A fully automatic pattern electroplating production device

A technology for graphic electroplating and production equipment, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of complex design, complicated production, maintenance, and maintenance work, high manufacturing and purchase costs, and achieve high production efficiency, beautiful appearance, Uniform and bright effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

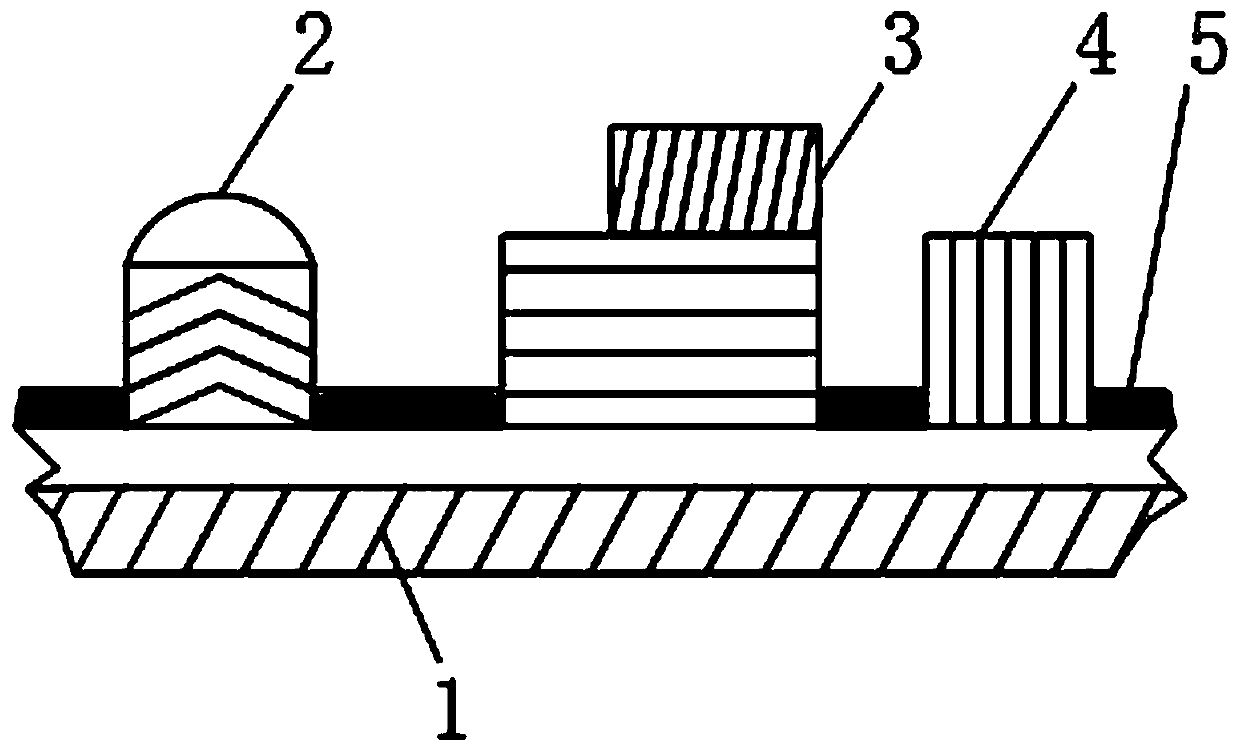

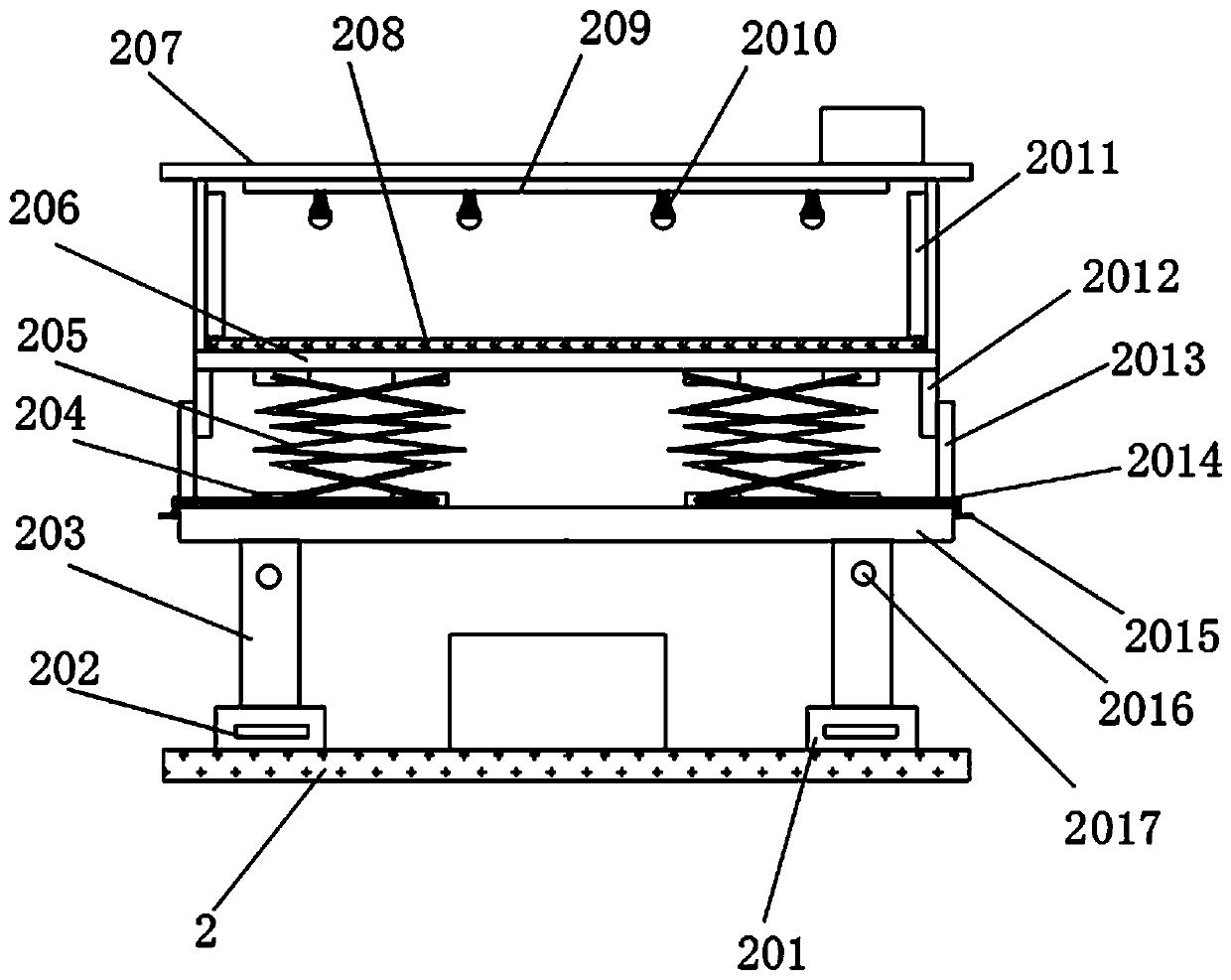

