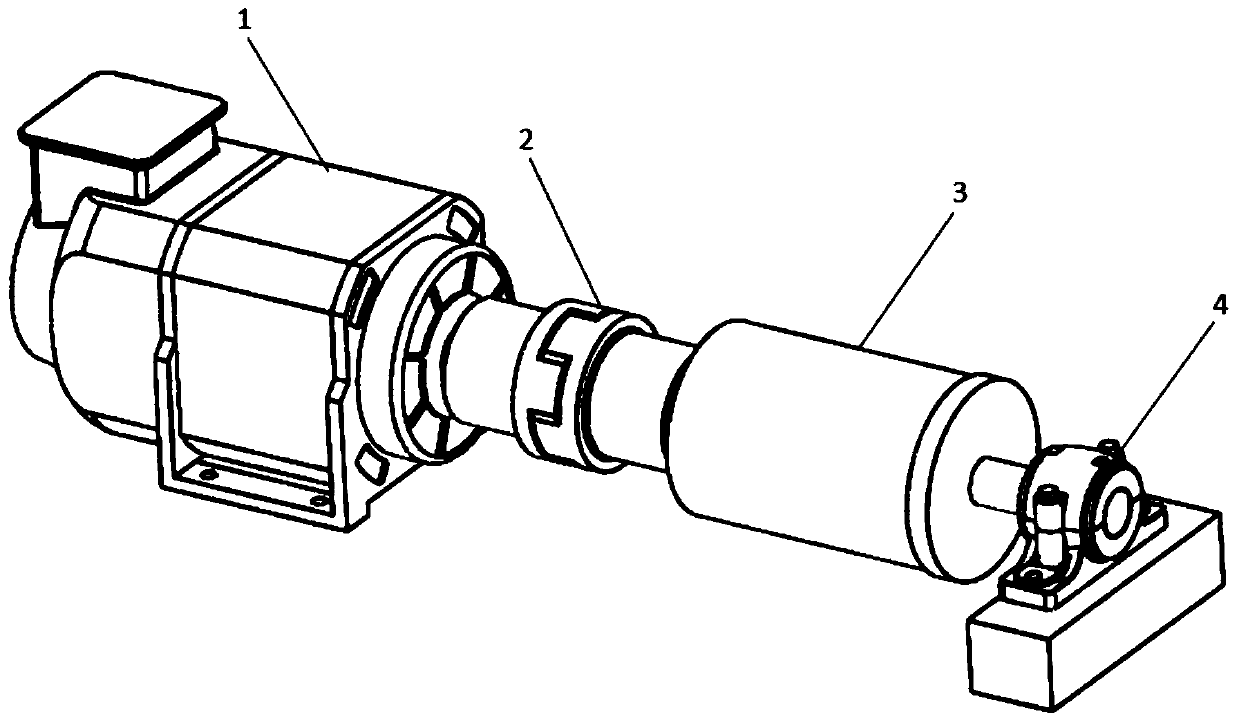

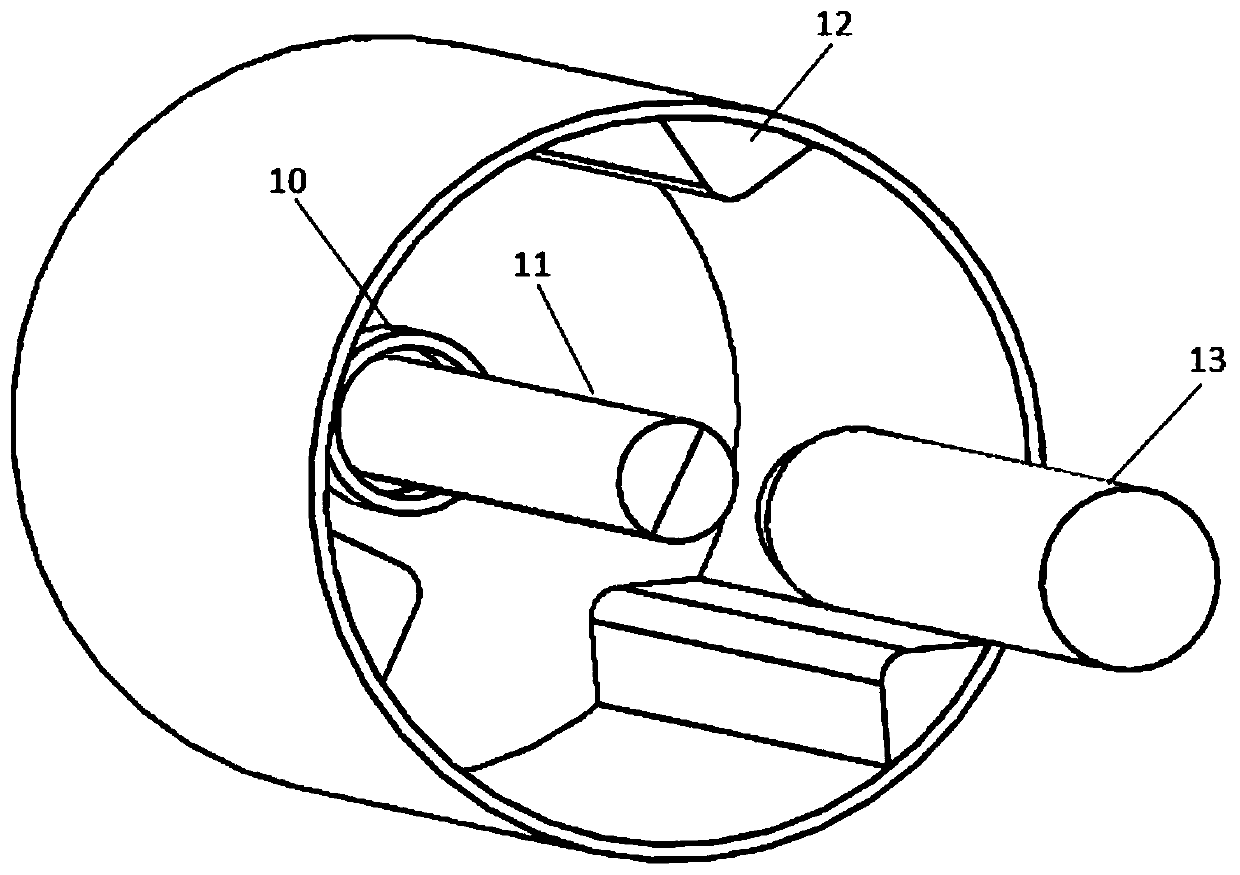

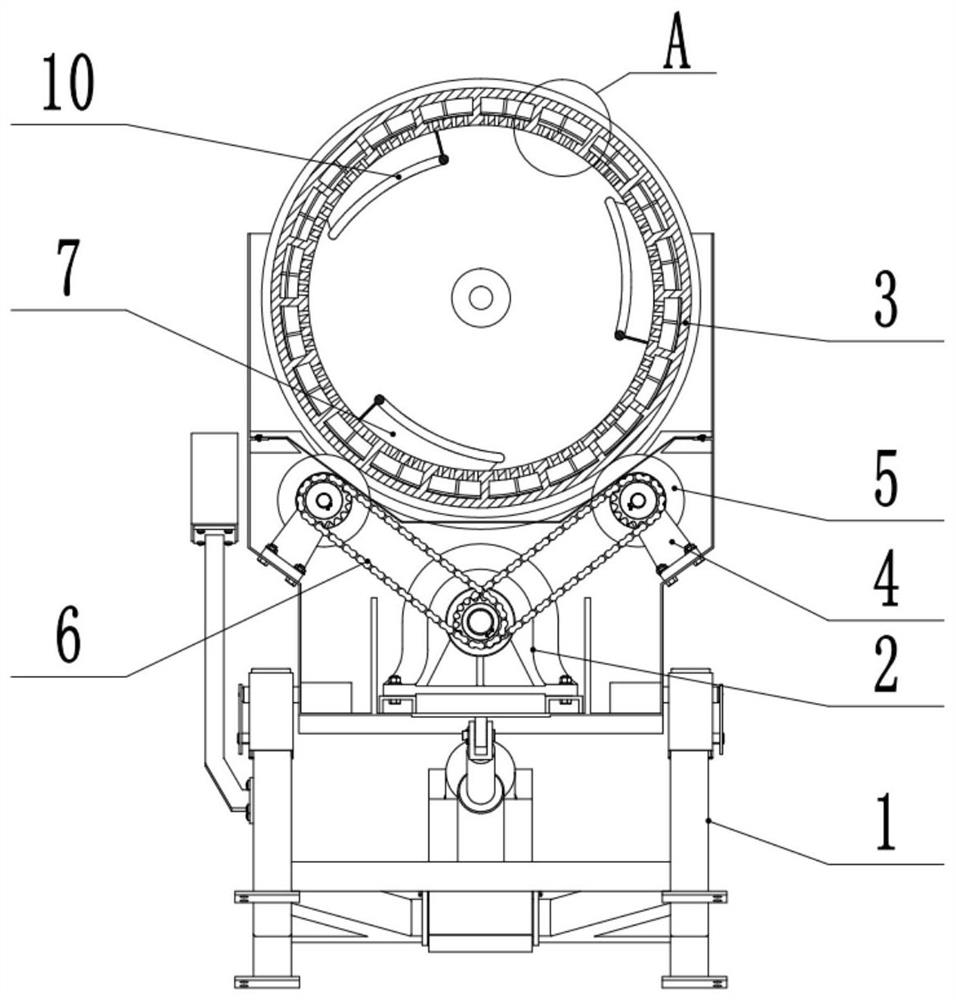

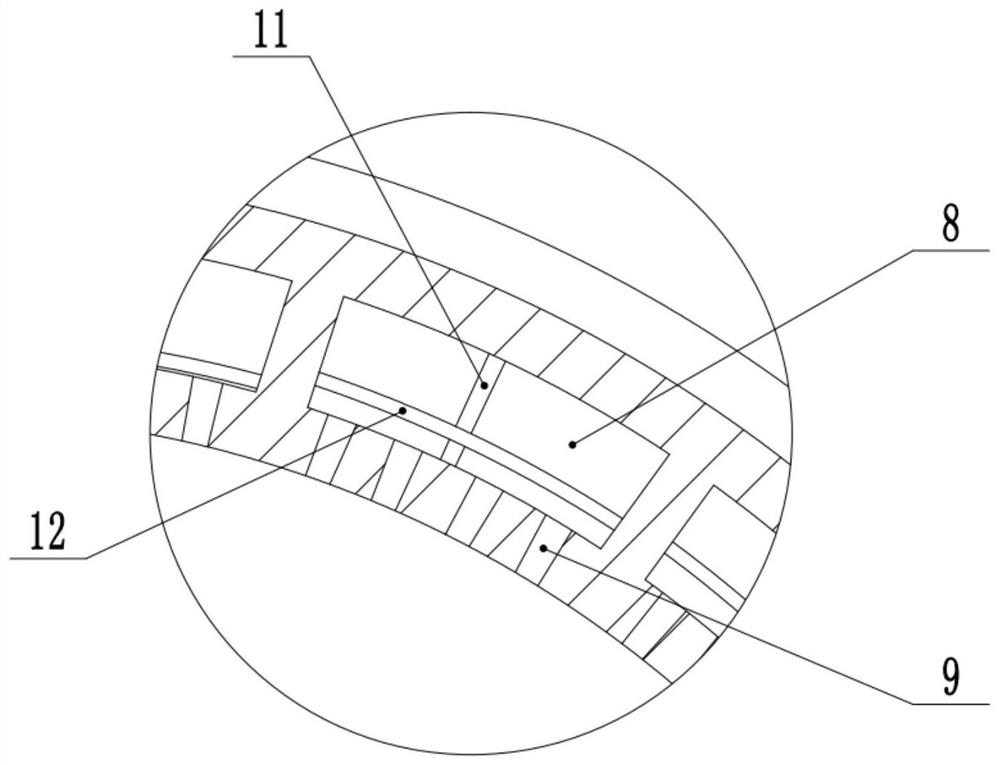

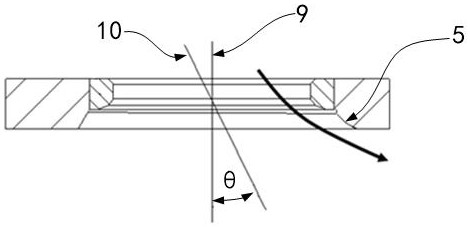

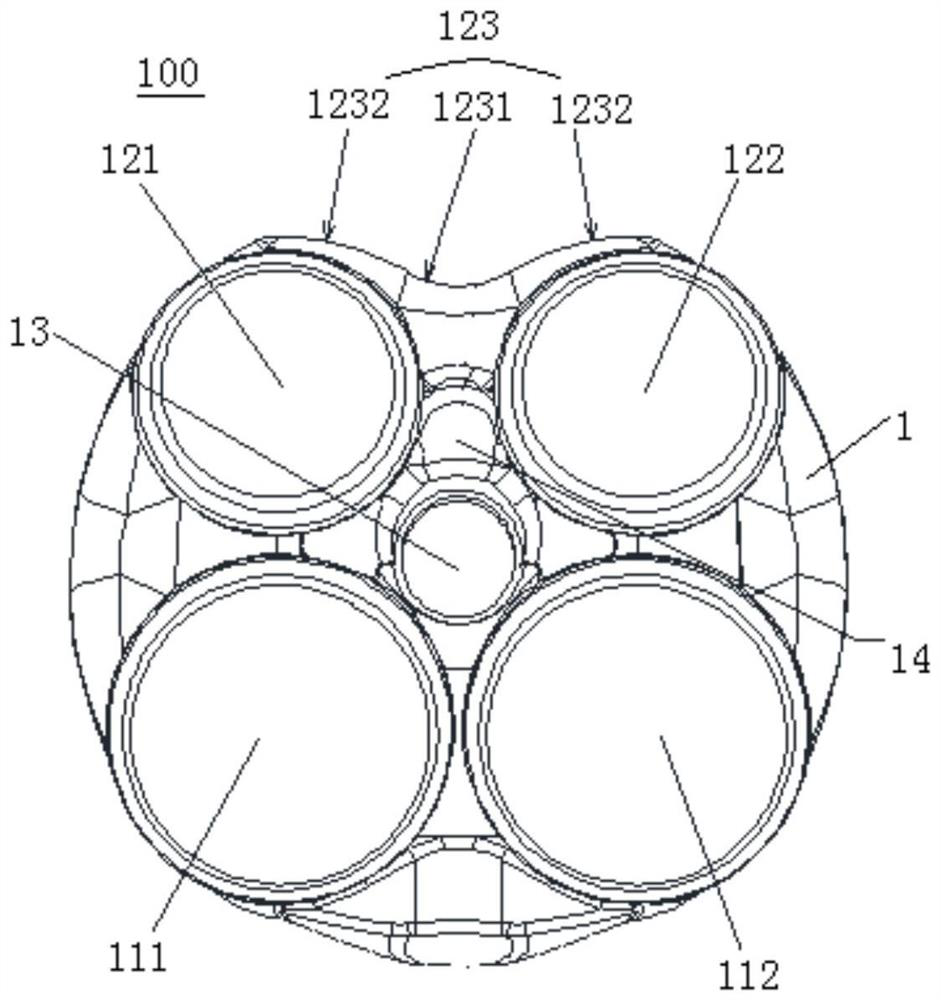

Magnetic grinding device suitable for spherical surfaces and irregular solid surfaces and method thereof

