Thermal remediation system for organic matter contaminated soil through double-phase transformation heat treatment

A technology for polluted soil and organic pollutants, which is applied in the thermal remediation system of two-phase transformation heat treatment of organic matter-contaminated soil, energy and environmental fields, and can solve the problem that dust-laden flue gas easily damages the combustion chamber and its pipes, and the heat of the tail flue gas does not further increase. Recycling, complex combustion system and difficult operation, etc., can prevent high-temperature oxidation and dioxin formation, reduce damage, and facilitate the organization of combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

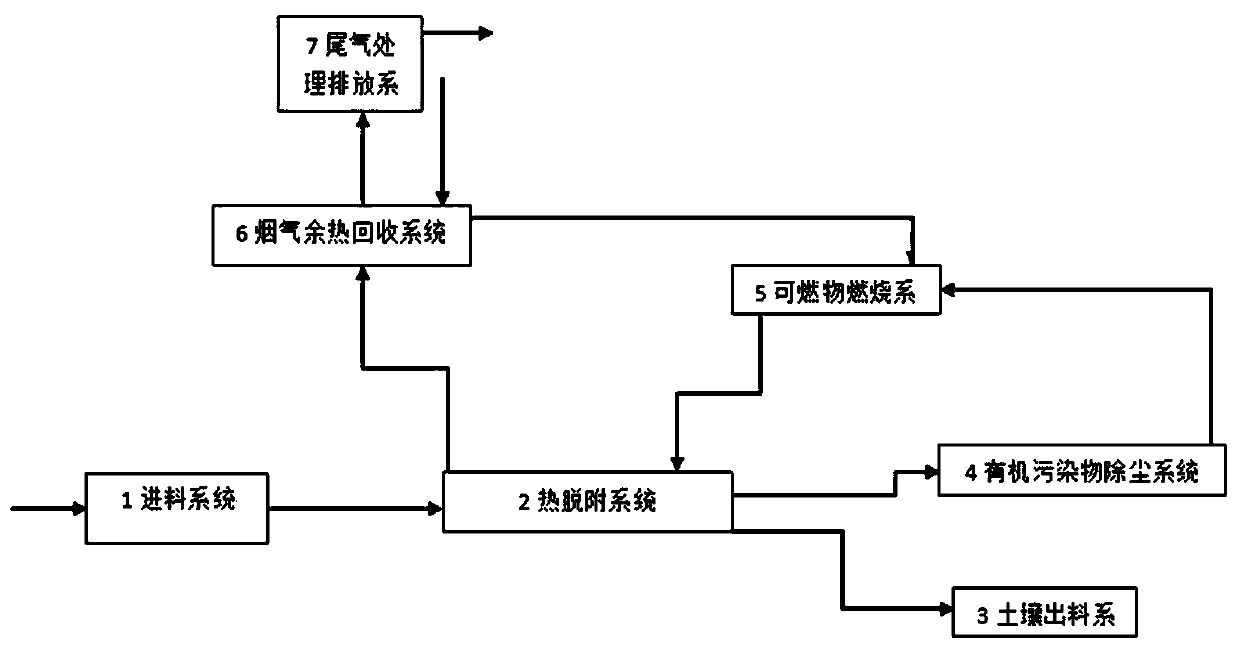

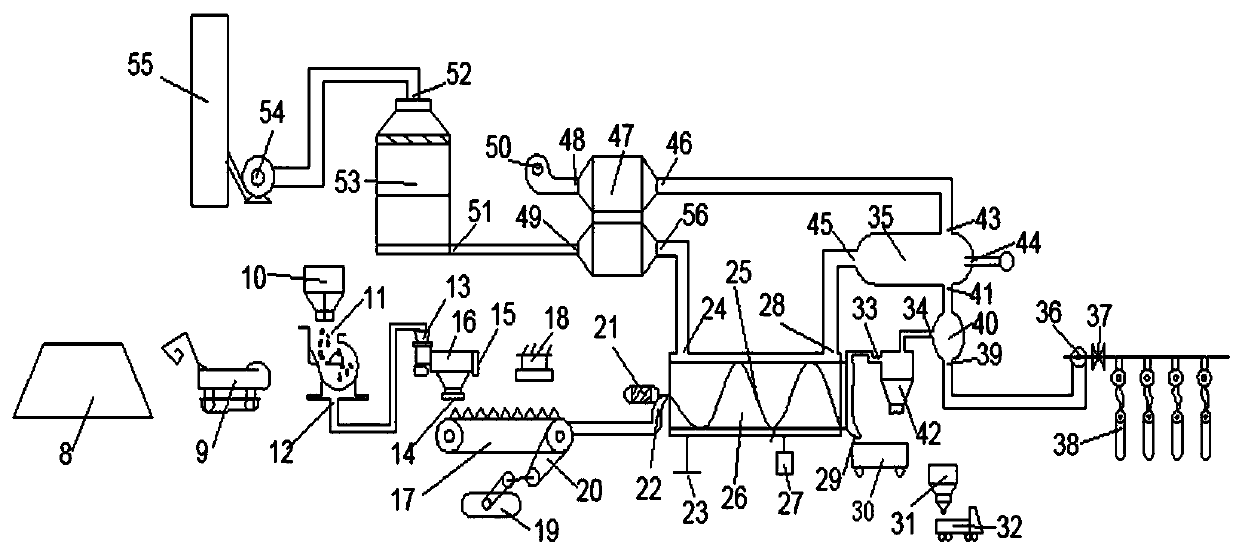

[0016] The invention provides a heat recovery system for dual-phase conversion heat treatment of soil polluted by organic matter. as attached figure 1 As shown, the system includes a feed system 1, a thermal desorption system 2, a soil discharge system 3, an organic pollutant dust removal system 4, a combustible combustion system 5, a flue gas waste heat recovery system 6 and a tail gas treatment and discharge system 7.

[0017] Feed system 1 is connected to thermal desorption system 2, thermal desorption system 2 is connected to soil discharge system 3 and organic pollutant dust removal system 4, organic pollutant dust removal system 4 is connected to combustible combustion system 5, and combustible combustion system 5 is connected to The thermal desorption system 2 is connected to the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com