Patents

Literature

32results about How to "Achieve pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

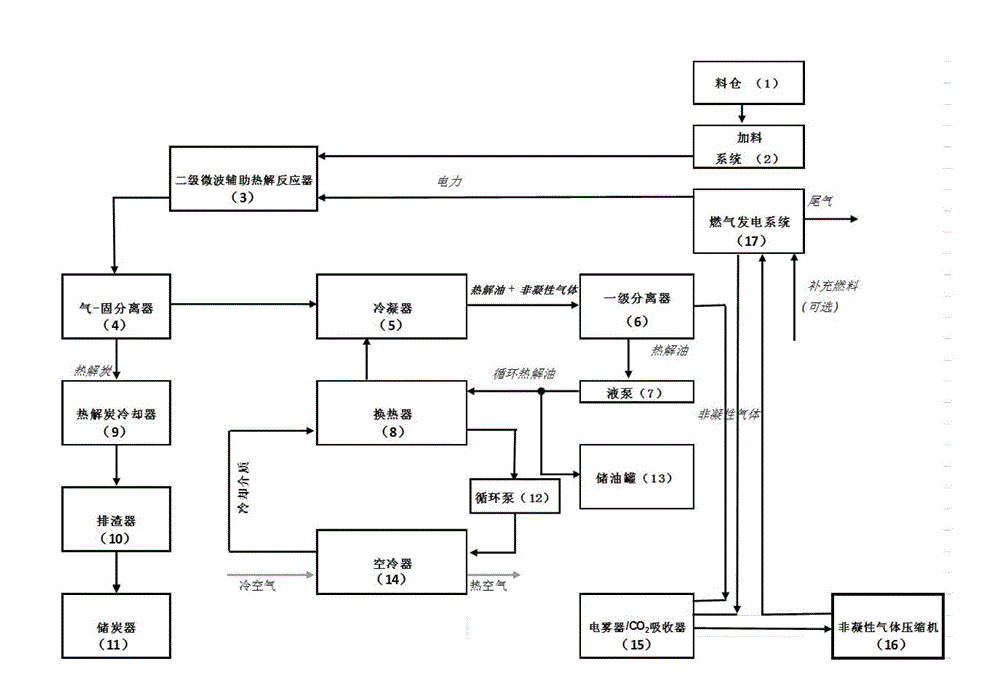

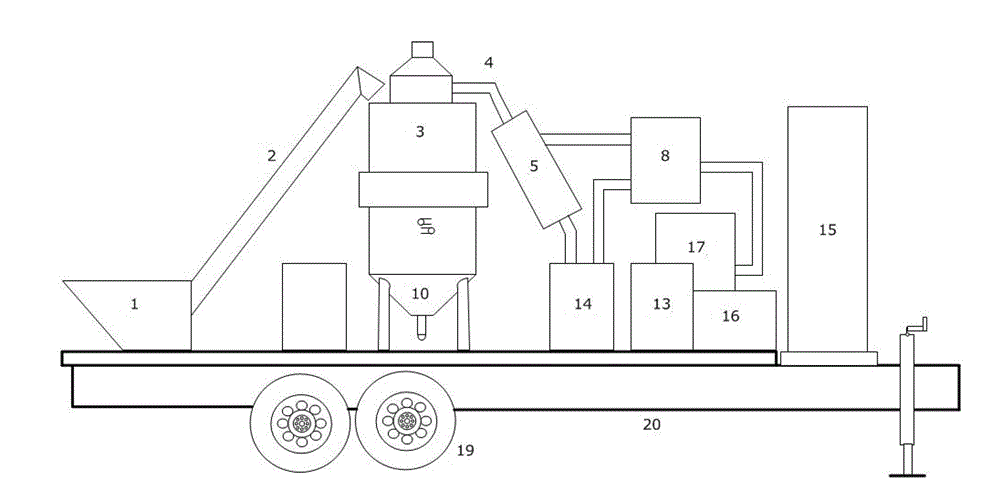

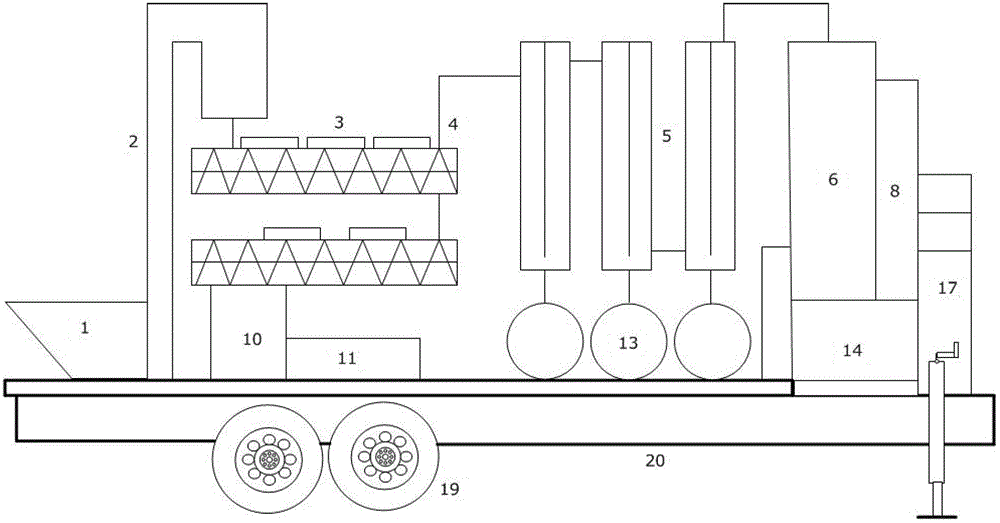

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device

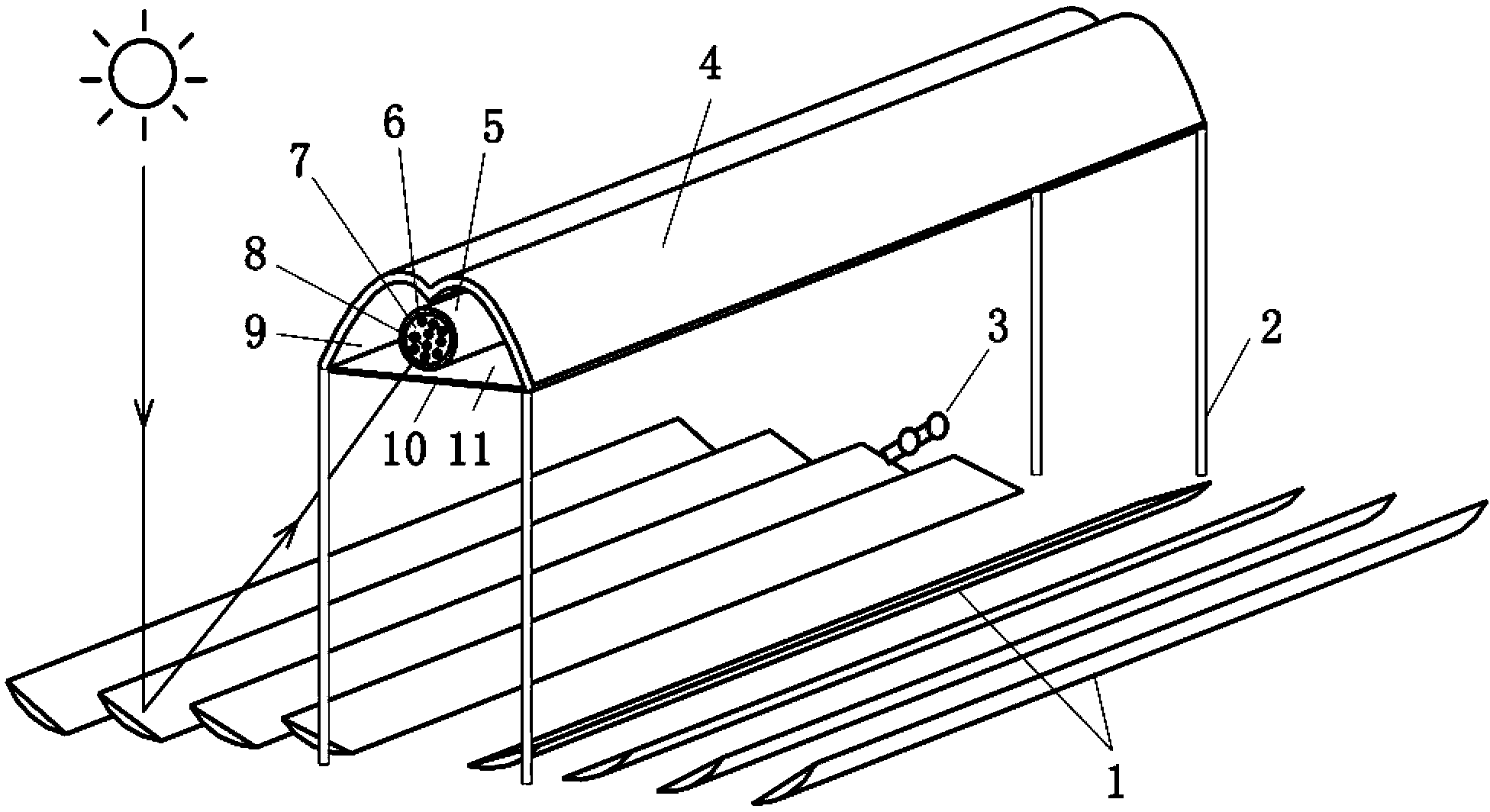

InactiveCN103383150ASimple structureManufacturing and running costs are lowSolar heating energySolar heat devicesSystem integrationEnergy transfer

A linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device comprises a linear Fresnel reflection condensing mirror array driven by a solar tracking device to real timely track the sun, and a thermal absorber matched with the condensing mirror array and independently arranged, wherein the thermal absorber is tubular, a selective absorption coating is coated on the surface of the outer wall, and a chemical reactant medium and a catalyst are filled in the tube; a solar energy light-focusing system formed by the Fresnel reflection condensing mirror array and the solar tracking device is adopted and is well matched with the hot grade of thermal chemical reaction of mid-and-low temperature fossil fuel, the structure is simple, the manufacturing and running cost is low and the wing resistance is good when the solar energy thermochemical utilization device is mounted close to the ground; with the chemical reactant medium and the catalyst in the thermal absorber, the solar energy thermochemical utilization device can serve as the thermochemical reaction place while absorbing the solar energy, so that the heat can be directly absorbed and utilized, and the system integration complexity and energy transfer loss can be effectively reduced; as the thermal absorber is independently arranged, the safety and the stability are higher during the heat absorption and reaction process.

Owner:XI AN JIAOTONG UNIV

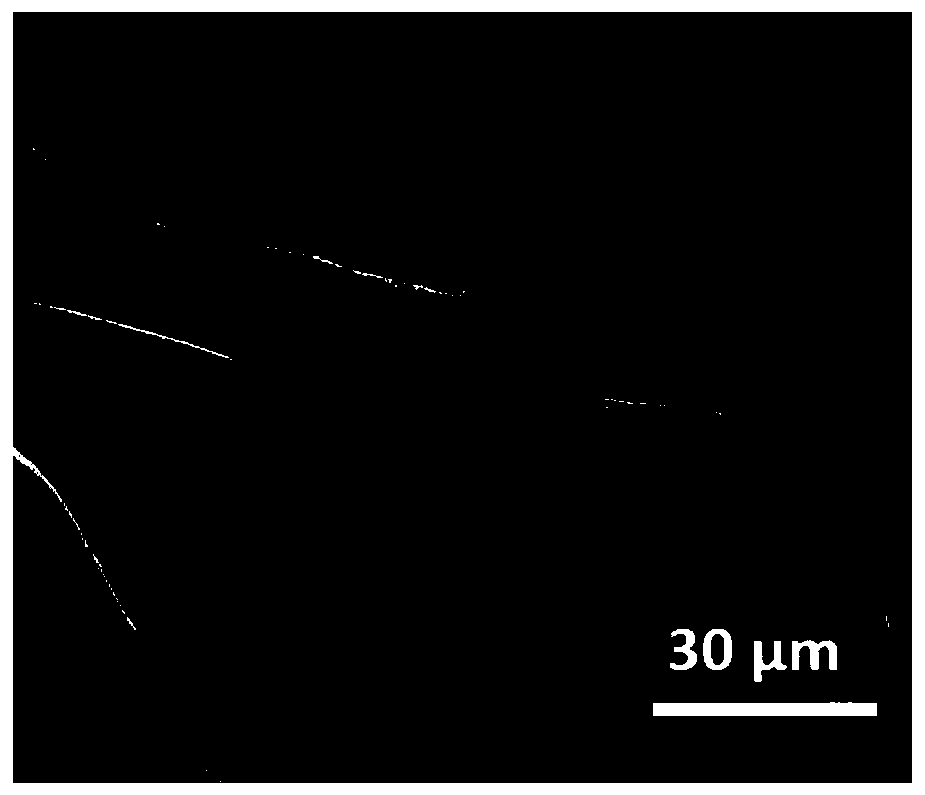

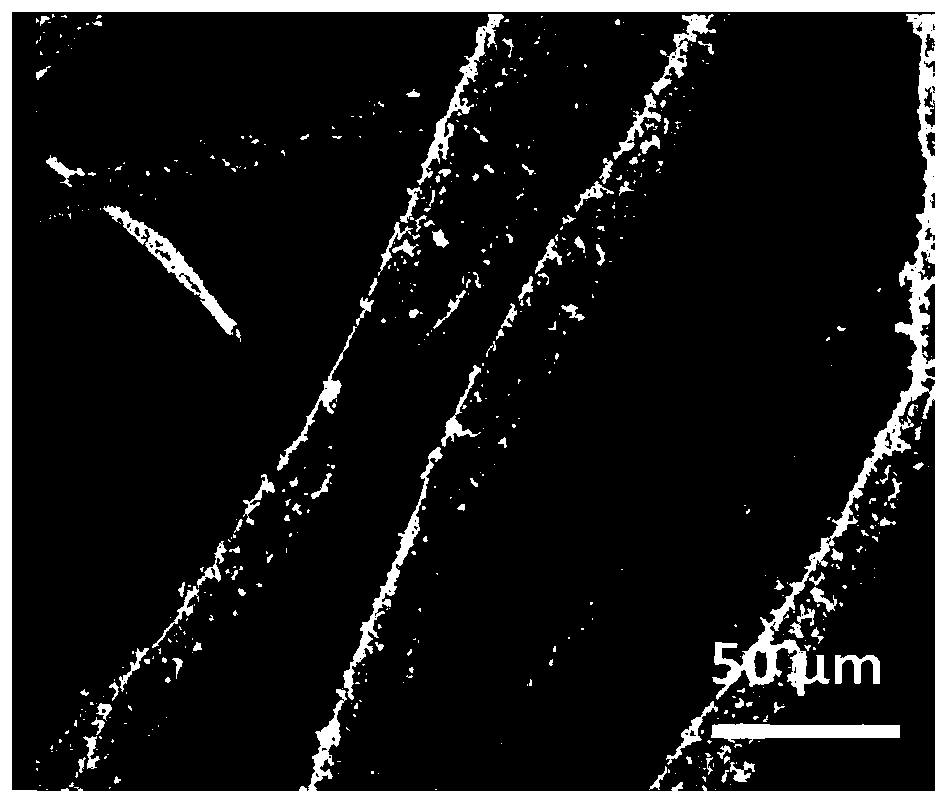

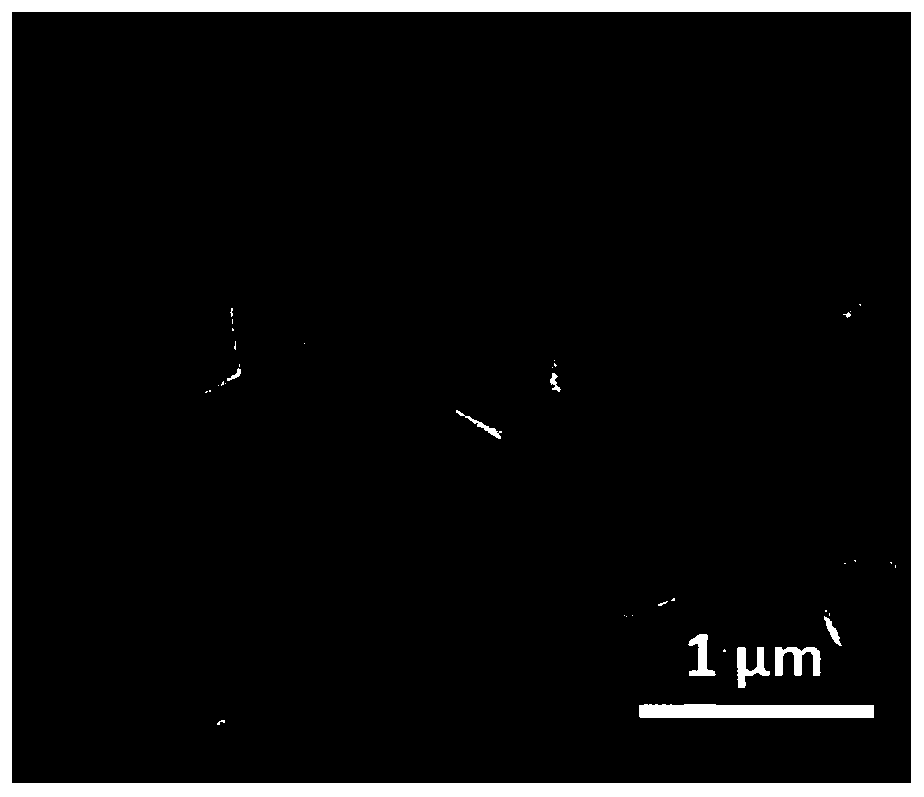

Hierarchical structure hollow CNTs/Co/C fiber wave-absorbing material and preparation method thereof

ActiveCN110938407ACoated evenlySolve reunionOther chemical processesCarbon nanotubesFiberPolymer science

The invention discloses a hierarchical structure hollow CNTs / Co / C fiber wave-absorbing material and a preparation method thereof, and belongs to the technical field of radar wave-absorbing materials.The method takes cotton fibers and Co-containing zeolite imidazole structure metal organic framework ZIF-67 nanoparticles as raw materials. ZIF-67 nanoparticles with a regular dodecahedron microstructure grow and coat the surfaces of the cotton fibers in situ, cotton fibers are carbonized into hollow carbon fibers through a high-temperature carbonization process in a reductive H2 / Ar mixed atmosphere, the pyrolysis of the ZIF-67 metal organic framework nanoparticles and the catalytic growth of the carbon nanotubes are realized so that the hollow CNTs / Co / C fiber wave-absorbing material with themicron carbon fiber-nanotube hierarchical structure is obtained, and under the conditions that the density is 0.02 g / cm<3> and the thickness is 2 mm, the maximum absorption intensity of electromagnetic waves at 14 GHz reaches -59.5 dB, and the effective absorption frequency band width reaches 6.2 GHz (11.8-18 GHz). The technical problems that a traditional wave-absorbing material is high in density, low in absorption strength and narrow in frequency band are solved.