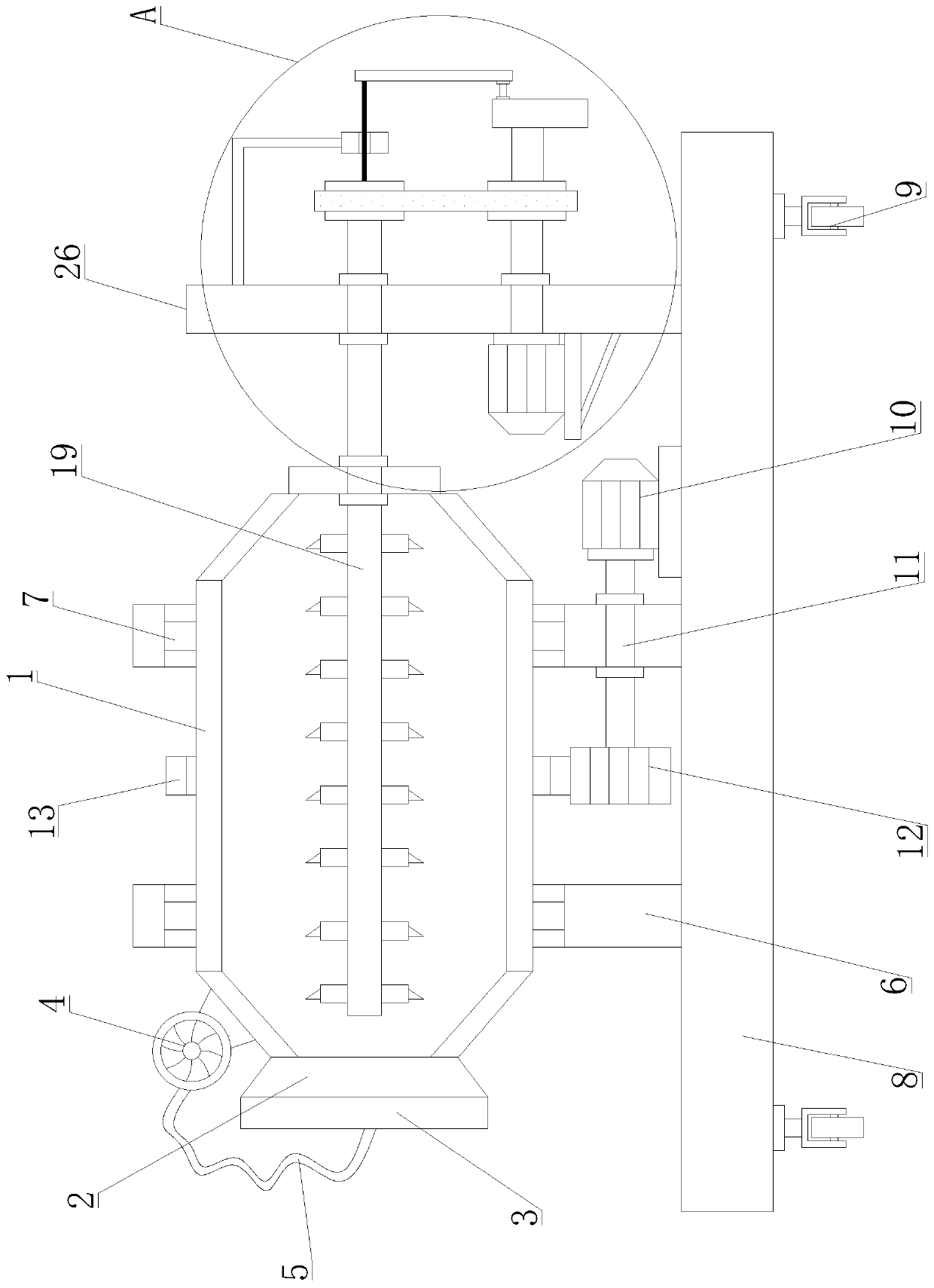

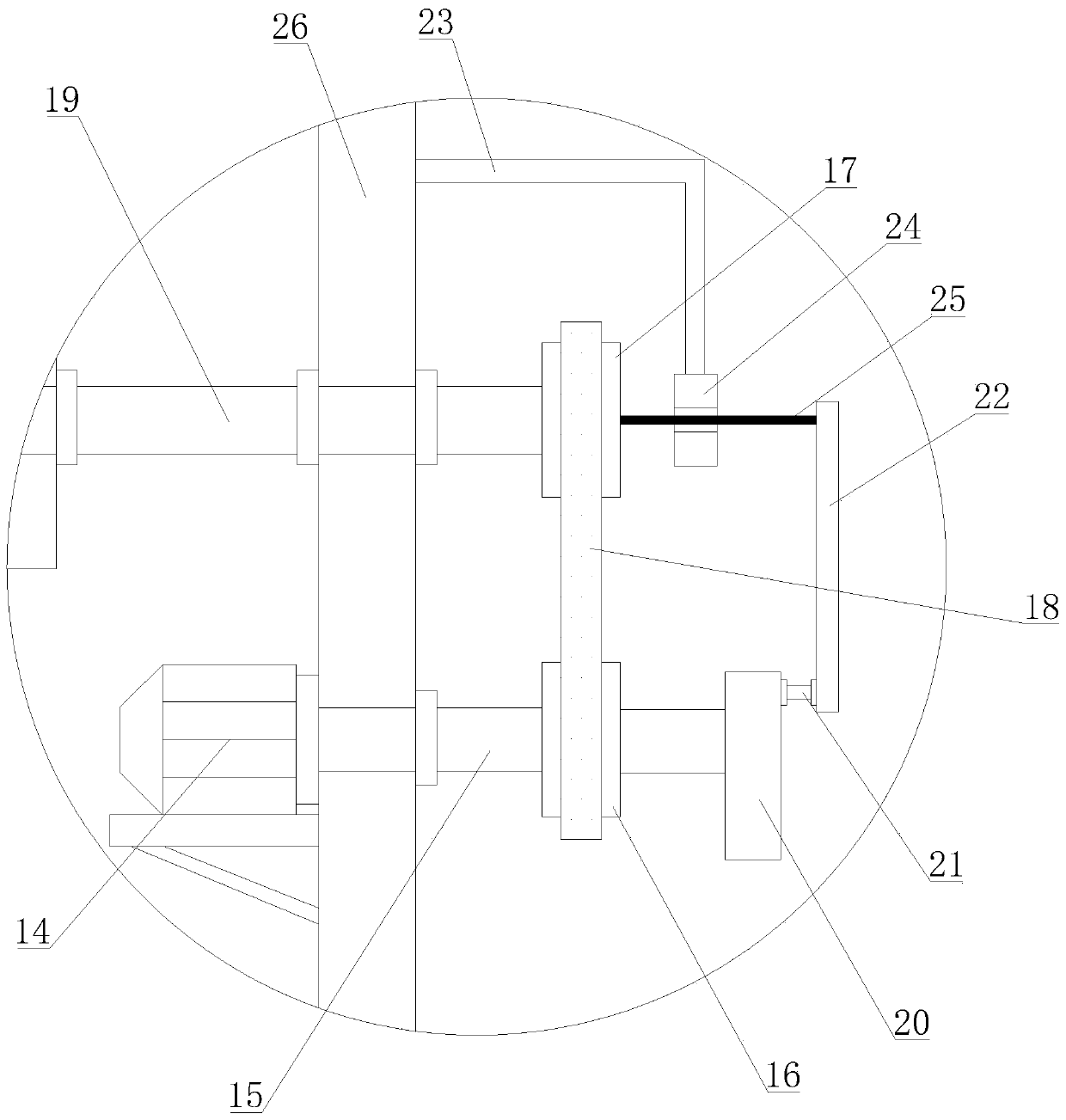

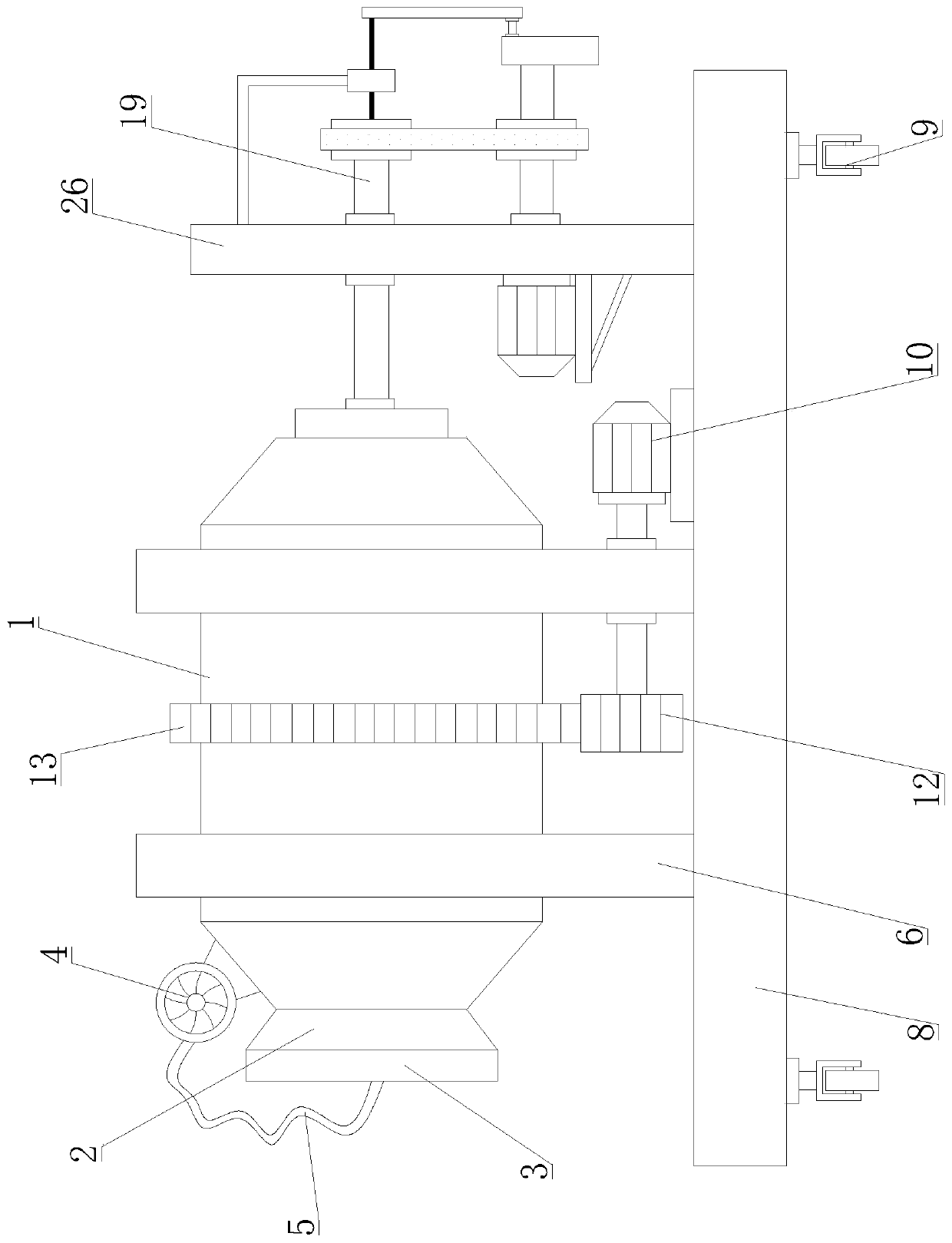

ActiveCN111216032AImprove tumbling effectRealize finishingEdge grinding machinesPolishing machinesMagnetic tension forceLaundry washing machine

The invention relates to the technical field of magnetic grinding, in particular to a magnetic grinding device suitable for spherical surfaces and irregular solid surfaces and a method thereof. The magnetic grinding device comprises a driving device and a magnetic grinding roller, wherein the driving device is connected with the magnetic grinding roller; a magnetic pole is arranged in the magneticgrinding roller to form a magnetic field, and a magnetic grinding material and parts to be processed are placed in the magnetic grinding roller; and the driving device drives the magnetic grinding roller to rotate, and the magnetic grinding material moves under the action of magnetic force and centrifugal force, so that the parts to be processed are processed. The magnetic grinding device is simple and is easy to operate, a principle of simulating a roller washing machine is adopted, the magnetic grinding material is rolled in a container with high fluidity and irregularity, and the polishingeffect on the parts placed in the container is realized; and the magnetic grinding device can be widely applied to the parts with various shapes, has good adaptability and can greatly improve the processing efficiency.