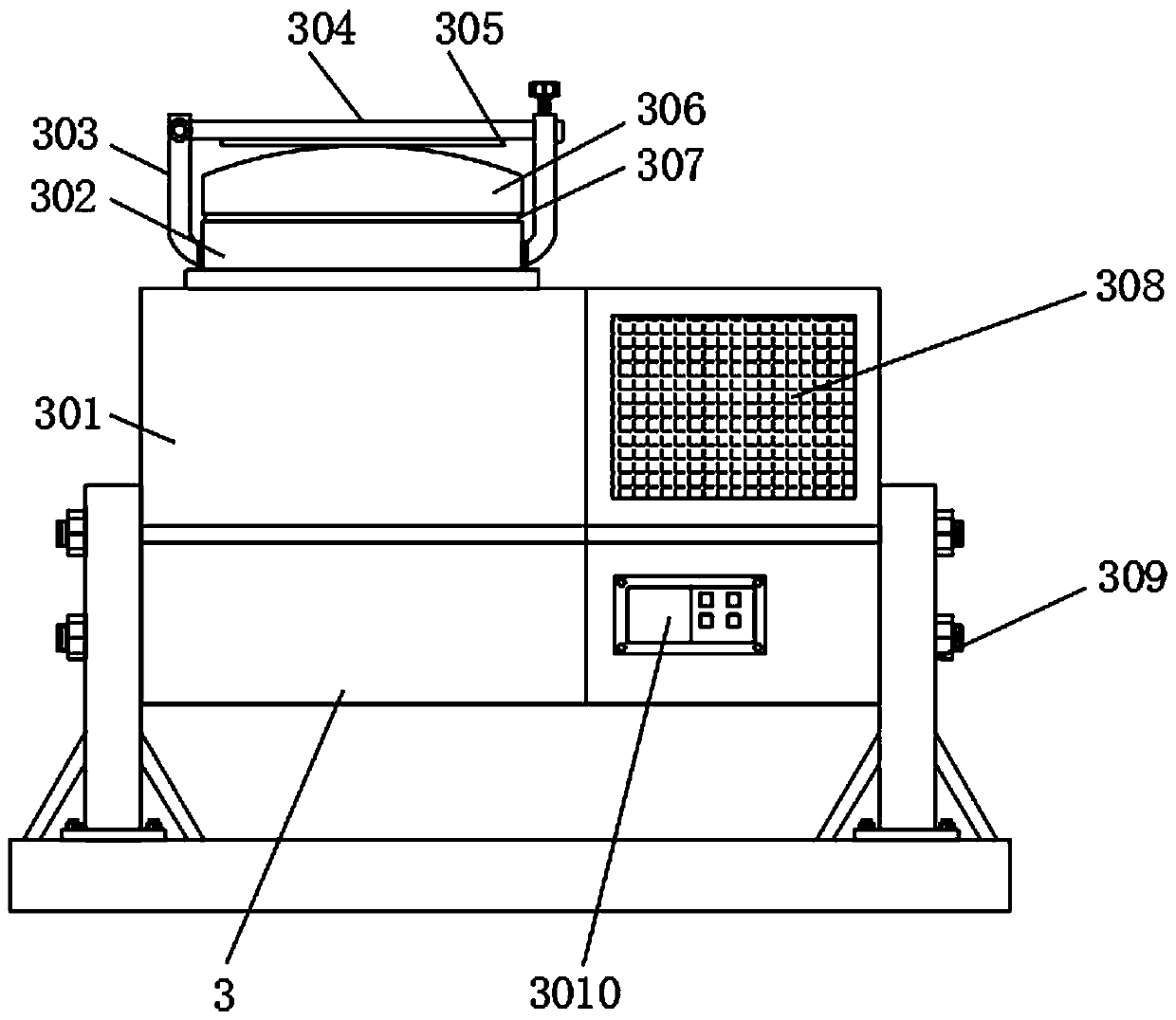

[0021] Example: such as Figure 1-4 As shown, the present invention provides a kind of automatic pattern electroplating production device, comprises base 1, cleaning assembly 2, drying assembly 3, antirust assembly 4 and transmission assembly 5, and the top of base 1 is provided with transmission assembly 5, and base 1 is provided with a cleaning assembly 2 on one side of the top, and the cleaning assembly 2 includes a hydraulic lift 201, a pedal control panel 202, a telescopic rod 203, a nut 204, a lifting link 205, a workbench 206, a support frame 207, an ESD pad 208, Circuit tube 209, LED energy-saving lamp 2010, dust collector 2011, upper connecting block 2012, lower connecting block 2013, screw mandrel 2014, handle 2015, horizontal frame 2016 and adjusting bolt 2017, a hydraulic lifter 201 is installed above the base 1, hydraulic The top of the lift 201 is provided with a telescopic rod 203, and the outside of the hydraulic lift 201 is provided with a pedal control board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com