Method and device for regenerating desulfurizing agents and sulfur serving as by-product in magnesium desulfurization

The technology of magnesium-based desulfurization and desulfurization agent is applied in the field of desulfurization agent regeneration and sulfur by-product in magnesium-based desulfurization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

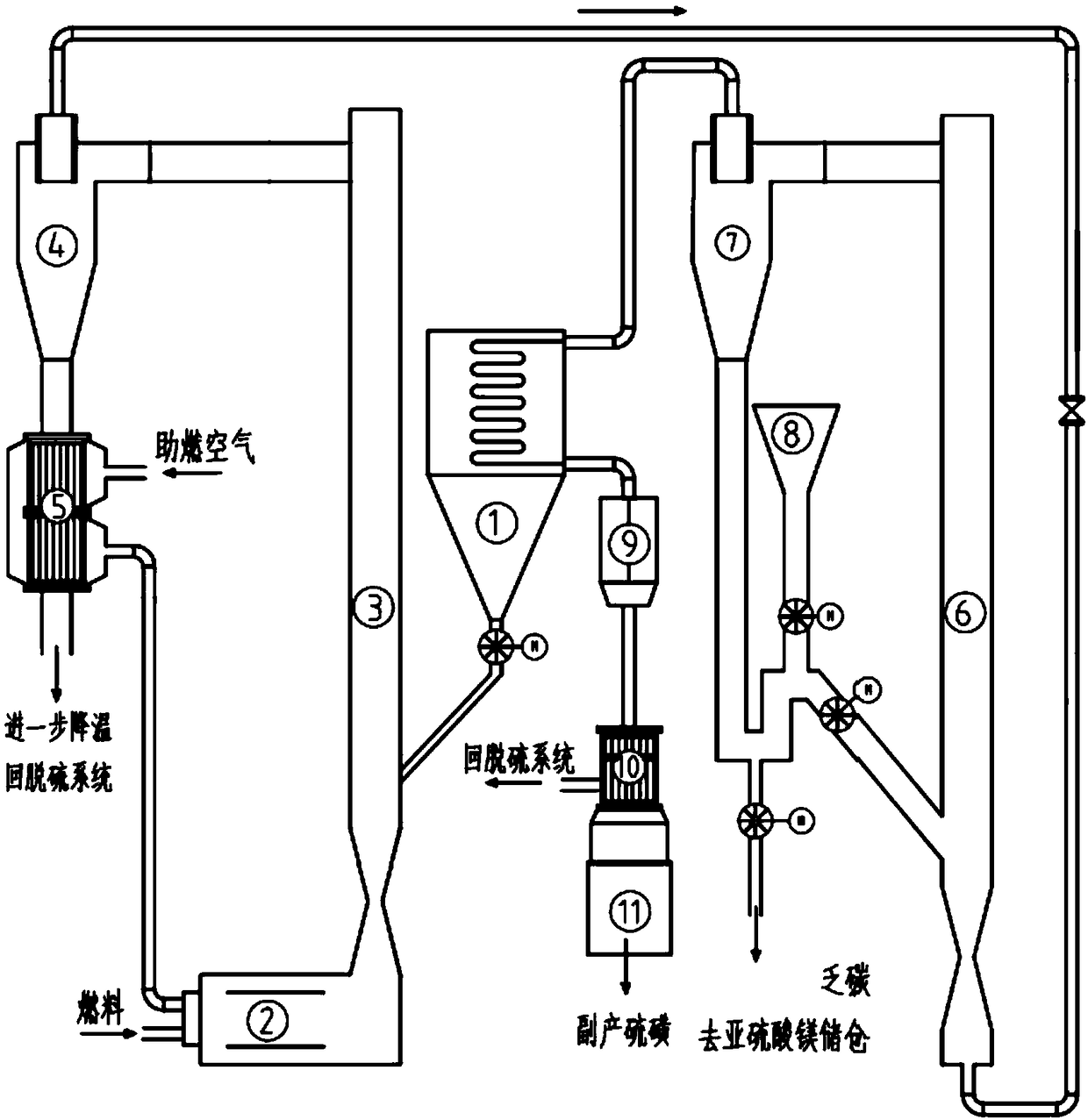

[0044] A device for regenerating desulfurizing agent and producing sulfur by-product in magnesium desulfurization, comprising a magnesium sulfite storage bin 1, a fluidized bed calcination unit, a fluidized bed carbothermal reduction unit and a sulfur recovery unit, the fluidized bed calcination unit includes Fluidized bed calciner 3, calciner high-temperature separator 4 and incinerator 2, magnesium sulfite storage bin 1 is connected with the lower part of fluidized bed calciner 3, the bottom of fluidized bed calciner 3 is connected with incinerator 2, fluidized The top decomposition gas outlet of the bed calciner 3 is connected to the calciner high temperature separator 4, and the fluidized bed carbothermal reduction unit includes a fluidized bed carbothermal reduction tower 6 and a reduction tower high temperature separator 7, and the top of the calciner high temperature separator 7 is The demagnesium removal decomposition gas outlet is connected to the bottom of the fluidiz...

Embodiment 2

[0056] Utilize the device of embodiment 1 to carry out the method for desulfurizing agent regeneration while by-product sulfur, concrete steps are:

[0057] 1) Magnesium sulfite, a by-product of desulfurization, enters the fluidized bed calciner 3 for fluidized calcination, and the magnesium sulfite is heated to 750°C in the flue gas of the incinerator 2 for pyrolysis, and the decomposition gas is separated by the high temperature separator 4 of the calciner The obtained MgO is cooled in the air preheater to 520°C and returned to the desulfurization system for recycling, and the obtained demagnesium decomposition gas enters the fluidized bed carbothermal reduction tower 6 at 750°C, and the demagnesium decomposition gas is N 2 , SO 2 , CO 2 、H 2 O, O 2 etc. mixed gas;

[0058] 2) Demagnesium decomposed gas and carbon powder undergo a fluidized reaction in the fluidized bed carbothermal reduction tower 6, the reaction time is 4s, the reaction temperature is 850°C, and C / SO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com