Owner:UNIV OF SCI & TECH LIAONING

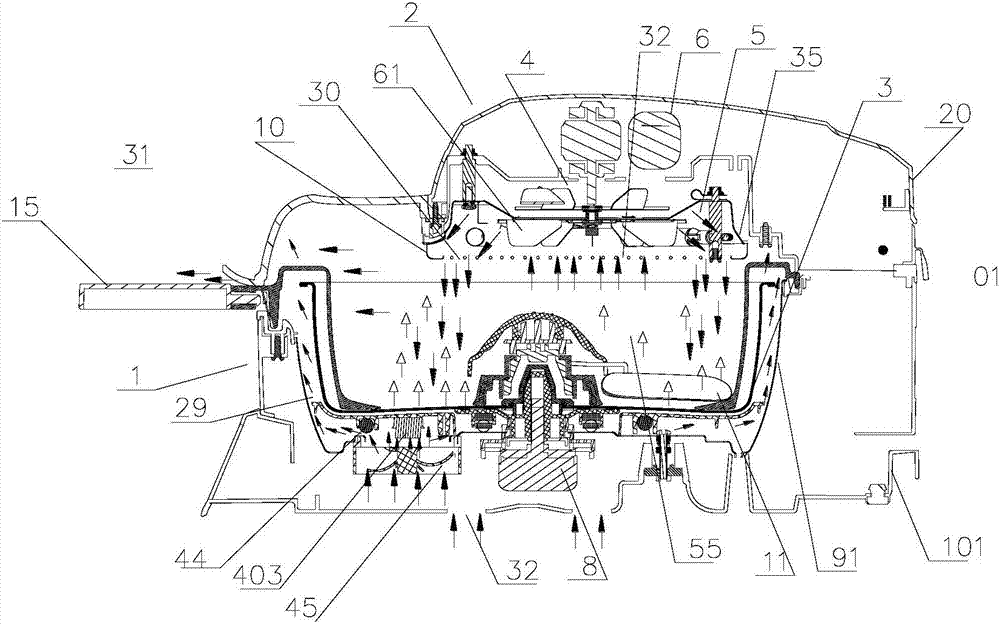

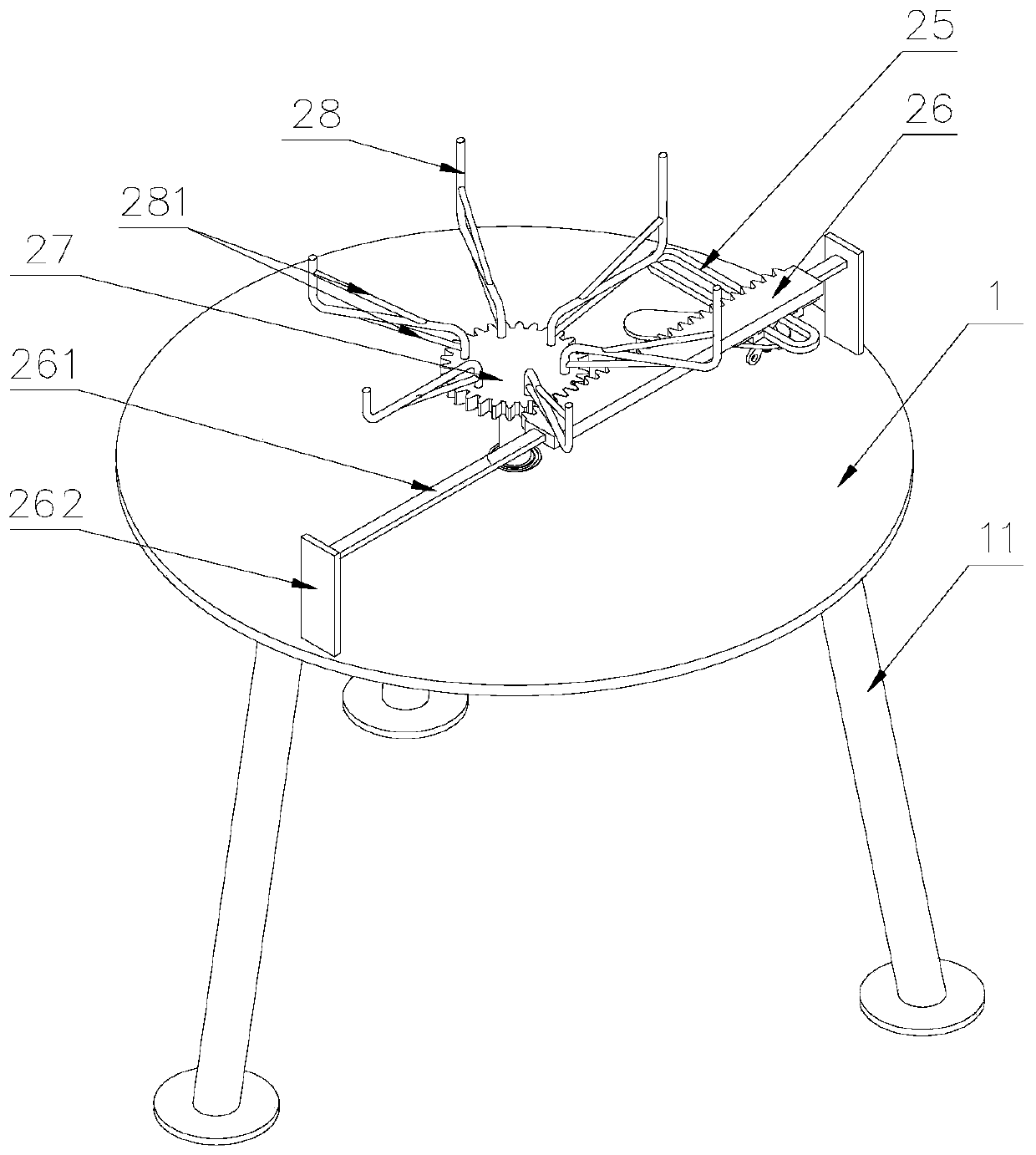

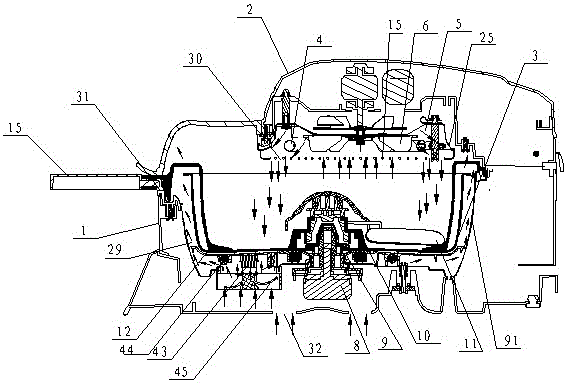

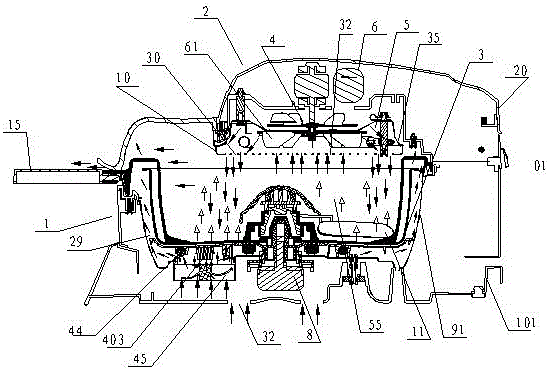

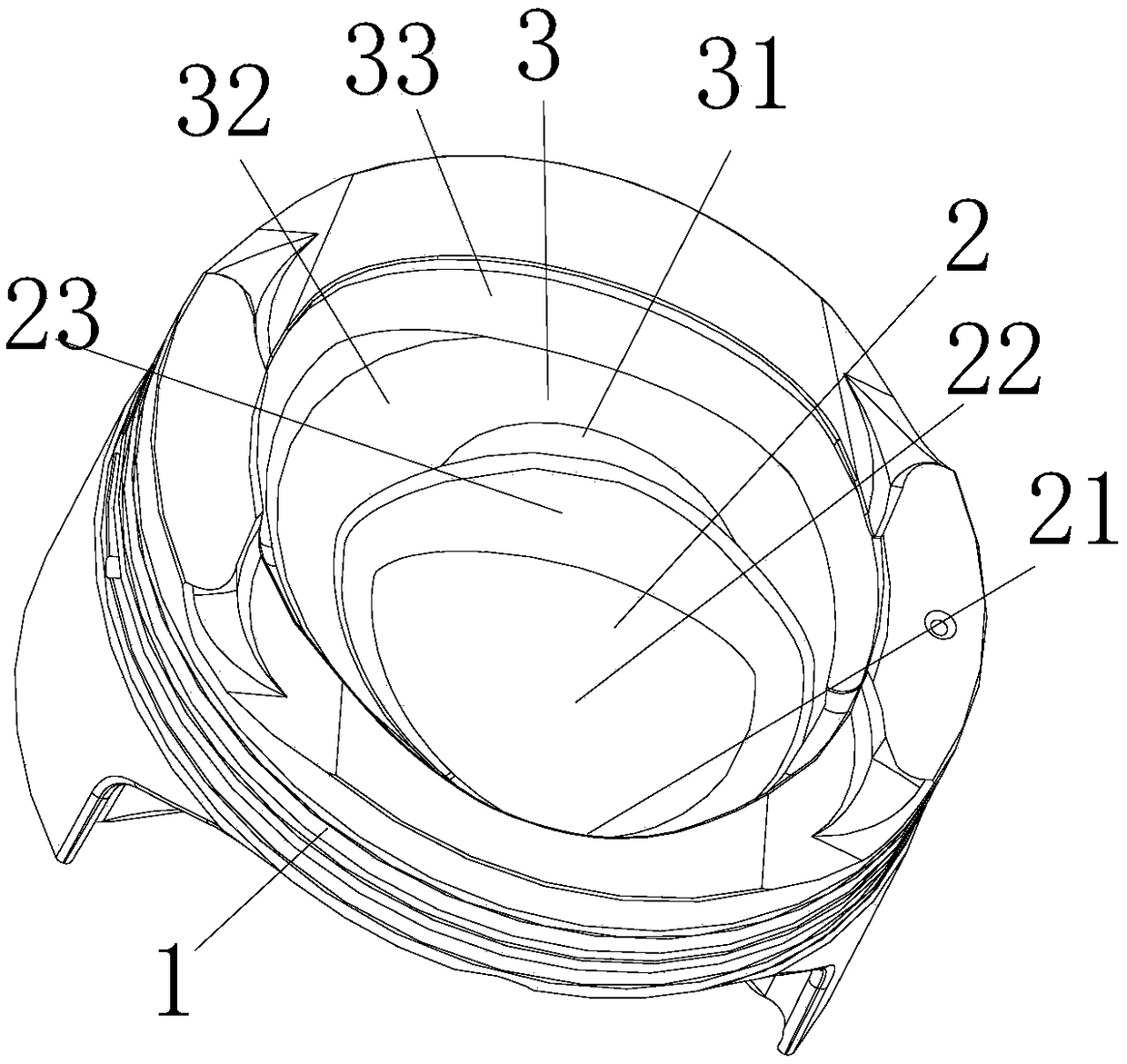

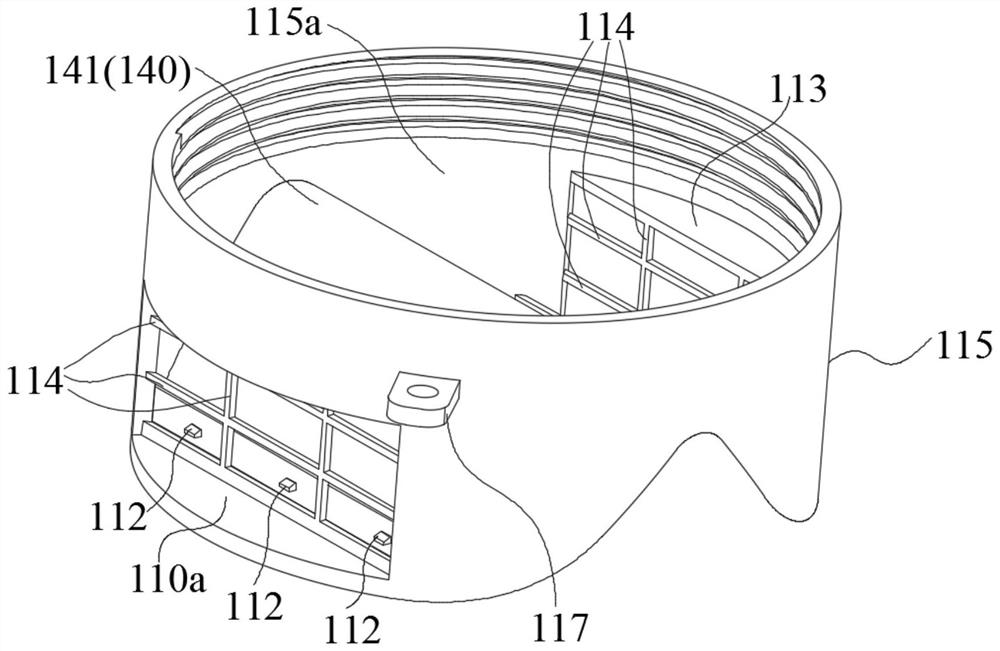

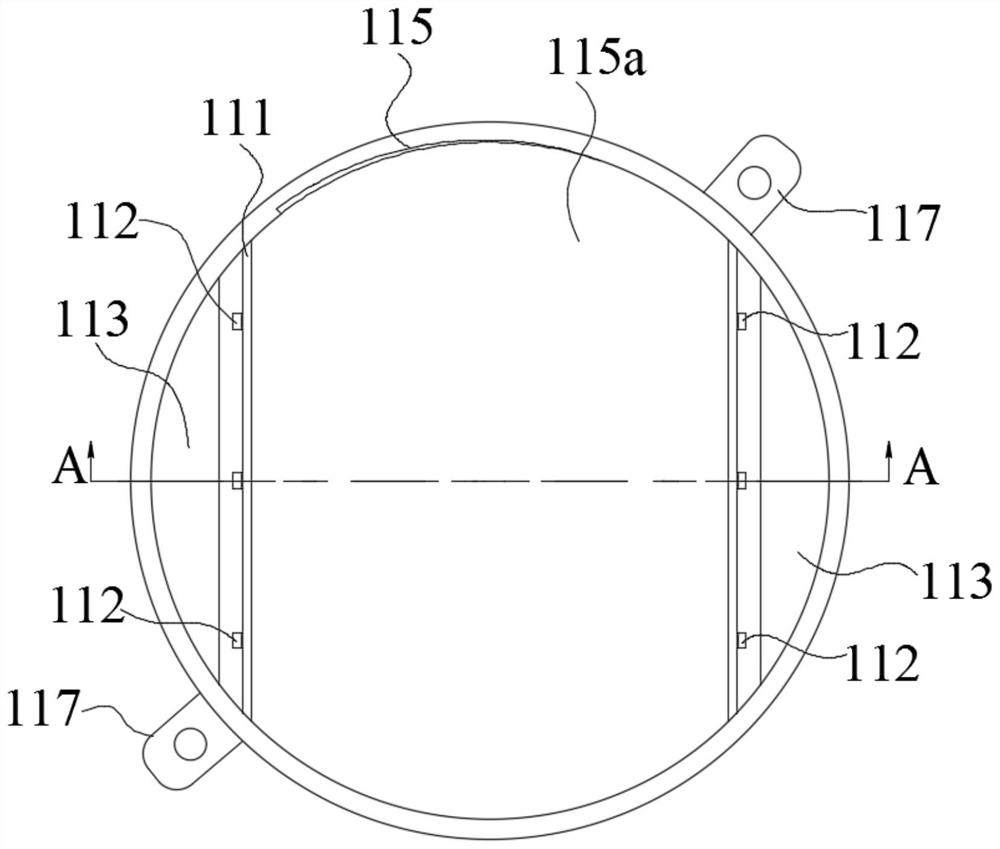

High-efficiency roasting pan

InactiveCN105686620AEvenly heatedHard on the outside and soft on the insideRoasters/grillsCooking vessel constructionsTemperature controlStopped work

The invention discloses a high-efficiency roasting pan which comprises a main body, an upper cover, a heater and a pot body (3), wherein the pot body (3) is arranged inside the main body; a food turning device, a heating cavity and a cooling fan (45) are arranged in the pot body (3). The high-efficiency roasting pan is characterized in that the cooling fan (45) or a cooling channel (29) are arranged outside the heating cavity; a temperature controller or a temperature control probe (43) is arranged at the air outlet of the cooling fan (45) or on the cooling channel (29); the cooling fan (45) or the cooling channel (29) is adopted to cool the temperature controller or the temperature control probe (43) by blowing air so as to prolong the heating working time of the temperature controller or the temperature control probe (43), or shorten the power-off time of the temperature controller or the temperature control probe (43) when stopping working, and thus the total working time can be shortened. The high-efficiency roasting pan has the characteristics of good cooking effect, easiness in assembling and disassembling, easiness in cleaning, and wide application range.

Owner:周林斌

Energy-saving toasting pan

InactiveCN105662119AEvenly heatedHard on the outside and soft on the insideCooking-vessel lids/coversCooking insertsTemperature controlStopped work

An energy-saving baking pan, the main body includes a large body (1), an upper cover (2), a heater (4), a pot body (3) is arranged in the body (1), and food rolling is arranged in the pot body (3) device, a heating chamber, and a cooling fan (45), the upper and lower heaters are arranged on the main body, and the feature is that a cooling fan (45) is arranged outside the heating chamber; a thermostat or a temperature controller is arranged downstream of the cooling fan (45). control probe (43); the cooling fan (45) blows air on the thermostat or temperature control probe (43) to cool down and prolong the heating time of the thermostat or temperature control probe (43), or shorten the temperature of the thermostat or temperature control probe (43). The power-off time during which the control probe (43) stops working, thereby shortening the total working time; or blowing air to the heater (4) allows the heater (4) to heat evenly. The invention has the characteristics of good cooking effect, easy assembly and disassembly, easy cleaning and wide application range.

