Method for producing hydrogen from biogas biomass

A biomass and biogas technology, applied in the field of hydrogen production, can solve environmental pollution and other problems, achieve the effect of solving environmental pollution and energy problems, promoting national economic development and protecting the ecological environment, and solving energy crisis and environmental crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

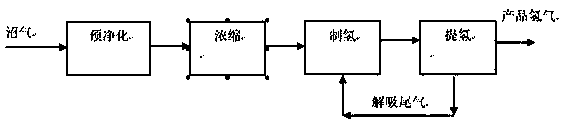

[0057] Such as Figure 5 As shown, a method for producing hydrogen from biogas-like biomass, the following operations are performed in sequence:

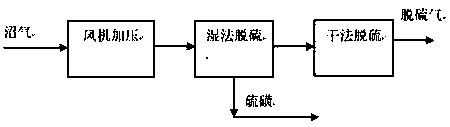

[0058] 1) Pre-purification

[0059] The biogas from the gas tank, with a sulfur content of about 800ppm, is pressurized by a Roots blower to 30kpag and then enters the lower part of the wet desulfurization tower, where it contacts the top-down desulfurization lean liquid on the packing surface from bottom to top. The desulfurization solution that has absorbed various reducing gases is sucked into the air by jetting, the solution is oxidized and regenerated, and sulfur foam is precipitated, and the clear desulfurization solution after the foam separation can be recycled. The sulfur foam is further passed through the sulfur melting kettle to produce sulfur. Biogas H2S after crude desulfurization: ≤300ppm. In order to ensure the desulfurization effect and protect the subsequent adsorbent, the biogas after rough desulfurization is fu...

Embodiment 2

[0068] Such as Image 6As shown, a method for producing hydrogen from biogas-like biomass, the following operations are performed in sequence:

[0069] 1) Pre-purification

[0070] The biogas from the air bag, with a sulfur content of about 200ppm, is pressurized to 50kpag by the Roots blower and then enters the dry desulfurization unit with iron oxide dry desulfurization; it consists of 3 dry desulfurization towers, 2 of which are in the state of adsorption, and the other 1 tower is on standby. The gas enters the desulfurization tower from the lower part, passes through the packing layer in the desulfurization tower, absorbs or reacts H2S into sulfide or polysulfide, and remains in the packing layer, and the purified gas is discharged from the top of the desulfurization tower. Gas H2S after desulfurization and purification: ≤25ppm.

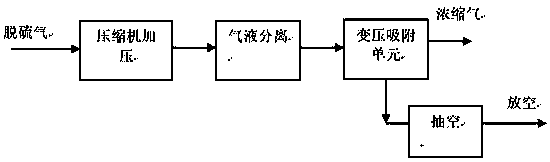

[0071] 2) concentrated

[0072] The pre-purified biogas is pressurized to 0.4Mpag by the compressor and then enters the pressure swing adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com