Safety retracement method for combined coal and oil shale mining

A combined mining and oil shale technology, applied in safety devices, ground mining, mining devices, etc., can solve problems such as high temperature, long withdrawal period, and inability to ensure withdrawal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

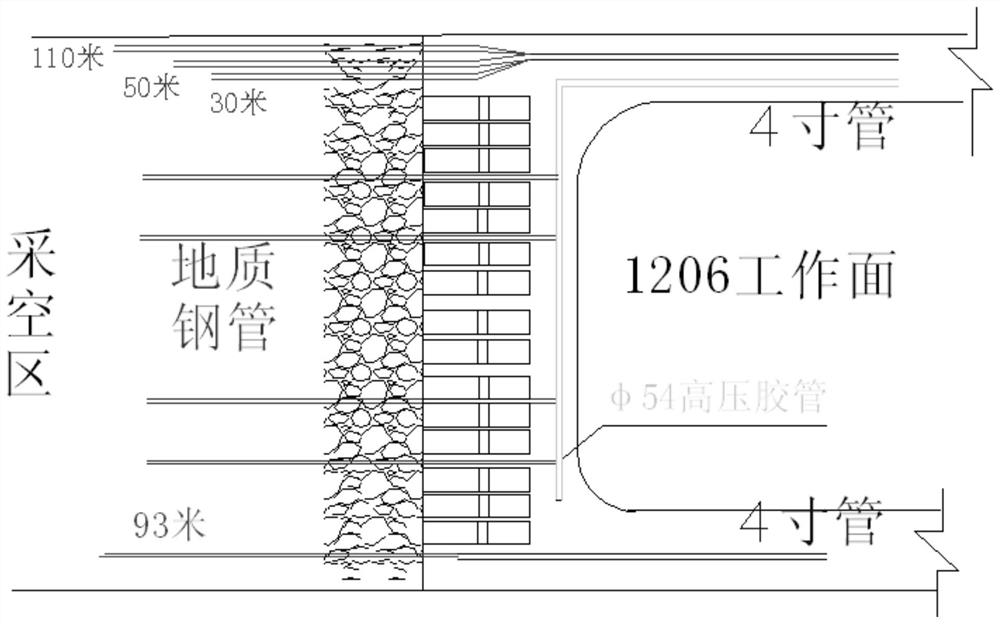

[0048] A safety retraction method for joint mining of coal and oil shale, comprising the following steps:

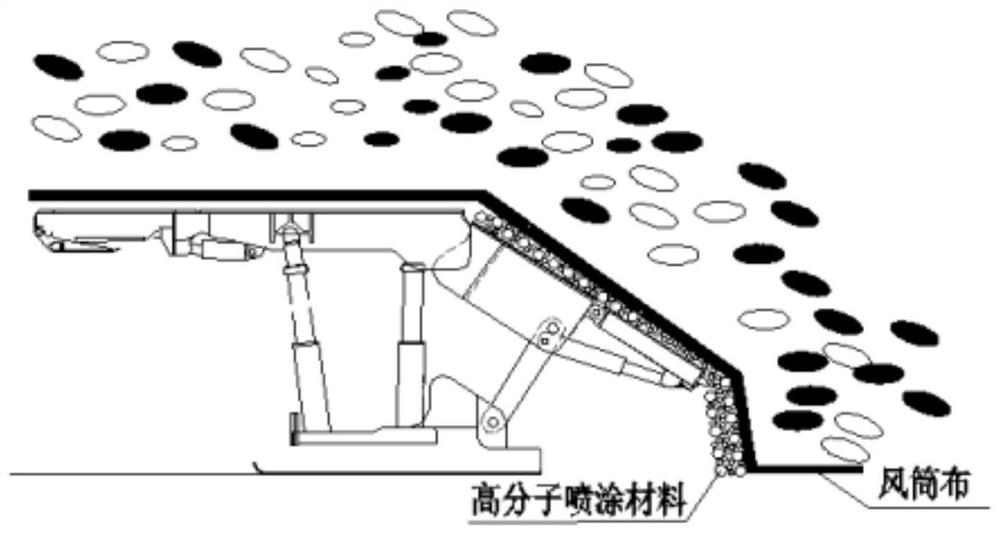

[0049] S1: Gas monitoring: Before laying the net rope, the key positions such as the inlet and return corners of the working face, and the crusher of the transportation lane are respectively installed to remove CO 2 , CO, O 2 Temperature and other probes, and use the bundle pipe buried in the corner of the return air to take gas samples for analysis every day, install a normally open water curtain at the two corners of the working face, and every 25 bracket nests on the working face, spray to the back of the frame Goaf, and keep it in the normal open state, disturb the gas and reduce the temperature of the goaf behind the rack;

[0050] Before partial ventilation of the working face, install a CO and a CO respectively at the front of the chassis 2 , O 2 、CH 4 Probes; install a CO at a position 3 meters outward from the large curve 2、 CO, CH 4 Probes; one O is insta...

Embodiment 2

[0068] A safety retraction method for joint mining of coal and oil shale, comprising the following steps:

[0069] S1: Gas monitoring: Before laying the net rope, the key positions such as the inlet and return corners of the working face, and the crusher of the transportation lane are respectively installed to remove CO 2 , CO, O 2 Temperature and other probes, and use the bundle pipe buried in the corner of the return air to take gas samples for analysis every day, install a normally open water curtain at the two corners of the working face, and every 30 bracket nests on the working face, spray to the back of the frame Goaf, and keep it in the normal open state, disturb the gas and reduce the temperature of the goaf behind the rack;

[0070] Before partial ventilation of the working face, install a CO and a CO respectively at the front of the chassis 2 , O 2 、CH 4 Probes; install a CO at a position 3 to 5 meters outward from the large curve 2、 CO, CH 4 Probes; one O is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com