Working and use method of high efficiency roasting pan

A high-efficiency, high-temperature water vapor technology, applied in applications, kitchen utensils, household utensils, etc., can solve the problems of inconvenient cleaning, inability to realize multi-functional one machine, high production cost, etc., and achieve the effect of preventing rapid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

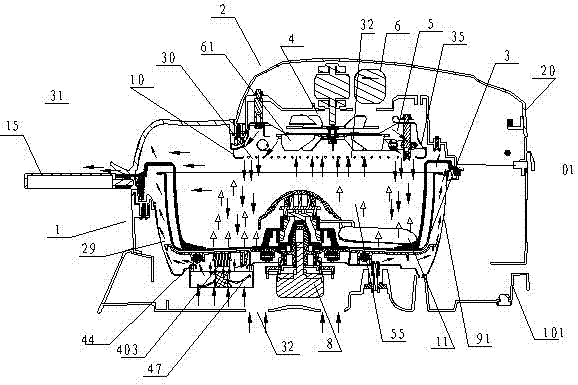

Image

Examples

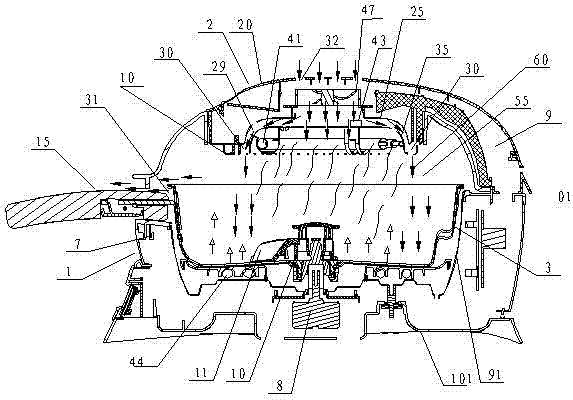

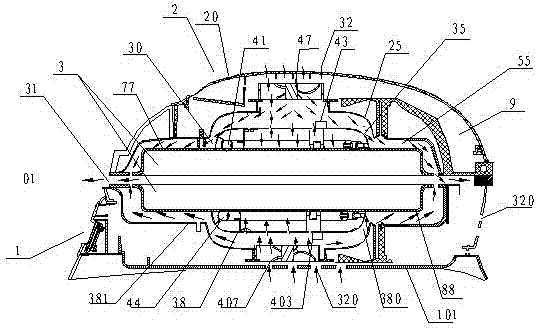

no. 2 example

[0138] The second embodiment: a high-efficiency baking pan, the main body 01 includes a first body 1, a second body 2, a heater, a first heat transfer body 3, and a food tumbling device 11, and the heater is a second heater 41 And the first heater 44 is characterized in that the first body 1 is used to support the first heat transfer body 3, the food rolling device 11, and the first heater 44, and the first heat transfer body 3 provides conduction heating to the bottom of the food heat source;

[0139] The second body 2 is used to fix the second heater 41 and the second heat transfer body 35, and the second heat transfer body 35 provides a heat source for heating the upper surface of the food;

[0140] The second body 2 is covered with the first body 1 to form a heat source for heat radiation or conduction heating on the upper part, and a three-dimensional heating chamber 55 for conduction heating at the bottom;

[0141] The second body 2 is rotationally connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com