Process for the continuous preparation of polyamidoamines

A polyamide and ethylenediamine technology, applied in the field of functional polymer preparation, can solve the problems of intermittent operation, separation and purification, and low product purity, and achieve the effects of preventing side reactions, easy operation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

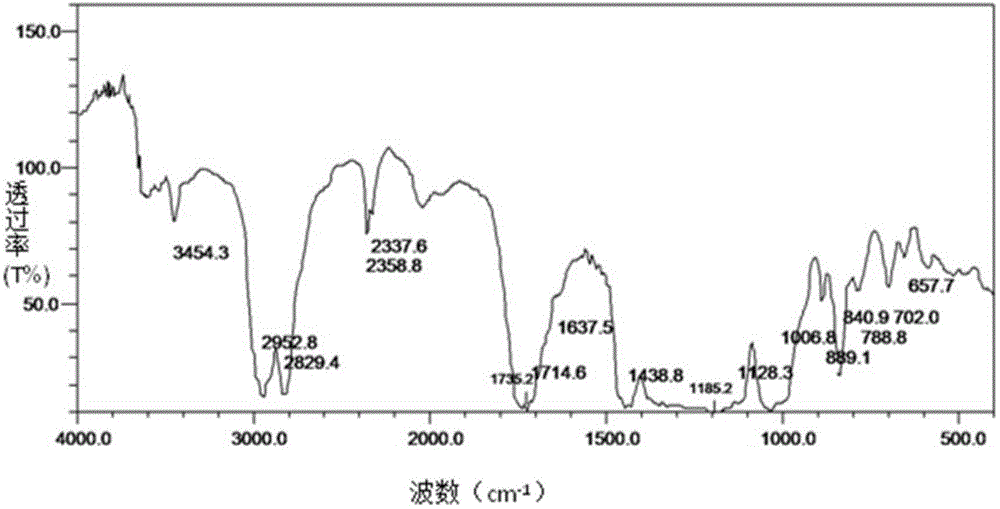

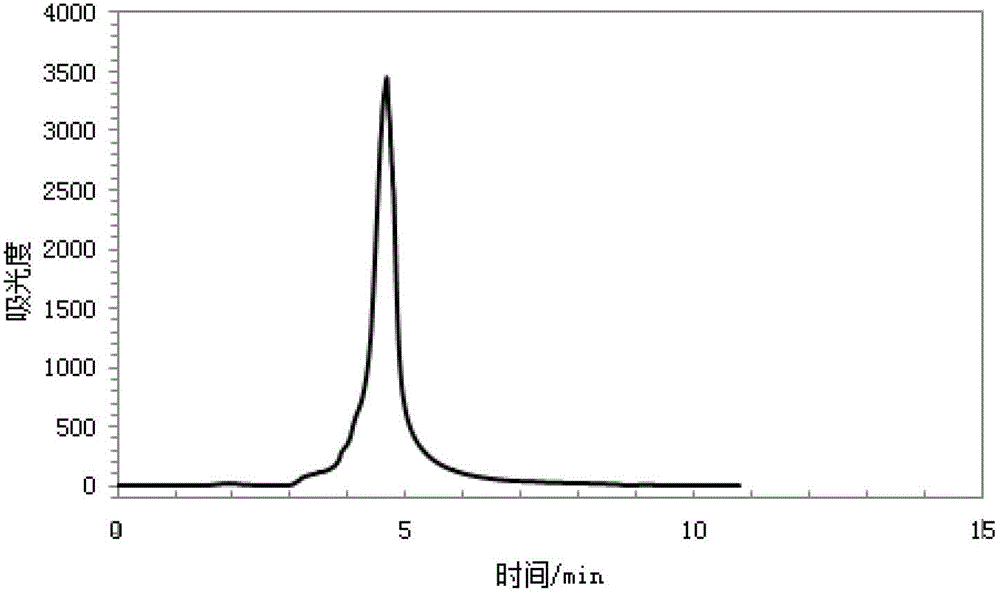

[0028] The preparation method of the semi-generation polyamide-amine product: dissolve ethylenediamine with methanol, add methyl acrylate under inert gas conditions to obtain it; the reaction temperature is a combination of low and high temperature, that is, react at 0°C for 1-2h, then naturally Raise the temperature to 25°C and react for 13-14 hours; in the early stage of the reaction, the function of the inert gas is to exclude oxygen, and in the late stage of the reaction, the main function is to blow away excessive small molecular substances.