Owner:周林斌 +1

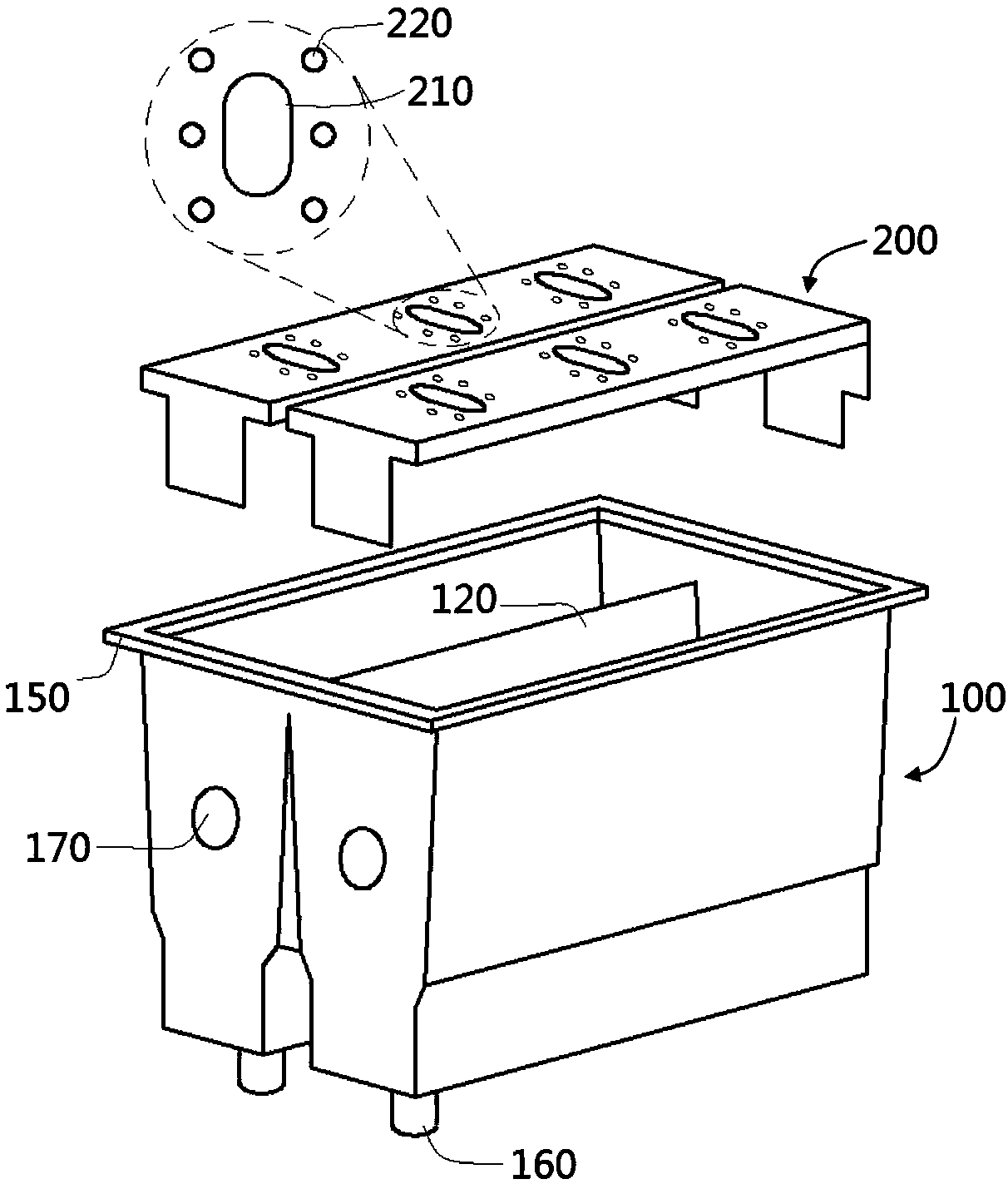

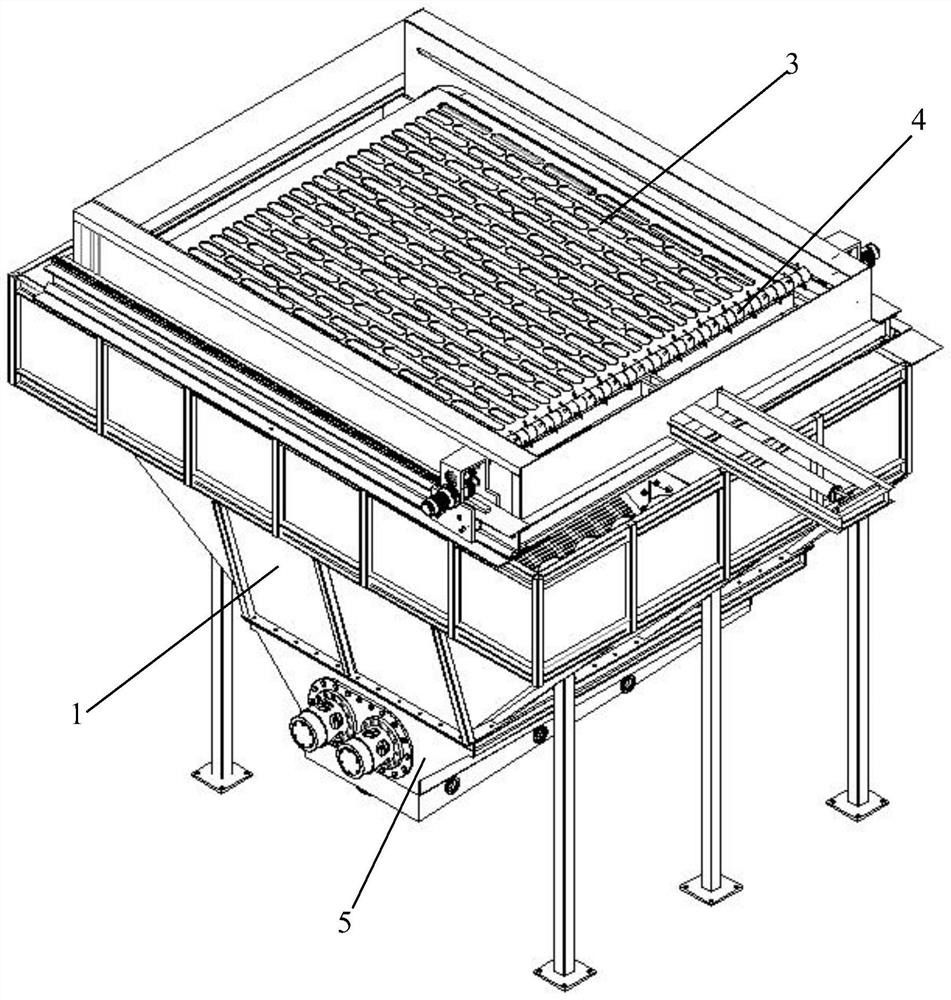

Noodle boiling furnace with jet flow plate and noodle boiling method thereof

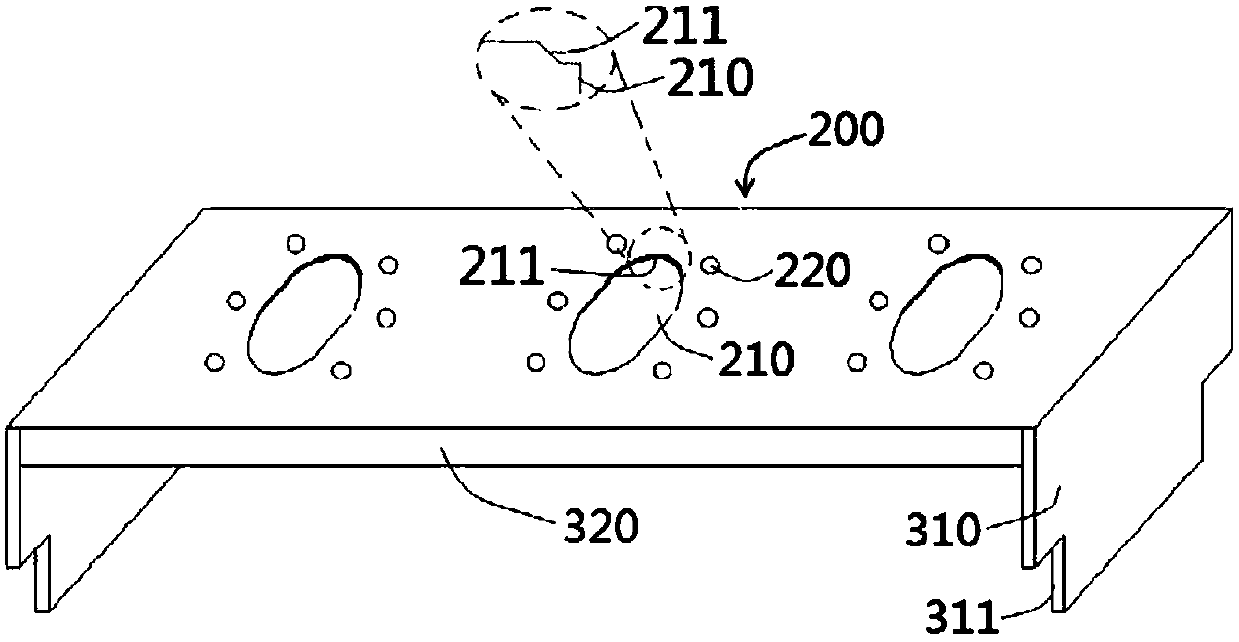

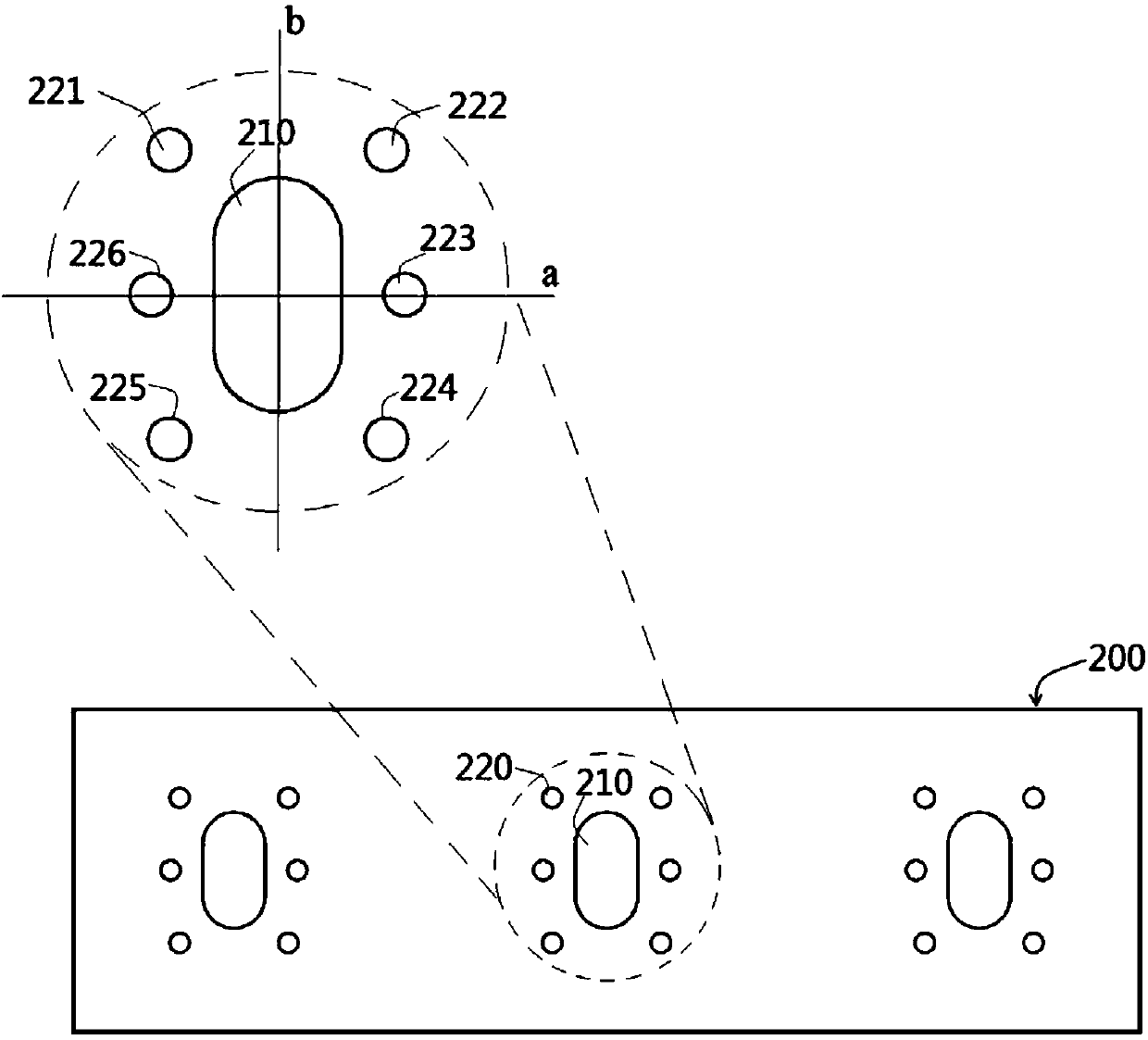

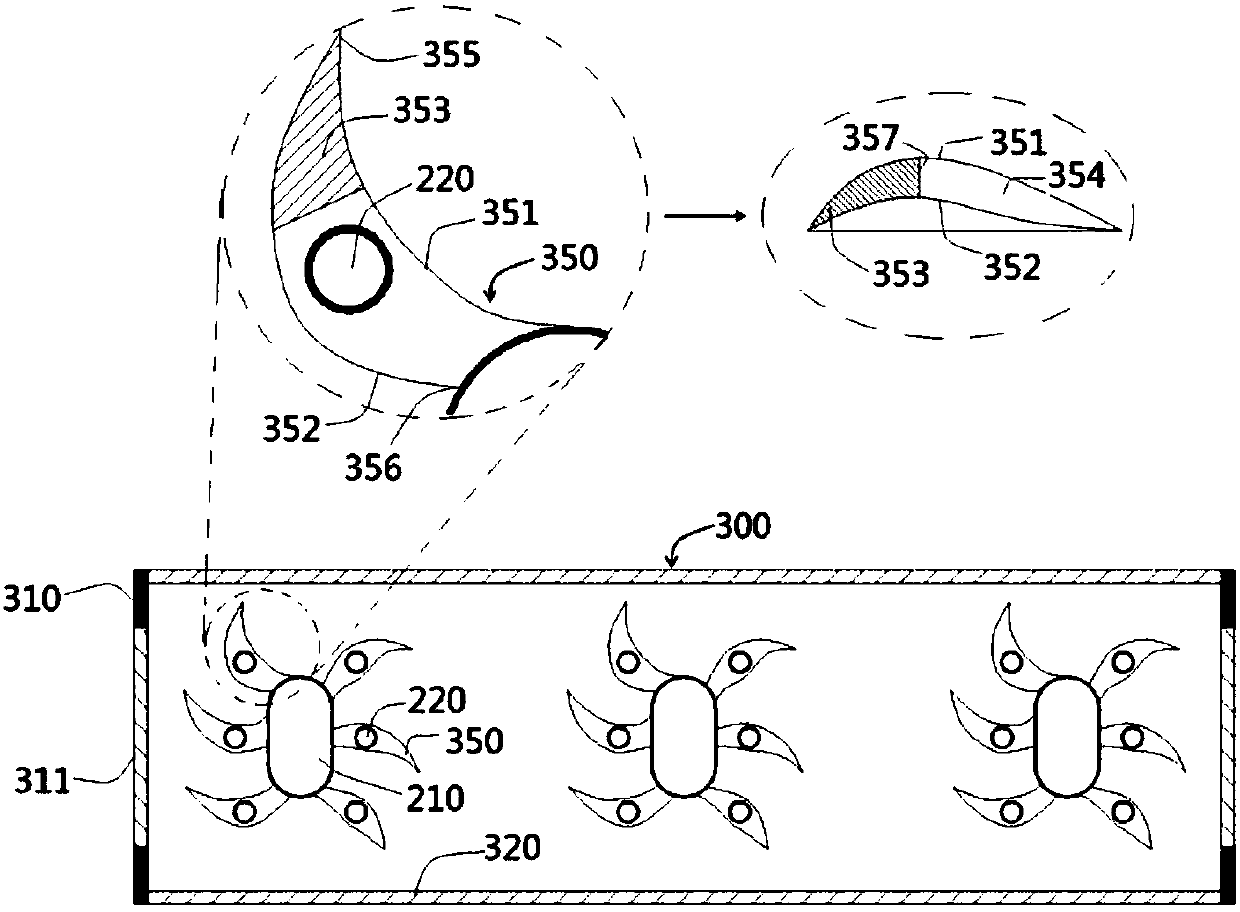

ActiveCN108158384APrevent undershockHigh heat transfer efficiencyCooking vessel constructionsEngineeringHeating effect

The invention relates to a noodle boiling furnace with a jet flow plate and a noodle boiling method thereof, and belongs to the field of food processing equipment. A jet flow plate main body is arranged on a noodle boiling furnace body; the jet flow plate main body is provided with main water spraying holes and auxiliary water spraying holes; the noodle boiling furnace body comprises a depositioncabin and heating pipes; the deposition cabin is used for collecting food residue; the heating pipes are used for heating water and are arranged at the upper end of the deposition cabin; the jet flowplate main body is arranged at the upper end of the heating pipes; and the jet flow plate main body is used for spraying water heated by the heating pipes at the lower part to the upper side for boiling noodles. The boiling hot water under the jet flow plate main body can be sprayed to the upper side of the jet flow plate main body through the water spraying holes; the hot water impacts the doughto generate a rolling effect; when the water flow of the main water spraying holes impacts the dough, the water flow sprayed from the auxiliary water spraying holes impacts the periphery of the dough;and the heating rate and the heating effect are further improved.

Owner:ANHUI HUALING KITCHEN EQUIP

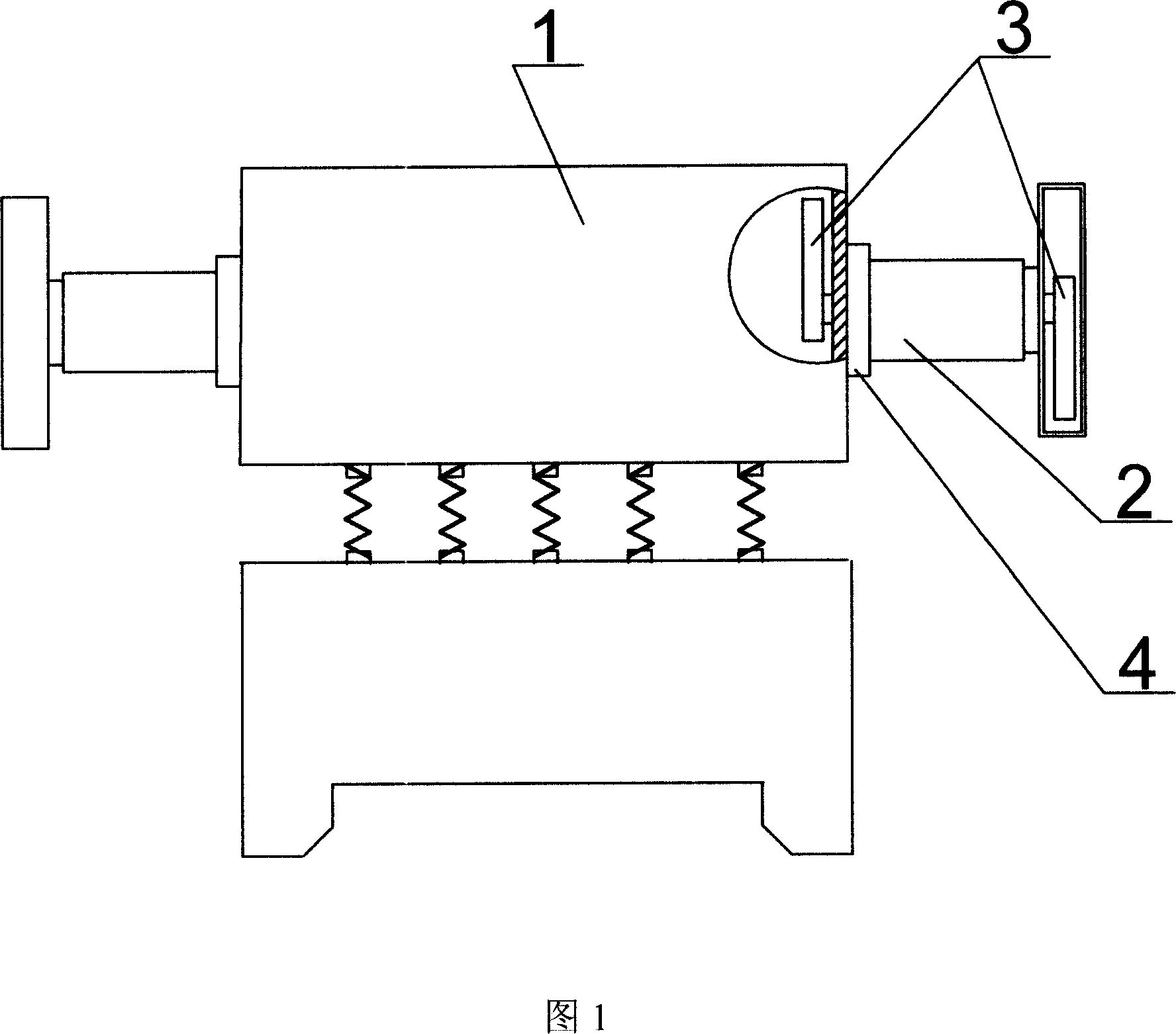

Vibrating electric motor mounting method for vibrating grinder

InactiveCN101148028AEasy to installLower the altitudeEdge grinding machinesPolishing machinesElectric machineryReduced height

The vibration motor installing method for vibratory grinding machine includes installing the vibration motor onto bed of the vibratory grinding machine, installing eccentric vibrating blocks in the two ends of shaft in the vibration motor, and making the axis of vibration motor shaft perpendicular to the installation pedestal plane of the vibration motor. The present invention has the advantages including reduced height and size of the vibratory grinding machine, raised processing efficiency, reduced grinding period, raised product quality and lowered production cost.