Owner:HARBIN INST OF TECH

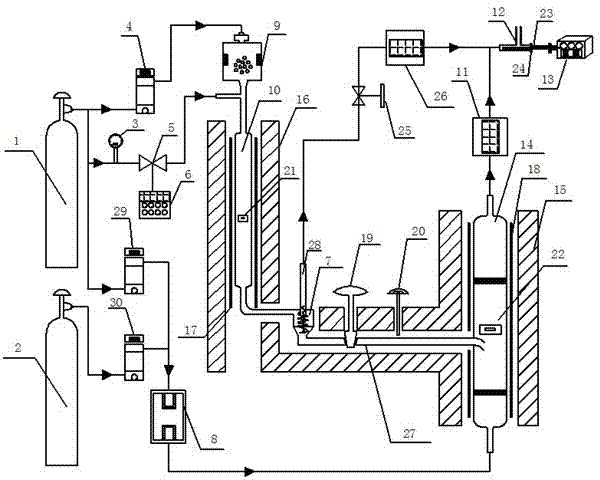

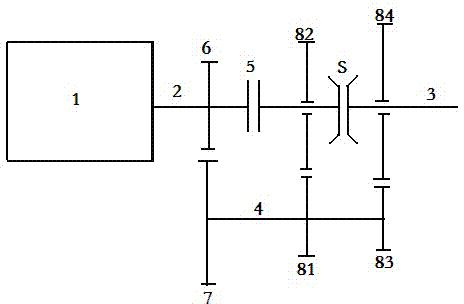

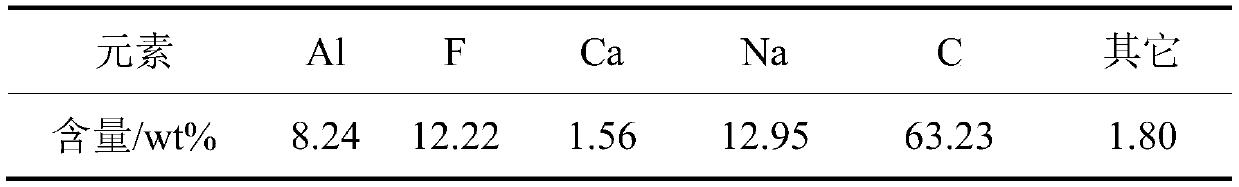

Micro double-bed solid fuel decoupling combustion reaction dynamic analyzer

ActiveCN103543237AAchieve pyrolysisRealize the coke combustion processChemical analysis using combustionAir atmosphereGas detector

The invention provides a micro double-bed solid fuel decoupling combustion reaction dynamic analyzer which comprises a fuel pyrolytic reaction generation device, a residual coke combustion reaction generation device, a double-bed high-temperature coupling device, a gas path device and an analysis test device, wherein solid fuel is firstly pyrolyzed under an inert atmosphere in a micro gas flow bed; then residual cokes enter the micro gas flow bed for combustion test under an air atmosphere; a quick gas detector is used for judging a reaction mechanism by measuring a generation sequence and a generation quantity characteristic of gas components in a fuel pyrolysis process and a coke combustion process, so that reaction dynamic parameters can be calculated. According to the micro double-bed solid fuel decoupling combustion reaction dynamic analyzer, the combustion dynamic parameters of the solid fuel can be tested through direct decoupling combustion through independent and quick switching of the atmospheres and the temperature; the pyrolyzed residual cokes are directly subjected to the combustion test without a cooling process; the temperature rising rates of the gas flow bed and a fluidized bed are high, so that a combustion condition in an actual boiler can be well simulated; the measured reaction dynamic parameters are close to intrinsic reaction dynamic parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

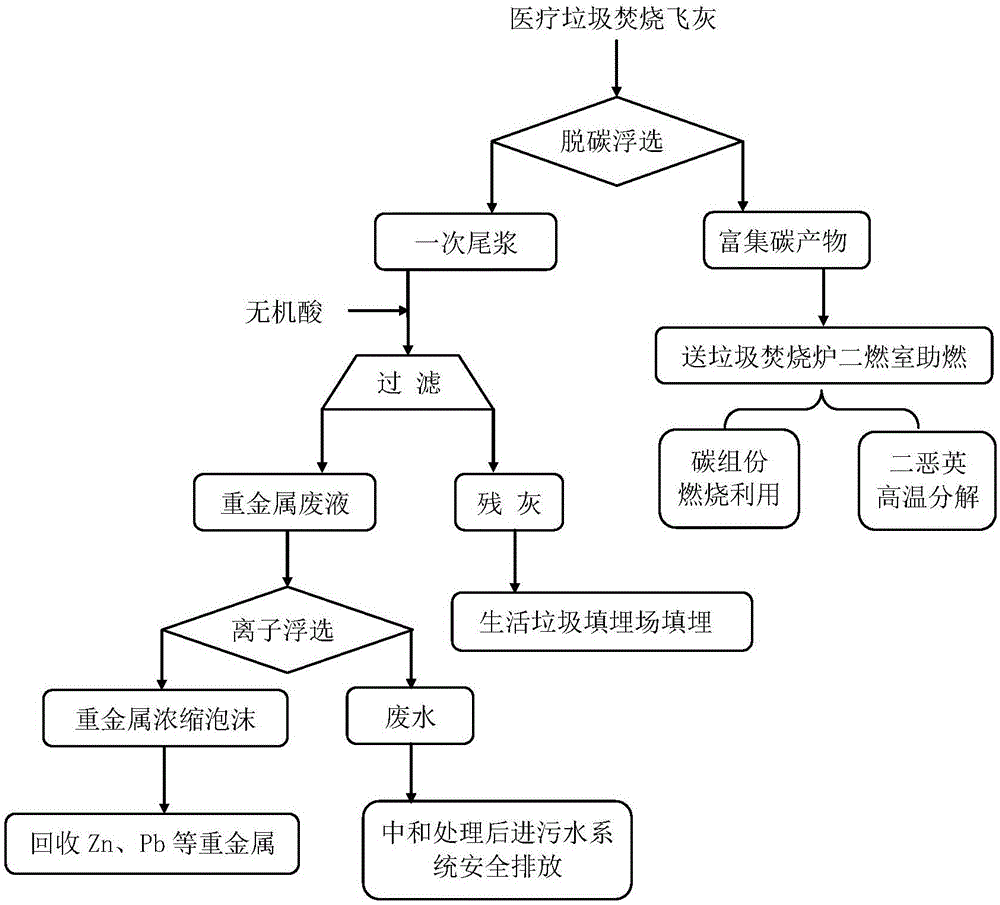

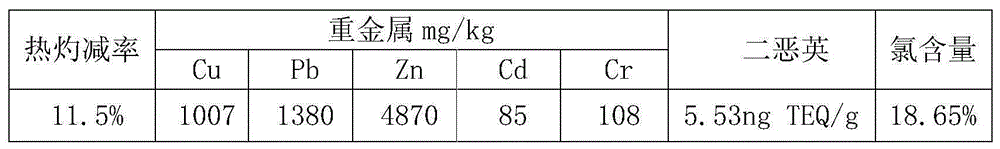

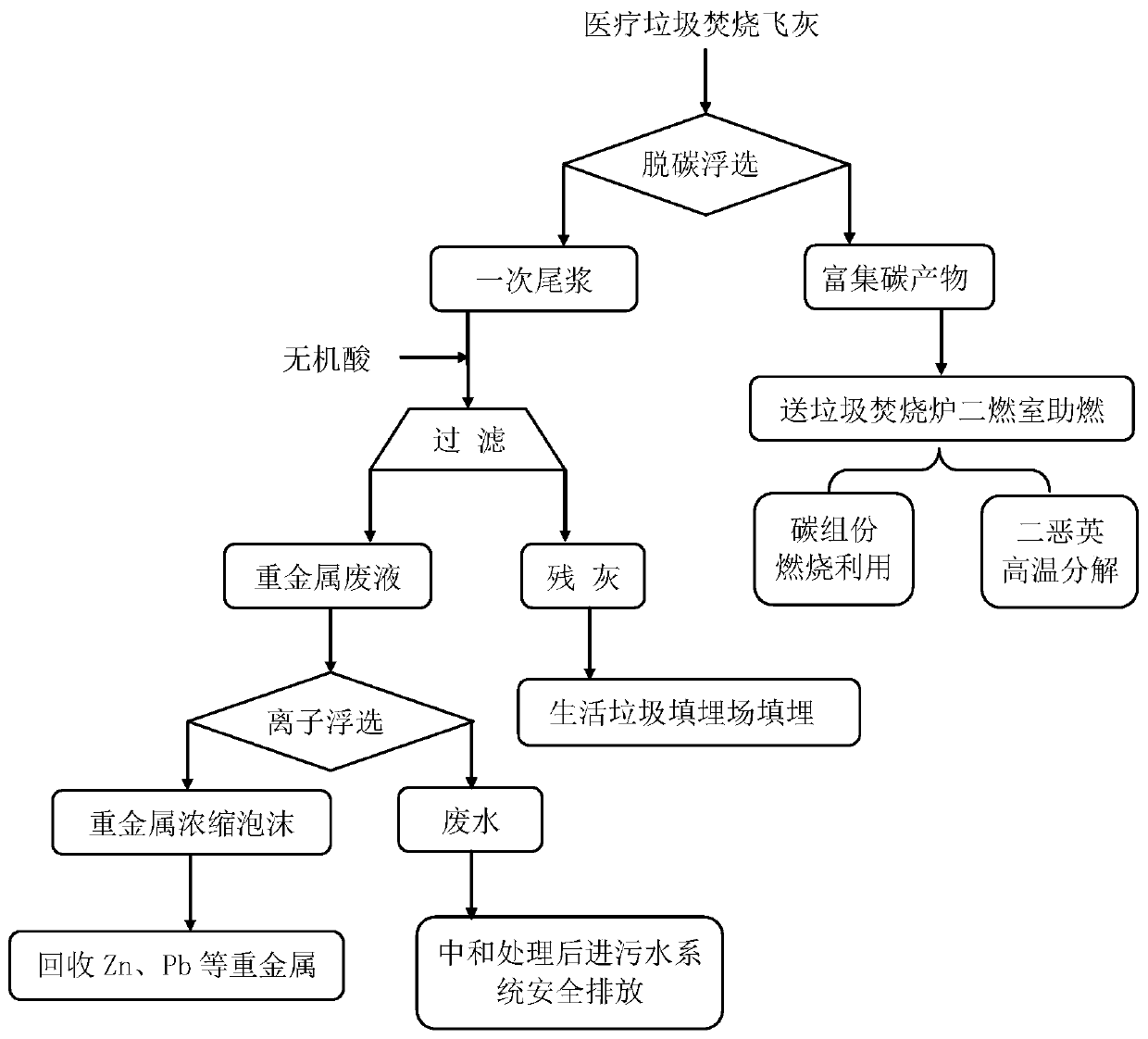

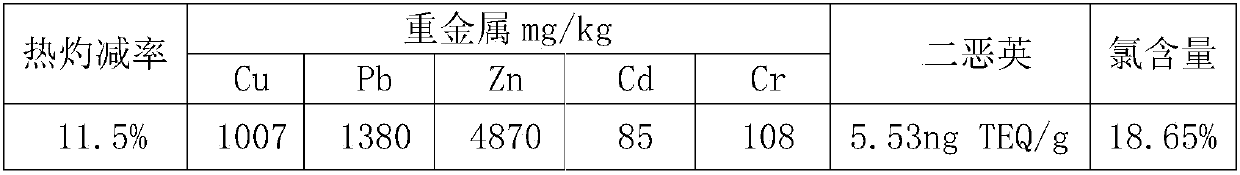

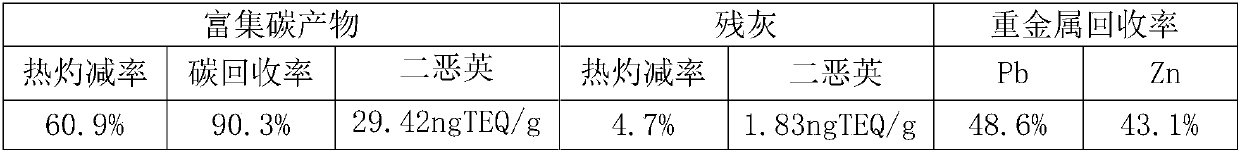

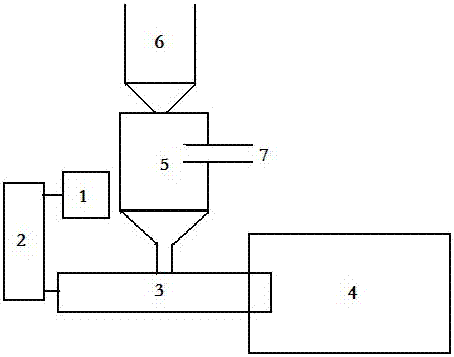

Treatment method for two-step flotation of medical waste incineration fly ash

ActiveCN105149101AReduce secondary synthesisRealize the utilization of fuelFlotationCombustion chamberMunicipal solid waste landfill

The invention discloses a treatment method for two-step flotation of medical waste incineration fly ash. The method includes the following steps that (1) decarbonization flotation is conducted, the two products of enriched carbon and primary tail pulp are obtained, and the enriched carbon product is fed into a secondary combustion chamber of a waste incinerator for helping to combust; (2) acid leaching and filtering are carried out, inorganic acid is added into the primary tail pulp which is obtained in the first step to be filtered after acid leaching is completed, and the two products of residual ash and heavy metal waste liquor are obtained; the residual ash is directly conveyed to a municipal solid waste landfill to be subjected to secure landfill disposal or reuse; (3) ion flotation is performed, flotation reagents are added into the heavy metal waste liquor which is obtained in the second step for ion flotation, and the two products of heavy metal concentration foam and waste water are obtained; the heavy metal concentration foam is fed into a smelting plant to recycle heavy metal Pb and Zn, and after reaching the standard through neutralizing treatment, the waste water is discharged into a sewage system. The treatment method has the advantages of being easy to operate, low in cost, good in treatment effect, free of secondary pollution and the like.

