Wet sludge drying and incinerating treatment method employing circulating fluidized bed with particle dryer

A technology of a circulating fluidized bed and a treatment method, which is applied in the field of waste treatment, can solve the problems of high energy consumption, high safety requirements and high operating costs of drying equipment, and can suppress the generation of CO, increase the adjustment range, The effect of enhancing the ability to regulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

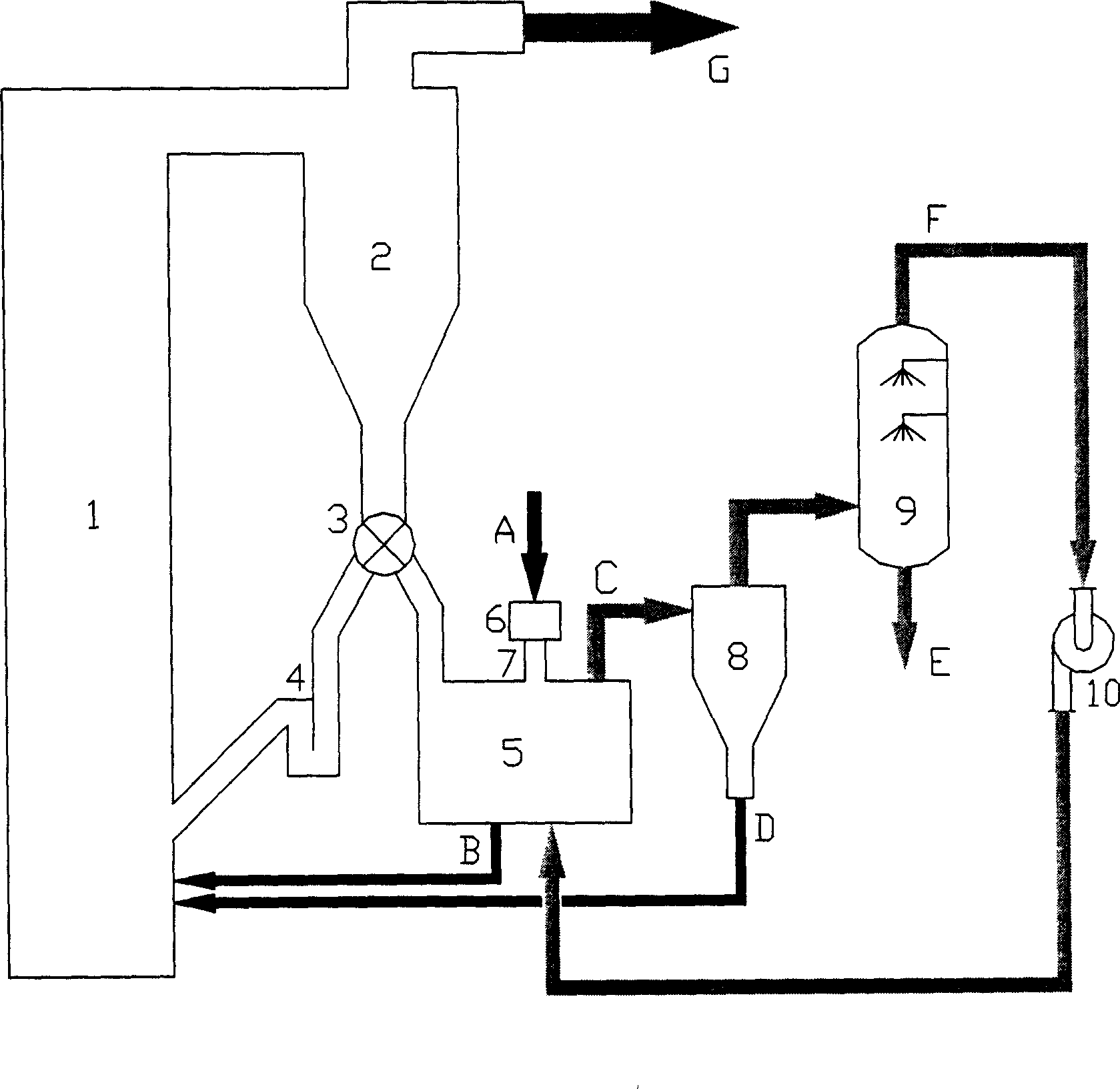

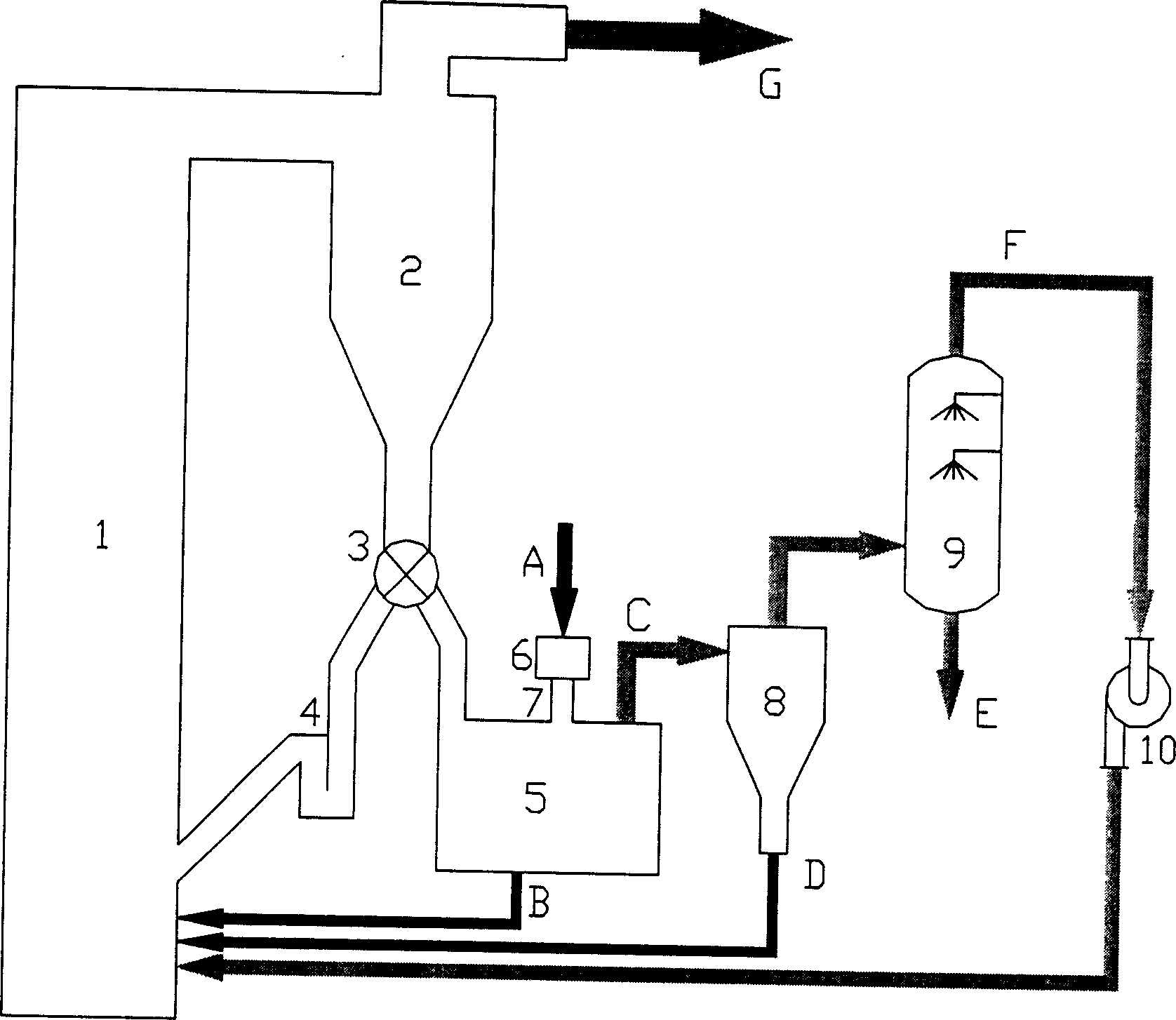

[0022] In the circulating fluidized bed incinerator, the wet sludge A with a moisture content of 60% is separately dried and incinerated, and the wet sludge A is added from the wet sludge inlet 7 provided on the particle dryer 5, and is installed in the The dispersing device 6 on the inlet 7 disperses; the particle dryer 5 is set in the circulating ash circulation circuit of the circulating fluidized bed incinerator, and the high-temperature circulating ash separated by the cyclone separator 2 passes through the mechanical hot ash distribution valve 3, and a part Enter the feeder 4 and return directly to the furnace 1, and the other part enters the particle dryer 5; the particle dryer 5 is a bubbling fluidized bed type, and the bottom is fed with fluidizing gas; sand is added from the lower part of the furnace 1 to increase the total circulation, and pass The hot ash distribution valve 3 adjusts the amount of high-temperature circulating ash entering the particle dryer 5, and c...

Embodiment 2

