Treatment method for two-step flotation of medical waste incineration fly ash

A technology for incinerating fly ash and medical waste, which is applied in the field of environmental pollution control. It can solve the problems that it is difficult to ensure that the leaching of heavy metals in residual ash reaches the standard, the separation and recovery of heavy metals cannot be achieved, and the effect of primary flotation decarbonization is affected, so as to achieve harmless The effects of efficient treatment and resource utilization, saving landfill space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

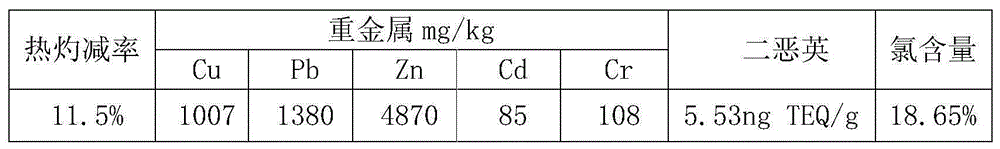

[0020] See Table 1 for the thermal loss rate, heavy metals, dioxins and chlorine contents of a certain medical waste incineration fly ash.

[0021] Table 1 Thermal burn rate, heavy metal, dioxin and chlorine content of fly ash from medical waste incineration

[0022]

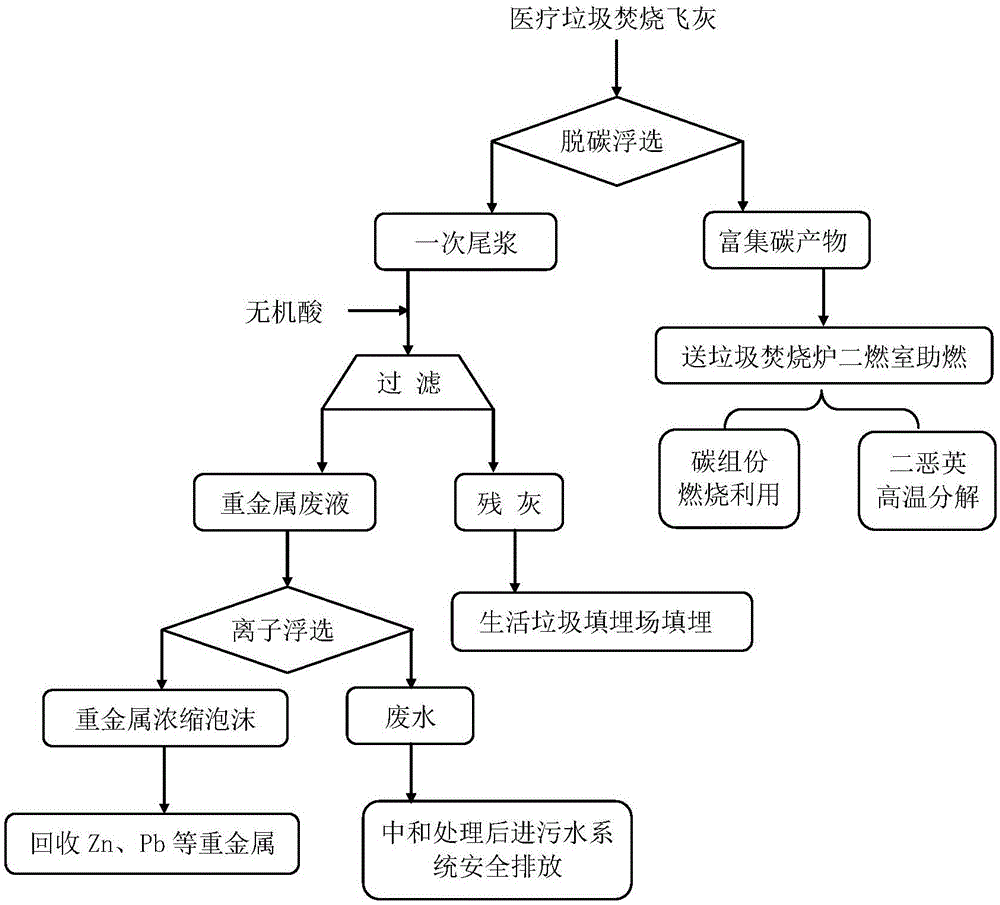

[0023] Adopt the method provided by the invention to process above-mentioned medical waste incineration fly ash, please refer to figure 1 , take the following steps:

[0024] 1) Decarbonization flotation

[0025] 1.1) Mix the incineration fly ash of medical waste with flotation agents and water to make mortar;

[0026] Add 200g of medical waste incineration fly ash and 4 liters of deionized water into the slurry mixing tank at the same time, and stir the mortar for 5 minutes to make the fly ash thoroughly wet. During this period, add 2.4 grams of kerosene and stir for several minutes to reconcile the slurry. During this time, 0.6 g of methyl isobutyl carbinol was added to the mortar and stirred for several...

Embodiment 2

[0041]The sample of fly ash from incineration of medical waste used is the same as in Example 1, the process flow for the fly ash from incineration of medical waste is the same as in Example 1, and the step 1) decarbonization flotation is also the same as in Example 1. The difference from Example 1 lies in step 2) and step 3), step 2): in the acid leaching procedure, nitric acid is added to the primary tailings to make the pH of the primary tailings=2, and then acid leaching, acid leaching After filtration, filter to obtain two products of residual ash and heavy metal waste liquid; step 3): add dodecylsulfuric acid (SDS) to the concentration of 0.2g / L in the heavy metal waste liquid, add methyl isobutyl at a concentration of 0.1% methyl alcohol (MIBC).

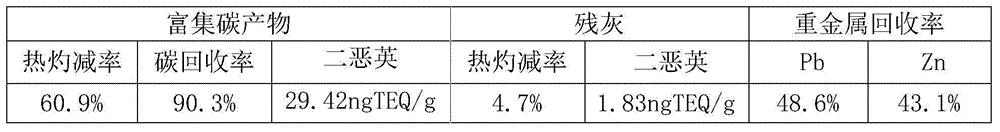

[0042] The above-mentioned enriched carbon products and residual ash were dehydrated and dried, and then tested and analyzed. The results are shown in Table 5. The dioxin content in the residual ash meets the dioxin limit requ...

Embodiment 3

[0051] The sample of fly ash from incineration of medical waste used is the same as in Example 1, the process flow for the fly ash from incineration of medical waste is the same as in Example 1, and the step 1) decarbonization flotation is also the same as in Example 1. The difference from Example 1 lies in step 2) and step 3), step 2): in the acid leaching procedure, nitric acid is added to the primary tailings to make the pH of the primary tailings=2, and then acid leaching, acid leaching After filtration, two products of residual ash and heavy metal waste liquid are obtained; step 3): add dodecyl sulfuric acid (SDS) according to the concentration of 0.30g / L in the heavy metal waste liquid, add methyl isobutylate according to the concentration of 0.1% methyl alcohol (MIBC).

[0052] The above-mentioned enriched carbon products and residual ash were dehydrated and dried, and then tested and analyzed. The results are shown in Table 8. The dioxin content in the residual ash mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com