W-shaped flame boiler with two-stage over-fire wind

A burn-out wind and flame technology, applied in the transportation of non-combustible liquid/gas, combustion methods, combustion equipment, etc., can solve the problems of low burn-out rate of pulverized coal and high content of fly ash combustibles, and achieve graded combustion, The content of combustibles in fly ash is reduced, which is beneficial to the effect of burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

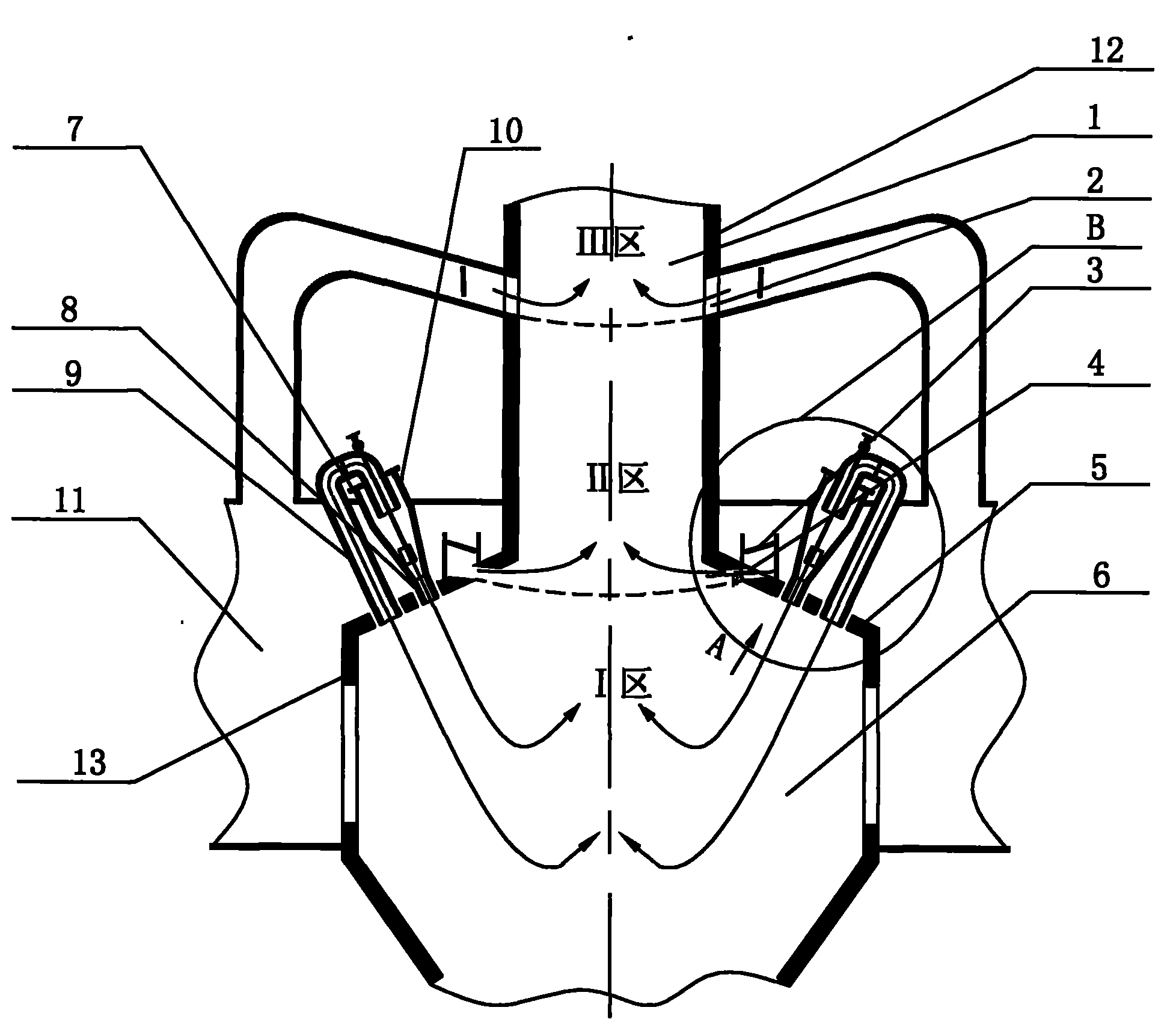

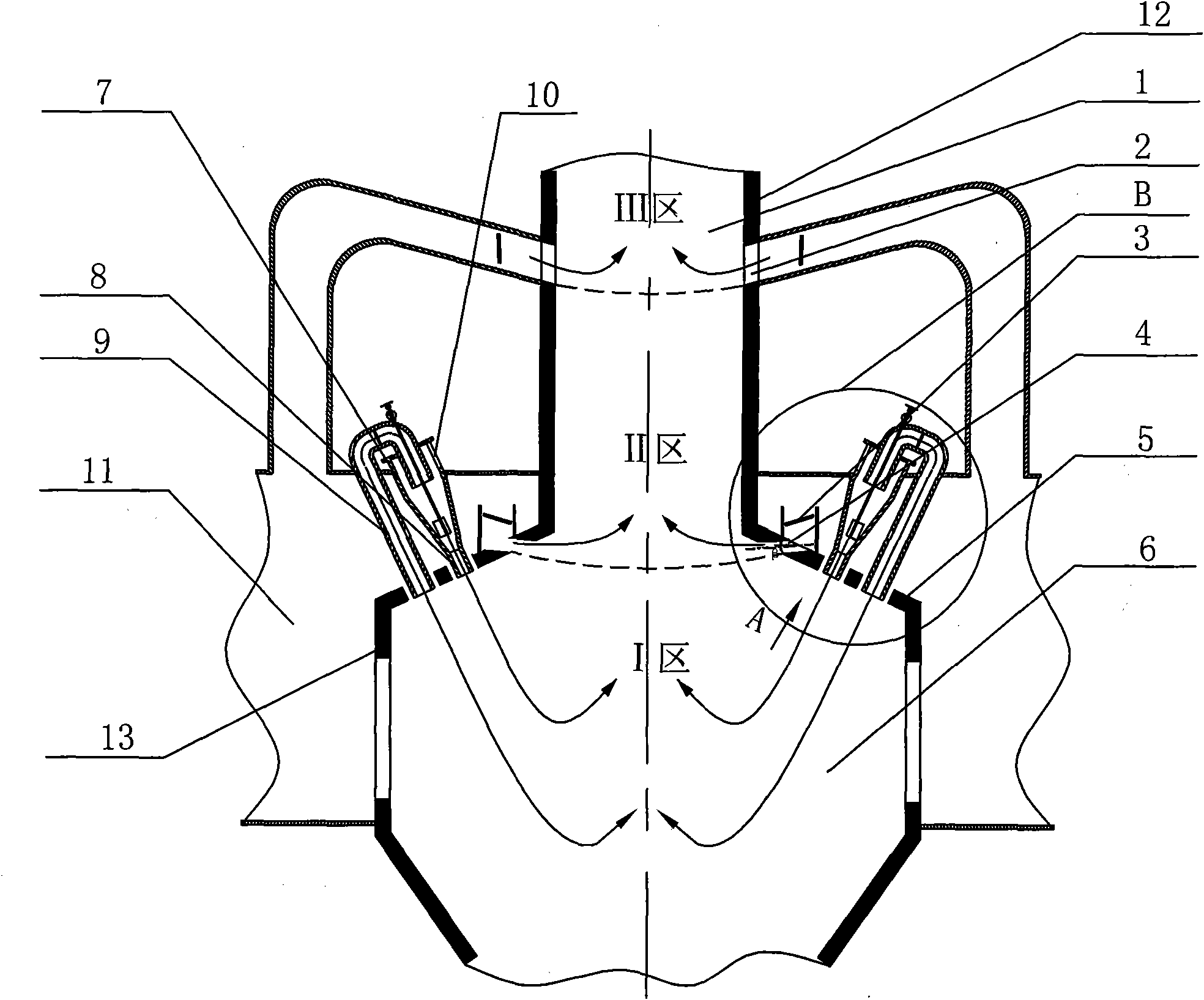

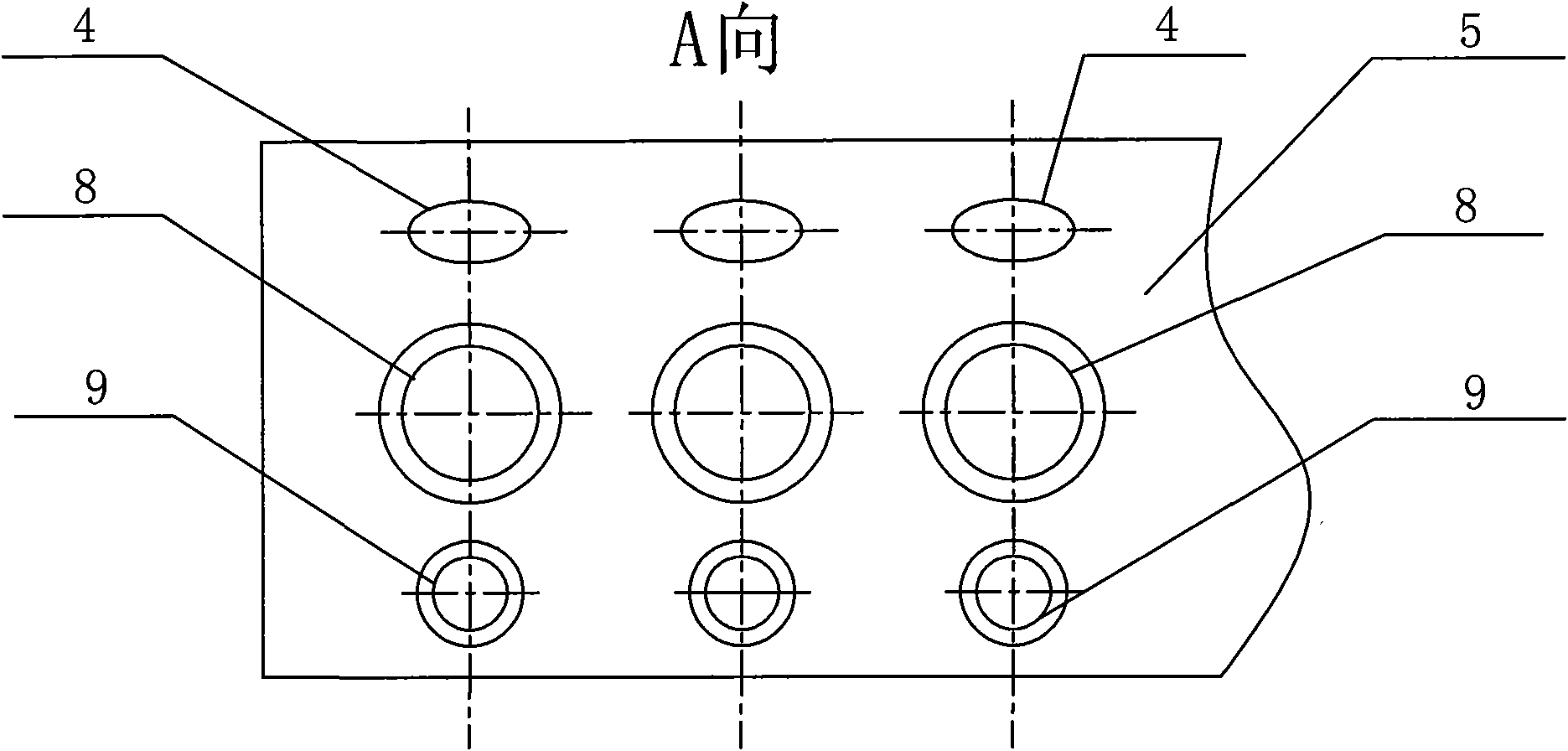

[0013] Specific Embodiment 1: As shown in Figures 1 to 3, the W-shaped flame boiler with two-stage overfire air described in this embodiment includes an upper furnace body 12, a lower furnace body 13, a furnace arch 5, and a cyclone separator 7 , burner 8, oil secondary air duct 9, secondary air box 11 and superior OFA spout 2; upper furnace body 12 communicates with lower furnace body 13 through furnace arch 5, and said burner 8 and oil secondary air duct 9 are all Vertically