Noodle boiling furnace with jet flow plate and noodle boiling method thereof

A technology of jet flow plate and noodle cooking stove, which is applied to the structure of cooking utensils, cooking utensils, household utensils, etc., can solve the problems of weakening the water pressure of the main spray hole and poor tumbling effect, so as to prevent insufficient impact and ensure Heating effect, effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

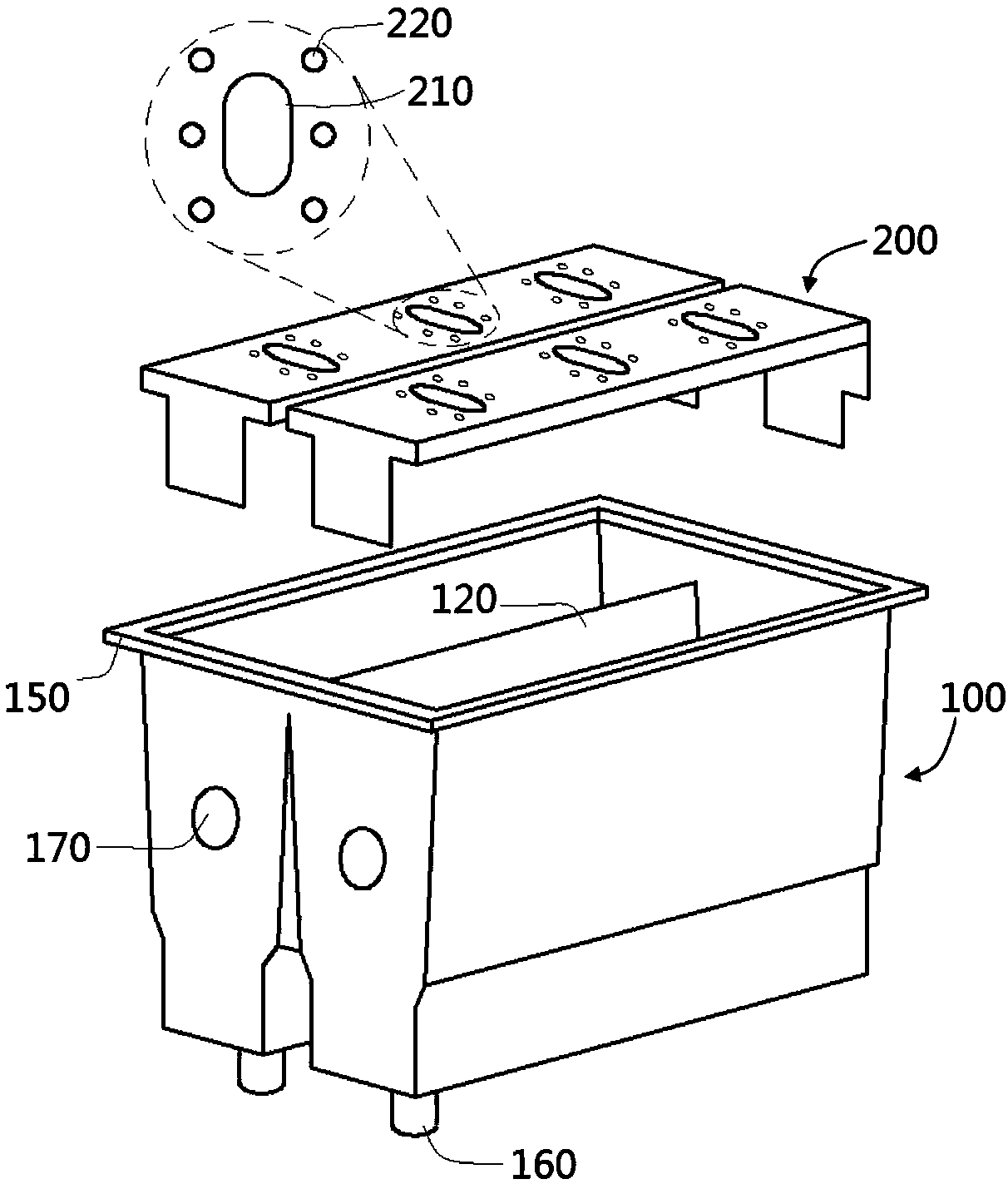

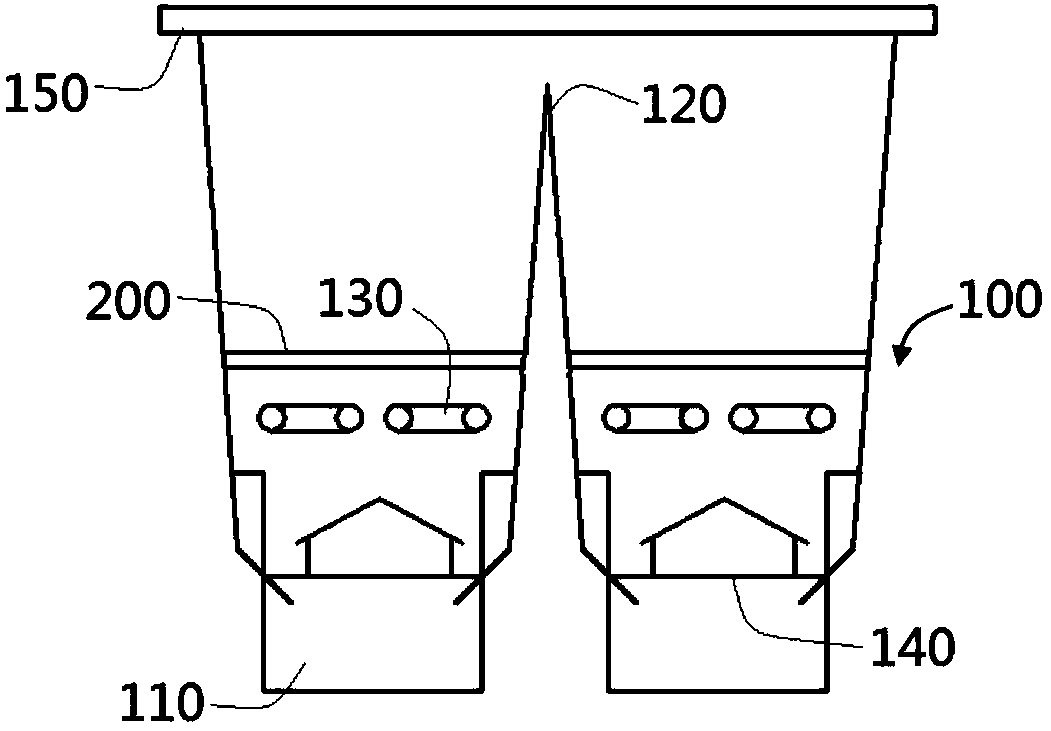

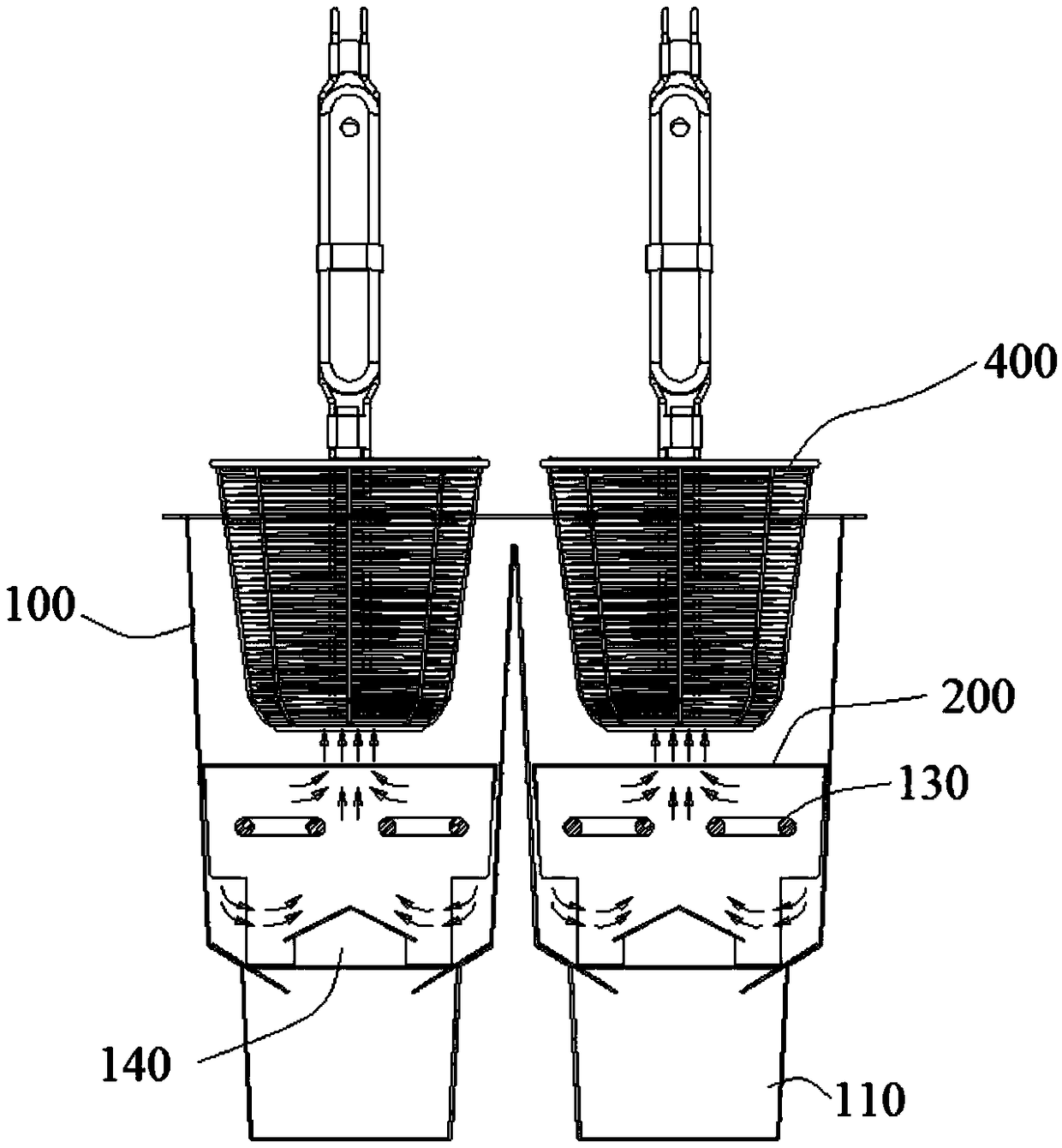

[0044] Refer to attached Figure 1 to Figure 6 As shown, a noodle cooking furnace with a jet flow plate in this embodiment, a noodle cooking furnace body 100 is provided with a jet flow plate main body 200, and the noodle cooking furnace body 100 includes a deposition chamber 110 and a heating tube 130, and the deposition The bin 110 is used to collect food residues, and the heating pipe 130 is used to heat water. The heating pipe 130 is arranged on the upper end of the deposition bin 110. The jet plate main body 200 is arranged on the upper end of the heating pipe 130. There is a noodle cooking cage 400, and dough is