Owner:杨平华 +2

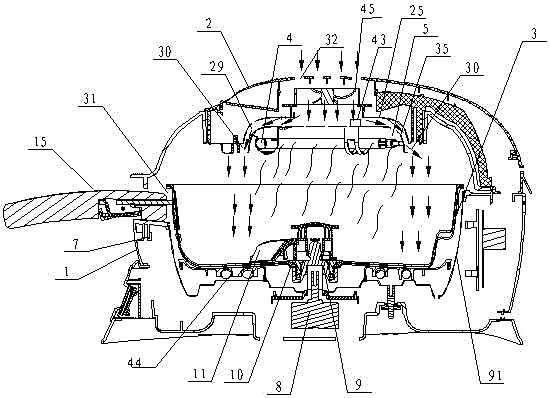

Efficient and energy-saving roasting pan

InactiveCN106388630AAvoid rapid exodusExtended stayRoasters/grillsThermal radiationElectrical and Electronics engineering

The invention provides an efficient and energy-saving roasting pan. A main body comprises a large body, an upper cover, heaters, a pan body, a food rolling-over device, an air inlet hole and a cooling fan, wherein the heaters comprise an upper heater and a lower heater; the efficient and energy-saving roasting pan is characterized in that the large body is used for containing the pan body (3), the food rolling-over device (11) and the lower heater (44); the large body (1) provides a heat source for providing conductive heating to bottoms of foods; the upper cover (2) provides a heat source for providing heat radiation or light illumination heating to upper surfaces of the foods; the upper cover (2) covers the large body (1) to form a three-dimensional heating cavity (55) with the upper part for carrying out heat radiation or light illumination heating and the bottom for providing conductive heating; the cooling fan is used for providing a constant temperature into the three-dimensional heating cavity (55) or relatively cooling and heating the inner part of the three-dimensional heating cavity (55); the cooling fan is arranged at the outer part of the three-dimensional heating cavity (55); and one food rolling-over device (11) is used for rolling over the foods to carry out uniform heating and three-dimensional heating on the foods. The efficient and energy-saving roasting pan has the characteristics of good cooking effect, easiness of dismounting and mounting, easiness of cleaning and wide applicable range.

Owner:周林斌

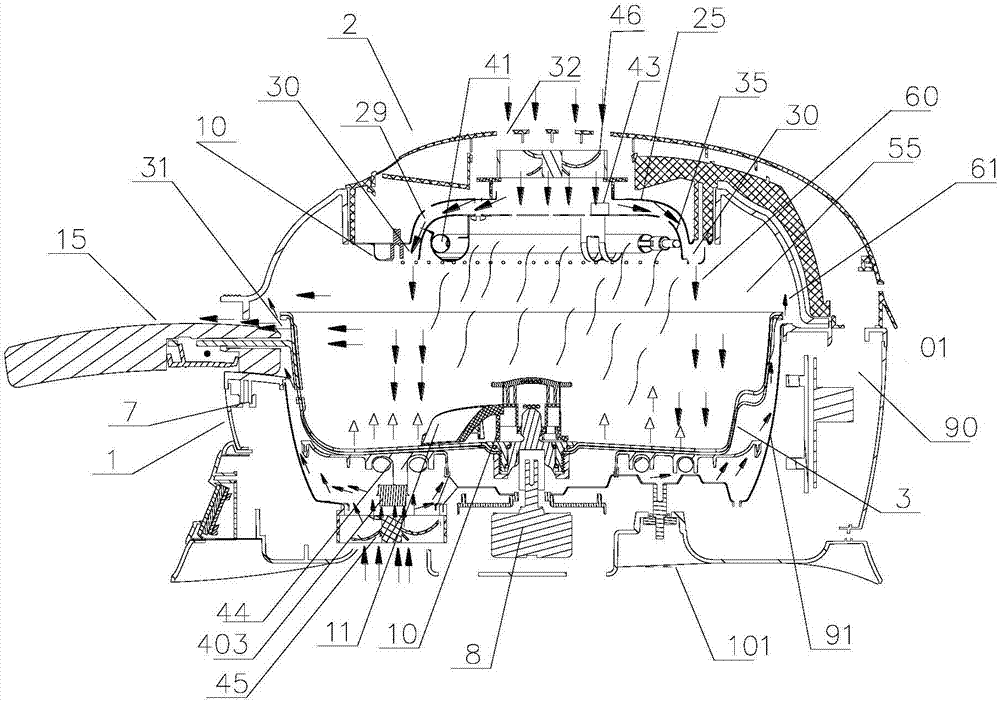

Working and use method of high efficiency roasting pan

InactiveCN106859385AEvenly heatedHard on the outside and soft on the insideRoasters/grillsCooking vessel constructionsWater vaporEngineering

A heating, cooling and air discharging method of a high efficiency roasting pan includes the following steps: a first reflective cover and a second reflective cover surround a relative sealed three-dimensional heating chamber; a periphery outer circulation cooling fan blows air to the three-dimensional heating chamber at a constant temperature, and relatively cools the three-dimensional heating chamber; low temperature air flow generated by the cooling fan enters the three-dimensional heating chamber via an air outlet or a clearance formed between a food holding vessel and the reflective covers; the low temperature air and high temperature air are mixed in the three-dimensional heating chamber, and high temperature water steam is discharged out via the clearance between the food holding vessel and the reflective covers; wet and hot air in the three-dimensional heating chamber and the food holding vessel flows out via a clearance or an opening formed in a large body; surfaces of food are hardened rapidly so as to block water in the food, rapid loss of water in the food can be prevented, and the processed food is hard in outer part, and is soft in inner part. The high efficiency roasting pan is excellent in cooking effect, is easy to demount and clean, and is wide in application range.

Owner:周林斌

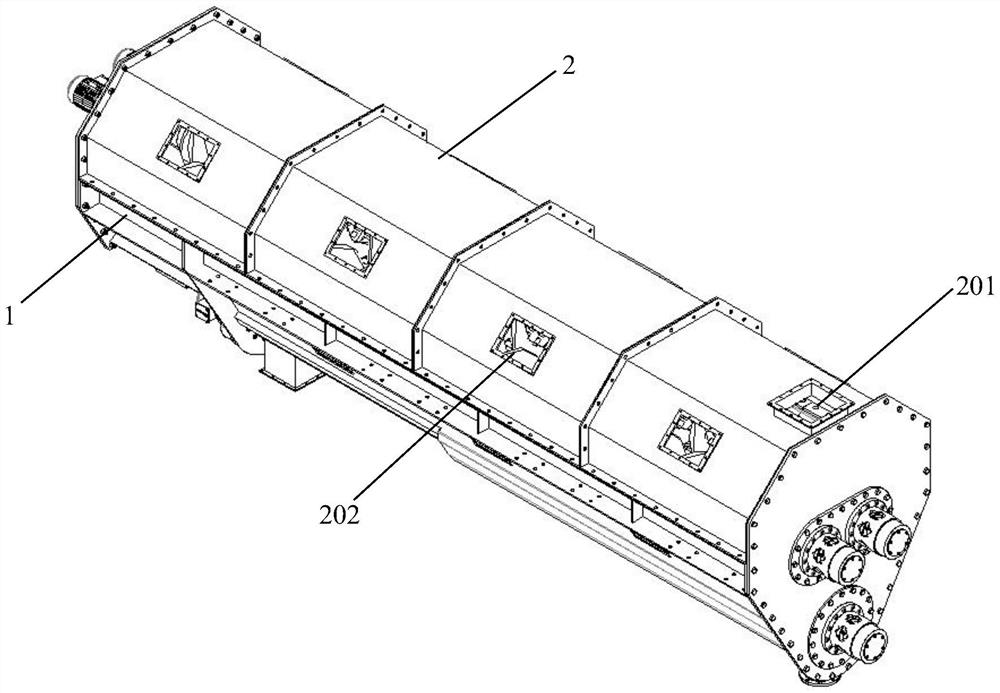

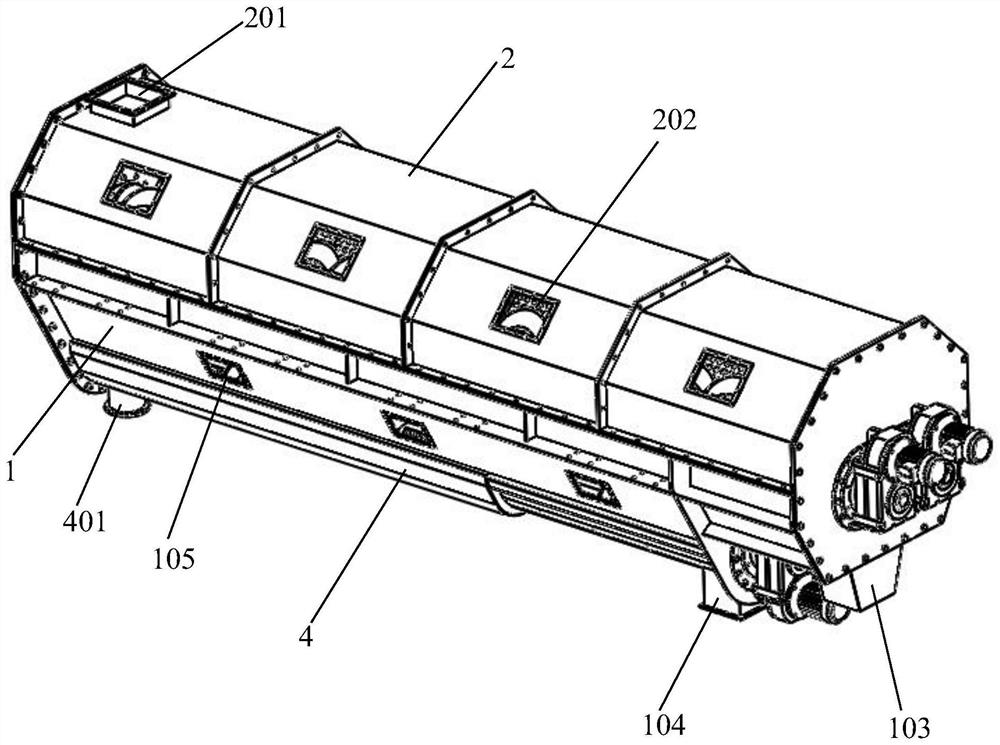

High-efficiency vacuum rolling and kneading machine for processing wild goose meat products

InactiveCN110692689APlay a supporting roleSmooth rotationBeating-based meat tenderisingBiotechnologyDrive wheel

The present invention discloses a high-efficiency vacuum rolling and kneading machine for processing wild goose meat products. The high-efficiency vacuum rolling and kneading machine comprises a roller, a sealing cover, a vacuum pump and rolling and kneading knives; a second gear is arranged on a peripheral surface of the roller, a first gear is arranged on a first output shaft, and the first gearis in meshed transmission connection with a second gear; a rotating piece is rotatably arranged on a vertical plate and also extends into the roller; a driving wheel is arranged on a second output shaft, a driven wheel is arranged on the rotating piece, and a transmission piece is in transmission connection with the driving wheel and the driven wheel; an eccentric wheel is arranged on the secondoutput shaft and a first connecting piece is rotatably connected with the eccentric wheel and a second connecting piece; a first pull rope is arranged on the second connecting piece and also extends into the rotating piece; fixed cylinders are arranged on the rotating piece and pistons are arranged in the fixed cylinders; fixed rods are connected with the pistons and the rolling and kneading knives, and elastic pieces are connected with the pistons and the rotating piece; and a second pull rope connects the pistons and the first pull rope. The high-efficiency vacuum rolling and kneading machine is simple to operate and convenient to use, significantly improves rolling and kneading efficiency and rolling and kneading effects of wild goose meat, helps reduce processing cost of the wild goosemeat and is extremely excellent in use effects.

Owner:JIUJIANG POYAN CULTIVATION CO LTD

Efficient tap water adsorption filter

ActiveCN106044882ARinse cleanImprove tumbling effectWater treatment parameter controlSpecific water treatment objectivesTurbidityWater quality

The invention provides an efficient tap water adsorption filter. The efficient tap water adsorption filter comprises a filter shell, a shell cover plate, a stirring motor, a water turbidity sensor, a water pressure sensor and a controller. The efficient tap water adsorption filter can effectively carry out adsorption filtering on tap water and achieve a self-cleaning function, and has low use and maintenance cost.

Owner:内蒙古丝绸之路供水有限公司

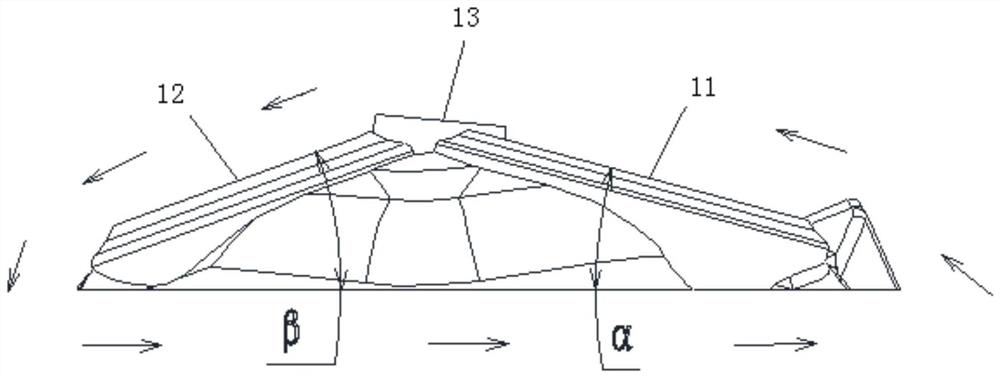

Aviation heavy oil engine and aircraft

PendingCN108757209ASmooth and even ignition and combustionFully ignitedFuel injection apparatusMachines/enginesAviationCombustion chamber

The invention discloses an aviation heavy oil engine and an aircraft. A concave guiding portion which is sunken relative to the top surface of a piston is formed in the top surface of the piston, theoutermost point of the outer side face outward in the radial direction exceeds or is flush with the fuel injection direction of a fuel injection assembly, and the extension surface exceeds the ignition position of a center spark plug inwards and in the radial direction. The top surface of the piston and the concave guiding portion which is sunken relative to the top surface of the piston and corresponding to the injection direction of the fuel injection assembly guide fuel injected-into to the ignition area of the spark plug, the top surface of the piston is optimized, so that a combustion chamber is optimized, the compression ratio is changed, the risk of knock is reduced, the tumble effect is enhanced, a relatively complete atomization mixing of heavy oil is realized, uniform burning mixture is formed after good mixing, fuel can be efficient combusted, the power, economy and emission performances of an engine which the heavy oil is applied to are ensured, and energy saving, environmental protection and low cost after the heavy oil is applied to the engine are achieved.

Owner:CHONGQING LONCIN ENGINE +1

High-efficiency energy-saving roasting pan and heating method thereof

InactiveCN107242803AEvenly heatedHard on the outside and soft on the insideRoasting apparatusRoasters/grillsWater vaporThermostat

The invention discloses a high-efficiency energy-saving roasting pan and methods for heating, cooling, and exhausting thereof. The roasting pan comprises a main body, an upper cover, a heater, a pot body, a food rolling-over device, a cooling fan, and at least a temperature controller or temperature control probe. The heater comprises an upper heater and a lower heater. The cooling fan is arranged on the outer part of a three-dimensional heating cavity, one end is communicated and connected with external air, and the other end is communicated and connected with the three-dimensional heating cavity. Through air blowing, external low-temperature air is mixed in the three-dimensional heating cavity at high temperature, to make temperature of the three-dimensional heating cavity constant or relatively cool or heat the three-dimensional heating cavity, and water vapor in the three-dimensional heating cavity is exhausted along an air outlet or a gap on the main body. The high-efficiency energy-saving roasting pan is characterized by good cooking effect, easy assembling and dismounting, easy cleaning, and wide application range.