installed on the furnace arch 5 and the burner 8 is close to the center side of the lower furnace 6. The burner 8 communicates with one end of the cyclone separator 7, and the other end of the cyclone separator 7 communicates with the oil secondary air pipe 9. The upper side wall of the separator 7 is provided with the original exhaust air duct installation port 10, and the upper OFA nozzle 2 is arranged on the side wall of the upper furnace body 12 and communicated with the upper furnace 1, and the secon...

specific Embodiment approach 2

[0014] Embodiment 2: As shown in FIGS. 1-3 , the included angle β between the centerline of the lower OFA nozzle 4 in this embodiment and the horizontal line is 0°-5°. If the β angle is too large, the confluence point of the lower burn-off air and the upward primary air and exhaust air will decrease, the scope of area I will shrink, and the scope of area II will expand accordingly. The reducing atmosphere of primary air and exhaust air in area I Medium residence time reduction, fuel type NO x Generated increased. When β is 0°~5°, it can reduce fuel-type NO x increase in production. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: As shown in Figures 1-3, the W-shaped flame boiler in this embodiment also includes a lower OFA nozzle baffle 3, and the lower OFA nozzle baffle 3 is arranged on the lower OFA nozzle 4. The lower-stage OFA nozzle baffle 3 is used to control the air volume of the lower-stage over-combustion air entering the furnace. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0016] working principle:

[0017] The present invention adopts two-stage OFA devices (upper-level OFA nozzle 2 and lower-level OFA nozzle 4), and part of the secondary air (accounting for 25% to 30% of the total air volume) provided by the secondary wind box 11 flows from the upper-level OFA nozzle 2 and the lower-level OFA nozzle respectively. 4 is sprayed into the furnace, wherein the air volume injected into the upper-level OFA nozzle 2 is 15% of the total air volume, and the air volume injected into the lower-level OFA nozzle 4 is 10-15% of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com