placed in the noodle cooking cage 400. The dough is lumpy noodles. The water stream rolled out by 200 can continuously roll and heat the dough, and the heating rate and heating effect are better. The jet plate main body 200 is used to spray the water heated by the heating tube 130 below to the top to cook the noodles. The distance between the flow plate main bod...

Embodiment 2

[0055] Refer to attached Figure 1 to Figure 5 with Figure 7 As shown, a kind of noodle cooker with jet flow plate in this embodiment has the same basic structure as that of embodiment 1, except that the lower end surface 300 of the jet flow plate in this embodiment is provided with a diversion groove 360. The diversion groove 360 is disposed between the auxiliary water spray holes 220, and the diversion groove 360 is used to guide the water flow into the main water spray hole 210, so that the water flow ejected from the main water spray hole 210 is more powerful and sufficient.

[0056] The diversion groove 360 of this embodiment is recessed and arranged on the lower end surface 300 of the spray plate, the bottom slope 361 and the side slope 362 of the flow diversion groove 360 are inclined slopes, and one end of the side slope 362 is connected to the bottom slope 361, The other end is connected to the main water spray hole 210, and the depth of the side slope 362 g...

Embodiment 3

[0060] The noodle cooking method adopting the above-mentioned noodle cooking stove of the present invention adopts the above-mentioned noodle cooking stove with jet flow plate, first puts the dough into the noodle cooking cage 400, and puts the noodle cooking cage 400 with the dough Into the top of the main water spray hole 210, when the water in the noodle cooker reached the boiling point, the water flow was sprayed upwards from the main water spray hole 210, and the high-temperature water flow of the injection entered the noodle cooker 400 from the bottom of the noodle cooker 400, sprayed The high-temperature water flow that comes out heats and stirs the dough in the noodle cage 400; the detailed description is as follows: the high-temperature water flow heats the dough in the noodle cage 400 during the upward movement, and at the same time, the high-temperature water flow heats the dough in the noodle cage The dough in the 400 is stirred and mixed, so that the dough in the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com