Method for recycling waste clay

A clay brick and recycling technology, which is applied in the field of resource utilization of waste clay bricks, can solve the problems of narrow application area, and achieve the effects of reducing combustible content, good grindability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

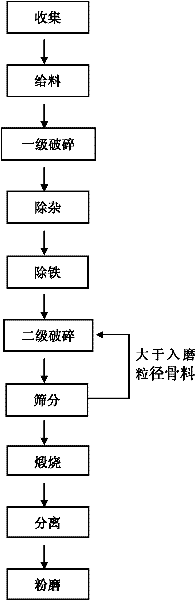

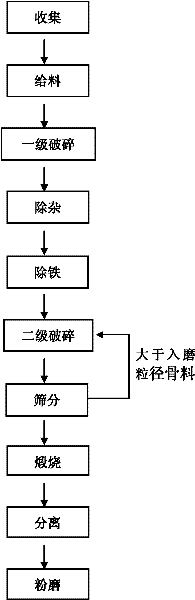

[0025] Embodiment 1, the resource utilization method of waste and old clay bricks in brick-concrete construction waste, its flow process is as follows figure 1 shown, including the following steps:

[0026] Collection: transport brick-concrete construction waste that is not easy to sort and collect to designated locations;

[0027] Feeding: transport the collected construction waste to the feeding hopper with a loading vehicle;

[0028] Primary crushing: use a jaw crusher to separate the steel bars and concrete in the large pieces of construction waste, and at the same time break the construction waste into smaller particles;

[0029] Impurity removal: Manual or mechanical sorting is used to remove steel bars, wood, plastics, cloth strips and other impurities in the construction waste after the primary crushing;

[0030] Iron removal: use electromagnets to remove steel bars, iron wires, iron blocks and other metal substances remaining in the construction waste after cleaning...

Embodiment 2

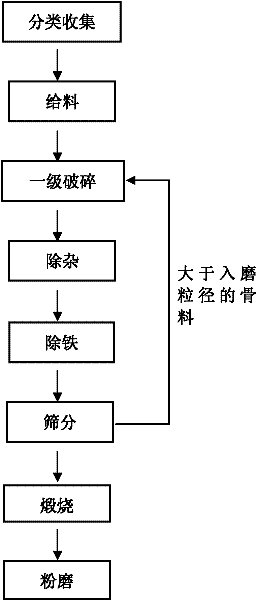

[0036] Embodiment 2, the resource utilization method of waste and old clay bricks in the construction waste not containing concrete, its flow process is as follows figure 2 shown, including the following steps:

[0037] Sorted collection: the main components of construction waste (waste concrete and waste clay bricks) are collected separately at the site of construction demolition and then transported to a designated place for concentration, or waste products from the production process of clay bricks are transported to a designated place for concentration;

[0038] Feeding: Use a loading vehicle or a reclaimer to transport the collected waste clay bricks into the feeding hopper;

[0039] Primary crushing: Clay bricks are crushed with a hammer crusher; clay bricks have low strength and low hardness, primary crushing can not only meet the requirements of large crushing ratio, but also increase the hourly output and simplify the disposal process;

[0040] Impurity removal: Man...

Embodiment 3

[0045] Embodiment 3, the resource utilization method of waste and old clay bricks in brick-concrete construction waste, its flow process is as follows figure 1 shown, including the following steps:

[0046] Collection: transport brick-concrete construction waste that is not easy to sort and collect to designated locations;

[0047] Feeding: transport the collected construction waste to the feeding hopper with a loading vehicle;

[0048] Primary crushing: use a jaw crusher to separate the steel bars and concrete in the large pieces of construction waste, and at the same time break the construction waste into smaller particles;

[0049] Impurity removal: Manual or mechanical sorting is used to remove steel bars, wood, plastics, cloth strips and other impurities in the construction waste after the primary crushing;

[0050] Iron removal: use electromagnets to remove steel bars, iron wires, iron blocks and other metal substances remaining in the construction waste after cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com