Nitrogen-insulating combustion and CO2 capture and utilization process for gas-fired boiler

A gas-fired boiler and process technology, applied in the field of combustion, can solve problems such as high fuel consumption, heat loss, acid rain environment, etc., and achieve the effects of reducing greenhouse effect, reducing unit consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

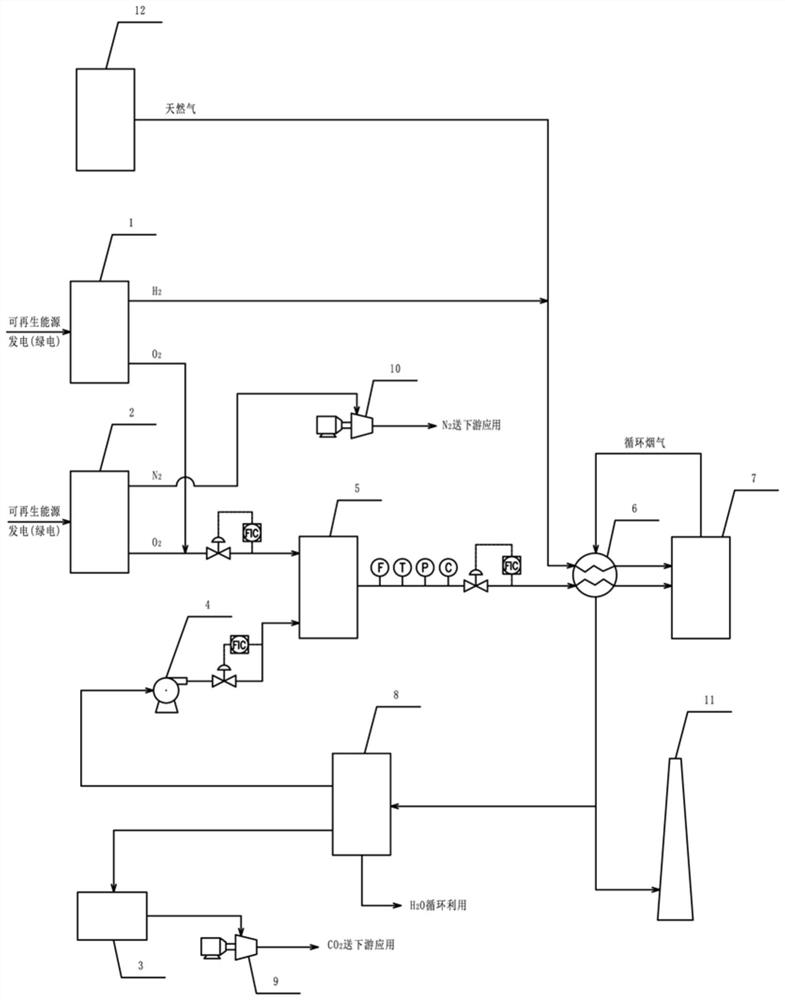

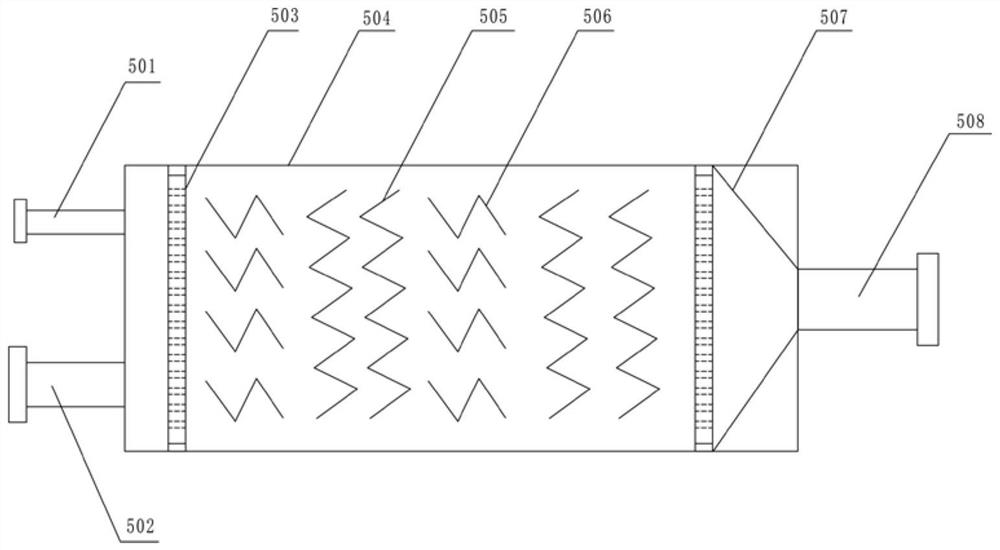

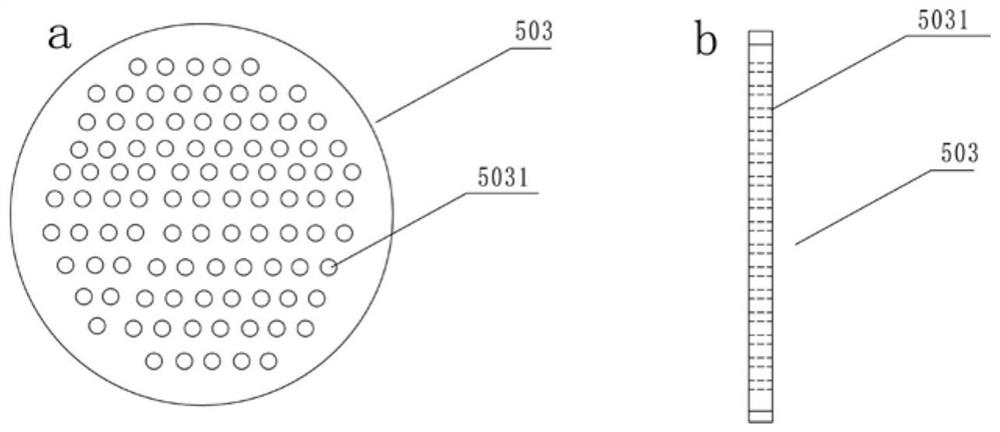

[0051] A gas-fired boiler with nitrogen-free combustion and CO 2 capture and utilization processes such as figure 1 As shown, the system required for the process includes a natural gas supply device 12, a water electrolysis hydrogen production device 1, an oxygen preparation device 2, a nitrogen compressor 10, a carbon-based nitrogen-absolute gas mixer 5, a gas heat exchanger 6, and a gas boiler 7 , chimney 11, flue gas dehydration device 8, blower 4, CO 2 Recovery unit 3 and CO 2 compressor9.

[0052] The natural gas supply device 12 is used for supplying natural gas.

[0053] Water electrolysis hydrogen production device 1, which is a conventional water electrolysis hydrogen production device 1 in the fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com