Method for improving W-type flame boiler efficiency

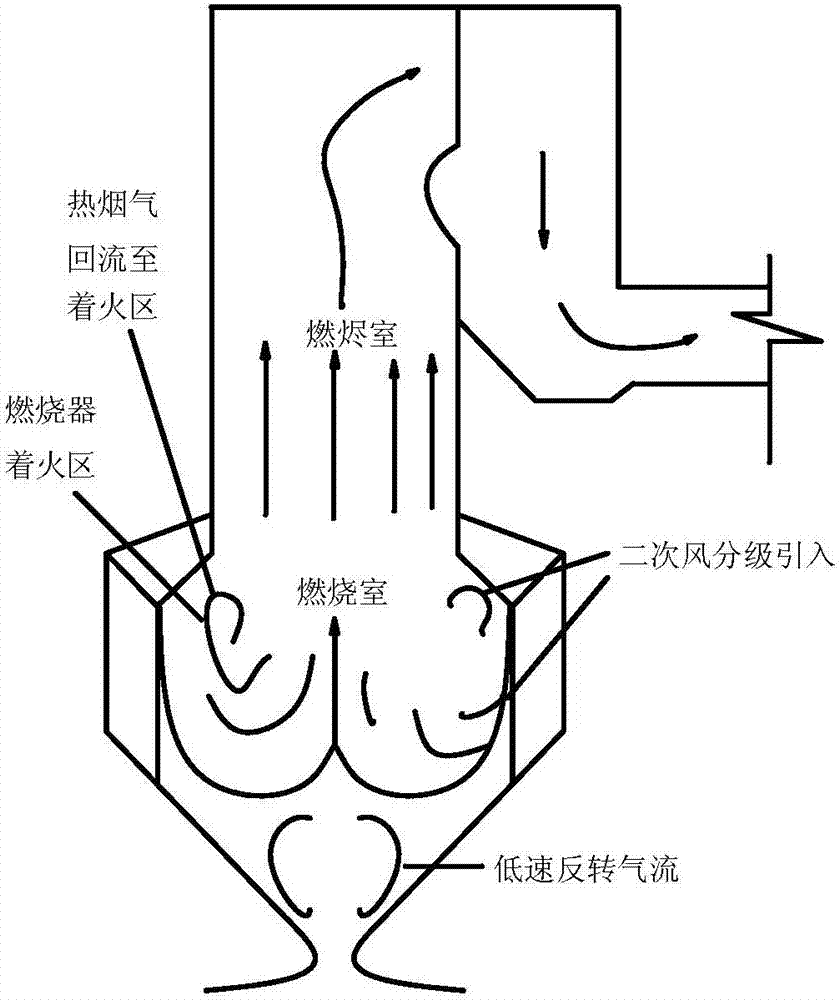

A boiler and flame technology, which is applied in the field of improving the furnace efficiency of W-type flame boilers, can solve the problems of large carbon content in fly ash, increased carbon content in slag, complicated aerodynamic field, and reduced furnace efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The method for improving the efficiency of a W-shaped flame boiler in this embodiment includes:

[0094] Select several coal types, and perform coal quality element and industrial analysis on the selected coal types based on thermogravimetric and infrared analysis;

[0095] Based on the coal elements and industrial analysis results, the combustion strategy of the boiler is predetermined. The combustion strategy specifically includes: (1) The proportion of coal types that can form staged combustion in the boiler and the corresponding coal mill coal grinding mode (2) Can not form a graded coal configuration ratio and the corresponding coal mill coal grinding method in the boiler; wherein, the staged combustion of the boiler is specifically: the use of combustible coal and oxygen to react to become the first-stage combustion , Where the combustible coal is bituminous coal or a mixture of bituminous coal and lean coal; the high-temperature flue gas atmosphere formed in the first...

Embodiment 2

[0155] The method for improving the furnace efficiency of the W-flame boiler in this embodiment, on the basis of Embodiment 1, further includes the steps of determining the F wind downward inclination angle F wind downward inclination angle and the D and E wind opening degrees, which specifically include:

[0156] The boiler uses the fuel staged combustion method for combustion under the following (1), (2), (3) three loads and F wind downtilt angles, and obtains the operating conditions of different F-layer secondary air downtilt angles , Wherein the operating conditions at least include: NOx, CO, O2 in the flue gas at the outlet of the economizer; NOx, CO, and O2 in the flue gas at the outlet of the air preheater; boiler thermal efficiency; coal industry, element analysis; fly ash, Slag sampling analysis; economizer outlet flue gas temperature; air preheater outlet flue gas temperature; raw coal sampling; ambient temperature, humidity and atmospheric pressure;

[0157] Among them,...