Owner:TIANJIN CHENGJIAN UNIV

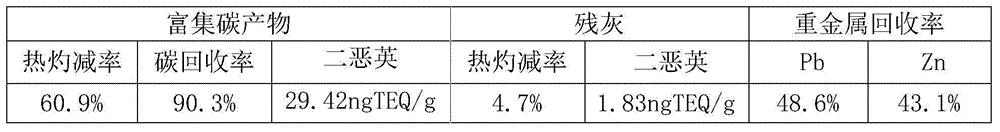

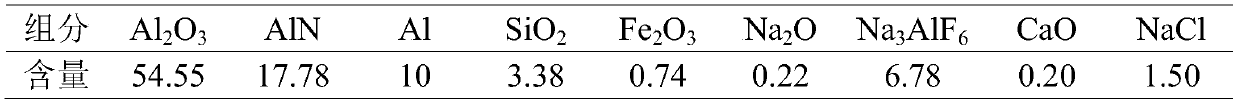

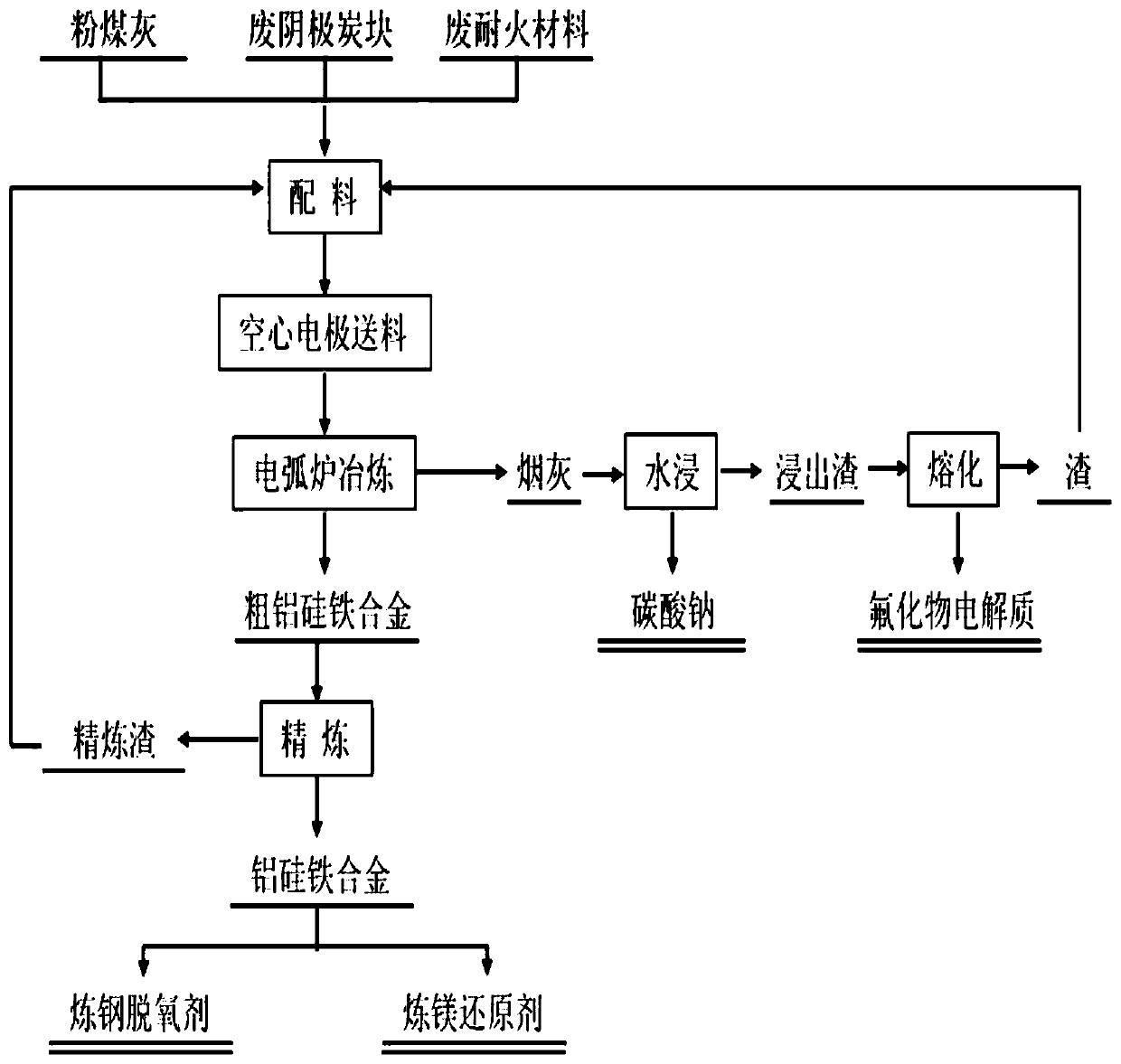

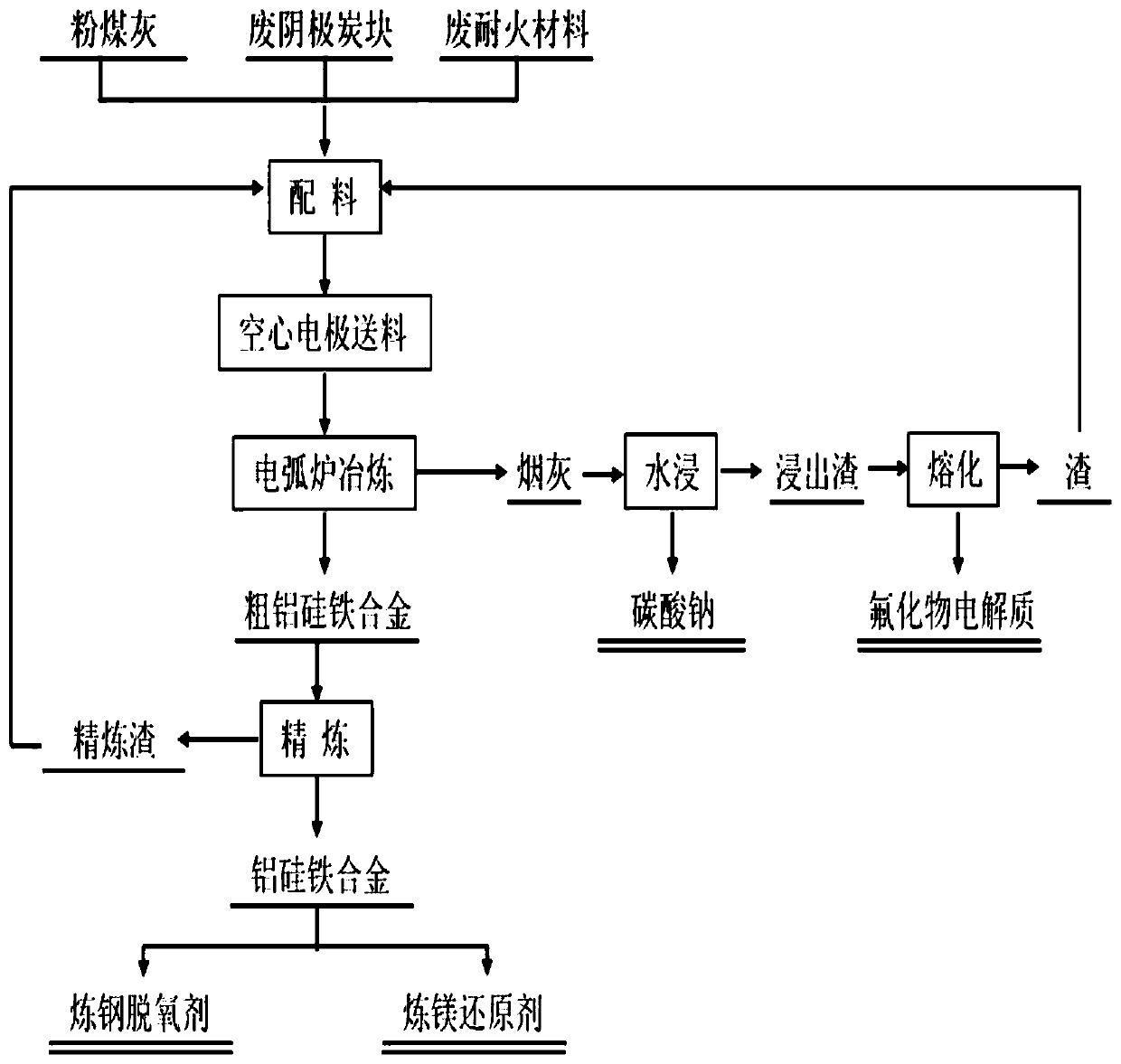

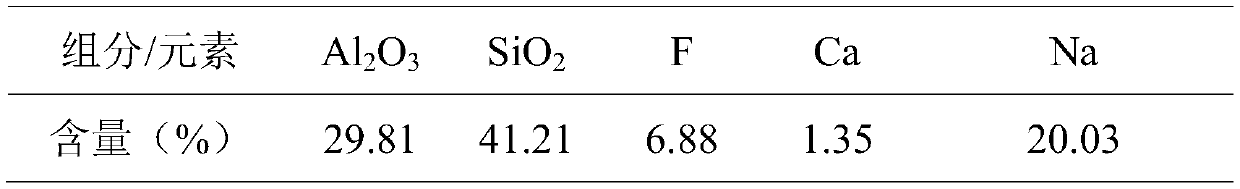

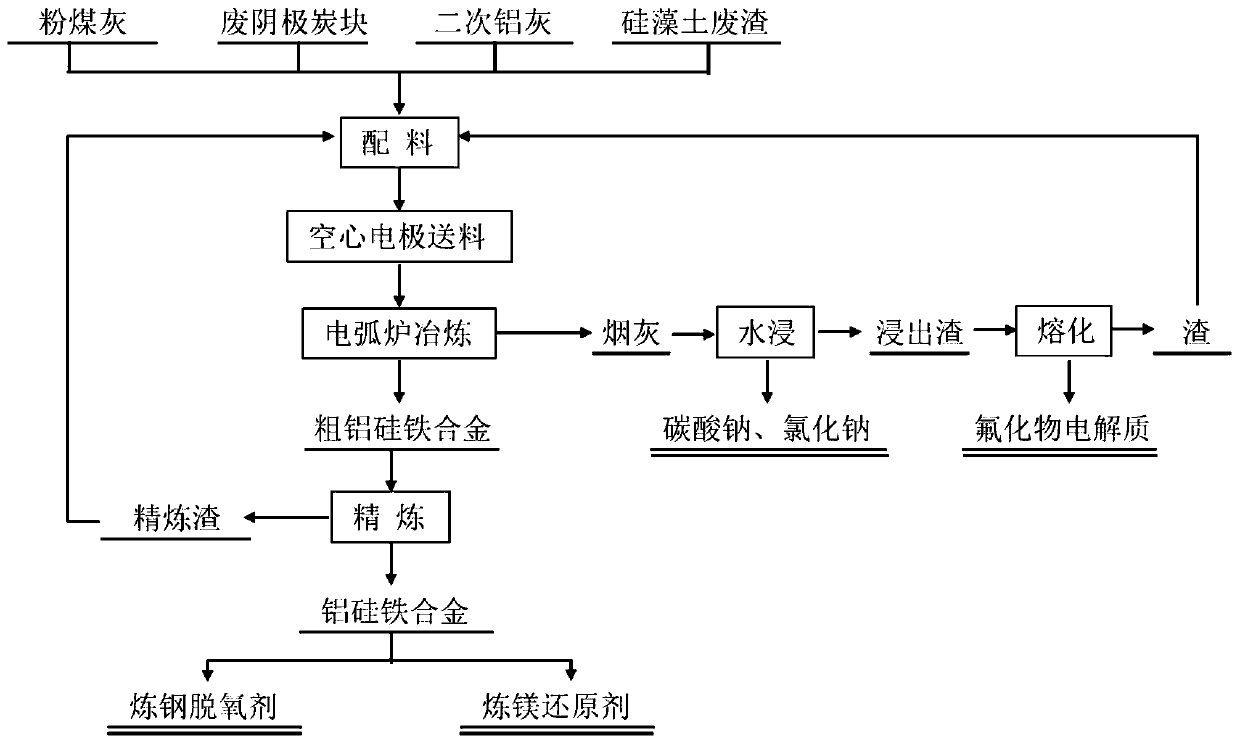

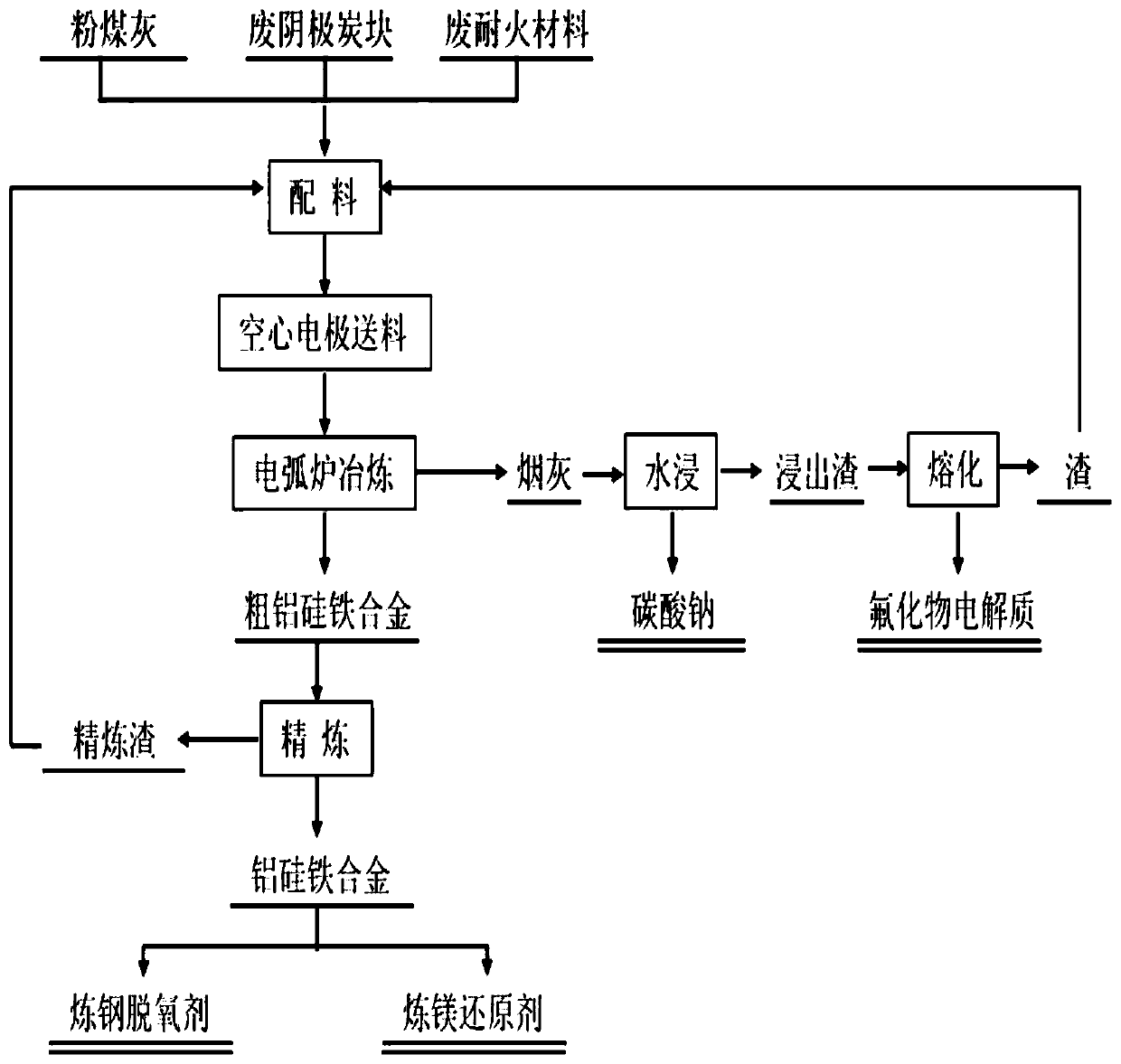

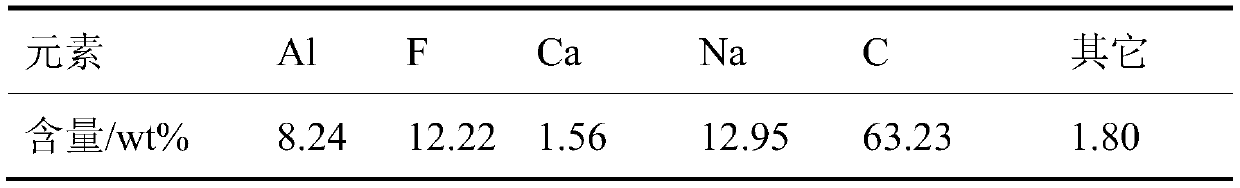

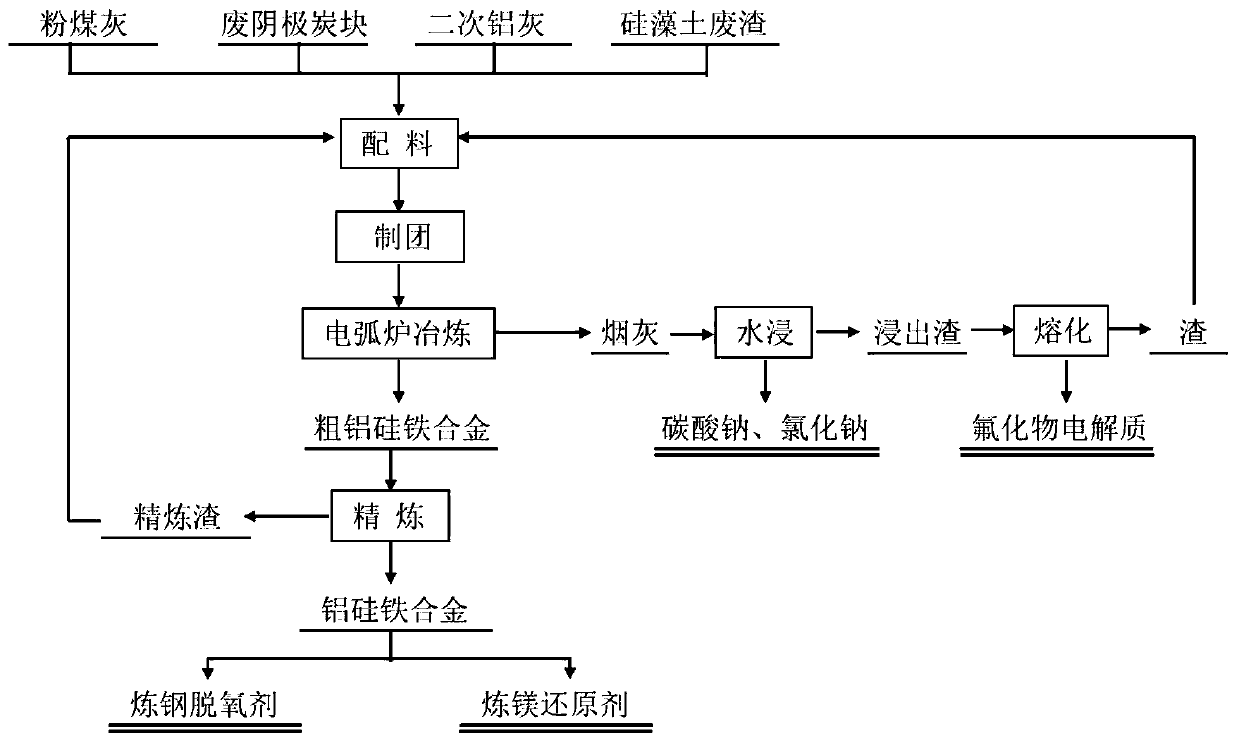

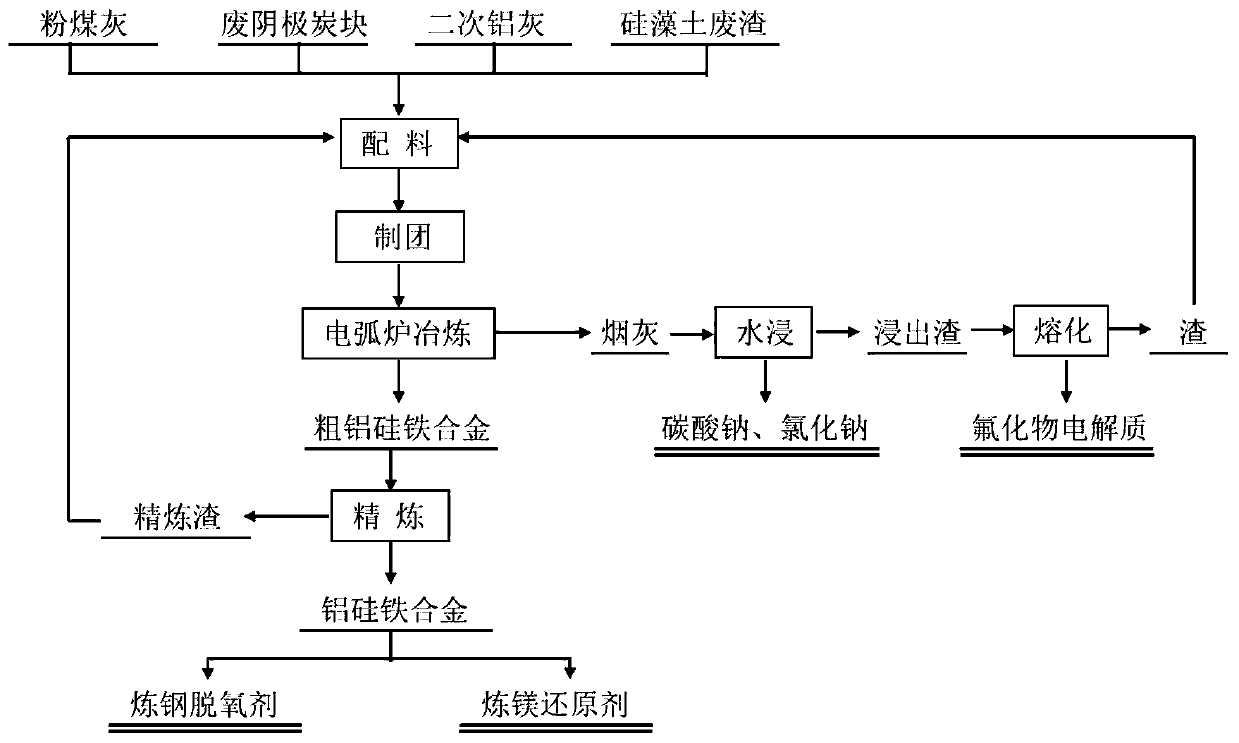

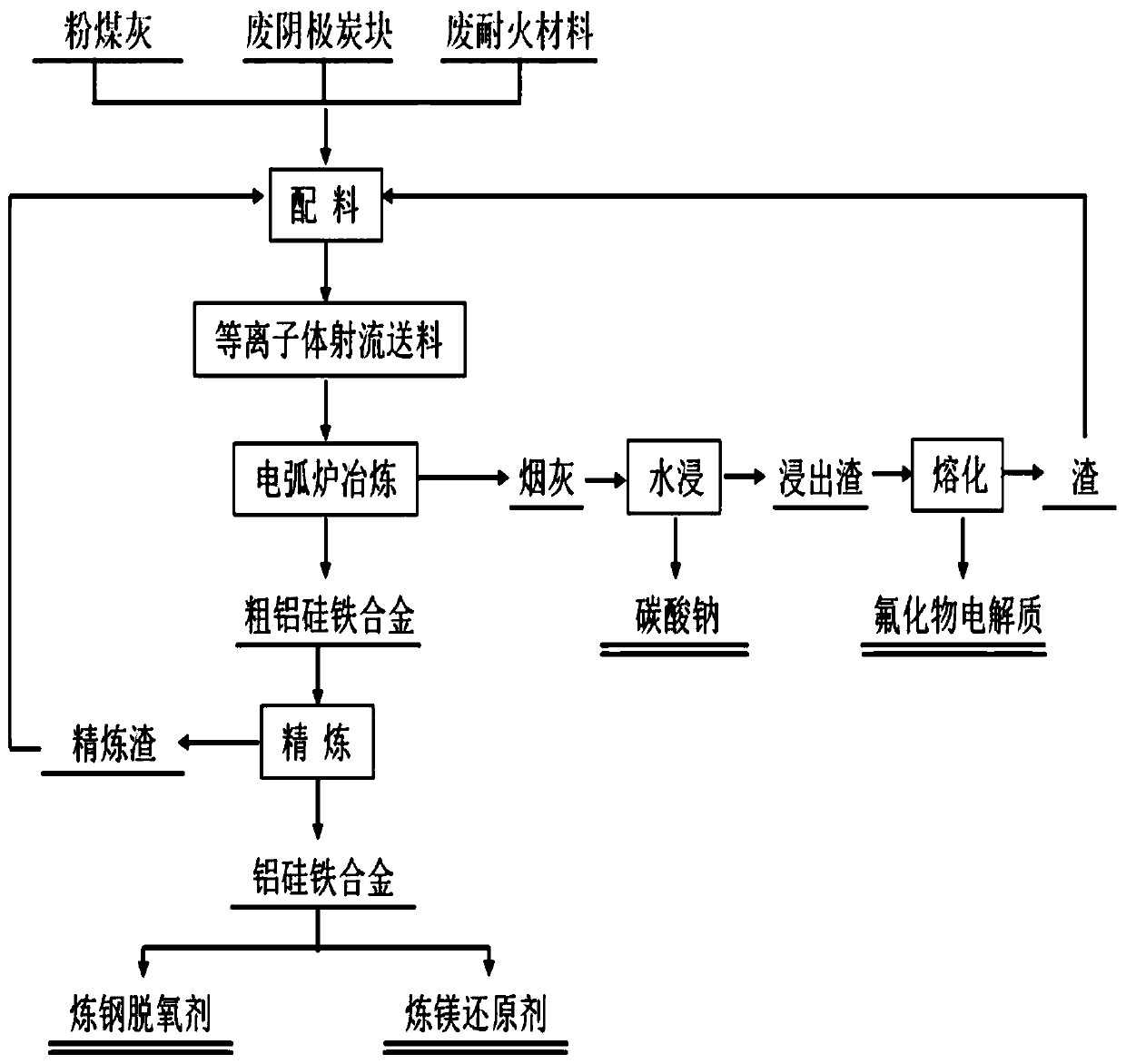

Method for preparing silicon-iron alloy by using aluminum ash as raw material and feeding material by hollow electrode

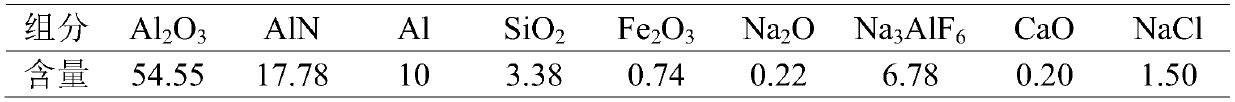

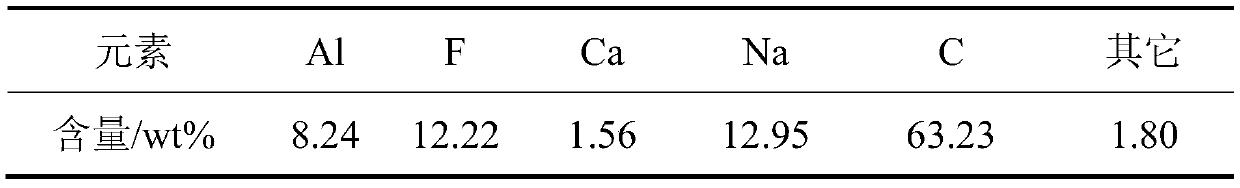

ActiveCN110129565AAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementDecompositionKeatite

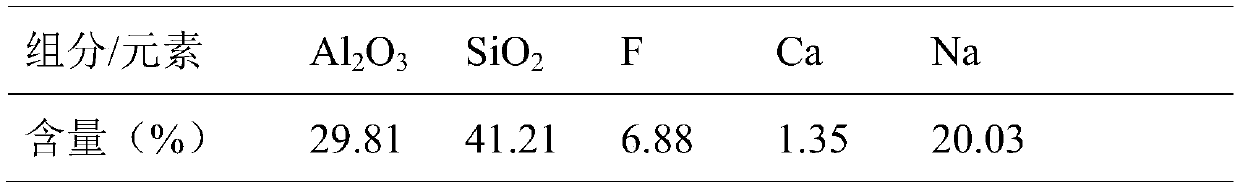

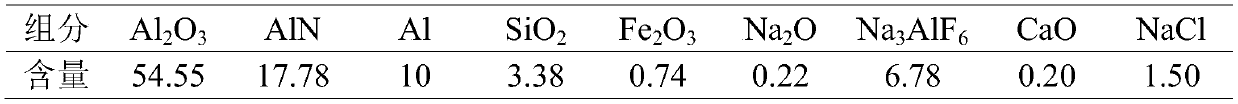

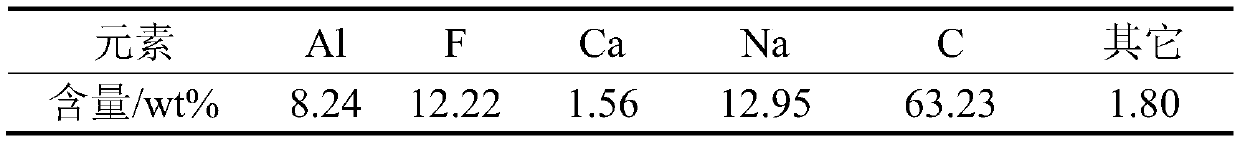

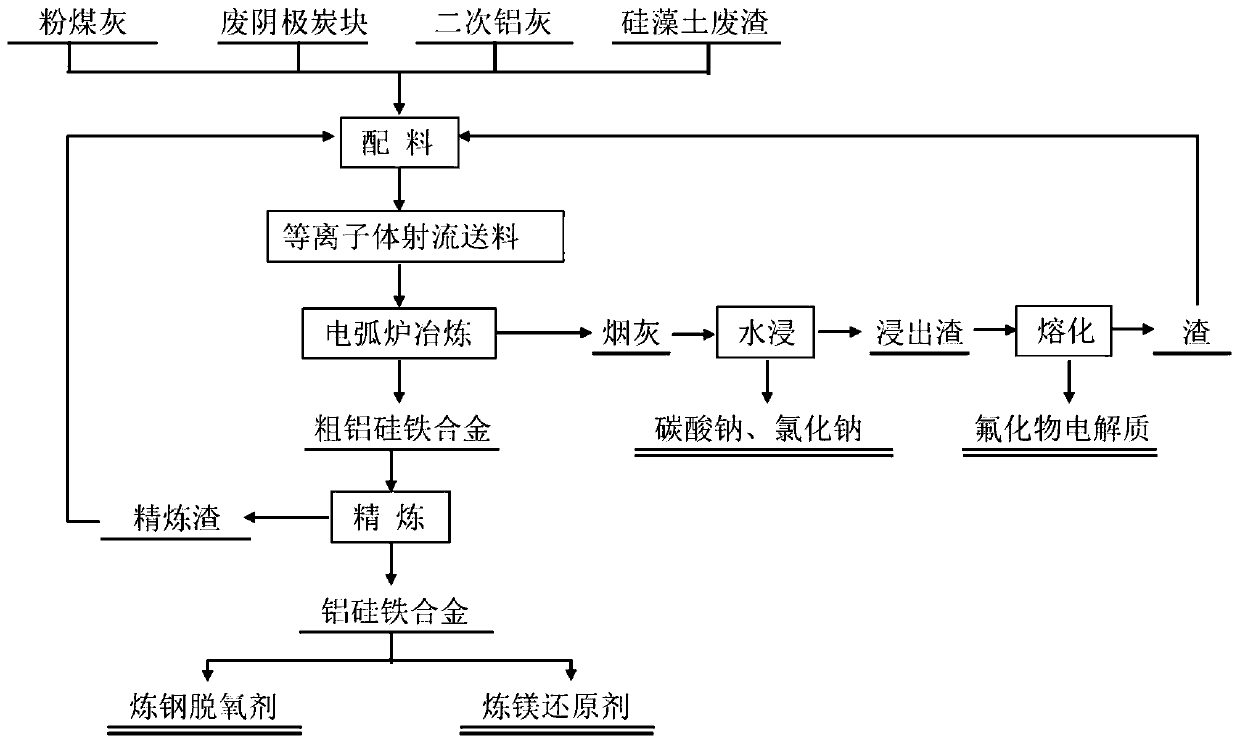

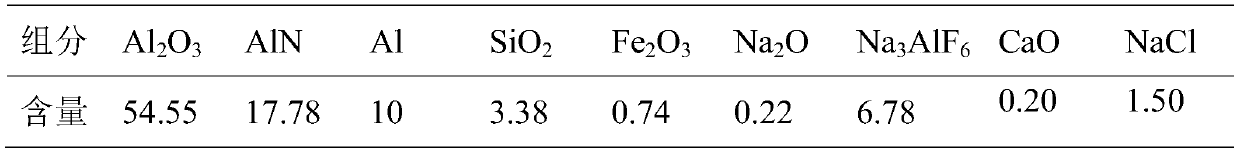

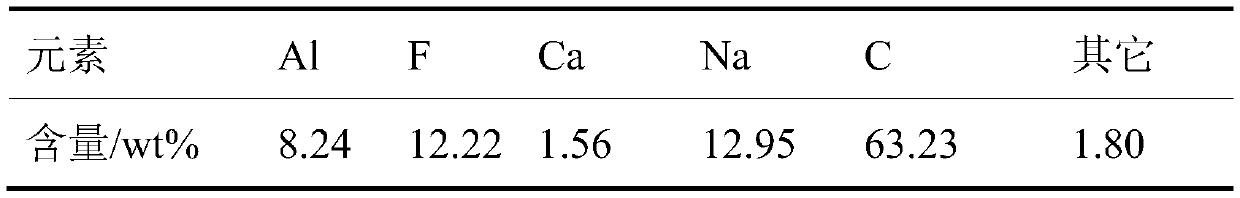

The invention provides a method for preparing a silicon-iron alloy by using aluminum ash as a raw material and feeding material by a hollow electrode. According to the method, secondary aluminum ash is used as a raw material, an aluminum electrolysis cell waste cathode carbon block serves as a reducing agent, fly ash serves as an additive to adjust the content of aluminum in the raw materials, diatomaceous earth waste residues serve as additives to adjust the content of silicon in the raw materials, and high-temperature reduction in an electric arc furnace takes aluminum oxide and silicon oxide as main materials so as to prepare a certain-component aluminum-silicon-iron alloy; the hollow electrode is used for conveying powdery materials, so that the smelting process of the whole electric arc furnace can be enhanced, reduction of oxides and volatilization of fluoride are promoted, particularly, decomposition of the toxic substance aluminum nitride and the cyanide is accelerated, the production efficiency is improved, the production cost is reduced, and comprehensive utilization of various dangerous waste and solid waste is realized in the same process.