Owner:ZHONGSHAN CITY GOLDLABO ELECTRIC CO LTD +1

Jet plate used for noodle cooking furnace

ActiveCN108041977AReduce the amount of waterPrevent undershockWater-bath cooking vesselsEngineeringFood processing

The invention relates to a jet plate used for a noodle cooking furnace, and belongs to the field of food processing equipment. A main body of the jet plate is provided with a main water jet hole and an auxiliary water jet hole; a noodle cooking furnace body includes a deposition bin and a heating pipe, the deposition bin is used for collecting food residues, and the heating pipe is used for heating water and arranged at the upper end of the deposition bin. The main body of the jet plate is arranged at the upper end of the heating pipe, and the main body of the jet plate is used for jetting water heated by the heating pipe from bottom to top for noodle cooking. The main water jet hole is used for jetting hot water boiled on the lower portion of the main body of the jet plate to the upper portion of the jet plate so as to impact noodles, the rolling effect is generated, when water flow from the main water jet hole impacts the noodles, water flow jetted from the auxiliary water jet hole impacts the peripheries of the noodles, and the heating speed and the heating effect are further improved.

Owner:ANHUI HUALING KITCHEN EQUIP

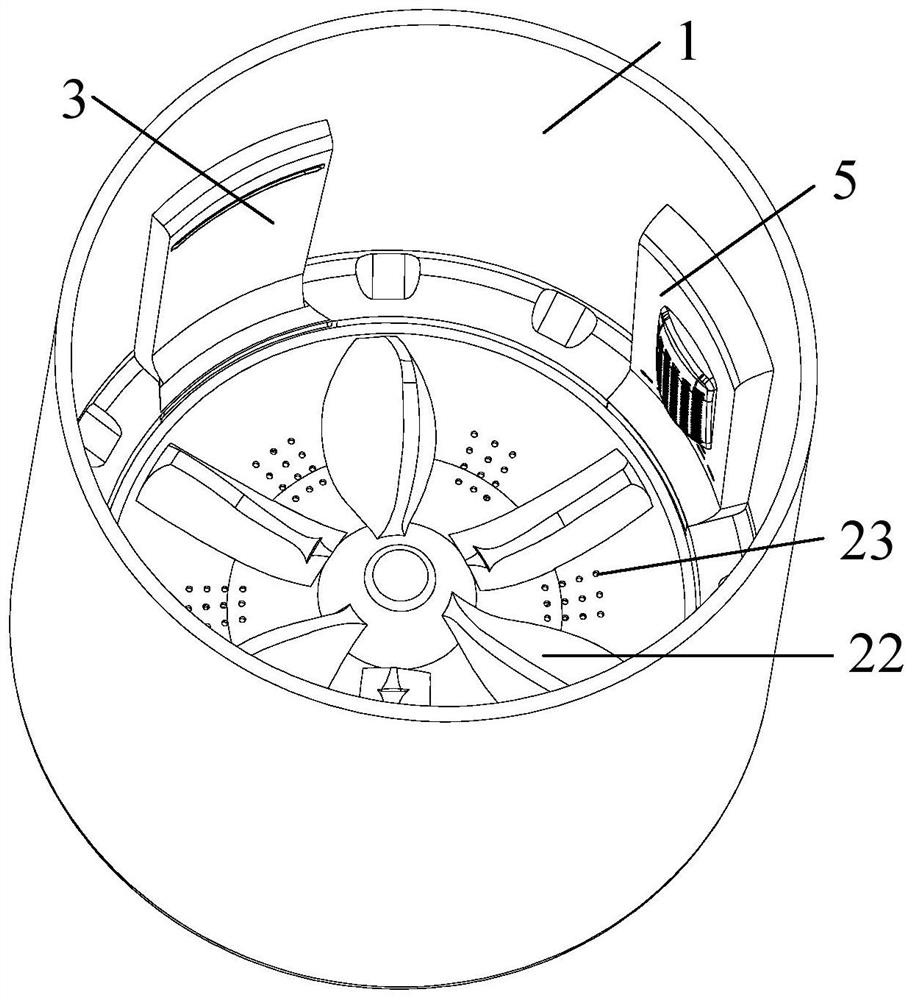

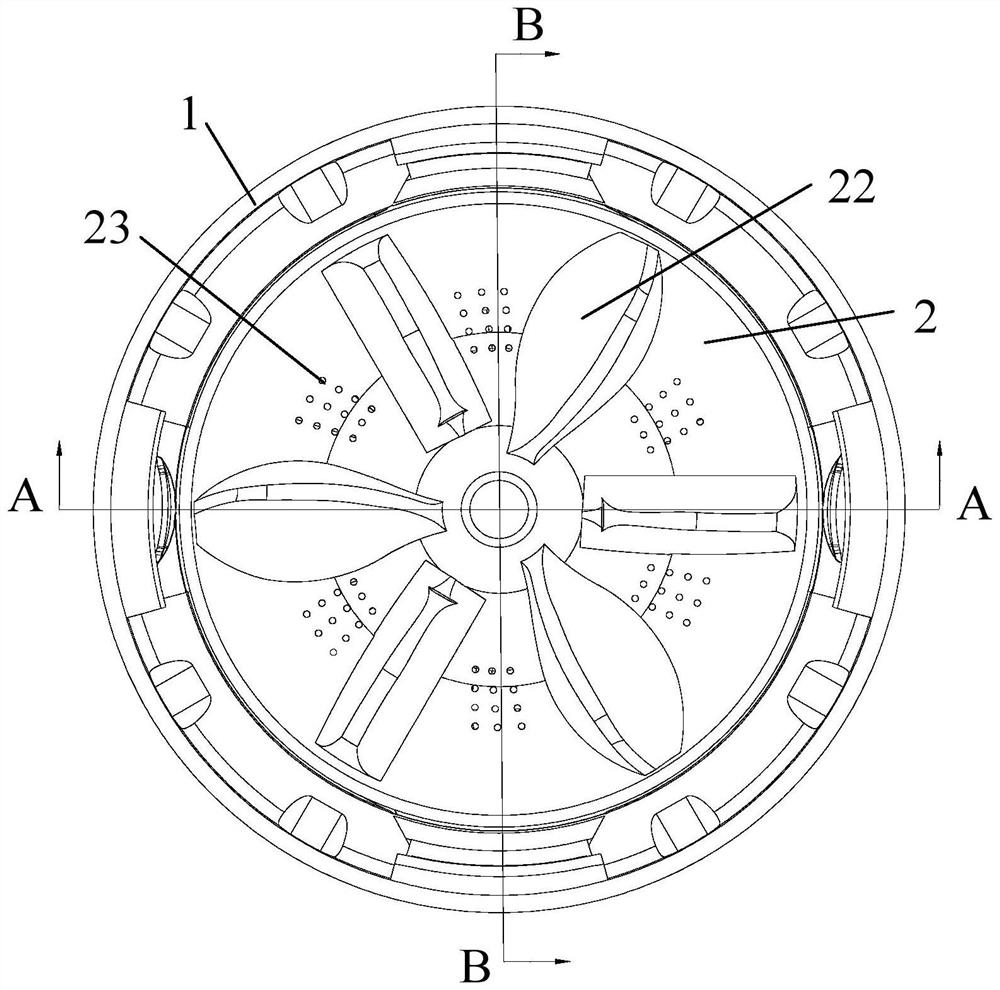

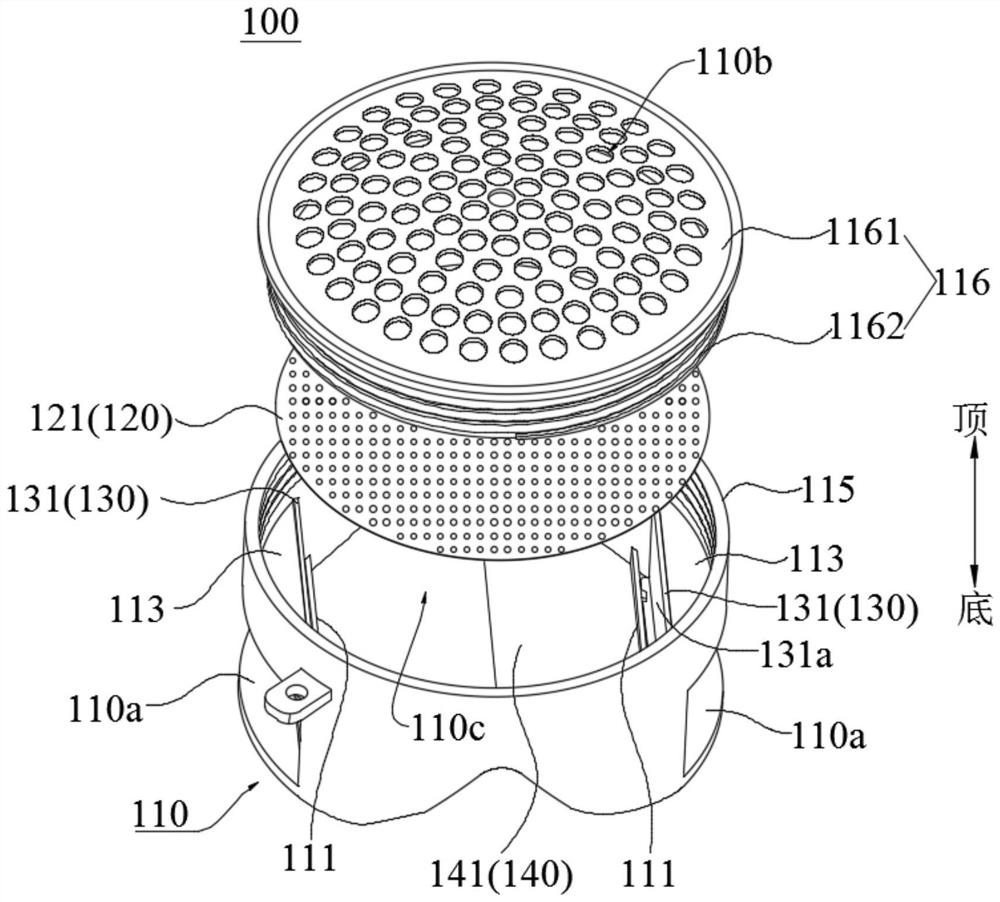

Pulsator washing machine and tub assembly thereof

PendingCN110656467AImprove toggle effectFast flowOther washing machinesWashing machine with receptaclesLaundry washing machineWash water

The invention belongs to the technical field of clothes processing equipment, and particularly provides a pulsator washing machine and a tub assembly thereof, aiming to solve the problem that clothesare easy to settle to the tub bottom and parts of the clothes cannot be cleaned effectively in use of existing pulsator washing machines. First water stirring members are arranged vertically or obliquely along the inner side wall of an inner tub of the pulsator washing machine, the thickness of the first water stirring members is increased gradually bottom to top, and the flow rate of washing water in the upper portion of the inner tub is higher than that of washing water in the lower portion of the inner tub, so that a pressure difference is formed between the upper portion and the lower portion of the inner tub; under the pressure difference, washing water in the lower portion of the inner tub is driven to flow to the upper portion having high flow rate and low pressure, while clothes atthe bottom of the inner tub are turned upwards to avoid settling at the bottom of the inner tub, and thus, turning effect of the clothes in the inner tub is improved greatly and the clothes can be cleaned more effectively.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Pressed salted duck production process

PendingCN112715860AAchieve seasoning mixAchieve repeated mixingMeat/fish preservation by freezing/coolingMeat tenderisingBiotechnologyAgricultural science

The invention belongs to the technical field of duck meat processing, and particularly discloses a pressed salted duck production process which comprises the steps: preparing frozen pressed salted ducks, placing the frozen pressed salted ducks on a platform, carrying out natural thawing, and completely mixing seasonings and the pressed salted ducks; putting the pressed salted duck into a tumbling machine to be tumbled, wherein the tumbling machine comprises a rack, a tumbling cylinder is horizontally, coaxially and rotationally connected to the rack, a tumbling plate is fixedly connected to the inner wall of the tumbling cylinder, a plurality of cavities are evenly formed in the inner wall of the tumbling cylinder in the circumferential direction, a plurality of through holes are evenly formed in the inner wall of the tumbling cylinder, and the through holes communicate with the cavities; performing cold drying on the pressed salted duck; and performing hot drying on the pressed salted duck. The invention aims to provide the pressed salted duck production process so as to solve the technical problem of insufficient rolling and kneading of the pressed salted ducks.

Owner:重庆九思食品有限公司

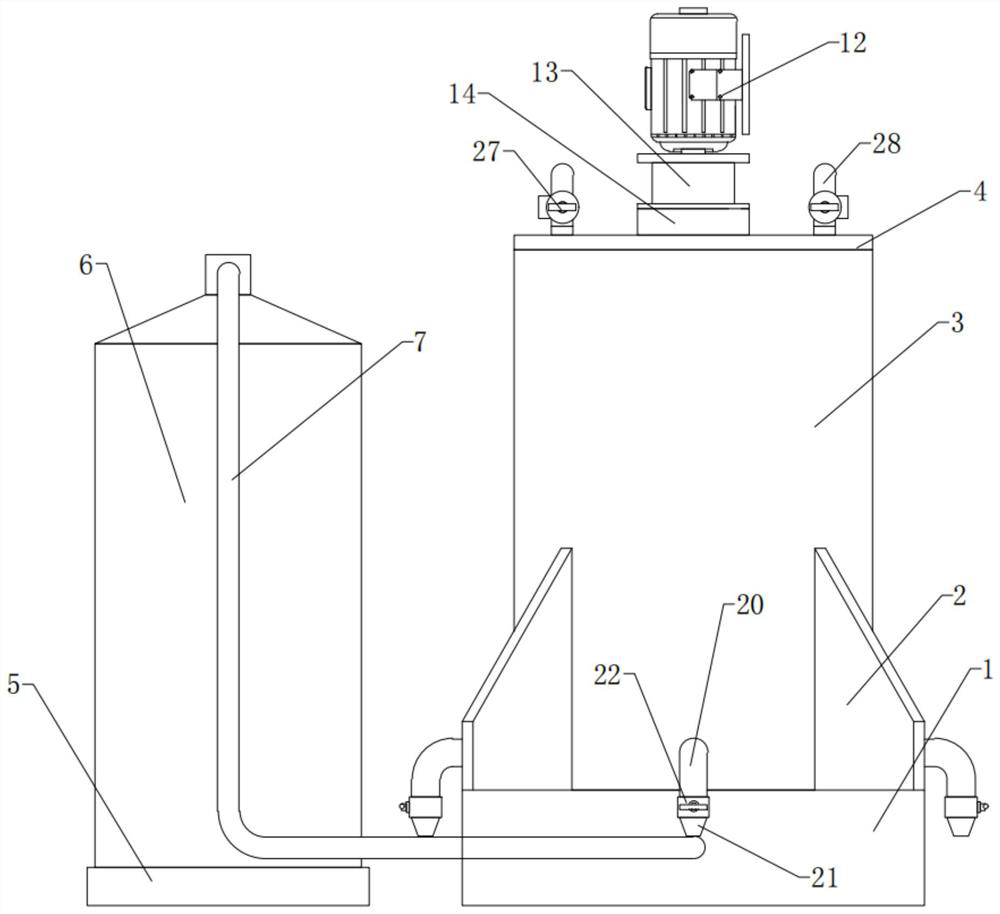

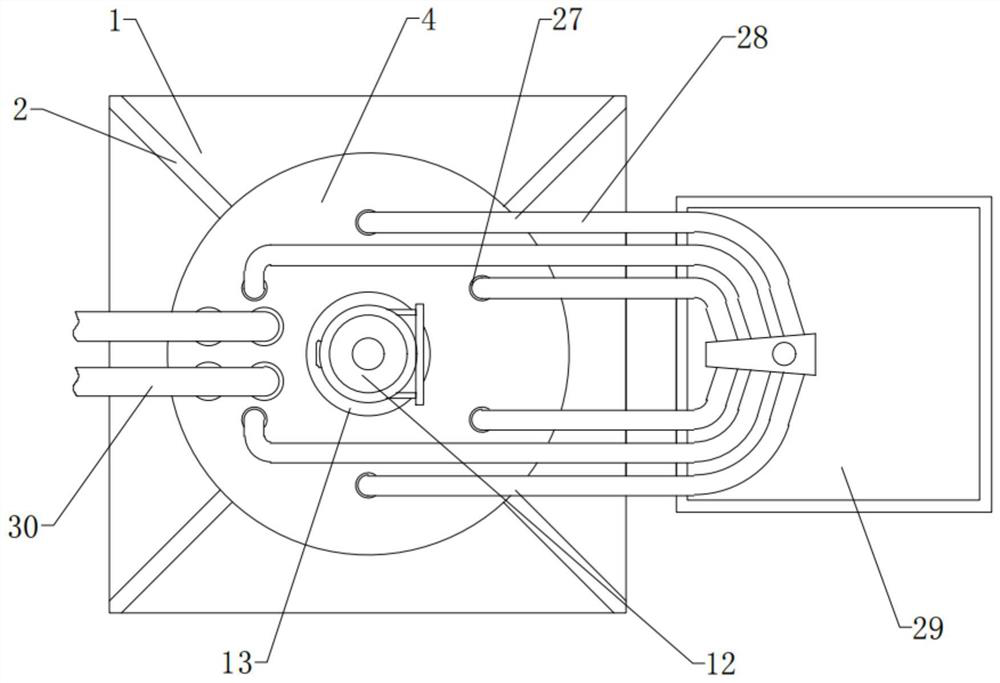

Medical multi-enzyme cleaning agent and large mixer thereof

PendingCN114164060AExtended storage timeImprove the effect in the preservation environmentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMedicineActive agent

The invention discloses a medical multi-enzyme cleaning agent and a large-scale mixer thereof. The medical multi-enzyme cleaning agent comprises 0.3-0% of the following components. The cutting fluid comprises the following components in percentage by weight: 5% of a solubilizer, 0.3%-0.5% of a low-foam surfactant, 31%-35% of polyoxyethylene ether, 6%-7.5% of an ammonium oxide surfactant, 17%-28% of composite multienzyme, 7%-9% of a bactericide, 1%-3% of an antirust agent, 3%-5% of glyceride and the balance of water. The medical multi-enzyme cleaning agent and the large-scale mixer thereof have the beneficial effects that the glyceride is added in the formula, and the medical multi-enzyme cleaning agent and the large-scale mixer thereof are mainly used for layering the glyceride and a main body sterilizing liquid after filling, sealing by utilizing the glyceride on the upper layer, improving the effect in a storage environment and prolonging the storage time of the multi-enzyme cleaning agent; in cooperation with an inert gas injection stirring structure, the stirring shearing force and the rolling effect are increased, so that the material proportioning process is more sealed, and meanwhile, the mixing is more sufficient.

