Device and method for preparing light aromatic hydrocarbon from biomass

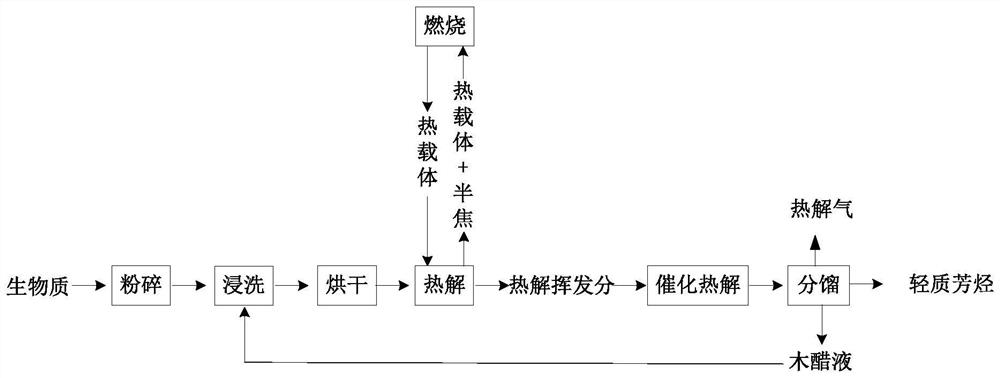

A technology of light aromatics and biomass, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, pyroligneous acid, etc., can solve problems such as high operating costs, poor heat transfer, and weak raw material processing capabilities, and achieve increased revenue. High efficiency, high heat transfer efficiency, and the effect of reducing fine ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

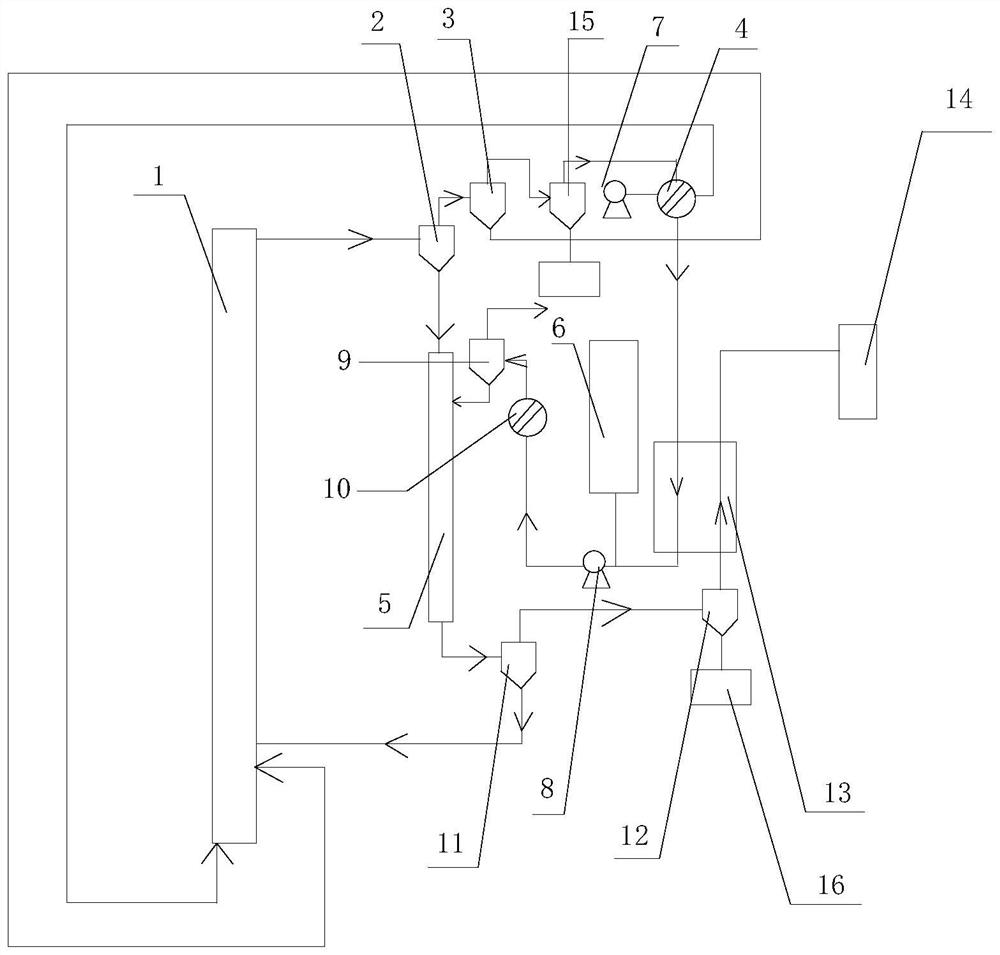

[0049] combine figure 1 with figure 2 As shown, a device for preparing light aromatics from biomass includes a raw material storage and drying system, a circulating fluidized bed heat carrier heating furnace 1, a reaction system, a gas-solid separation system, a power system, a heat exchanger 4 and a condensation tower 14;

[0050] The raw material storage and drying system comprises a raw material storage tank 6 and a riser dryer 10;

[0051] The reaction system includes a down-bed reactor 5 and a plurality of tubular fixed-bed reactors 13, the down-bed reactor 5 and the tubular fixed-bed reactors 13 are connected in series, and the plurality of tubular fixed-bed reactors 13 are Parallel connection, recycling;

[0052] The gas-solid separation system includes a group A gas-solid separation system, a group B gas-solid separation system and a group C gas-solid separation system. The gas-solid separation system of group C is arranged at the outlet of the down-bed reactor 5, ...

Embodiment 2

[0086] combine figure 1 with figure 2 As shown, a device for preparing light aromatics from biomass includes a raw material storage and drying system, a circulating fluidized bed heat carrier heating furnace 1, a reaction system, a gas-solid separation system, a power system, a heat exchanger 4 and a condensation tower 14;

[0087] The raw material storage and drying system comprises a raw material storage tank 6 and a riser dryer 10;

[0088] The reaction system comprises a down-bed reactor 5 and a plurality of tubular fixed-bed reactors 13, the down-bed reactor 5 and the tubular fixed-bed reactors 13 are connected in series, and the plurality of tubular fixed-bed reactors 13 are Parallel connection, recycling;

[0089] The gas-solid separation system includes a group A gas-solid separation system, a group B gas-solid separation system and a group C gas-solid separation system. The gas-solid separation system of group C is arranged at the outlet of the down-bed reactor 5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com