Energy saving type phosphorus reaction tower for producing high pure phosphoric acid

A high-purity phosphoric acid and energy-saving technology, applied in the field of reaction towers, can solve problems such as the inability to fundamentally inhibit corrosion, and achieve the effects of improving the effective heat utilization rate of the system, facilitating processing and manufacturing, and taking into account equipment economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

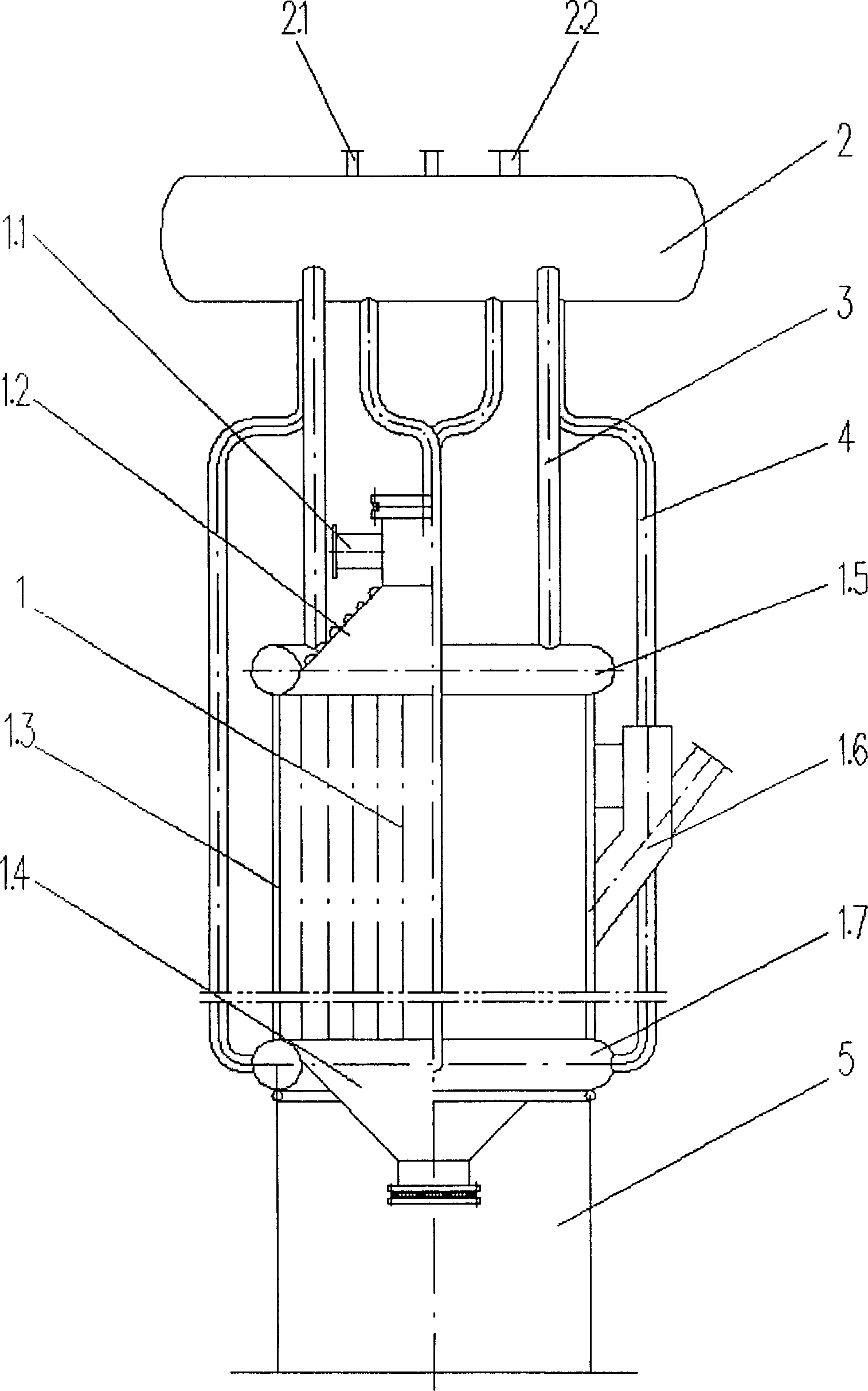

[0015] As shown in the accompanying drawings, the present invention includes a closed vertical tower body 1 , a steam-water separator 2 , a steam collecting pipe 3 , a downcomer 4 and a skirt base 5 . The surrounding wall of the airtight vertical tower body 1 is an annular membrane water cooling wall 1.3 formed by welding multiple stainless steel tubes and fins at intervals. There is a flue gas outlet pipe 1.1 at the end of the conical head 1.2, and the lower end of the annular membrane water wall 1.3 is connected with the lower header 1.7 and the lower conical head 1.4 in sequence; The interface pipe 1.6 of the phosphorus spray gun, the bottom of the closed vertical tower body 1 is a skirt base 5 connected with the lower header 1.7, the two ends of the steam collecting pipe 3 are respectively connected with the steam-water separation device 2 and the upper header 1.5, and the downcomer 4 is two The ends are respectively connected with the steam-water separation device 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com