Vibrating electric motor mounting method for vibrating grinder

A technology of vibration motor and installation method, which is applied to the parts of grinding machine tools, grinding drive devices, machine tools suitable for grinding workpiece edges, etc. Reduce the height of the vibrating grinder, inconvenient operation for the operator, etc., to achieve the effect of reducing the volume, reducing the height, and enhancing the tumbling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

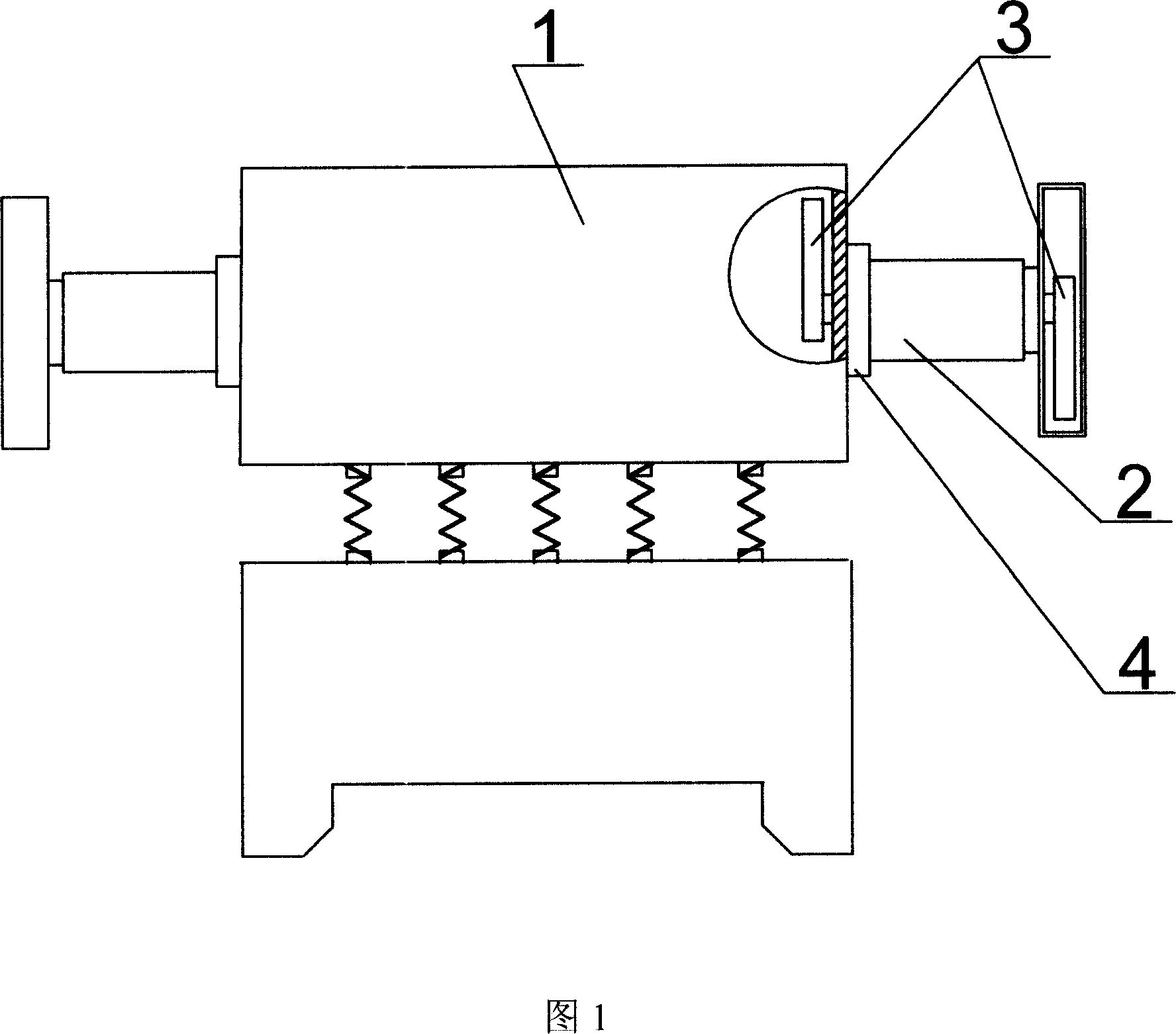

[0008] Embodiments of the present invention: the method of the present invention can be directly implemented on the existing vibratory grinding machine, that is, when the vibrating motor 2 is installed on the existing vibrating bed 1, the motor shaft axis of the vibrating motor 2 is vertical on the installation base surface 4 of the vibration motor 2, so that the vibration motor 2 can be installed on the side of the vibration bed 1, and then the vibration eccentric blocks 3 are respectively installed on the motor shafts at both ends of the vibration motor 2 in the traditional way, and the The vibrating eccentric block 3 at one end of the vibrating motor 2 is arranged in the vibrating bed 1, and the vibrating eccentric block 3 at the other end of the vibrating motor 2 is arranged on the outside of the vibrating bed 1, so that not only the height of the vibrating grinder can be effectively reduced, but also While ensuring the stable operation of the vibrating grinder, the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com