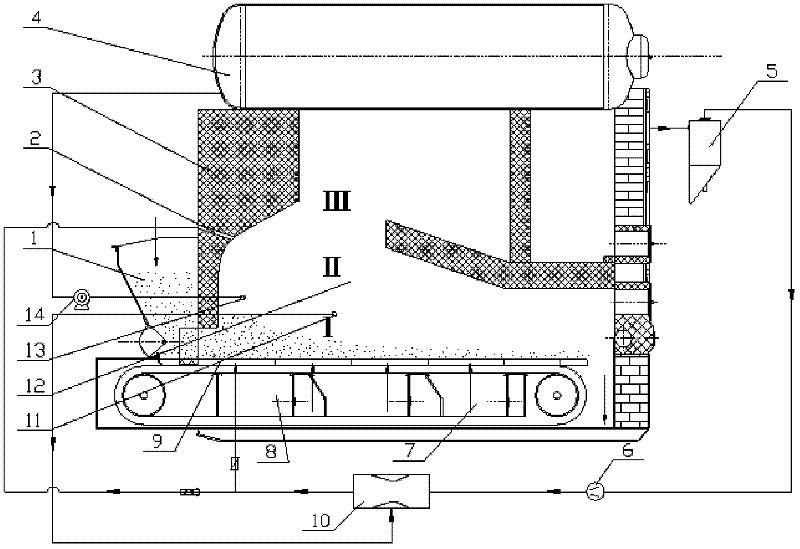

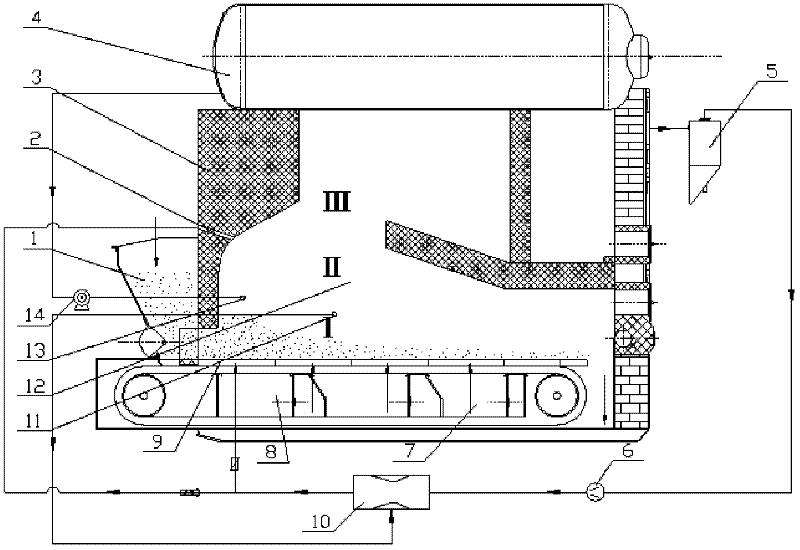

Low emission high efficiency grate-firing combustion device and method

A combustion method and combustion device technology, applied in the direction of combustion method, solid fuel combustion, combustion equipment, etc., can solve the problems of less reducing gas, affecting boiler output, construction difficulties, etc., and achieve the effect of improving combustion efficiency and combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A low-emission and high-efficiency layer combustion method. The pulverized coal and sulfur-fixing agent are fully mixed and sent into the combustion chamber. The pulverized coal is heated and injected with a small amount of water vapor. solution, producing reducing gas (NH i , HCN, CH i 、H 2 and CO, etc.), the resulting reducing gas and mixed small particles of semi-coke enter the reburning zone under the action of the injected medium-high temperature recirculation airflow, reducing the NOx generated by combustion in the main combustion zone, and the unburned particles are discharged in the combustion chamber The burning area continues to burn, and the tail gas generated after combustion is drawn out to form medium-temperature recirculating flue gas, which is mixed with high-temperature circulating flue gas drawn from the main combustion area to form medium-high temperature recirculating flue gas, which enters the combustion chamber for the above-mentioned burning use...

Embodiment 2

[0061] A low-emission and high-efficiency layer combustion method. The pulverized coal and sulfur-fixing agent are fully mixed and sent into the combustion chamber. The pulverized coal is heated and injected with a small amount of water vapor. solution, generating reducing gases (NHi, HCN, CH i 、H 2 and CO, etc.), the resulting reducing gas and mixed small particles of semi-coke enter the reburning zone under the action of the injected medium-high temperature recirculation airflow, reducing the NOx generated by combustion in the main combustion zone, and the unburned particles are discharged in the combustion chamber The combustion zone continues to burn, and the tail gas generated after combustion is drawn out to form medium-temperature recirculating flue gas after dust removal. The medium-temperature recirculating flue gas is mixed with the high-temperature circulating flue gas drawn from the main combustion area to form medium-high temperature recirculating flue gas and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com