A method of drying sludge using solar energy and waste heat of flue gas

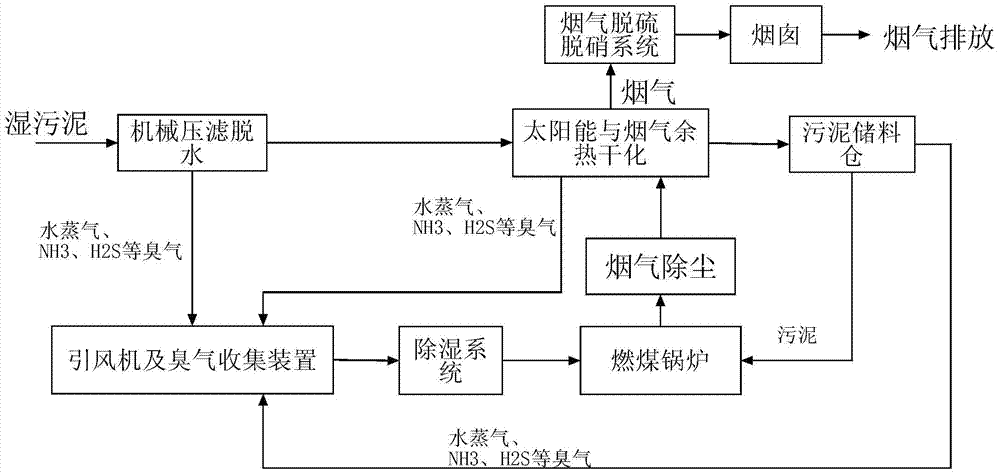

A technology of waste heat from flue gas and sludge drying, which is applied in dewatering/drying/concentrating sludge treatment, sludge treatment through temperature control, energy and wastewater treatment, etc. Low treatment efficiency and other problems, to achieve the effect of reducing the moisture content of sludge, realizing the utilization of fuel, and reducing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

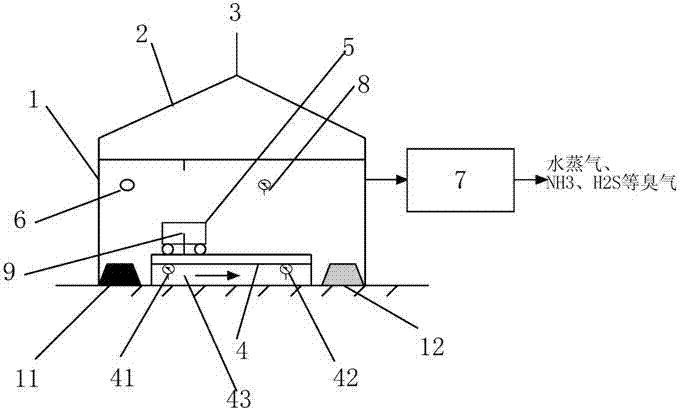

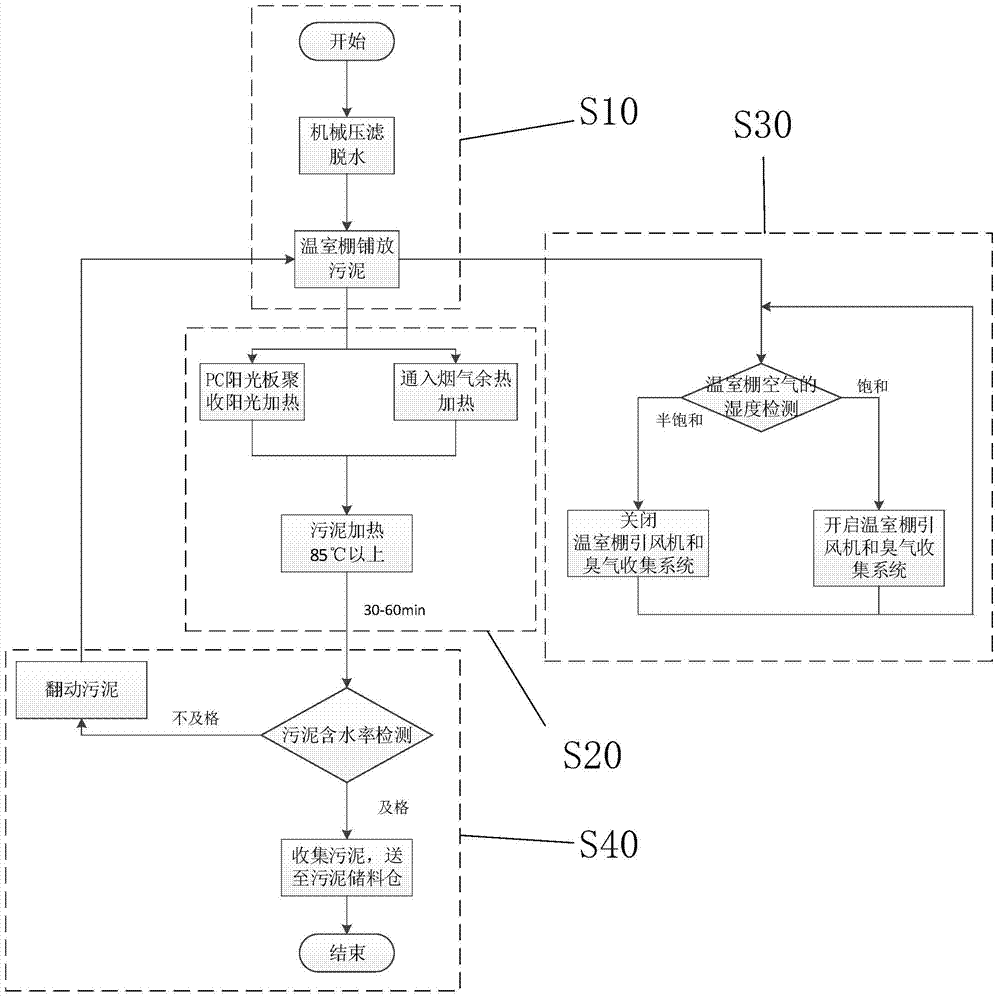

[0028] see figure 1 , is a schematic diagram of the steps of the method for drying sludge using solar energy and waste heat of flue gas according to the present invention.

[0029] A method for drying sludge utilizing solar energy and flue gas waste heat of the present invention comprises the following steps:

[0030] Step S10, using mechanical dehydration to dehydrate the sludge, and then laying the mechanically dehydrated sludge on the stainless steel platform in the greenhouse; the function rate of the original sludge is about 80%, and the sludge after mechanical dehydration still has About 60% moisture content, in the greenhouse, the thickness of the sludge is 5-10cm;

[0031] Step S20, use the solar panel installed on the roof of the greenhouse to collect sunlight to heat the sludge, and the cavity set in the stainless steel platform heats the sludge through the heat release of high-temperature flue gas, which is controlled by the above two methods and an infrared online...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com