Method for adjusting combustion of W flame furnace by changing quantity of oil secondary air

A secondary air volume, flame furnace technology, applied in the combustion method, adjusting the air supply, controlling the combustion and other directions, can solve the problem of high content of combustibles in fly ash, reduce the content of combustibles in fly ash, increase the stroke, and facilitate burnout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

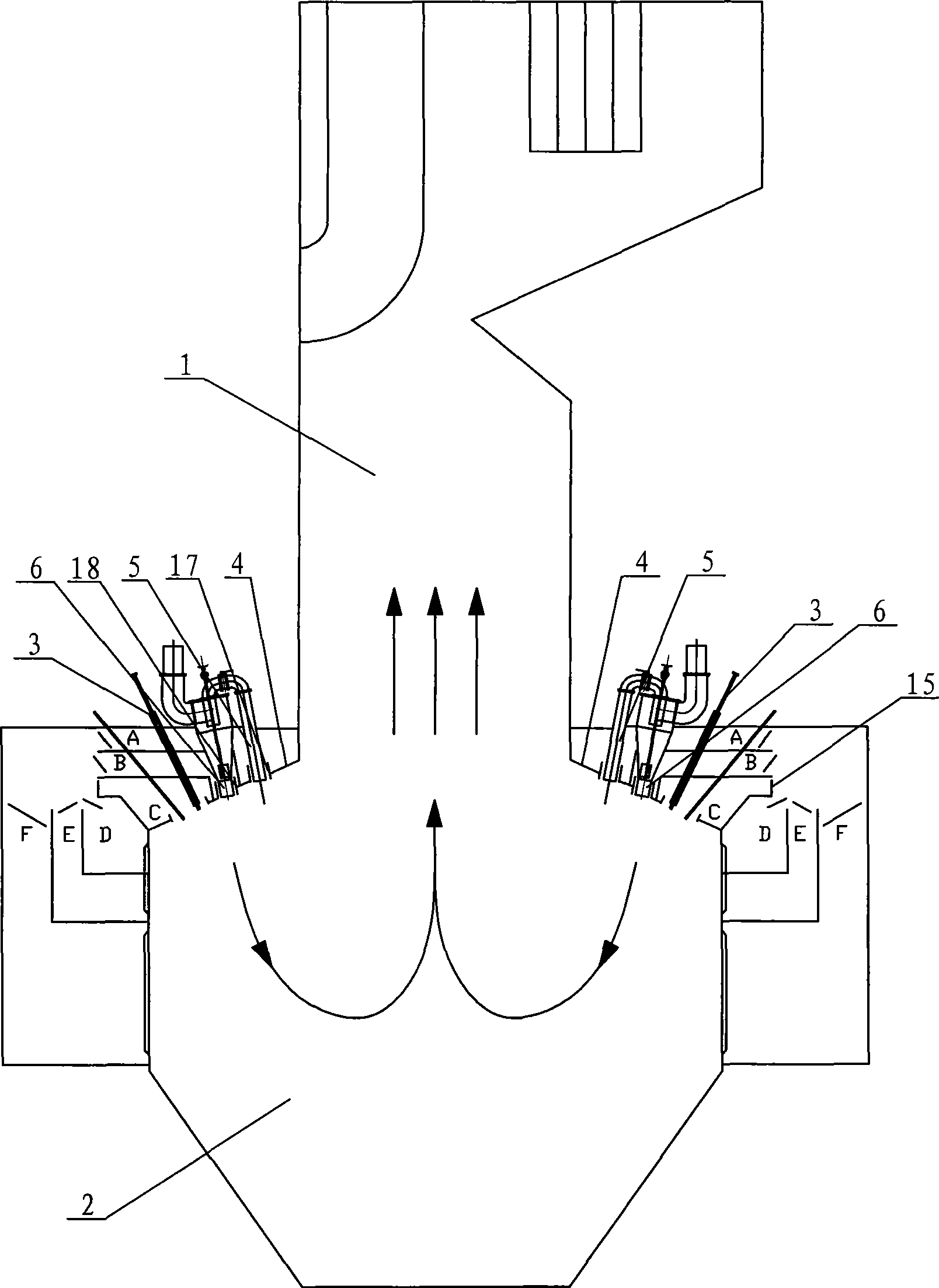

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is realized by the following method: when oil gun 3 ignites boiler normal operation, open damper 9 in the 3rd wind layer C, feed oil secondary air continuously, the oil that passes into The secondary air volume is 12% to 40% of the secondary air volume, and the opening of the damper 9 is between 20% and 100%. The opening degree of the damper 9 can ensure that the oil secondary air continuously passes into the combustion chamber between 20-100%.

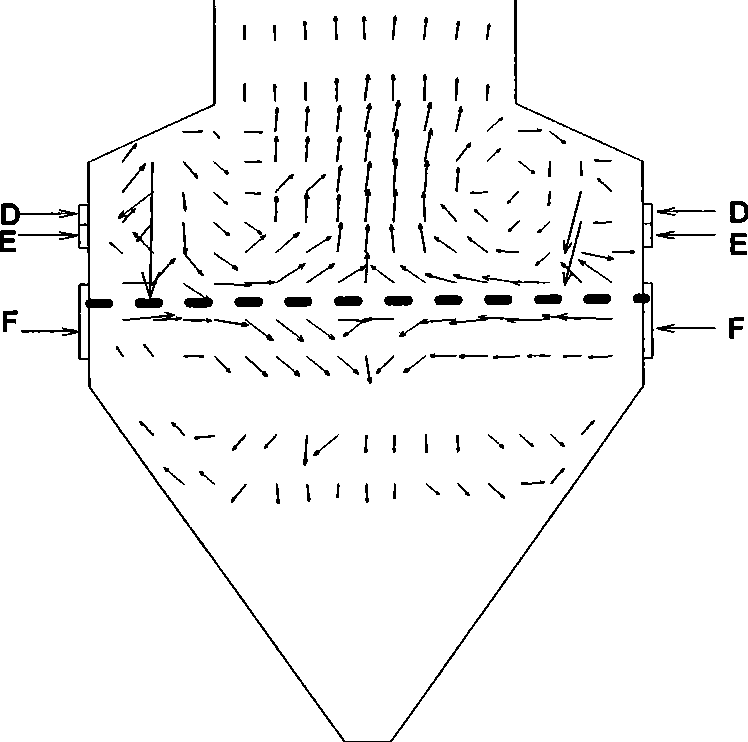

[0008] Because the oil secondary air passed into the combustion chamber 2 is on the leeward side, the introduction of the oil secondary air will not affect the combustion situation in the burnout chamber 1 . After the oil secondary air with higher wind speed is introduced (the wind speed is higher than the concentrated coal powder flow), the upward momentum of the arch is increased, and the primary air powder can be driven downward, pr...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, when the calorific value of coal in this embodiment is above 24 megajoules, the opening degree of damper 9 is 100%, and the secondary air volume of the oil that passes through is 40% of the secondary air volume. When the calorific value of the coal quality is above 24 MJ, the calorific value of the coal quality is very high, the amount of coal supply is very small, and the primary air volume is very small, resulting in a serious shortage of oxygen supply, and a large damper needs to be opened9. Other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe the present embodiment, when the coal calorific value of the present embodiment is 22-24 megajoules, the opening degree of the damper 9 is 80%-100%, and the secondary air volume of the oil introduced is 37%-40% of the secondary air volume. %. When the calorific value of coal is 22-24 megajoules, the calorific value of coal is higher, the amount of coal feed is less, and the primary air volume is small, resulting in a serious shortage of oxygen supply, and a large damper 9 needs to be opened. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com