Combustion system and method for boiler at front wall or rear wall of power station

A technology of combustion system and front wall, which is applied in the direction of combustion method, combustion with multiple fuels, combustion with block fuel and liquid fuel, etc., can solve the problems of poor combustion stability and high emission, and achieve low economic benefits, Reduce floor space and help to ignite in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

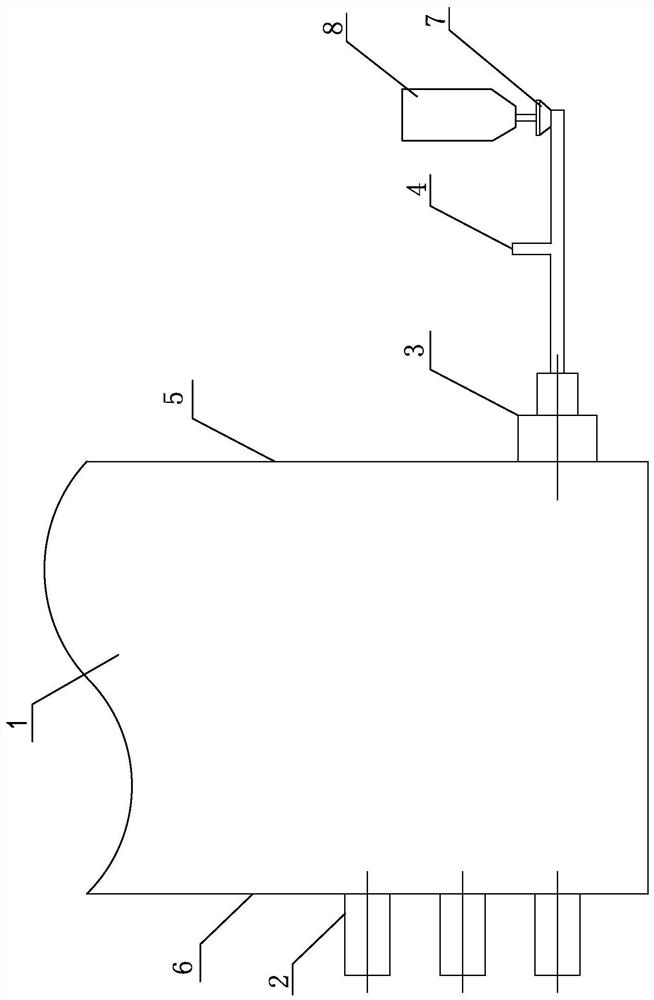

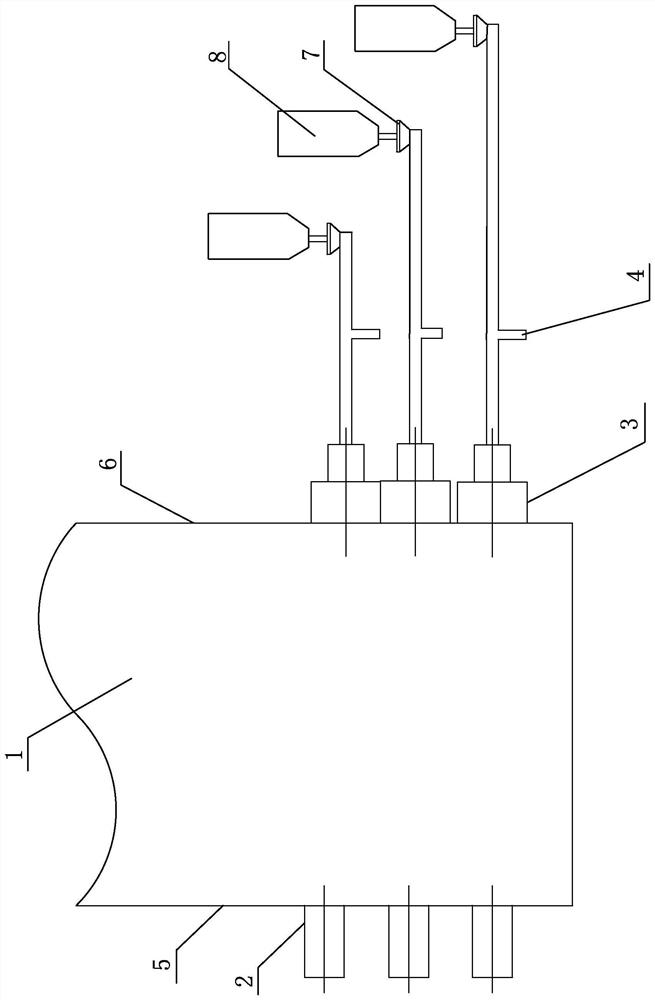

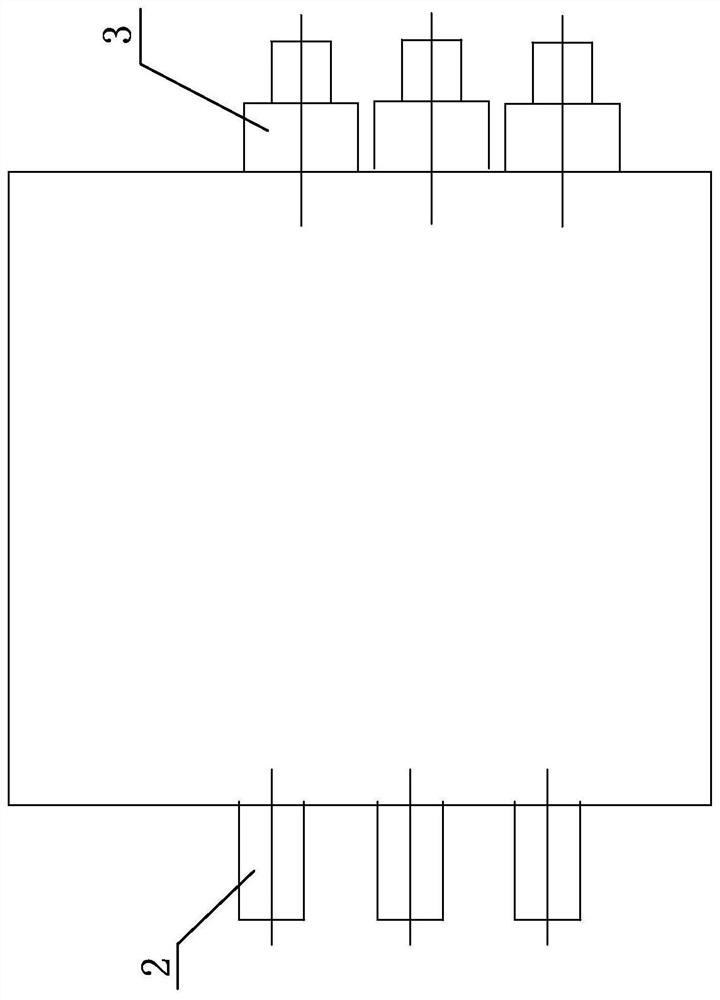

[0026] see Figure 1-Figure 3 As shown, 1. A combustion system of a boiler on the front wall or rear wall of a power station in this embodiment is characterized in that it includes a furnace 1, a main burner 2, a pre-chamber burner 3, a powder feeder 7 and a powder storage bin 8 , the front wall 5 and the rear wall 6 are arranged on the furnace wall of the furnace 1, wherein the pre-combustion chamber burner 3 is connected to the powder feeder 7, the powder storage bin 8 is connected to the powder feeder 7, and the main burner 2 is arranged on the rear wall 6 or the front wall. wall 5, the pre-combustion chamber burner 3 is arranged on the front wall 5 or the rear wall 6, and the boiler is a wall-type boiler. The main burner 2 is arranged correspondingly to the pre-chamber burner. When the main burner is arranged on the rear wall 6, the pre-chamber burner 3 is arranged on the front wall 5, and vice versa. The boiler operates the pre-combustion chamber burner under low load an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com