Owner:山东消博士消毒科技股份有限公司

Filtration and washing equipment

ActiveCN112962273BImprove tumbling effectConvenient careOther washing machinesWashing machine with receptaclesFiltrationEngineering

An embodiment of the present application provides a filtering device and washing equipment. The filtering device includes a housing, a filtering structure and a one-way control structure. The housing is used to connect with the pulsator of the washing equipment. The housing is formed with a water inlet along the rotational direction of the pulsator. A water outlet is formed on the top of the shell, and the water inlet and the water outlet are used to communicate with the washing chamber of the washing equipment. A filter chamber is formed in the shell to communicate with the water inlet and the water outlet; the filter structure is arranged in the filter chamber; the one-way control structure is arranged in the At the water inlet, the one-way control structure controls the liquid to flow into the filter chamber from the water inlet in one direction; because the flow rate of the liquid flowing through the filter device is faster, the flow rate of the liquid increases and the filtration efficiency is higher.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

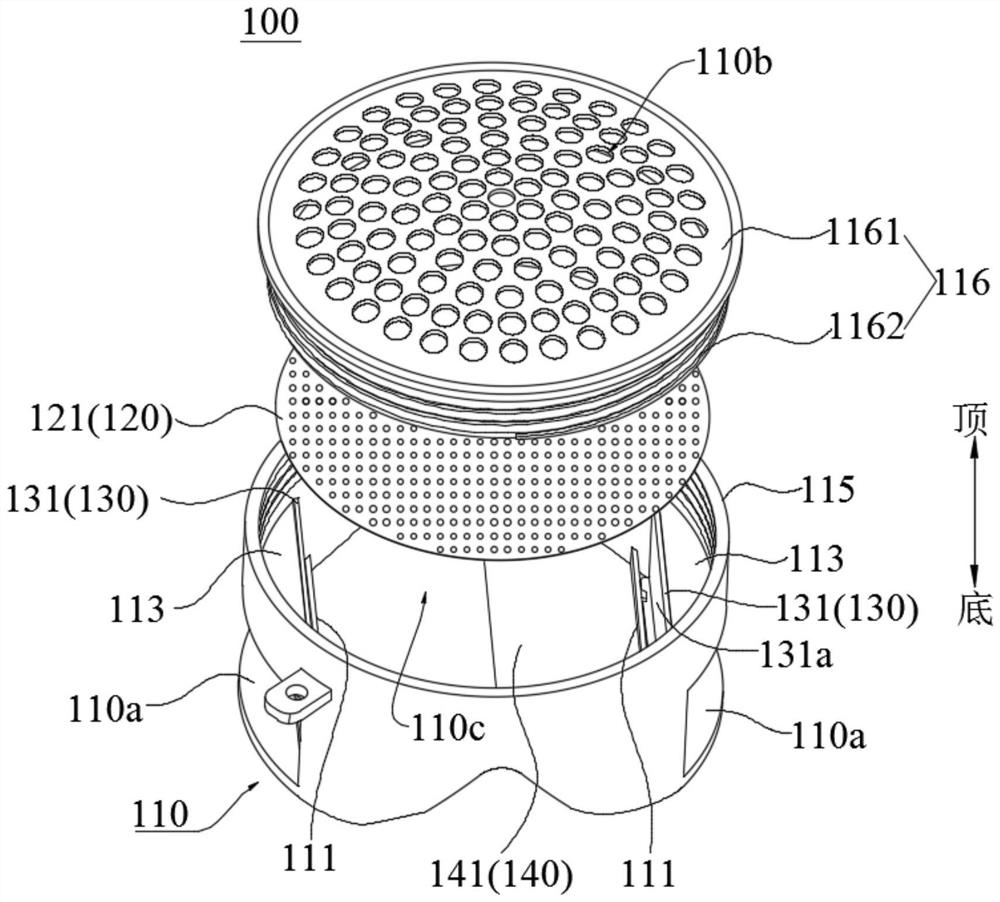

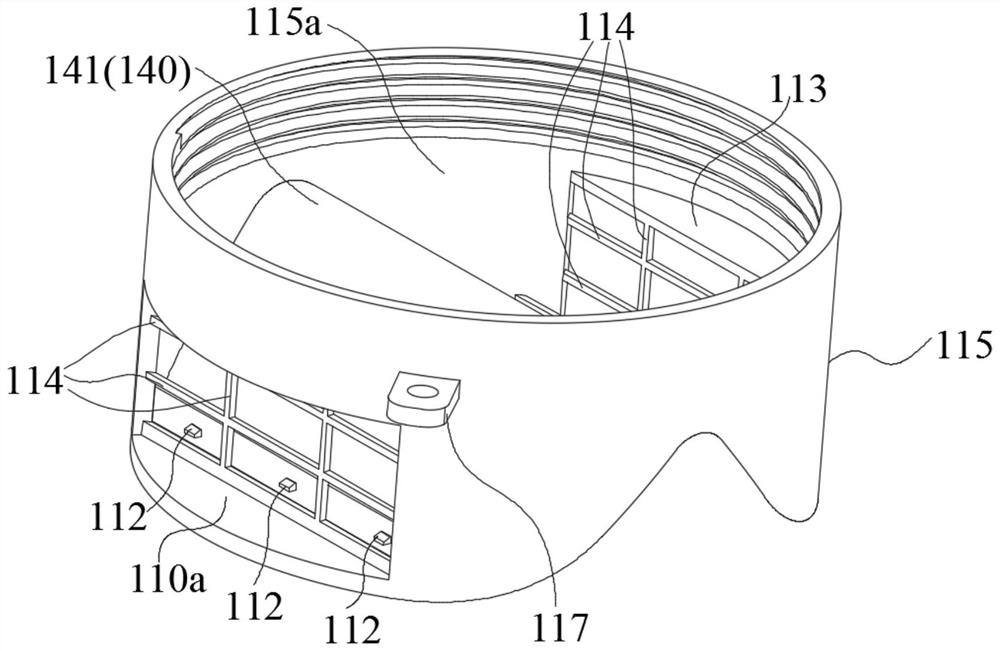

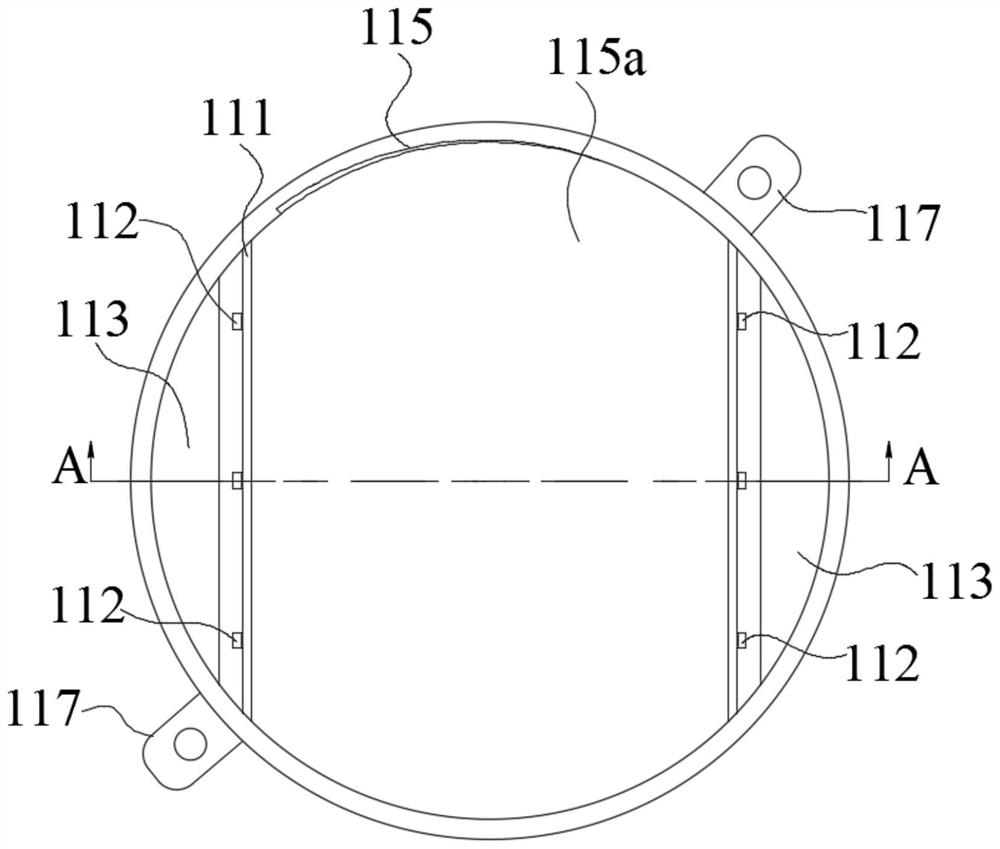

Washing machine and its inner tub assembly

ActiveCN109667095BImprove tumbling effectImprove cleanlinessOther washing machinesWashing machine with receptaclesLaundry washing machineWash water

The invention provides a washing machine and an inner tub assembly thereof. The inner tub assembly includes a tub body, a wave wheel and a waterfall plate. The barrel defines an accommodation chamber; the pulsator is rotatably arranged at the bottom of the barrel, and a drainage chamber is defined between the pulsator and the bottom wall of the barrel; the waterfall plate extends along the axial direction of the barrel and is arranged on the barrel On the inner wall of the water spray plate and the inner wall of the bucket body, a water spray flow channel connected with the drainage cavity is defined, and the water spray plate is provided with a water spray mouth connected with the water spray flow channel; the barrel body An upwardly protruding deflector is provided on the bottom wall of the bottom wall, and the deflector is located in the drainage cavity and is used to guide the water flow in the drainage cavity to flow into the entrance of the water spray channel. In the inner tub assembly of the washing machine provided by the present invention, the design of the flow guide can greatly increase the amount of washing water entering the water spray channel, and form a powerful jet of water to be sprayed from top to bottom from the water spray port, so as to strengthen the beating and washing of the clothes by the water flow. Penetrating wash effect.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Filtering device and washing equipment

ActiveCN112962273AImprove tumbling effectImprove cleaning effectOther washing machinesWashing machine with receptaclesImpellerEngineering

The embodiments of the invention provide a filtering device and washing equipment. The filtering device comprises a shell, a filtering structure and a one-way control structure, wherein the shell is used for being connected with an impeller of the washing equipment; a water inlet is formed in the shell in the rotating circumferential direction of the impeller; a water outlet is formed in the top of the shell; the water inlet and the water outlet communicate with a washing cavity of the washing equipment; a filtering cavity communicating with the water inlet and the water outlet is formed in the shell; the filtering structure is arranged in the filtering cavity; and the one-way control structure is arranged at the water inlet and controls liquid to flow into the filtering cavity from the water inlet in a one-way mode. As the flow speed of the liquid flowing through the filtering device is relatively high, the flow of the liquid is increased, and the filtering efficiency is higher.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

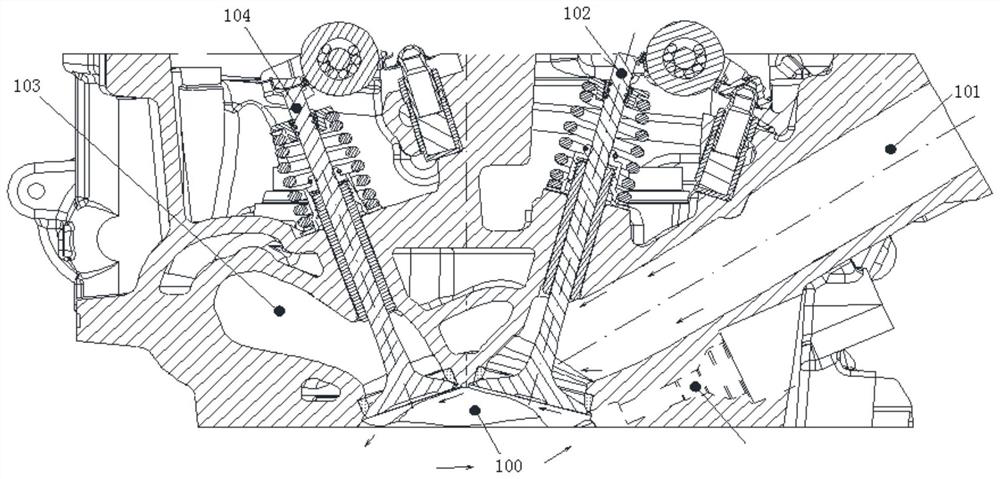

Cylinder head and gas engine

ActiveCN113404613BReduce hedging interferenceReduce lossesInternal combustion piston enginesCylinder headsCombustion chamberCylinder head

Owner:WEICHAI POWER CO LTD

Shell cleaning device for decorative material production

InactiveCN112547582AImprove tumbling effectEfficient removalCleaning using toolsCleaning using liquidsStructural engineeringBucket elevator

The invention belongs to the technical field of buildings, and particularly relates to a shell cleaning device for decorative material production. The following scheme is provided currently in order to solve the problem that the silt cleaning time is long, so that the shell processing efficiency is influenced, the shell cleaning device comprises a box body, a feeding hopper and a discharging hopper are fixedly mounted at the top of the box body separately, and a bucket elevator is fixedly mounted in the discharging hopper; and a filter and a circulating pump which communicate with each other are fixedly mounted at the bottom of the box body, the inlet end of the filter communicates with the box body, a three-way valve is fixedly mounted at the outlet end of the circulating pump, and a plurality of rectangular pipes are fixedly mounted in the box body. According to the device, impurities such as silt remaining inside can be effectively removed, belt strips with soft cylinder portions move between the rectangular pipes, shells are driven to continuously change positions on the surfaces of the belt strips and the surfaces of the rectangular pipes and be impacted by water columns of spraying heads, and the rolling effect of the shells in water is improved; and the removal efficiency of the silt in concave holes is further improved.