Owner:NORTHEASTERN UNIV

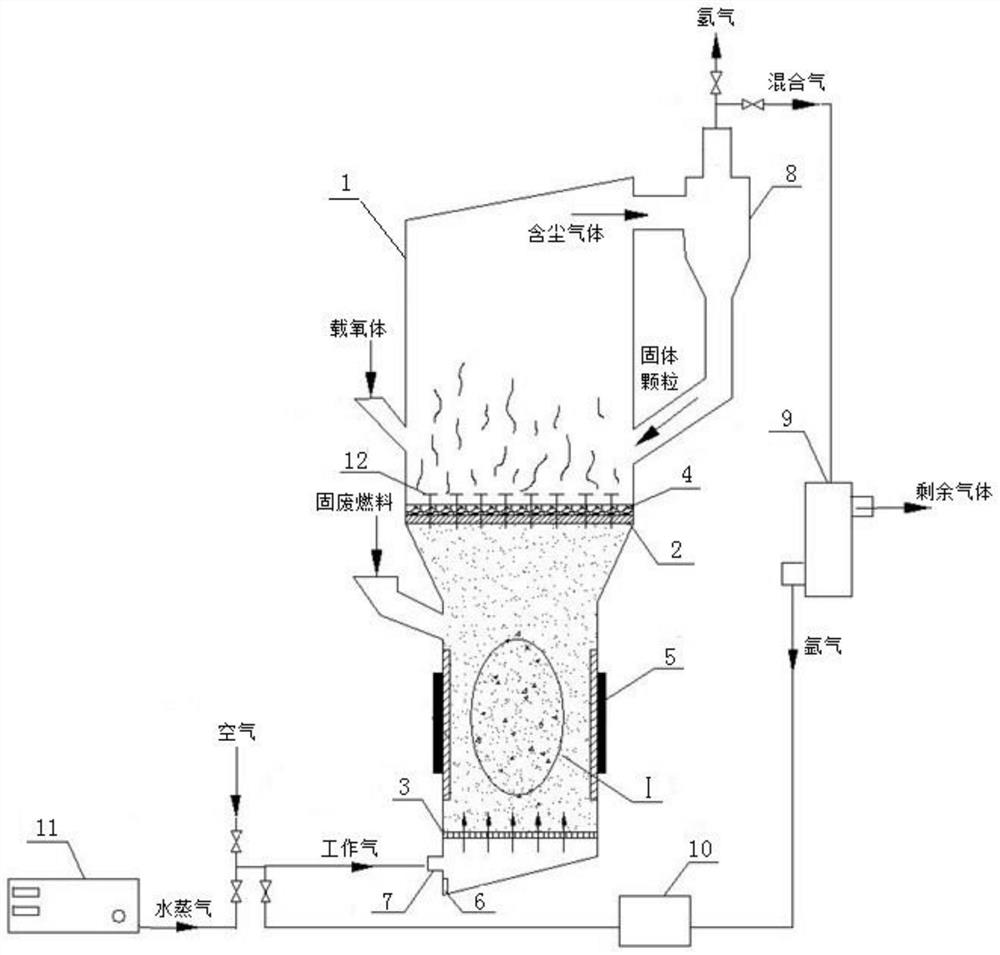

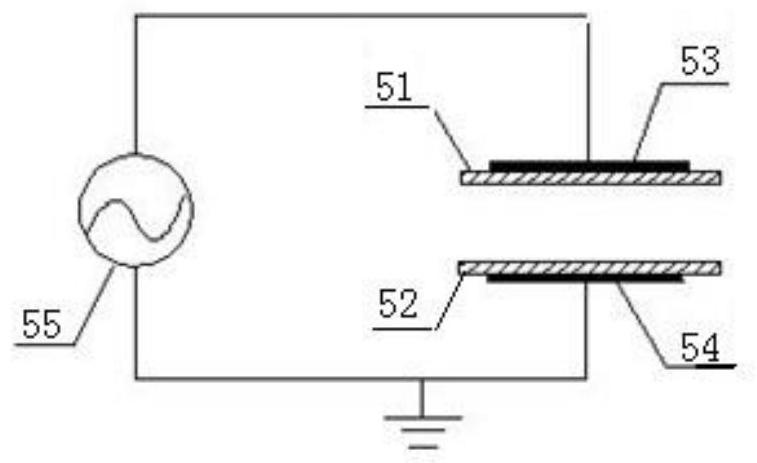

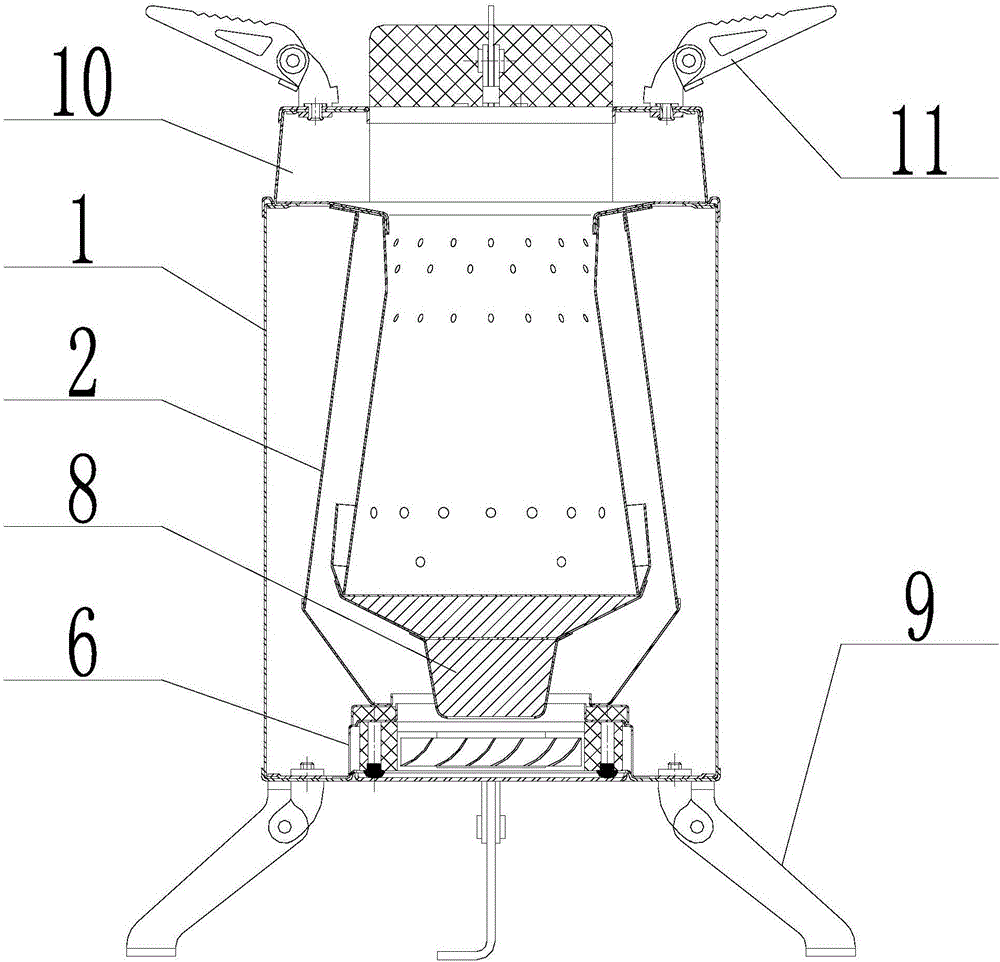

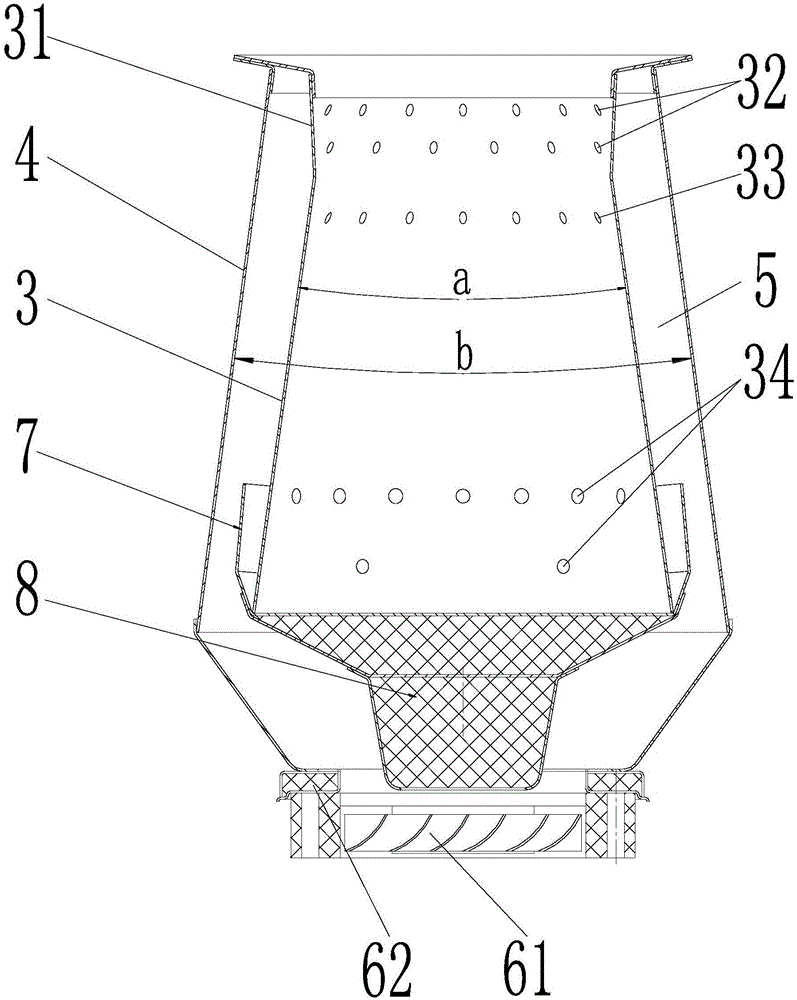

Double-tray chemical-looping hydrogen production device and method for treating sludge biomass solid waste

ActiveCN113401869AAvoid pollutionImprove reaction efficiencyGasification processes detailsHydrogen productionSludgePlasma technology

The invention relates to a double-tray chemical looping hydrogen production device and method for treating sludge biomass solid waste. The device comprises a tower body, an upper-layer tower plate, a lower-layer tower plate, a low-temperature plasma generator, a cyclone separator and a gas separator, the interior of the tower body is divided into an upper-layer chemical-looping hydrogen production reaction zone and a lower-layer low-temperature plasma reaction zone, and an oxygen carrier is laid on an upper-layer tower plate; a solid waste fuel inlet is formed in the upper part of the low-temperature plasma reaction area; and a working gas inlet is formed in one side of an air inlet and ash discharge chamber under the lower-layer tower plate. Based on the principle of reduction, harmlessness and recycling in the solid waste treatment process of sludge, biomass and the like, solid waste fuel is pyrolyzed in combination with a low-temperature plasma technology, and the solid waste fuel and the oxygen carrier are arranged in a layered manner by arranging double trays in the same tower body, so that the influence of ash content on the activity of the oxygen carrier is avoided, and a new thought is opened up for efficient conversion of high-ash biomass solid wastes.

Owner:UNIV OF SCI & TECH LIAONING

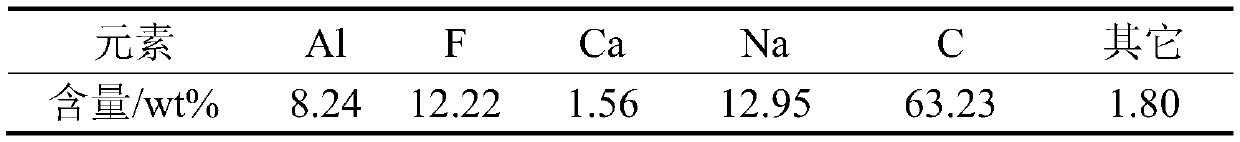

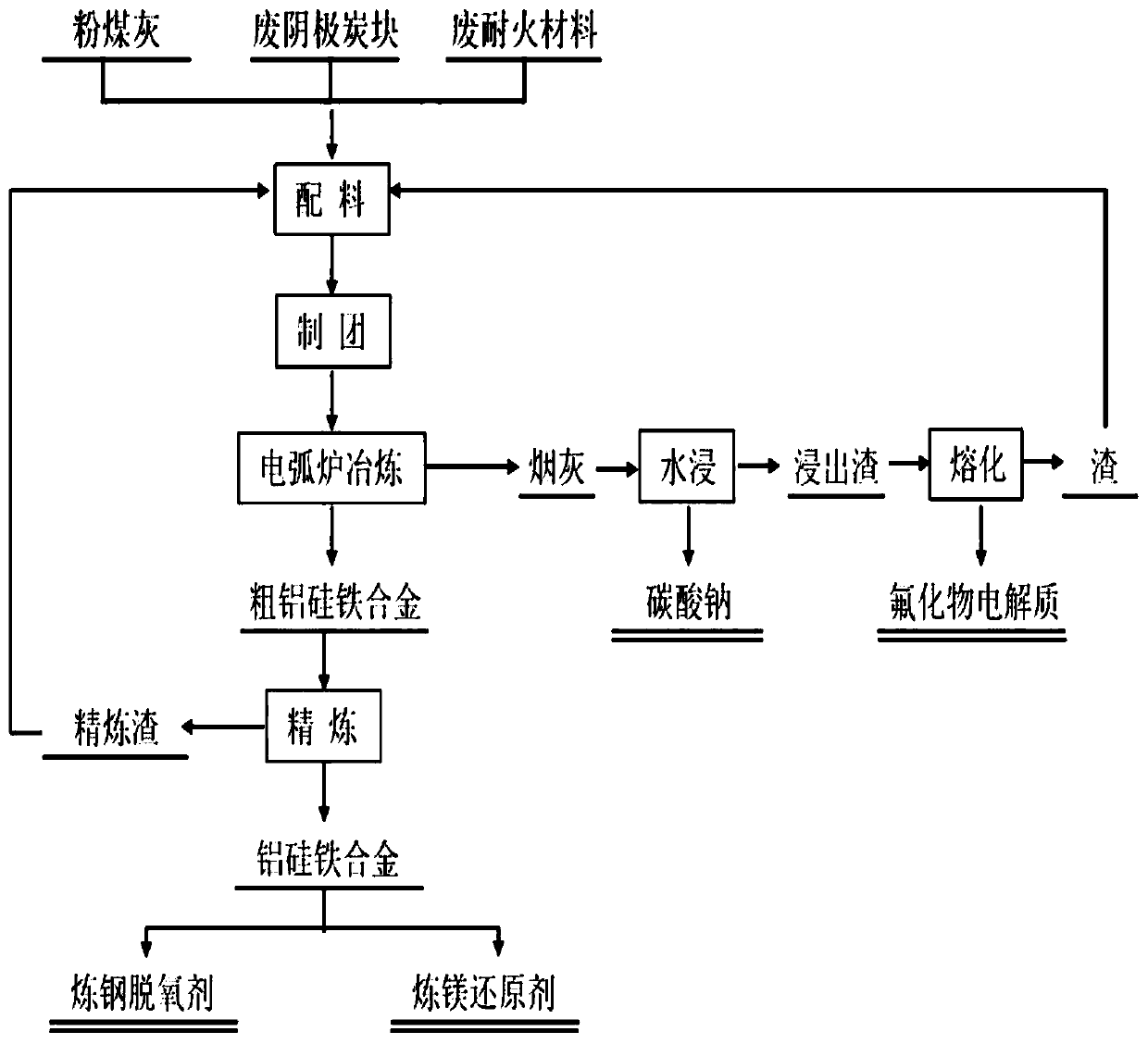

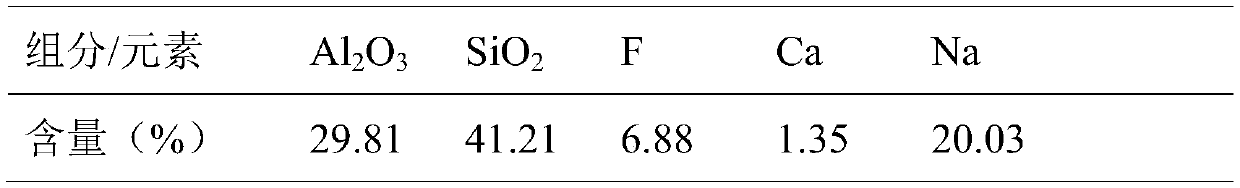

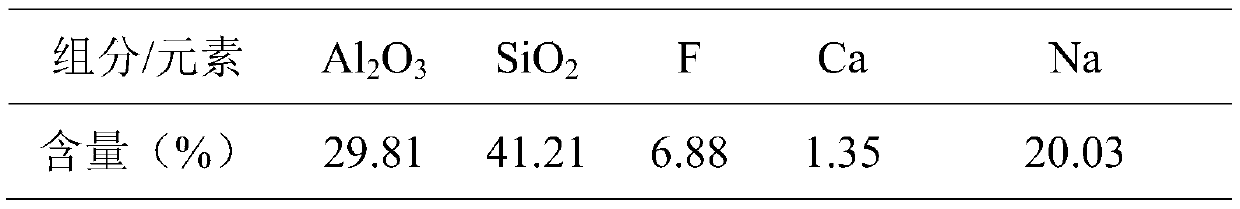

Method for preparing aluminum silicon iron alloy through hollow electrode feeding by using waste refractory material as raw material

ActiveCN110016565ARealize high temperature volatile separationAchieve pyrolysisProcess efficiency improvementGas emission reductionElectric arc furnaceSilicon oxide

The invention provides a method for preparing an aluminum silicon iron alloy through hollow electrode feeding by using a waste refractory material as a raw material. The waste refractory material is used as the raw material, an aluminum cell waste cathode carbon block is used as a reducing agent, pulverized fuel ash is used as an additive to adjust the aluminum content in the raw material, kieselguhr waste residues are used as an additive to adjust the silicon content in the raw material, and high temperature reduction is carried out on materials with aluminum oxide and silicon oxide as main in an electric-arc furnace to prepare the certain-component aluminum silicon iron alloy; and a hollow electrode is used for transporting powder materials, the entire electric-arc furnace smelting process can be strengthened, reduction of oxide and volatilization of fluoride are promoted, the decomposition of toxic substances cyanide and volatilization and recovery of the fluoride, chloride and alkali metals in the materials are especially accelerated, the production efficiency is improved, the production cost is reduced, and comprehensive utilization of a variety of hazardous waste and solid waste in the same process is achieved.

Owner:NORTHEASTERN UNIV

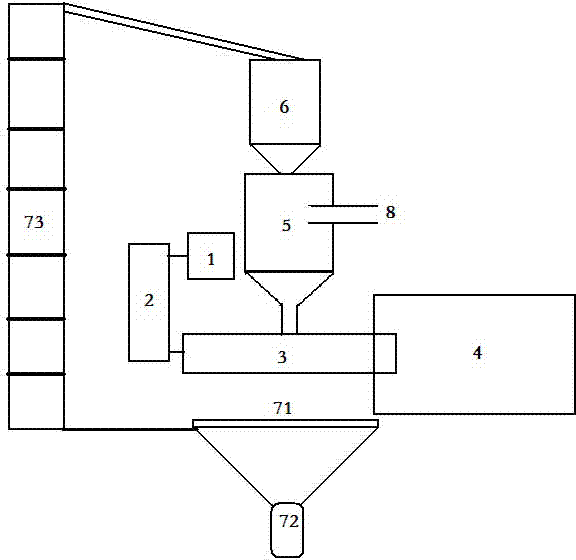

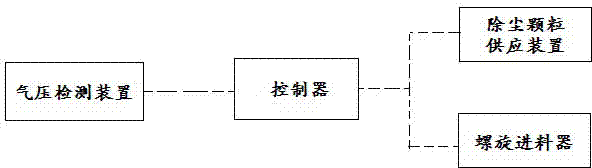

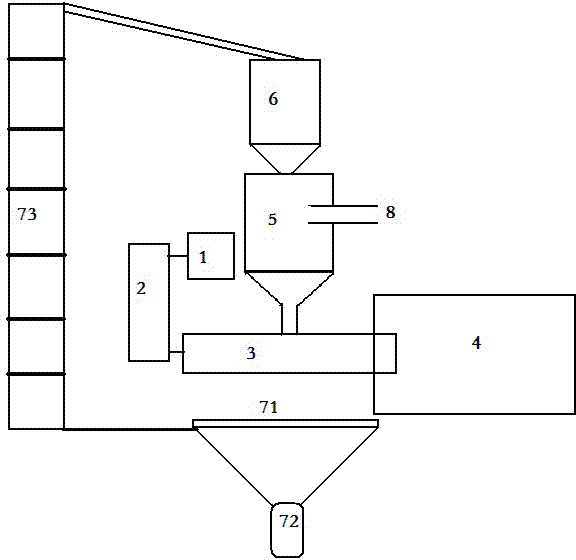

Coal pyrolysis apparatus

InactiveCN104726117AAchieve pyrolysisAchieve purificationSpecial form destructive distillationProcess engineeringCoal pyrolysis

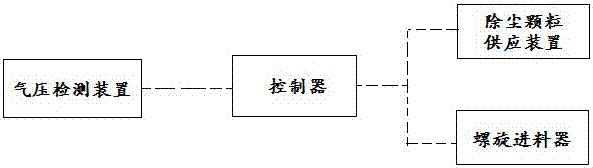

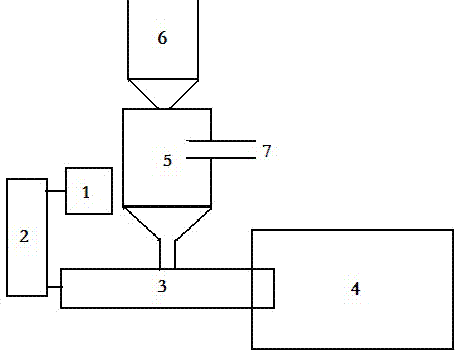

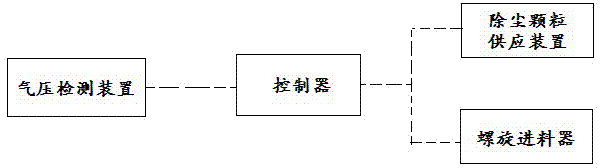

The invention discloses a coal pyrolysis apparatus. The coal pyrolysis apparatus comprises a coal pyrolysis device, a coal conveying device, a power source, a pyrolysis gas dust-removal device and a dust-removal particle supply device, wherein the coal pyrolysis device is used for carrying out pyrolysis on coals; the coal conveying device is used for conveying coals to the coal pyrolysis device; the power source is used for providing power for the coal conveying device; the pyrolysis gas dust-removal device is used for carrying out dust removal on gas subjected to pyrolysis; and the dust-removal particle supply device is used for supplying dust-removal particles to the pyrolysis gas dust-removal device. The coal pyrolysis apparatus disclosed by the invention is high in degree of automation, and high in utilization rate of dust-removal particles.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Preparation method of rice straw black carbon

InactiveCN109809384ASolve the idle problemAvoid wastingCarbon preparation/purificationSpecial form destructive distillationHydrofluoric acidTube furnace

The invention discloses a preparation method of rice straw black carbon and belongs to the field of black carbon preparation. The preparation method comprises the following steps: (1) conveying rice straws into a tubular furnace and carrying out thermal decomposition to obtain plant ash; (2) adding the plant ash into hydrochloric acid and obtaining a mixed solution I; (3) carrying out standing andfiltering on the mixed solution I to obtain a filtering solid matter; (4) after washing the filtering solid matter, adding hydrofluoric acid and hydrochloride to obtain a mixed solution II; conveyingthe rice straws into the tubular furnace and carrying out the thermal decomposition to obtain plant ash; adding the plant ash into the hydrochloric acid and carrying out standing and filtering to obtain a filtering solid matter; after adding the hydrochloric acid and the hydrofluoric acid into the filtering solid matter, carrying out refining and filtering to obtain a solid matter, and washing the solid matter with ionized water to prepare a neutral solid; after drying the neutral solid, grinding and crushing to obtain powdery black carbon. By adopting the preparation method provided by the invention, the problem that rural crop straws are wasted can be solved and a foundation also can be laid for resource utilization of solid wastes; the preparation method can be used for preparing the rice straw black carbon.

