Solid fuel furnace with thermoelectric power generation device

A solid fuel, temperature difference power generation technology, applied in the direction of solid heating fuel, circuit devices, battery circuit devices, etc., can solve the problems of difficulty in providing stable power supply, complex structure of power generation devices, inconvenient use and carrying, and achieve compactness, lightness, The effect of simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

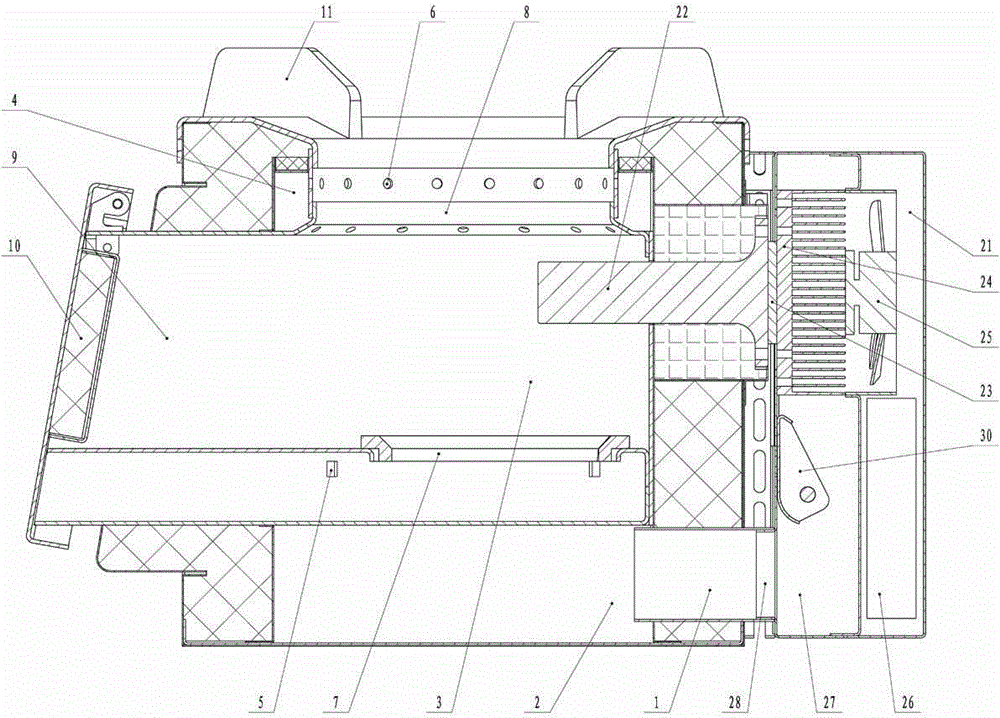

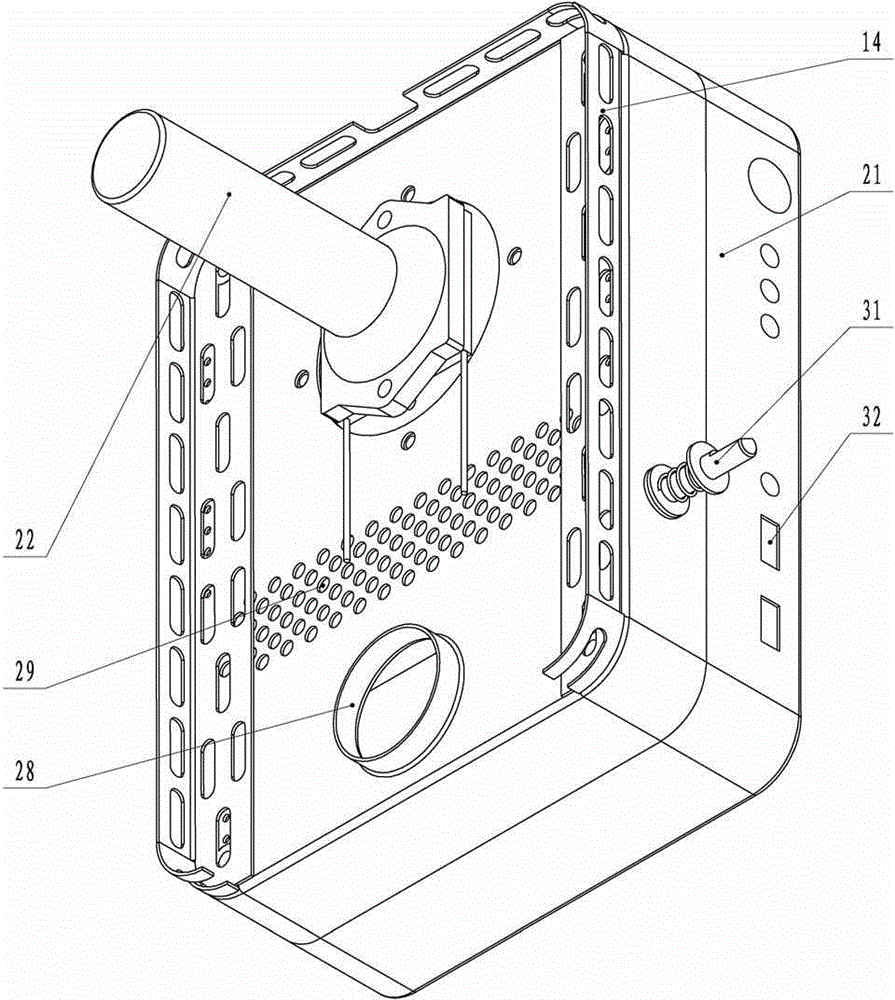

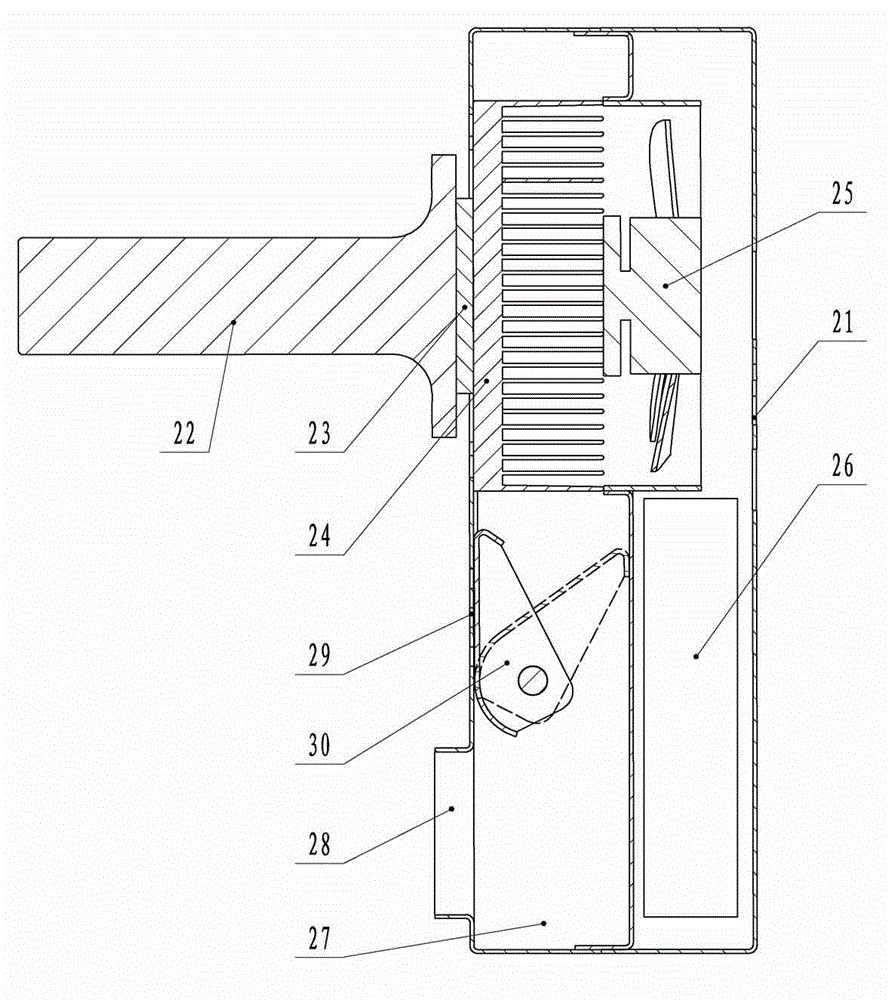

[0022] Such as figure 1 As shown, a solid fuel furnace with a thermoelectric power generation device includes a solid fuel furnace and a thermoelectric power generation device. Such as figure 1 , Figure 4 As shown, there is an air duct 1 for providing combustion-supporting air at the bottom of the solid fuel furnace. The air duct 1 is connected to the ventilation chamber 2. The air chamber 2 is a square structure. The furnace 3 of the solid fuel furnace is a cylindrical structure located in the wind chamber. Inside the chamber 2, the furnace wall of the furnace 3 is connected to the four vertical sides of the air chamber 2 to form four independent air ducts 4, and the air duct 4 is provided with a primary air hole 5 and a secondary air hole 6 corresponding to the furnace connected to the bottom of the furnace. The bridge 7 and the fire outlet 8 on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com