Owner:刘明航

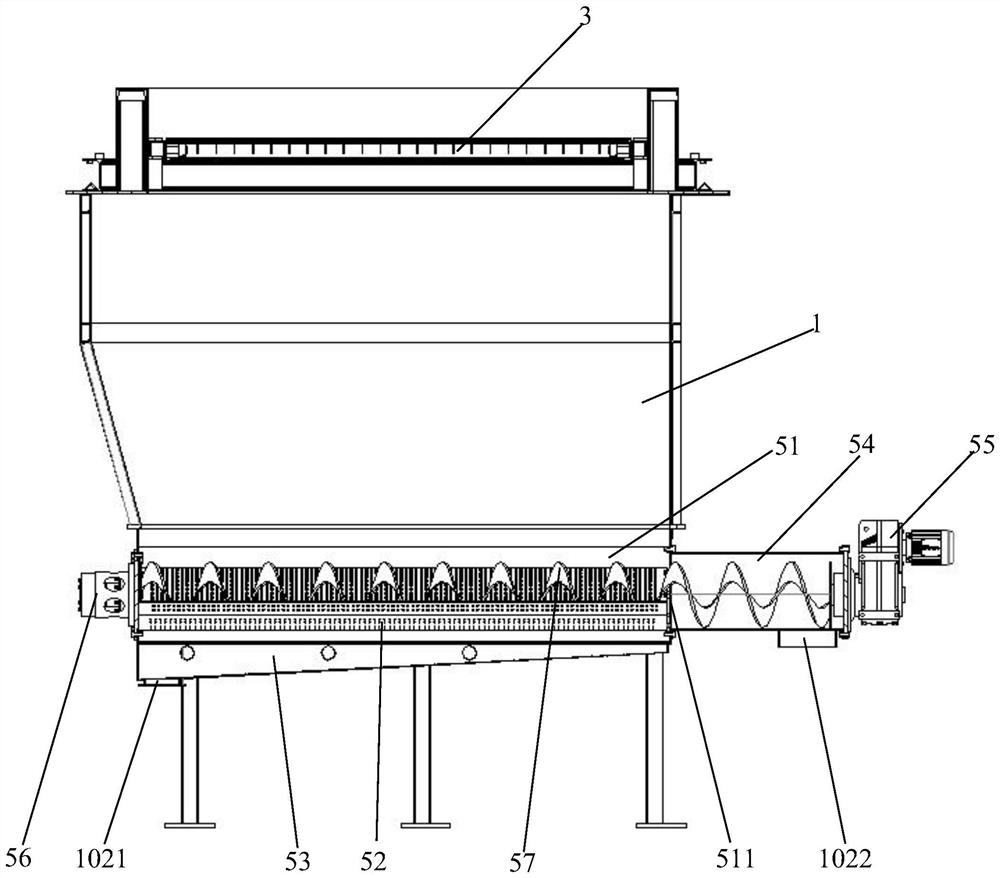

Spiral material conveying and sorting machine for kitchen waste pretreatment system

PendingCN114345678AAffect normal workRealize deliverySievingScreeningInterior spaceProcess engineering

The invention discloses a spiral material conveying and sorting machine for a kitchen waste pretreatment system, comprising: a sorting box, the top end of which is open and is covered with a box cover, and one side of the top end of the box cover is provided with a waste throwing port; the screen partition plate is fixed to the open end of the sorting box and divides the internal space of the sorting box into an upper slag chamber and a lower slurry chamber, a slag outlet is formed in one side of the bottom end of the upper slag chamber, a plurality of draining holes are formed in part of the bottom wall of the lower slurry chamber, and outer draining sleeves are fixed to the positions, located at the draining holes, of the lower slurry chamber; a slurry outlet is formed in one side of the bottom end of the outer draining sleeve, and a slurry outlet is formed in the other side, away from the outer draining sleeve, of the bottom wall of the lower slurry chamber; the two first shaftless spiral conveying mechanisms are arranged side by side and are both arranged in the upper slag material chamber; and the second shaftless spiral conveying mechanism is arranged in the lower slurry chamber. Compared with a traditional drum screen or a vibrating screen, the spiral material sorting machine is stable in equipment operation, balanced in material processing speed and low in equipment failure rate.

Owner:银川保绿特生物技术有限公司

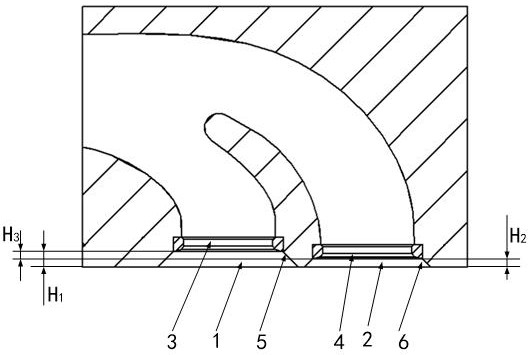

Cylinder cover and gas engine

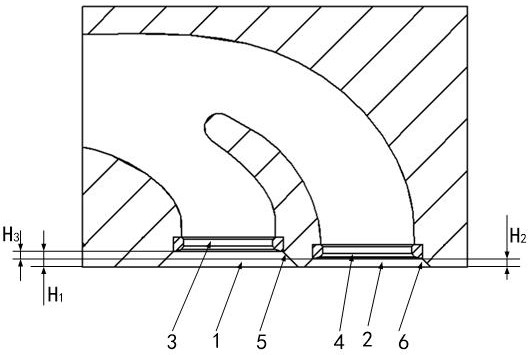

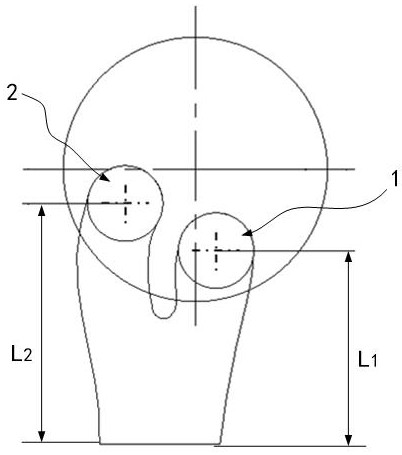

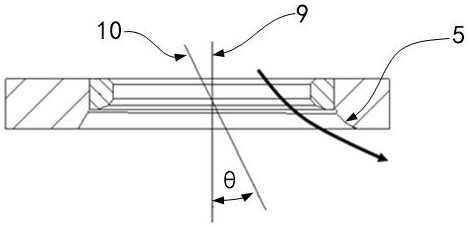

ActiveCN113404613AReduce hedging interferenceReduce lossesInternal combustion piston enginesCylinder headsCombustion chamberInlet valve

The invention discloses a cylinder cover and a gas engine. The cylinder cover is applied to the gas engine transformed on the basis of a diesel engine; the cylinder cover comprises a first air inlet throat and a second air inlet throat which are formed in the cylinder cover, a first air inlet valve seat ring is arranged in the first air inlet throat, a second air inlet valve seat ring is arranged in the second air inlet throat, and the height H1 from the first air inlet valve seat ring to the bottom surface of the cylinder cover is greater than the height H2 from the second air inlet valve seat ring to the bottom surface of the cylinder cover. Compared with a traditional mode that two air inlet valve seat rings are symmetrically arranged, the cylinder cover has the advantages that airflow hedging interference in the direction of the center connecting line of the two air inlet valves can be effectively reduced, then the airflow kinetic energy loss is reduced, and the tumble effect in a combustion chamber can be better improved.

Owner:WEICHAI POWER CO LTD

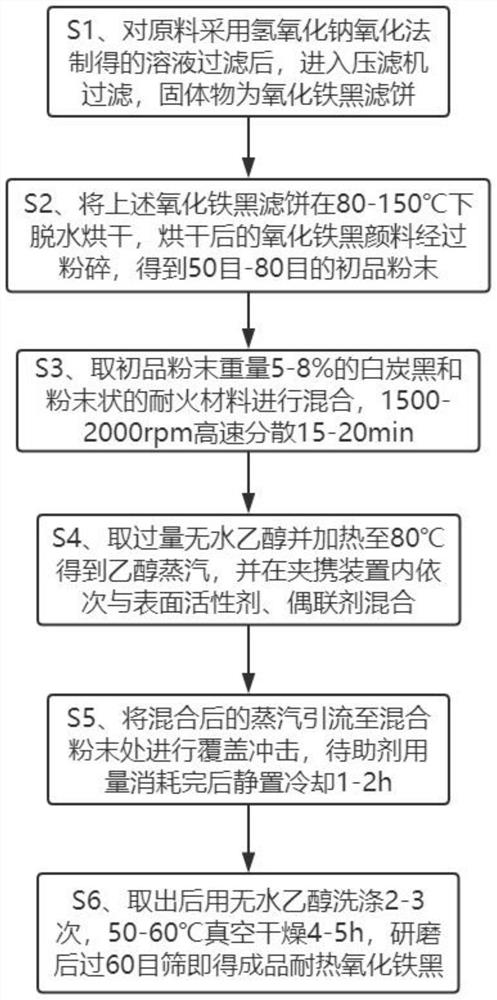

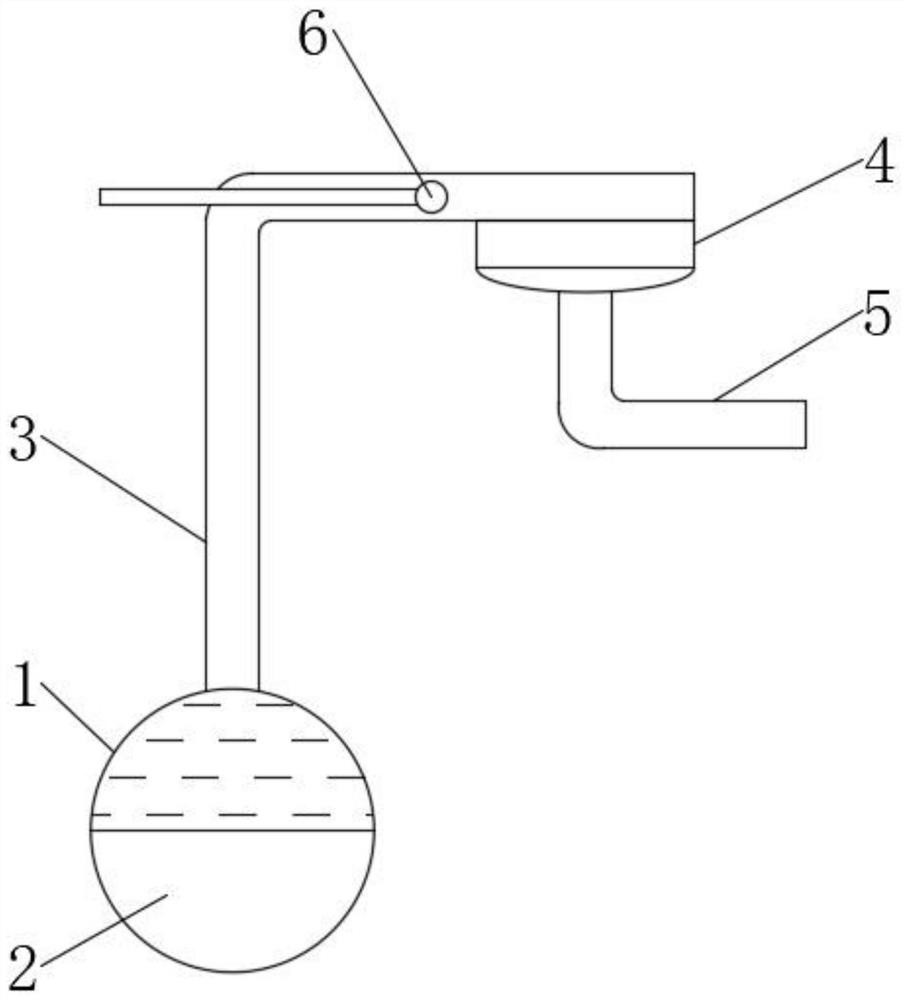

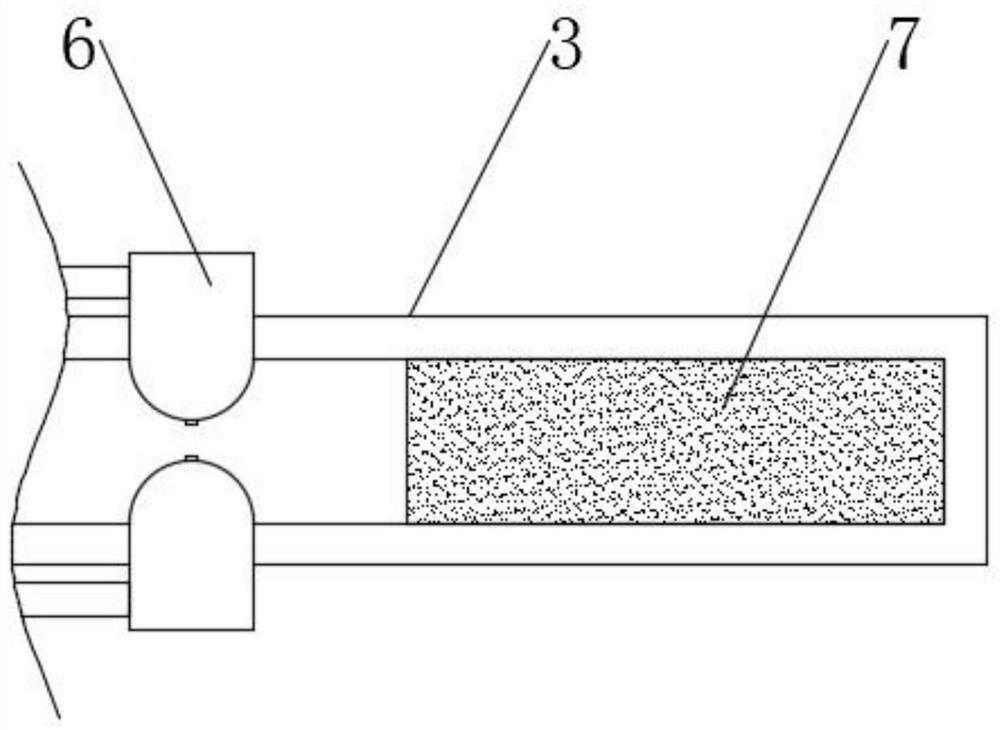

A kind of production technology of heat-resistant iron oxide black

ActiveCN112111179BImprove temperature resistanceGood alkali resistanceFerroso-ferric oxidesPigment flushingIron oxide blackActive agent

The invention discloses a production process of heat-resistant iron oxide black, which belongs to the field of chemical pigments. It is a production process of heat-resistant iron oxide black. The invention can realize dehydration and drying after the iron oxide black filter cake is obtained by adopting the sodium hydroxide oxidation method dry, and preliminarily powdered and mixed with white carbon black and powdered refractory materials, and then after high-speed uniform dispersion, innovatively introduce an entrainment device, using anhydrous ethanol vapor to entrain surfactants and coupling agents , based on the fluidity and contact properties of the gas, the powdery refractory material is uniformly and comprehensively covered on the surface of the iron oxide black, and the coating dead angle is not easy to appear, forming a dense high temperature resistant film, which significantly improves the resistance of the iron oxide black High temperature performance, acid resistance, alkali resistance, light absorption, tinting strength, compatibility and dispersibility have all been greatly improved.

Owner:YIXING YUXING IND & TRADE

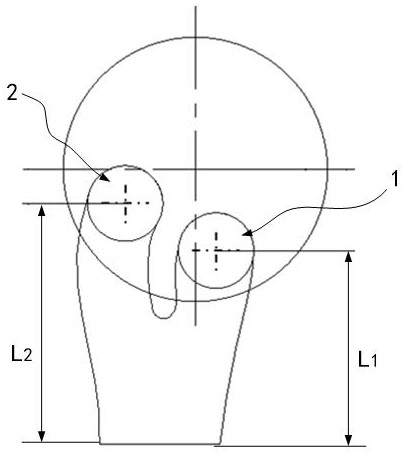

Cylinder cover combustion chamber and vehicle

PendingCN114076051AImprove tumbling effectIncreased turbulence intensityInternal combustion piston enginesCylinder headsCombustion chamberEngineering

The invention discloses a cylinder cover combustion chamber and a vehicle, the cylinder cover combustion chamber comprises a combustion chamber body, the combustion chamber body is of a ridge type, and the combustion chamber body is provided with an air inlet side and an air outlet side which are located on the two sides of a spark plug hole correspondingly; the air inlet side and the air outlet side correspond to an air inlet channel and an air outlet channel of the cylinder cover respectively, at least one of the air inlet side and the air outlet side is provided with an air squeezing area, and at least part of the air squeezing area is right opposite to the spark plug hole in the arrangement direction of the air inlet side and the air outlet side. According to the cylinder cover combustion chamber, the combustion chamber body is constructed to be in the ridge shape, air flow is promoted to circularly flow around the combustion chamber body, the rolling effect of the air flow in the circulation process is enhanced by arranging the air squeezing area, oil and gas in the combustion chamber are mixed more evenly, the performance of an engine can be improved, and the effects of energy conservation and emission reduction can be achieved, and the performance of the engine is improved.

Owner:深圳臻宇新能源动力科技有限公司

Multifunctional integrated discharging bin for kitchen waste treatment

PendingCN114308997AEasy to moveGuaranteed linearitySievingSolid waste disposalEngineeringProcess engineering

The invention discloses a multifunctional integrated discharge bin for kitchen waste treatment, comprising: a waste treatment box, the top end and the bottom end of the waste treatment box are respectively provided with a waste inlet and a waste outlet; the slag bin is fixed to one side of the garbage treatment box, and a slag pouring-in opening is formed in the top end of the slag bin; the slag dumping sieve mechanism is fixed at the garbage inlet and is used for dumping slag to the slag dumping inlet; the two ends of the bag breaking roller moving mechanism are in sliding connection with the two sides of the slag dumping sieve mechanism correspondingly; and the draining spiral slurry conveying mechanism is fixed to the garbage outlet, and a slurry outlet and a slurry outlet are formed in the two sides of the bottom end of the draining spiral slurry conveying mechanism correspondingly. The discharging bin is high in automation degree, manual sorting is not needed, one machine has multiple purposes, energy consumption is reduced, and the occupied area of equipment is reduced.

Owner:银川保绿特生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com