Owner:江成明

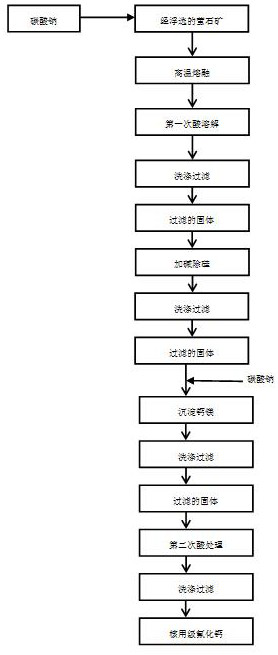

Process for purifying calcium fluoride from floated fluorite mine

PendingCN113683113AAchieve pyrolysisMeet quality requirementsCalcium/strontium/barium fluoridesAcid dissolutionOrganic matter

The invention provides a process for purifying calcium fluoride from floated fluorite ore. The floated fluorite ore is taken as a raw material, a multi-time purification process is adopted, a corresponding treatment process for purification is formulated according to the characteristics of different impurities, a melting method for gasification decomposition and conversion, acid dissolution, alkali addition for silicon removal and carbonate addition for calcium and magnesium removal are implemented sequentially, acid is added to remove carbonate precipitate, and finally nuclear-grade high-quality calcium fluoride is obtained. Particularly, impurities which are insoluble in water are effectively converted into substances which are soluble in water through alkalifying and melting, and high-temperature decomposition of impurities such as organic matters and sulfate is realized, so that the content of impurity elements of the finally obtained product meets the requirement of nuclear-grade calcium fluoride, and the quality requirement of the nuclear-grade calcium fluoride is met.

Owner:JIAYUGUAN HONGSHENG ELECTRIC HEATING CO LTD

Coal pyrolysis equipment

InactiveCN104774630AAchieve pyrolysisAchieve purificationDispersed particle filtrationSpecial form destructive distillationCoal pyrolysisDust particles

The invention discloses coal pyrolysis equipment. The coal pyrolysis equipment comprises a coal pyrolysis device, a coal conveying device, a power source, a pyrolysis gas dust removal device and a dust removal particle supply device, wherein the coal pyrolysis device is used for pyrolyzing coals; the coal conveying device is used for removing the dust of the gas subjected to the coal pyrolysis; the power source is used for supplying power to the coal conveying device; the pyrolysis gas dust removal device is used for removing the dust of the gas subjected to the coal pyrolysis; the dust particle supply device is used for supplying dust removal particles to the pyrolysis gas dust removal device. The coal pyrolysis equipment is high in utilization rate of the dust removal particles.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Energy-saving and environment-friendly firewood burning furnace

ActiveCN106247410APromote gasificationImprove stabilityDomestic stoves or rangesLighting and heating apparatusFirewoodProcess engineering

The invention discloses an energy-saving and environment-friendly firewood burning furnace. The energy-saving and environment-friendly firewood burning furnace comprises a furnace shell and a hearth, and is characterized in that the furnace shell is of a closed cylindrical structure arranged outside the hearth in a sleeving manner, the hearth comprises a burning barrel and an outer barrel arranged on the outer side of the burning barrel in a sleeving manner, a gap is formed between the outer wall of the burning barrel and the outer barrel to form an airflow cavity, an air supply assembly communicating with the airflow cavity is arranged at the bottom of the outer barrel, and the burning barrel and the outer barrel are of a conical structure with the small upper portion and the large lower portion. According to the energy-saving and environment-friendly firewood burning furnace, the whole hearth is set to be of the conical structure, the air supply efficiency is improved, higher airflow can be obtained through burning, the air and fuel gas mixing ratio needed for premixed burning is achieved, pyrolysis of combustible molecules and better gasification of carbon particles are achieved, combustibles are completely burned to obtain high-heat-value fuel gas, accordingly, the higher hearth temperature and the continuous and stable furnace opening high temperature are obtained, the burning furnace opening temperature is continuously stabilized to be above 1,050 DEG C, energy consumption is low, and output is high.

Owner:成都市沛源五金制品有限公司

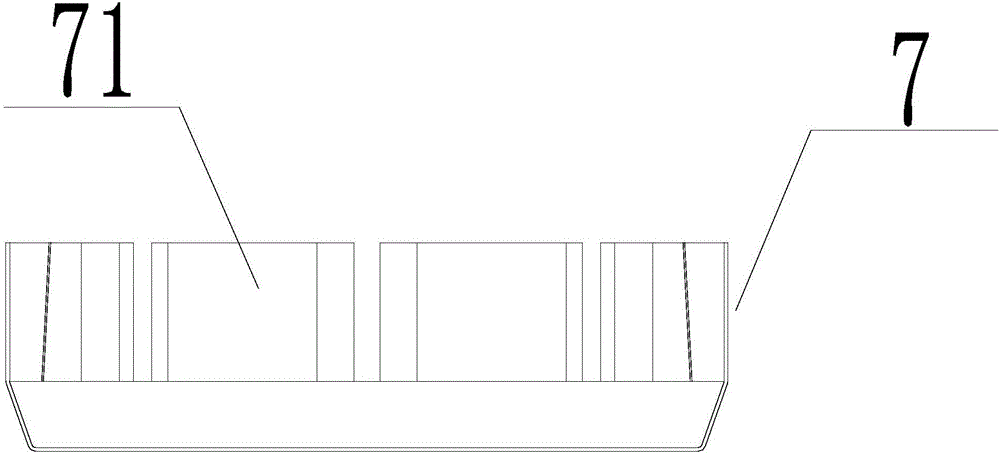

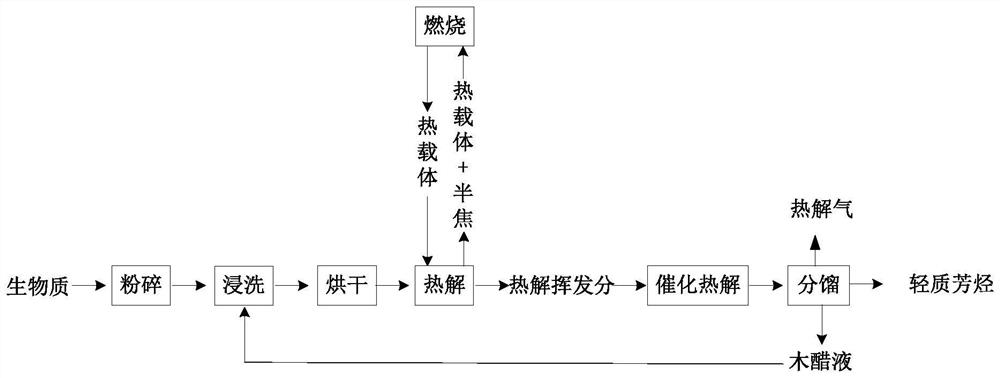

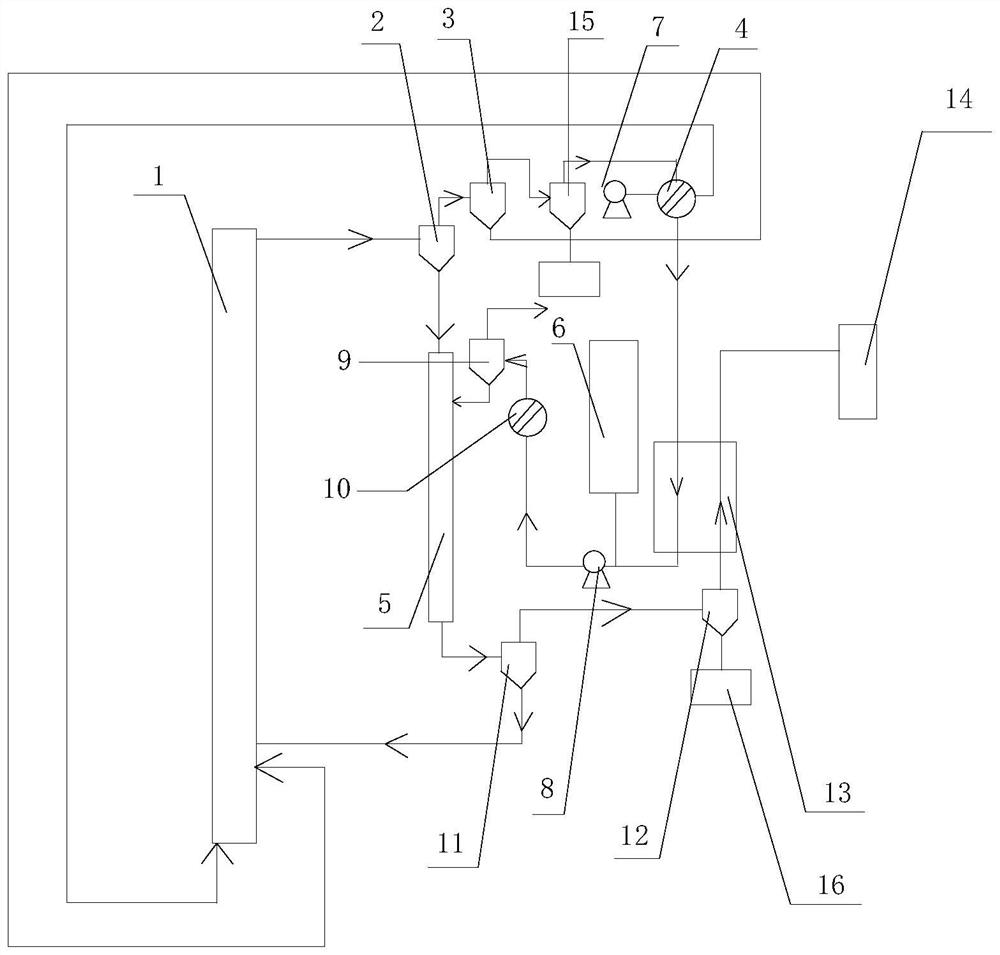

Device and method for preparing light aromatic hydrocarbon from biomass

PendingCN112779034ASolving inseparable puzzlesAchieve pyrolysisBiofuelsLiquid hydrocarbon mixture productionHeat carrierCyclonic separation

The invention provides a device and method for preparing light aromatic hydrocarbon from biomass, the device comprises a raw material storage drying system, a circulating fluidized bed heat carrier heating furnace, a reaction system, a gas-solid separation system, a power system, a heat exchanger and a condensing tower, the reaction system comprises a downer reactor and a tubular fixed bed reactor which are connected in series; the gas-solid separation system comprises a group A gas-solid separation system arranged at a discharge port of the circulating fluidized bed heat carrier heating furnace, a group B gas-solid separation system arranged at a discharge port of the downer reactor and a group C gas-solid separation system arranged at a feed port of the downer reactor, and the group A gas-solid separation system comprises a three-stage cyclone separation device; the group B gas-solid separation system comprises a second-stage cyclone separation device, and the group C gas-solid separation system comprises a first-stage cyclone separation device, so that the system has the advantages of high efficiency, energy conservation, high yield of light aromatic hydrocarbon and easiness in industrial continuous production.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing ferrosilicon by electric arc furnace smelting waste refractory material as raw material

ActiveCN110117718BRealize high temperature volatile separationAchieve pyrolysisProcess efficiency improvementAlkali metal carbonatesElectric arc furnaceFerrosilicon

Owner:NORTHEASTERN UNIV LIAONING

Coal pyrolysis equipment

InactiveCN104745213AAchieve pyrolysisAchieve purificationSpecial form destructive distillationGas dust removalProcess engineeringCoal pyrolysis

The invention discloses coal pyrolysis equipment. The equipment comprises a coal pyrolysis device used for performing pyrolysis on coal, a coal conveying device used for conveying coal to the coal pyrolysis device, a power source used for providing power to the coal conveying device, a pyrolysis gas dust collection device used for collecting dust for gas after coal pyrolysis, and a dust-removing particle supply device used for supplying dust-removing particle supply device to the pyrolysis dust-collection device. The coal pyrolysis equipment has high utilization of dust-removing particles.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

A two-step flotation treatment method for medical waste incineration fly ash

ActiveCN105149101BReduce secondary synthesisRealize the utilization of fuelFlotationLiquid wasteCombustion chamber

The invention discloses a two-step flotation treatment method for incineration fly ash of medical waste. The following steps are adopted: 1) decarbonization flotation to obtain two products of enriched carbon and primary tailings, and sending the enriched carbon product into garbage Combustion in the second combustion chamber of the incinerator; 2) acid leaching filtration: add inorganic acid to the primary tailings obtained in step 1) to carry out acid leaching and then filter to obtain two products: residual ash and heavy metal waste liquid; the residual ash is directly sent to domestic garbage Landfill for safe landfill disposal or reuse; 3) Ion flotation: Add flotation agents to the heavy metal waste liquid obtained in step 2) to carry out ion flotation to obtain two products of heavy metal concentrated foam and waste water; concentrate the heavy metal The foam is sent to the smelter to recover heavy metals Pb and Zn, and the wastewater is neutralized and discharged into the sewage system after reaching the standard. The invention has the advantages of simple operation, low cost, good treatment effect and no secondary pollution.

Owner:TIANJIN CHENGJIAN UNIV

A kind of coal pyrolysis equipment

ActiveCN104745214BAchieve pyrolysisAchieve purificationSpecial form destructive distillationProcess engineeringCoal pyrolysis

The invention discloses coal pyrolysis equipment. The equipment comprises a coal pyrolysis device used for performing pyrolysis on coal, a coal conveying device used for conveying coal to the coal pyrolysis device, a power source used for providing power to the coal conveying device, a pyrolysis gas dust collection device used for collecting dust for gas after coal pyrolysis, and a dust-removing particle supply device used for supplying dust-removing particle supply device to the pyrolysis dust-collection device. The coal pyrolysis equipment has high automatic degree and high utilization of dust-removing particles.

Owner:HEBEI LONGCHENG COAL COMPREHENSIVE UTILIZATION CO LTD

Coal pyrolysis equipment

ActiveCN104745214AAchieve pyrolysisAchieve purificationSpecial form destructive distillationProcess engineeringCoal pyrolysis

The invention discloses coal pyrolysis equipment. The equipment comprises a coal pyrolysis device used for performing pyrolysis on coal, a coal conveying device used for conveying coal to the coal pyrolysis device, a power source used for providing power to the coal conveying device, a pyrolysis gas dust collection device used for collecting dust for gas after coal pyrolysis, and a dust-removing particle supply device used for supplying dust-removing particle supply device to the pyrolysis dust-collection device. The coal pyrolysis equipment has high automatic degree and high utilization of dust-removing particles.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Method for preparing ferrosilicon alloy by feeding hollow electrode with aluminum ash as raw material

ActiveCN110129565BAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementElectric arc furnaceFerrosilicon

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing ferrosilicon alloy with aluminum ash as raw material by plasma jet feeding

ActiveCN110004300BAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementAlkali metal chloridesPlasma jetElectric arc furnace

Owner:NORTHEASTERN UNIV LIAONING

A kind of adsorption material for adsorbing perfluorinated compounds in water body

ActiveCN111330542BImprove adsorption capacityEfficient removalOther chemical processesWater contaminantsRoastingPerfluoro compound

The invention discloses an adsorbing material for adsorbing perfluorinated compounds in a water body. The adsorbing material is prepared by taking iron tailings as a main raw material, taking straw powder and fly ash as doping agents, adding cement, mixing, granulating, maintaining and performing anoxic roasting. The raw materials comprise the following components in percentage by mass: 50-75% ofiron tailings, 5-35% of straw powder, 5-15% of fly ash and 10-25% of cement. The iron tailings comprise, by mass, 48%-53% of SiO2, 13%-18% of CaCO3, 8%-13% of Fe2O3, 6%-8% of Al2O3 and 5%-13% of othercomponents. The adsorbing material is low in cost, simple and convenient in process and high in removal efficiency.

Owner:HEBEI UNIV OF TECH +1

Method for preparing aluminum silicon ferroalloy by feeding hollow electrode with waste refractory material as raw material

ActiveCN110016565BRealize high temperature volatile separationAchieve pyrolysisProcess efficiency improvementGas emission reductionElectric arc furnacePulverized fuel ash

The invention provides a method for preparing aluminum-silicon ferroalloy by feeding hollow electrodes as raw materials, using waste refractory materials as raw materials, aluminum electrolytic cell waste cathode carbon blocks as reducing agents, and fly ash as additives to adjust the raw materials. The aluminum content in the material is adjusted by using diatomite waste as an additive to adjust the silicon content in the raw materials. Materials mainly composed of alumina and silicon oxide are reduced at high temperature in the electric arc furnace to prepare a certain composition of aluminum-silicon ferroalloy; hollow electrodes are used to transport the powder. Materials can strengthen the entire electric arc furnace smelting process, promote the reduction of oxides and the volatilization of fluorides, especially accelerate the decomposition of toxic cyanide, as well as the volatilization and recovery of fluorides, chlorides and alkali metals in the materials, and improve production efficiency. , reduce production costs, and achieve comprehensive utilization of multiple hazardous wastes and solid wastes in the same process.

