Special impregnating compound for glass fiber swelled yarn and preparation method thereof

A glass fiber and sizing technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of affecting the performance of the muffler, poor expansion, etc., and achieve the effect of low cost, low fiber combustible content, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

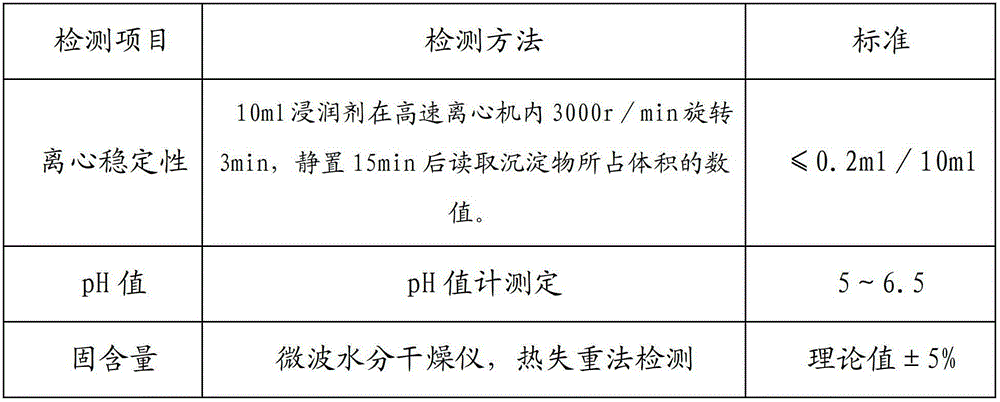

Image

Examples

Embodiment Construction

[0032] The present invention is a swelling yarn sizing agent for automobile muffler filler, which is mainly made of coupling agent, lubricant A, lubricant B, lubricant C, film forming agent, pH regulator and deionized water, the sizing agent The total solid mass accounts for 1.7-3.6% of the total mass of the wetting agent, and the balance is deionized water.

[0033] Specifically, the coupling agent is a silane coupling agent, preferably methacryloxypropyltrimethoxysilane; the lubricant A is polyethylene glycol; the lubricant B is an amide salt lubricant with a ring structure , preferably cationic film; lubricant C is mineral oil lubricant, preferably 7607 lubricant; film-forming agent is ultra-low molecular weight bisphenol F epoxy emulsion, and its molecular weight is 140-160; pH regulator is preferably glacial acetic acid .

[0034] The proportion of each component of the sizing to the total mass of the sizing based on its solid content is as follows:

[0035] Coupling ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com