[0024] In the circulating fluidized bed incinerator, coal is added as an auxiliary fuel to dry and incinerate wet sludge A with a moisture content of 90%, and the wet sludge A is added from the wet sludge inlet 7 provided on the particle dryer 5, and the The particle dryer 5 is set in the circulating ash circulation loop of the circulating fluidized bed incinerator, and the high-temperature circulating ash separated by the cyclone separator 2 is passed through the pneumatically controlled hot ash Part of the distribution valve 3 enters the feeder 4 and directly returns to the furnace 1, and the other part enters the particle dryer 5; the particle dryer 5 is a bubbling fluidized bed type, and fluidized gas is fed into the bottom; For the amount of high-temperature circulating ash in dryer 5, the temperature of exhaust gas C of the particle dryer is controlled at about 120°C; wet sludge A is directly mixed with circulating ash in particle dryer 5, and heated to evaporate the mois...

Embodiment 3

[0026]In the circulating fluidized bed coal-fired boiler, wet sludge A with a moisture content of 80% is blended, and a particle dryer 5 and a pneumatically controlled hot ash distribution valve 3 are added to the high-temperature circulating ash circuit of the boiler to make part of the high-temperature circulating ash It enters the feeder 4 and directly returns to the furnace, and the other part enters the particle dryer 5, and adjusts the amount of high-temperature circulating ash entering the particle dryer 5 through the hot ash distribution valve 3, and controls the temperature of the exhaust C of the particle dryer at about 150°C; Sludge A is added from the particle dryer 5, directly mixed with circulating ash in the particle dryer 5, and heated to evaporate the contained water, and the wet sludge A is dried to dry sludge B with a moisture content of 5%. , and return to the furnace 1 for incineration together with the circulating ash through mechanical transportation; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com