Owner:NORTHEASTERN UNIV LIAONING

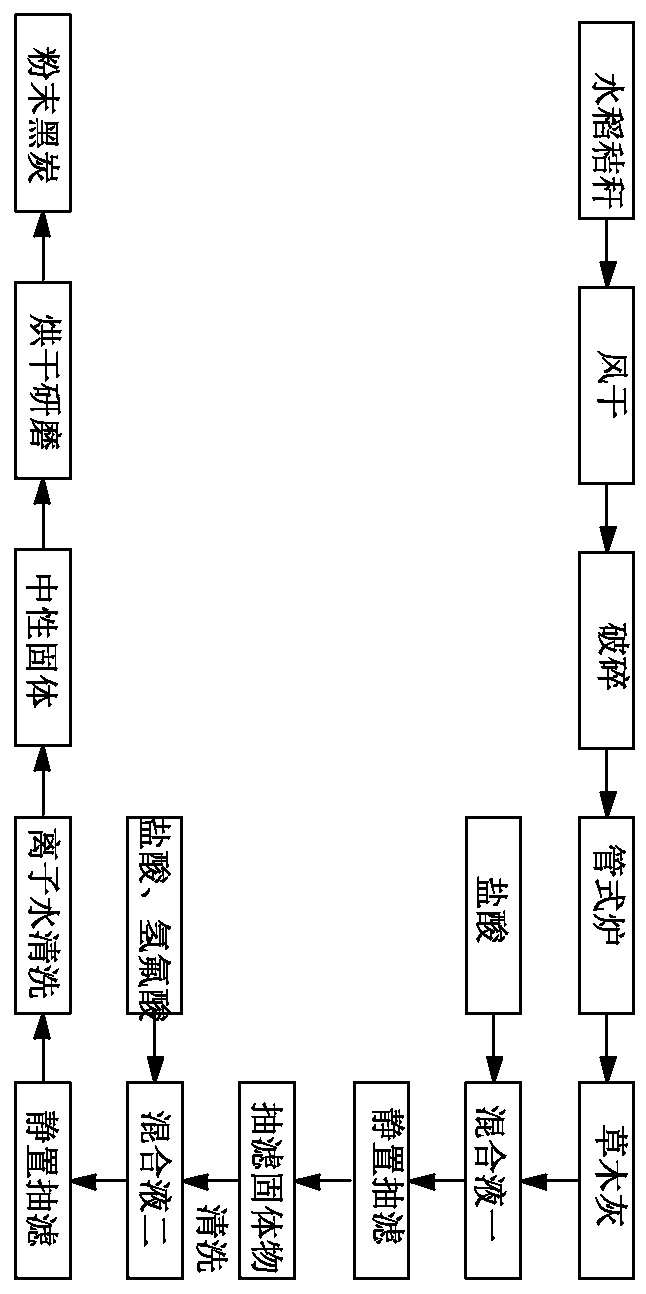

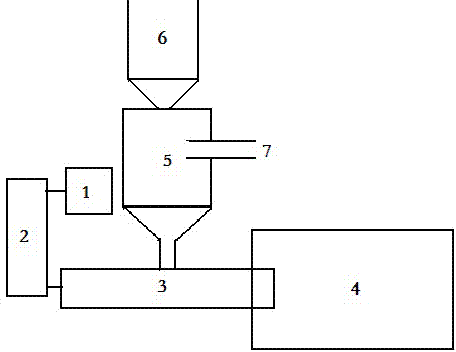

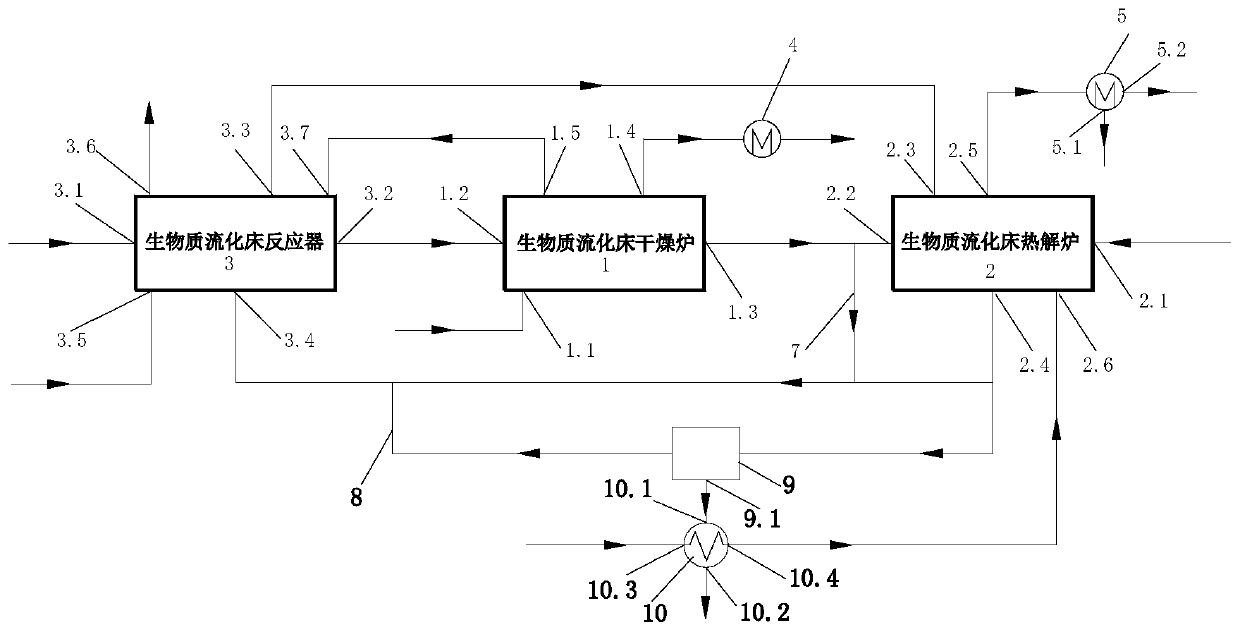

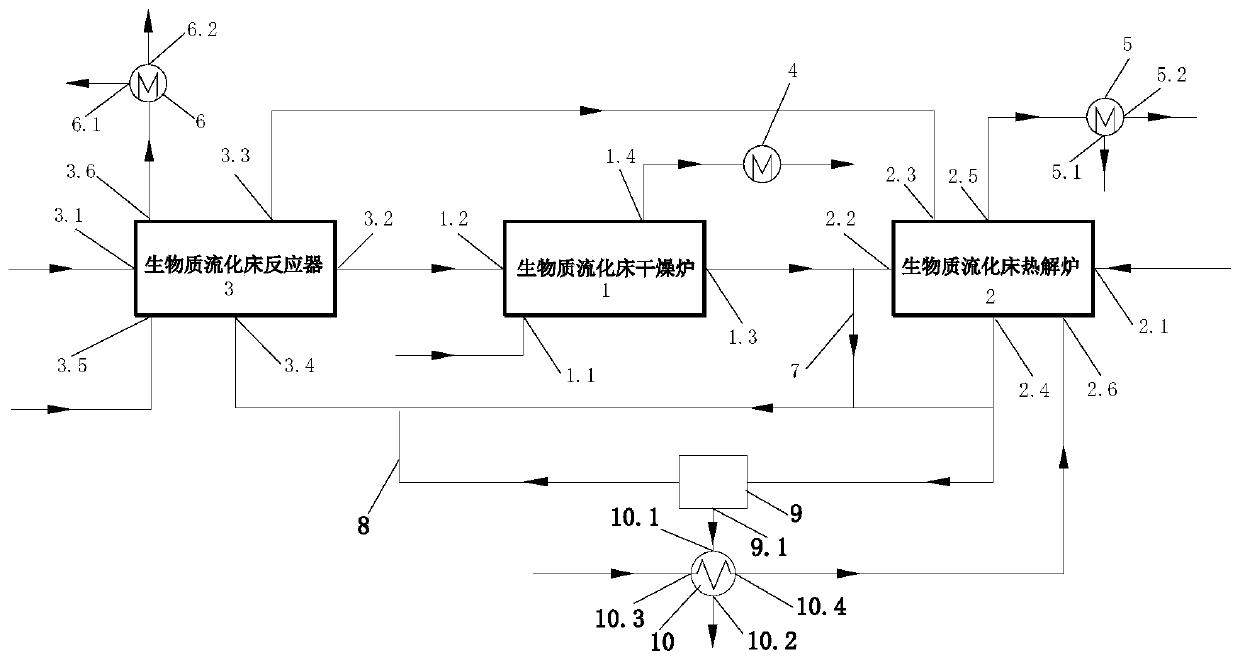

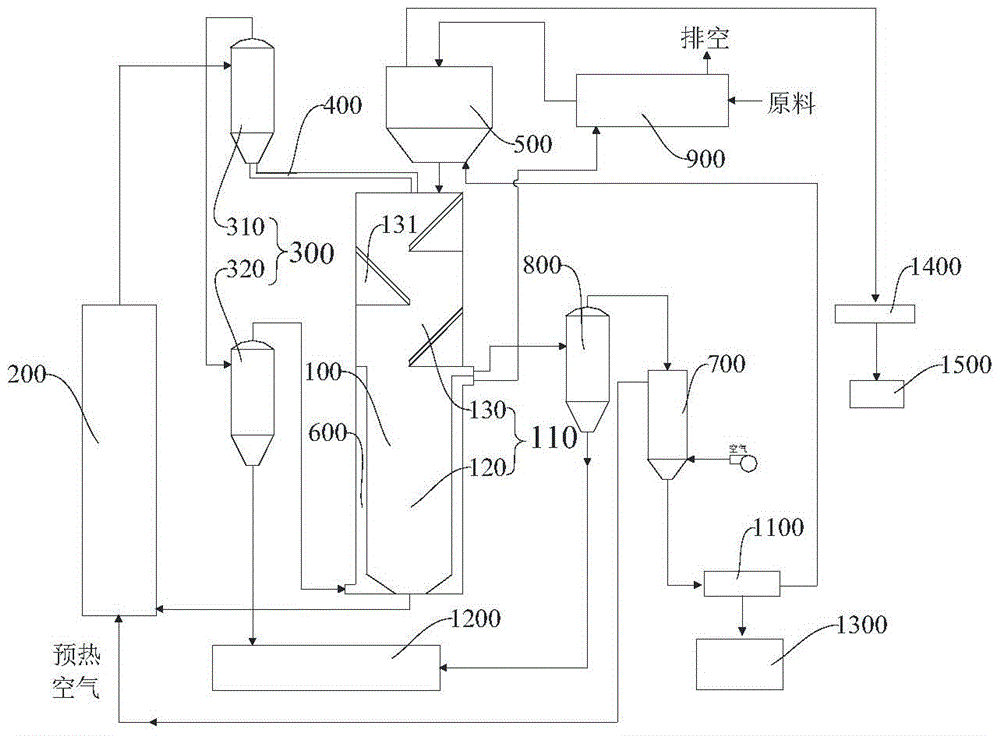

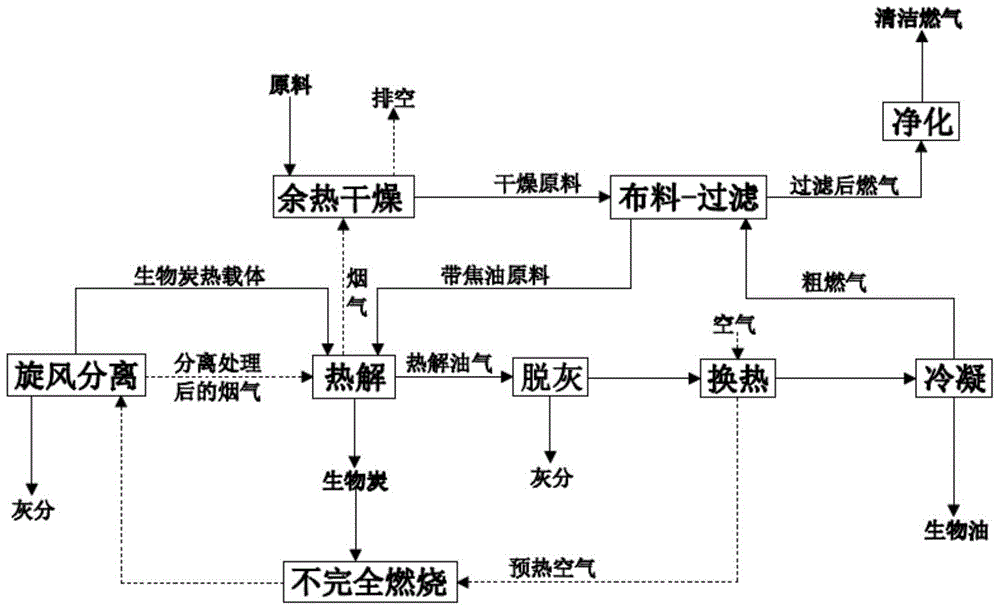

Biomass polygeneration method and system based on triple medium and low temperature fluidized bed

ActiveCN108070405BAchieve dryingAchieve pyrolysisGasification processes detailsCombustible gas productionFluidized bed dryingFluidized bed gasifier

The invention discloses a biomass poly-generation method and a system based on a triple medium and low temperature fluidized bed. The system comprises a biomass fluidized bed drying furnace, a biomassfluidized bed pyrolyzing furnace and a biomass fluidized bed gasification furnace, wherein a first biomass inlet for allowing biomass with a high water content to enter is formed in the biomass fluidized bed drying furnace; a second biomass inlet for allowing biomass with a low water content and a high volatile matter content to enter is formed in the biomass fluidized bed pyrolyzing furnace; anda third biomass inlet for allowing a biomass raw material to enter is formed in the biomass fluidized bed gasification furnace. According to the system and the method, graded utilization of the biomass raw material is achieved by the triple fluidized bed; sectional conversion of drying, pyrolyzing and gasification of the biomass raw material can be achieved; products of all conversion working sections can achieve efficient poly-generation; and the best economic benefit of a whole project can be achieved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Method for preparing aluminum silicon ferrosilicon by electric arc furnace smelting with aluminum ash as raw material

ActiveCN110016557BAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementElectric arc furnaceFerrosilicon

The invention provides a method for producing aluminum ferro-silicon alloy by electric arc furnace smelting using aluminum ash as raw material, using secondary aluminum ash as raw material, aluminum electrolytic cell waste cathode carbon block as reducing agent, and fly ash as additive to adjust the content of the raw material. The aluminum content in the raw material is adjusted by using diatomite waste as an additive. Materials mainly composed of alumina and silicon oxide are reduced at high temperature in an electric arc furnace to prepare a certain composition of aluminum-silicon ferroalloy; during the high-temperature reduction process, aluminum is achieved The decomposition of aluminum nitride in the ash and the decomposition of cyanide in the spent cathode carbon block, as well as the volatilization and recovery of fluoride, chloride and alkali metals in the materials, this batching method not only utilizes a variety of wastes, but is also easy to prepare various The aluminum-silicon ferroalloy with this composition is adapted to the smelting process of the electric arc furnace, making it easy to control the smelting process and alloy composition, which helps reduce production costs and creates conditions for subsequent processing.

Owner:NORTHEASTERN UNIV LIAONING

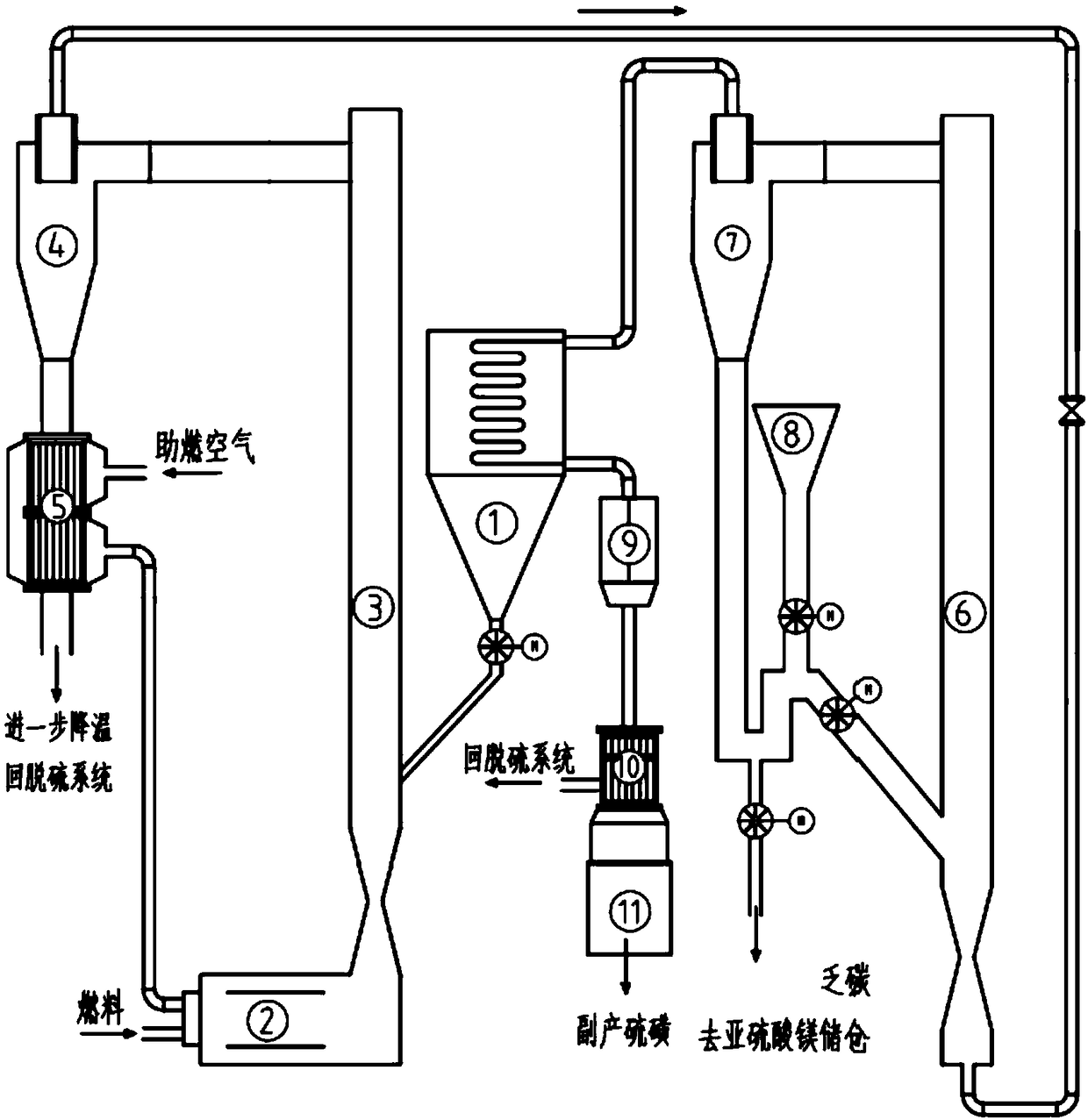

Method and device for regenerating desulfurizing agents and sulfur serving as by-product in magnesium desulfurization

PendingCN109264752APromote decompositionContribute to pyrolysisDispersed particle separationSulfur preparation/purificationFluidized bedDecomposition

The invention belongs to the field of industrial waste treatment, and relates to a method and a device for regenerating desulfurizing agents and sulfur serving as a by-product in magnesium desulfurization. The device comprises a magnesium sulfite storage bin, a fluidized bed calcining unit, a fluidized bed carbon thermal reduction unit and a sulfur recovery unit, the fluidized bed calcining unit comprises a fluidized bed calcining furnace, a calcining furnace high-temperature separator and an incinerator, the magnesium sulfite storage bin is connected with the lower portion of the fluidized bed calcining furnace, the bottom of the fluidized bed calcining furnace is connected with the incinerator, a top decomposition gas outlet of the fluidized bed calcining furnace is connected with the calcining furnace high-temperature separator, the fluidized bed carbon thermal reduction unit comprises a fluidized bed carbon thermal reduction tower and a reduction tower high-temperature separator, atop magnesium removal decomposition gas outlet of the calcining furnace high-temperature separator is connected with the bottom of the fluidized bed carbon thermal reduction tower, a top reduction gas outlet of the fluidized bed carbon thermal reduction tower is connected with the reduction tower high-temperature separator, and the reduction tower high-temperature separator is connected with themagnesium sulfite storage bin. Magnesium sulfite decomposition rate is higher than 99%, and the purity of recovered sulfur reaches 99.7% or more.