Embodiment 3

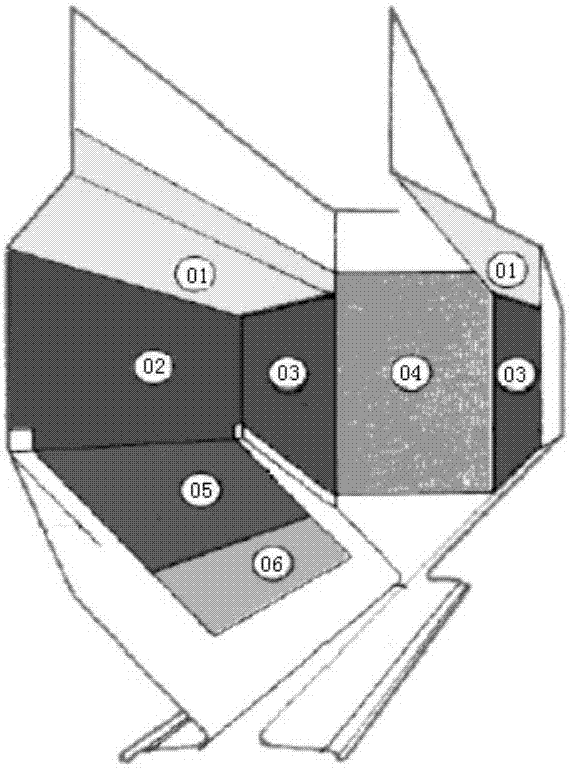

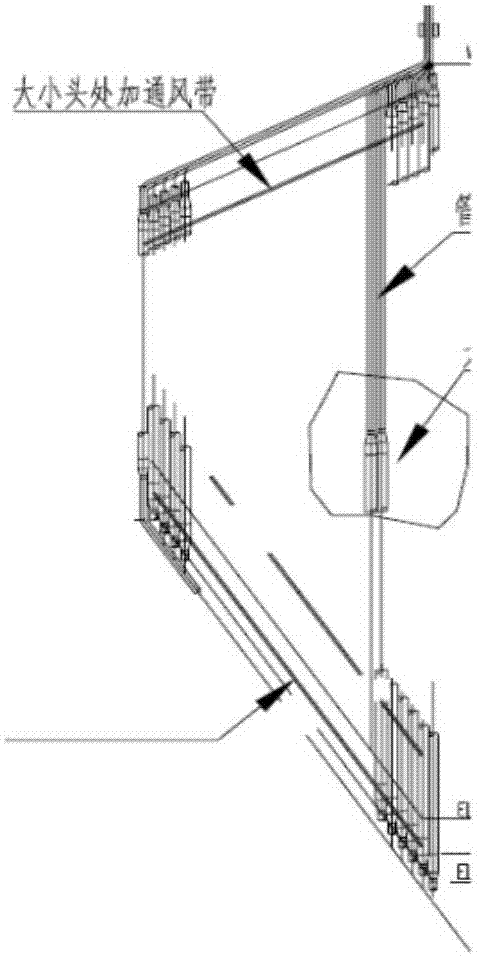

[0233] Such as figure 2 As shown, the method for improving the efficiency of the W-flame boiler in this embodiment is that the wing wall is longitudinally opened with 4 ventilation slits to blow the secondary air inward, the outer diameter of the water wall tube at the wing wall is larger (120.65mm), and the center distance is 146.4 mm, the pipe gap is 25.4mm, and the outer diameter of the upper and lower pipes on the wing wall is small (69.85mm). The original design uses a reducing pipe to connect the two ends, and only needs to replace the thick pipes at the four ventilation belts that need ventilation For the thin tube (moving the upper and lower head position down), the tube gap can be changed to 76.55mm wide, and the ventilation effect is good, which can prevent large-area coking of the wing wall water wall tube, and increase the wing wall anti-coking wind optimization plan such as figure 2 Shown. The height of the ventilation belt can be set to the total length of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com