[0029] The specific operation steps are:

[0030] Step 1. Dissolve ethylenediamine in methanol, add a catalyst, place the obtained mixed solution in an ice-water bath, pass through nitrogen and exhaust oxygen, add methyl acrylate dropwise under stirring conditions, raise the temperature to make the reaction complete, and obtain half-generation Polyamide-amine product; the rate of dropping methyl acrylate is 8-16d / min; the molar rati...

Embodiment 1

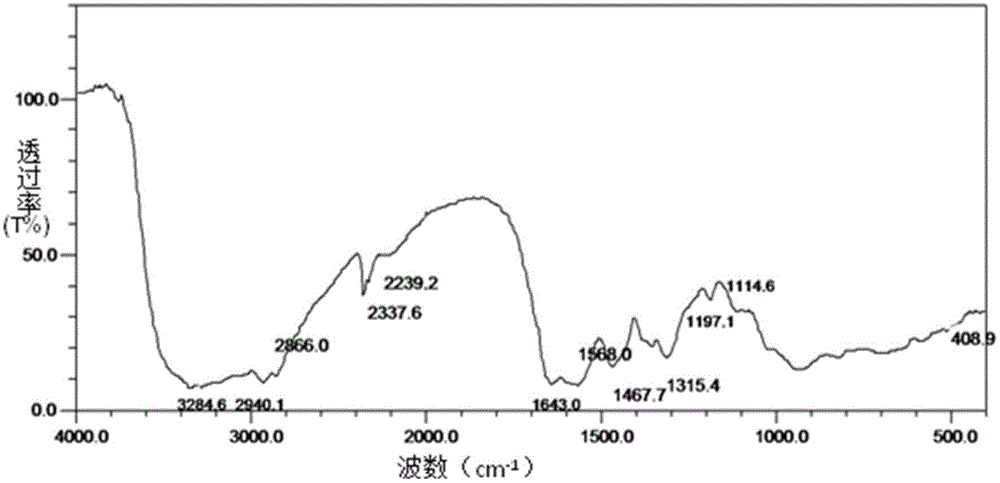

[0035] A synthetic method for preparing highly purified 1.0 generation polyamide-amine, comprising the following steps:

[0036] Step 1, synthetic 0.5 generation polyamide-amine, its concrete steps are:

[0037] Step 1a, weighing 4.5g (0.075mol) of ethylenediamine and 51.6g (0.6mol) of methyl acrylate, the molar ratio of the two is 1:8;

[0038] Step 1b. Put the ethylenediamine weighed in step 1a into a 250 mL three-necked flask, add 20 mL of methanol and 0.05 g of sodium methoxide catalyst, and stir to completely dissolve it. Then it was placed in a water bath, cooled to 0°C in an ice-water bath, and nitrogen was passed through to exhaust oxygen for 10 min.

[0039] Step 1c, under the conditions of rapid stirring and nitrogen protection, keep the reaction temperature of the system at 0°C, add the methyl acrylate weighed in step 1a dropwise, the dropping speed is 16d / min, and the dropping time is about 1h.

[0040] Step 1d, after the dropwise addition, continue to react at 0...

Embodiment 2

[0050] A synthetic method for preparing highly purified 1.0 generation polyamide-amine, comprising the following steps:

[0051] Step 1, synthetic 0.5 generation polyamide-amine, its concrete steps are:

[0052] Step 1a, weighing 4.5g (0.075mol) of ethylenediamine and 77.4g (0.9mol) of methyl acrylate, the molar ratio of the two is 1:12;

[0053] Step 1b. Put the ethylenediamine weighed in step 1a into a 250 mL three-necked flask, add 25 mL of methanol and 0.2 g of sodium ethoxide catalyst, and stir to completely dissolve it. Then it was placed in a water bath, cooled to 0°C in an ice-water bath, and nitrogen was passed through to exhaust oxygen for 10 min.

[0054] Step 1c, under the conditions of rapid stirring and nitrogen protection, keep the reaction temperature of the system at 0°C, add the methyl acrylate weighed in step 1a dropwise, the dropping speed is 8d / min, and the dropping time is about 2h.

[0055] Step 1d, after the dropwise addition, continue to react at 0°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com