Owner:SHANDONG UNIV

Method for producing AlSiF from waste refractory material by plasma jet feeding

ActiveCN110029227BRealize high temperature volatile separationAchieve pyrolysisProcess efficiency improvementPlasma jetAluminium electrolysis

The invention provides a method for producing ferrosilicon aluminum by plasma jet feeding, using waste refractory materials as raw materials, aluminum electrolytic cell waste cathode carbon blocks as reducing agents, and fly ash as additives to adjust the raw materials. The aluminum content in the material is adjusted by using diatomite waste as an additive to adjust the silicon content in the raw materials. Materials mainly composed of alumina and silicon oxide are reduced at high temperature in the electric arc furnace to prepare a certain composition of aluminum-silicon ferroalloy; in the high-temperature reduction process, The decomposition of cyanide in the spent cathode carbon block, as well as the volatilization and recovery of fluoride, chloride and alkali metals in the materials, realize the comprehensive utilization of various hazardous wastes and solid wastes in the same process.

Owner:NORTHEASTERN UNIV LIAONING

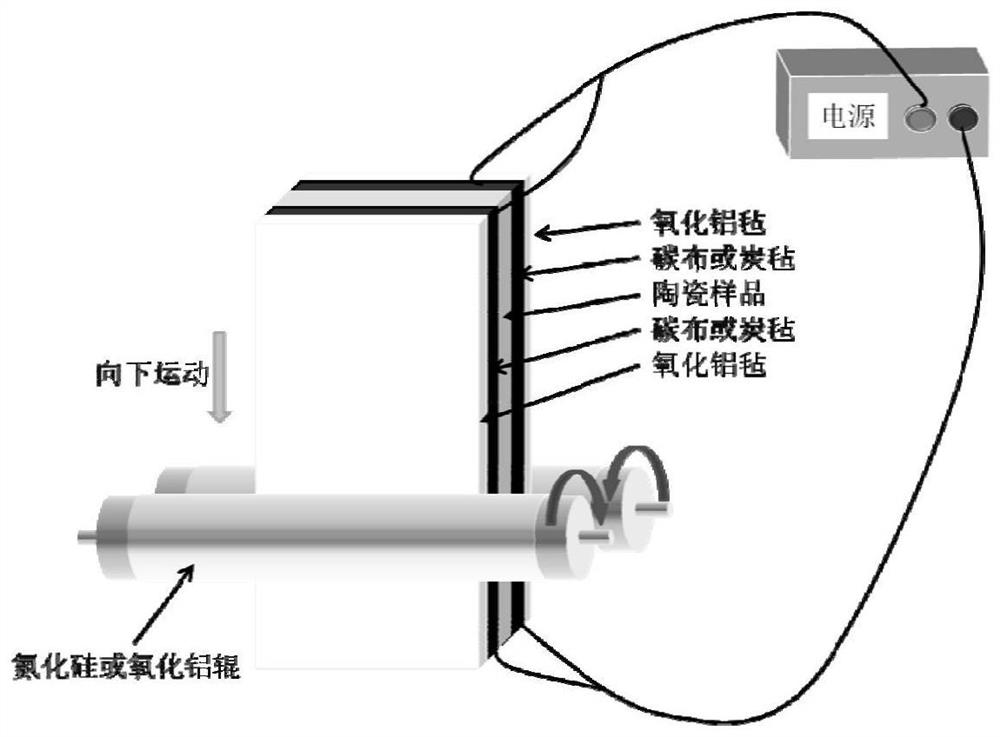

Ceramic rolling device and method

PendingCN114750265AFast sinteringHeating up fastCharge composition/statePress rollersCarbon feltCeramic

The embodiment of the invention discloses a ceramic rolling device and method, the ceramic rolling device comprises a rolling machine comprising a first compression roller and a second compression roller, and a power supply for electrifying and heating a ceramic laminated part, and a gap between the first compression roller and the second compression roller is used for placing ceramic so as to roll the electrified and heated ceramic laminated part when the rolling machine is started. The conductive heating materials such as the carbon felt and the carbon cloth are heated by electrifying, and the materials arranged inside are heated, so that the aim of quickly heating the ceramic by using very simple devices and steps is fulfilled, and the ceramic can be quickly heated to the temperature at which the ceramic can be plastically deformed within several seconds.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

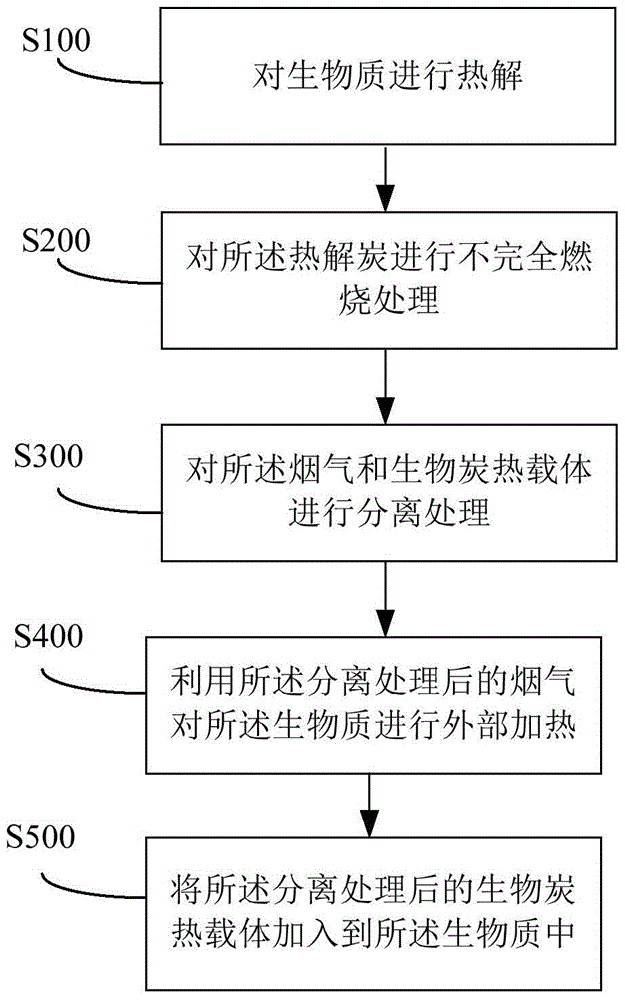

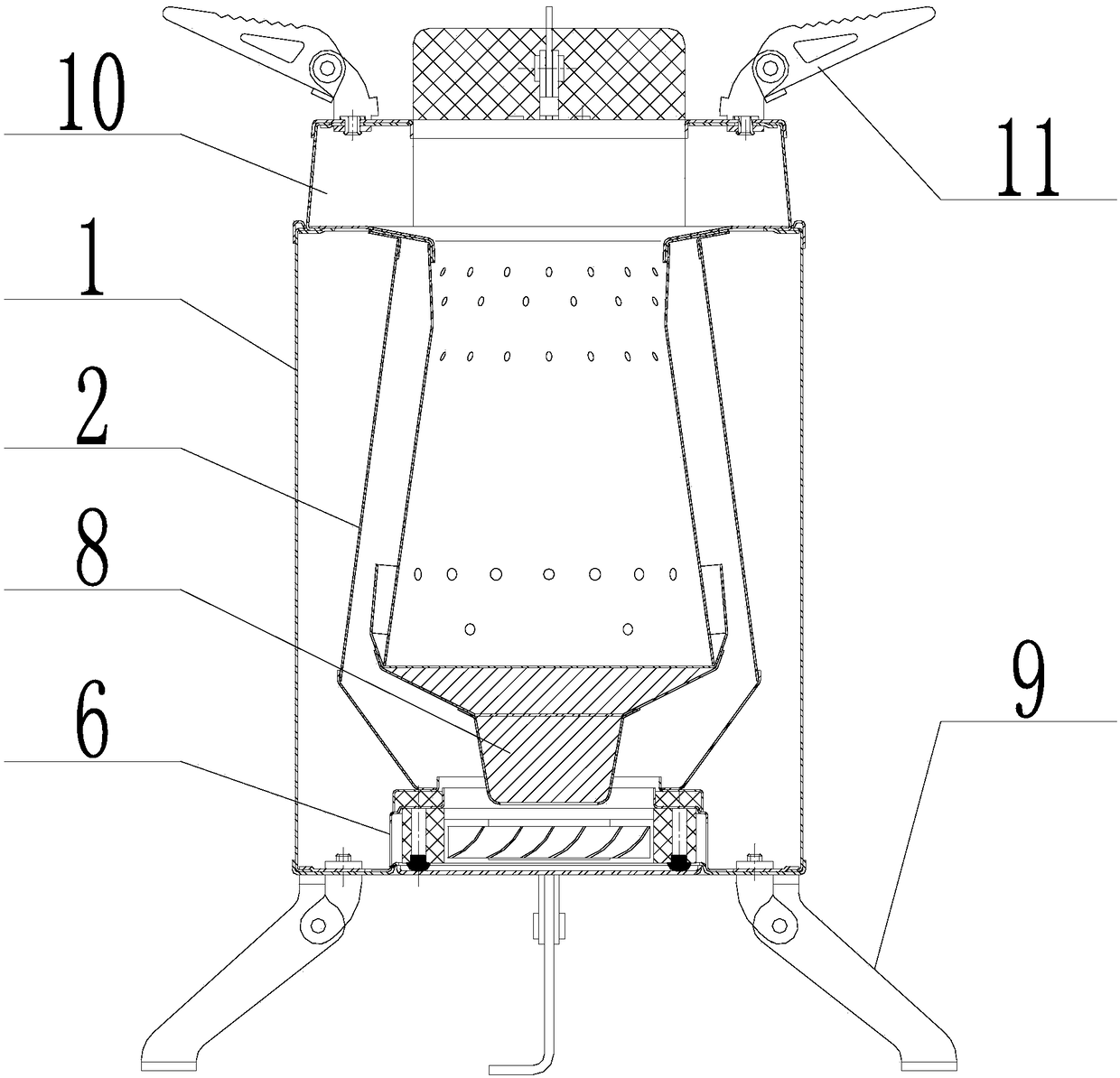

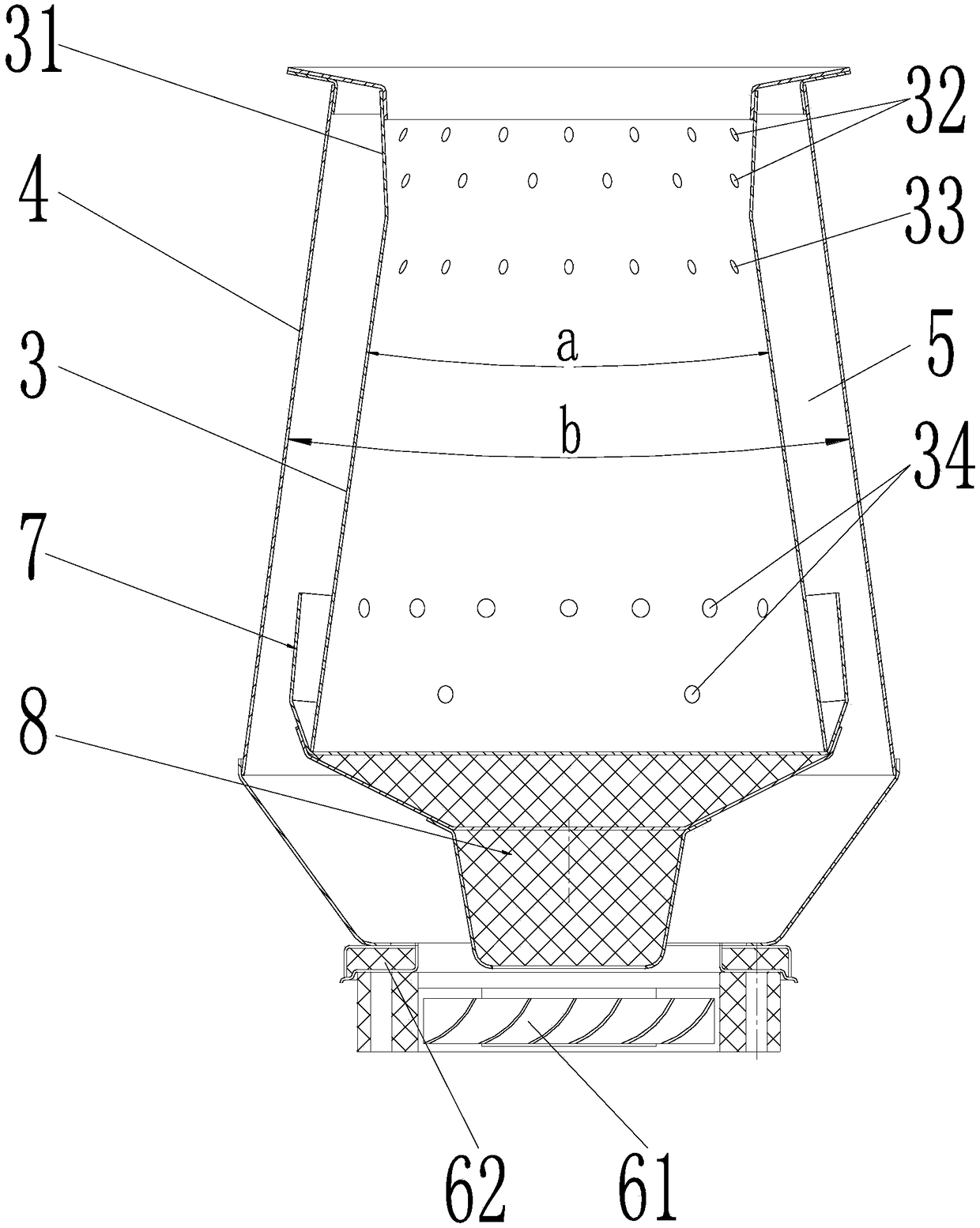

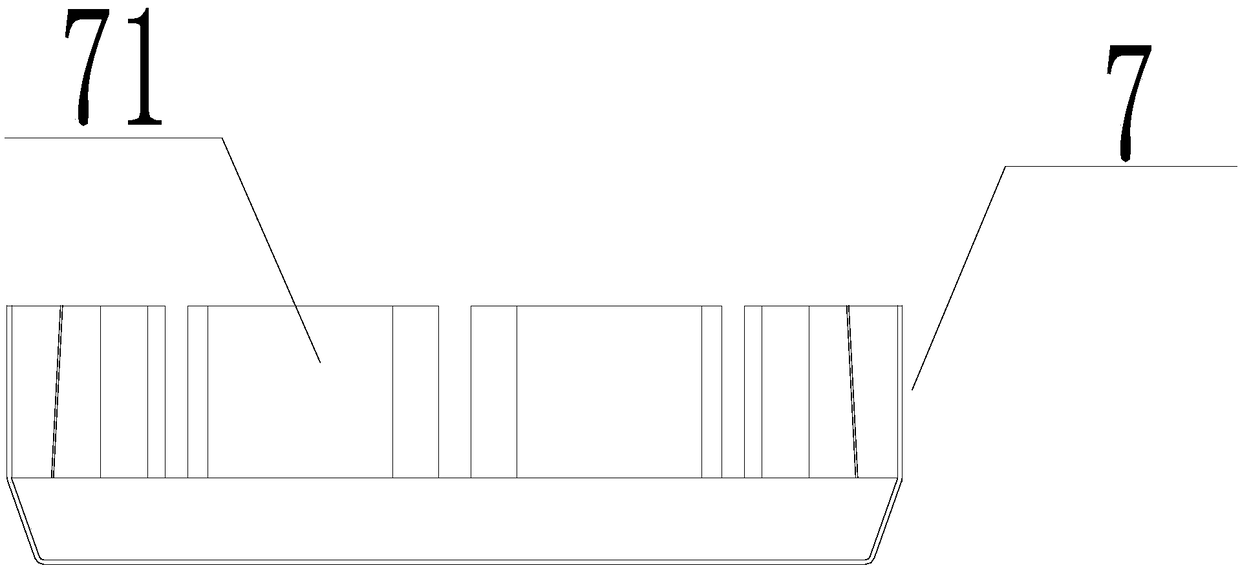

Biomass pyrolysis system and method for pyrolyzing biomass

ActiveCN105219417BAchieve pyrolysisLow costBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

The invention discloses a biomass pyrolysis system and a biomass pyrolysis method. The biomass pyrolysis system comprises a pyrolysis furnace, a combustion lift pipe, a separation device, a biochar heat carrier pipeline and a smoke flue. According to the biomass pyrolysis system, efficient biomass pyrolysis is realized through simultaneous heating by the aid of internal biochar heat carriers and external smoke.

Owner:SHENWU TECH GRP CO LTD

An energy-saving and environment-friendly wood-burning stove

ActiveCN106247410BPromote gasificationImprove stabilityDomestic stoves or rangesLighting and heating apparatusFirewoodHearth

The invention discloses an energy-saving and environment-friendly firewood burning furnace. The energy-saving and environment-friendly firewood burning furnace comprises a furnace shell and a hearth, and is characterized in that the furnace shell is of a closed cylindrical structure arranged outside the hearth in a sleeving manner, the hearth comprises a burning barrel and an outer barrel arranged on the outer side of the burning barrel in a sleeving manner, a gap is formed between the outer wall of the burning barrel and the outer barrel to form an airflow cavity, an air supply assembly communicating with the airflow cavity is arranged at the bottom of the outer barrel, and the burning barrel and the outer barrel are of a conical structure with the small upper portion and the large lower portion. According to the energy-saving and environment-friendly firewood burning furnace, the whole hearth is set to be of the conical structure, the air supply efficiency is improved, higher airflow can be obtained through burning, the air and fuel gas mixing ratio needed for premixed burning is achieved, pyrolysis of combustible molecules and better gasification of carbon particles are achieved, combustibles are completely burned to obtain high-heat-value fuel gas, accordingly, the higher hearth temperature and the continuous and stable furnace opening high temperature are obtained, the burning furnace opening temperature is continuously stabilized to be above 1,050 DEG C, energy consumption is low, and output is high.

Owner:成都市沛源五金制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com