Crude oil swirling low-nitrogen burner of steam-injection boiler

A low-nitrogen burner and steam injection boiler technology, which is applied in the direction of burners, lighting and heating equipment, can solve the problems of inability to reduce nitrogen oxide emissions, high maintenance costs, and poor fuel applicability, and achieve compact structure and low maintenance. Low cost, strong burning and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

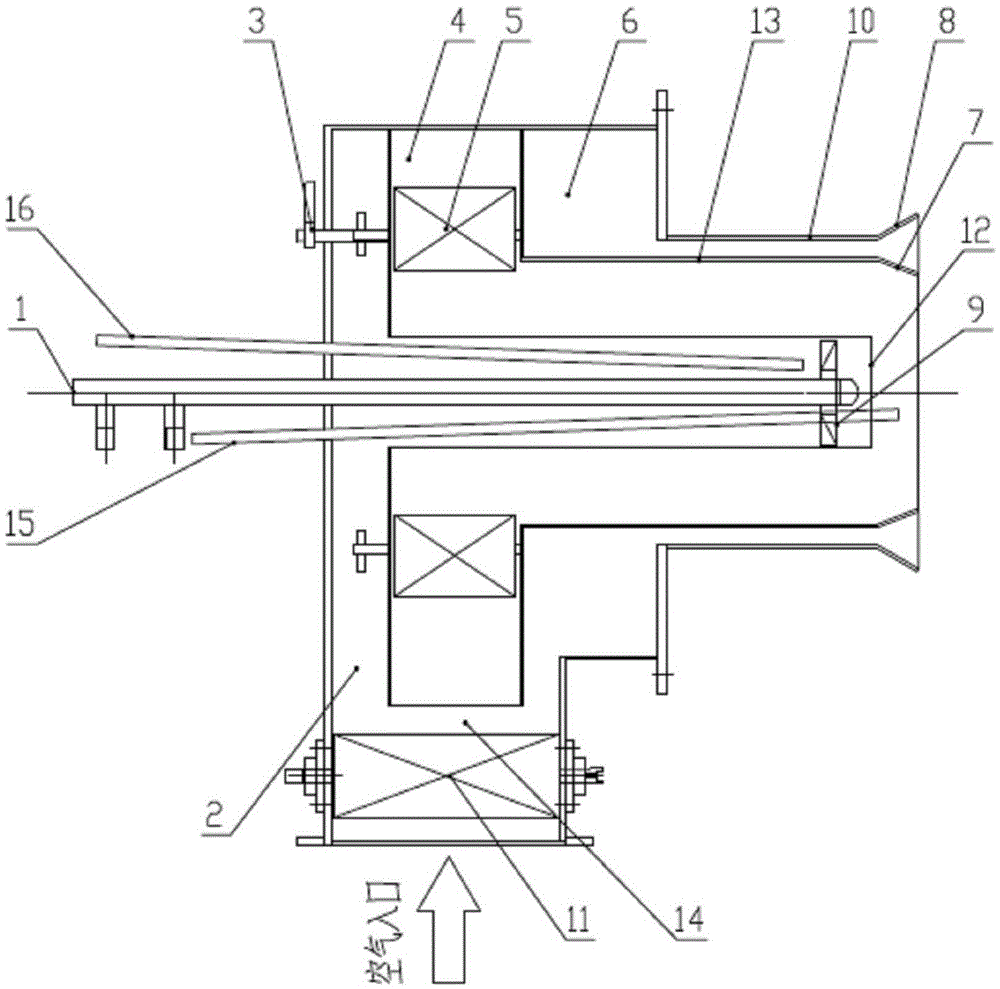

[0015] The following combines the manual with the figure 1 The crude oil swirl low-nitrogen burner of the steam injection boiler for the rotary combustion of crude oil is further explained.

[0016] The crude oil swirl low nitrogen burner of the steam injection boiler for the rotary combustion of crude oil, when burning crude oil, the crude oil gas swirl low nitrogen burner follows the air flow direction, in order: air inlet, damper 11, central air chamber 2, secondary Air chamber 4, perimeter air chamber 6, secondary air spout 7, perimeter air spout 8. Wherein, the central wind flows through the central air chamber 2, the central air pipe 12, and the burner 9 in sequence. The secondary air flows through the secondary air chamber 4, the secondary air swirl plate 5, the secondary air pipe 13, and the secondary air nozzle 7 in sequence. The perimeter wind flows through the perimeter air chamber 6 , the perimeter air duct 10 , and the perimeter wind nozzle 8 in sequence. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com