Novel boiler

A boiler and a new type of technology, applied in the field of boilers, can solve the problems of insufficient combustion of organic macromolecules, increase the content of combustibles in flue gas, and low combustion efficiency, so as to ensure heat conversion efficiency, improve energy saving and emission reduction effects, and reduce combustibles The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

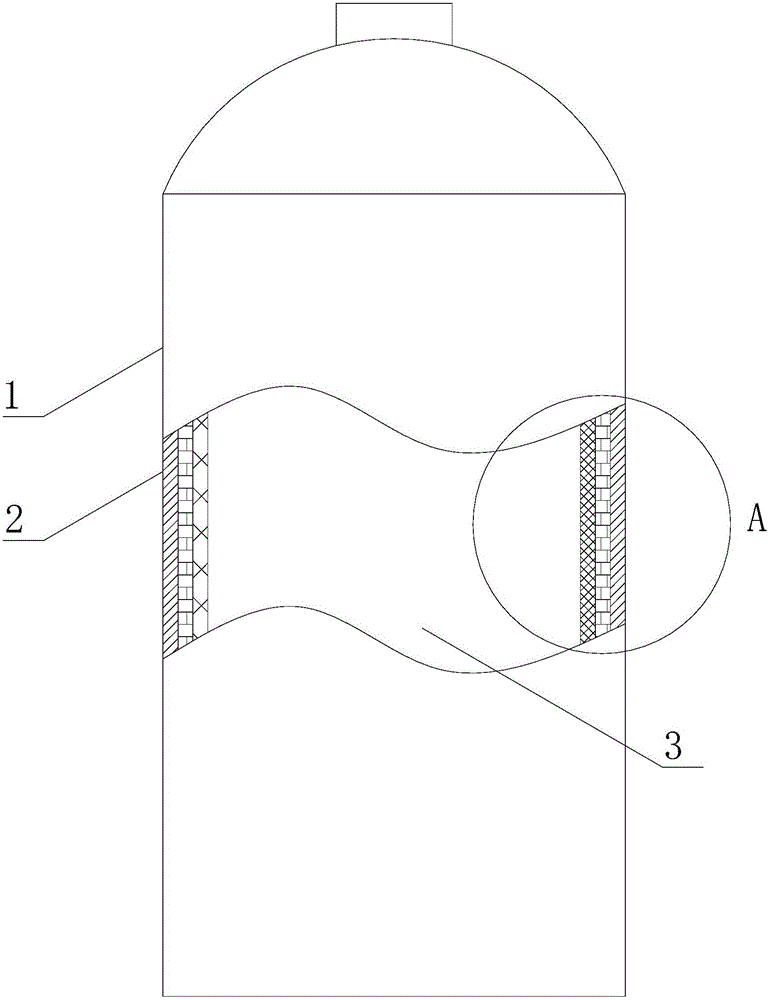

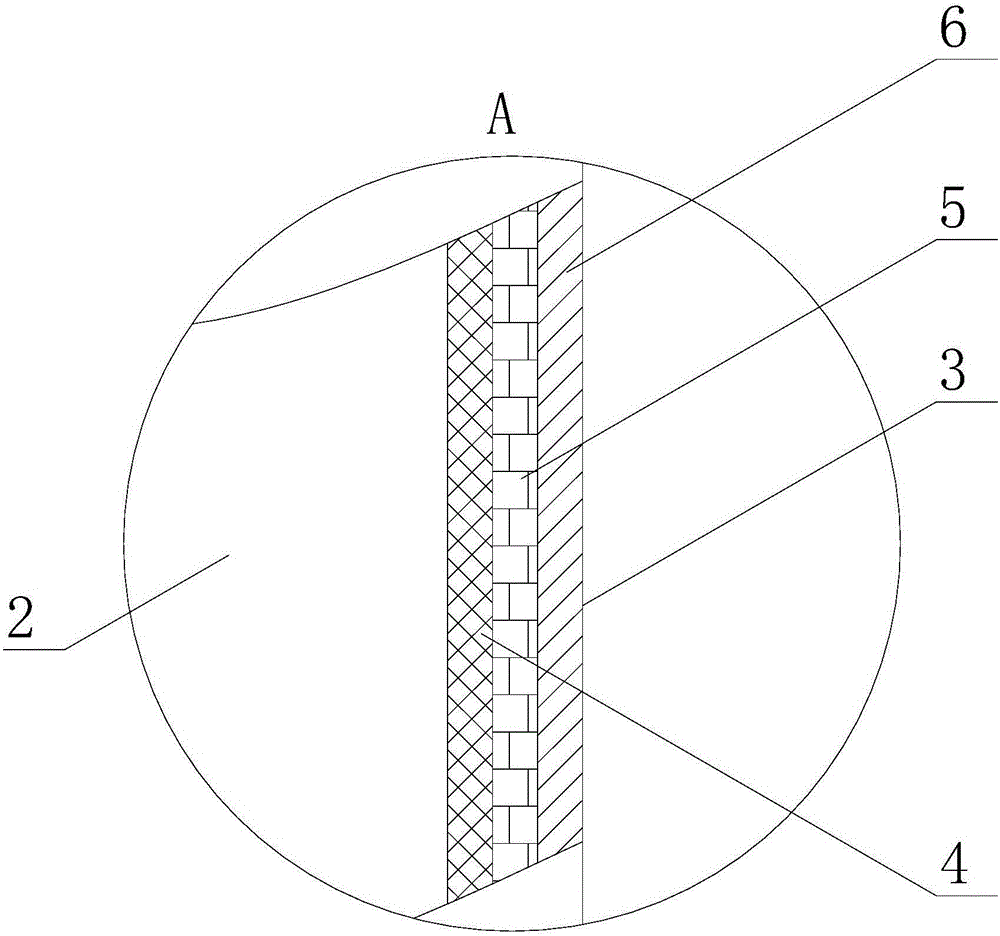

[0011] Such as figure 1 with figure 2 As shown, a new type of boiler includes a boiler body 1, and the furnace wall 3 of the combustion chamber 2 in the boiler body 1 is sequentially composed of a refractory layer 4, an insulation layer 5, and a heat exchange layer 6 from inside to outside.

[0012] Principle of use: An insulation layer 5 is set outside the refractory layer 4, so that the heat in the combustion chamber 2 will not be easily lost, and the temperature in the combustion chamber 2 can be effectively guaranteed, so that the organic macromolecules that need to be cracked and burned under high temperature conditions can be fully Combustion, by setting a water jacket on the heat exchange layer 6 outside the insulation layer 5, the heat dissipated by the insulation layer 5 is fully absorbed by the medium in the water jacket, which improves the combustion efficiency of the boiler while ensuring the heat conversion efficiency. And the combustion utilization rate of coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com